Transformed grabbing bucket of slag dredging crane

A crane and pulley block technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of high maintenance and replacement parts costs, failure to catch ash in time, and full water in the ash settling tank. It is easy to implement, unique in measures, The effect of reducing maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

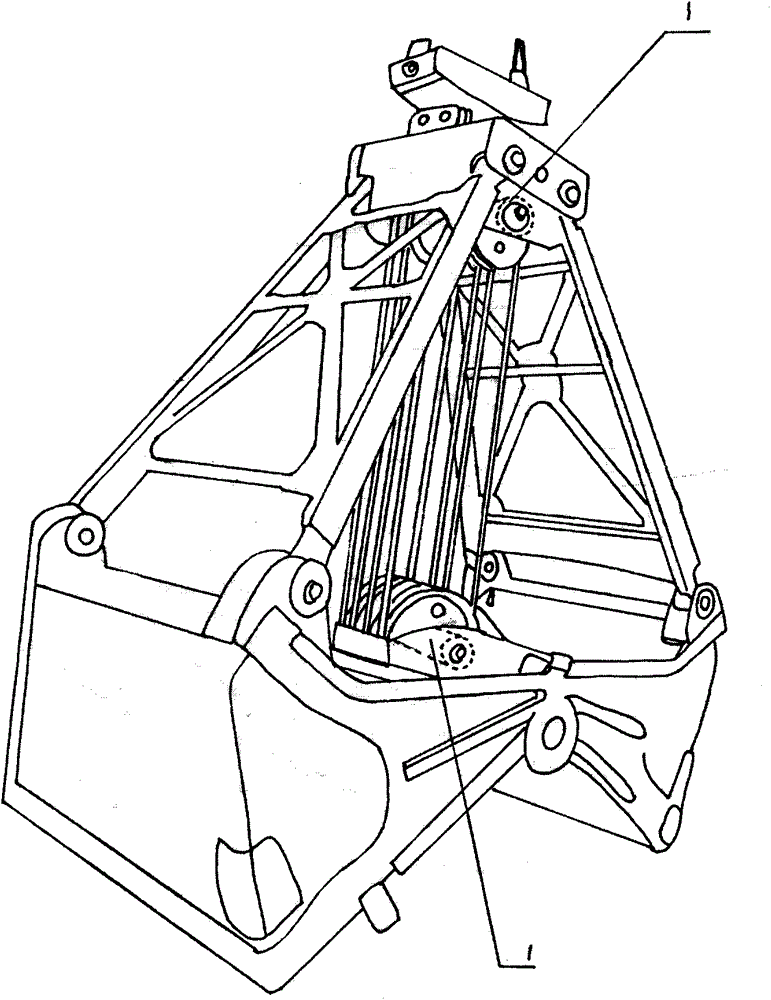

[0015] Now in conjunction with accompanying drawing, the present invention is described in detail:

[0016] A modified grab bucket of a slag removal crane. In the technical proposal, the 6019 radial ball bearing in the pulley block of the grab bucket of the crane is replaced with a sliding bearing (1) processed by polymer nylon rods.

[0017] The specific implementation method is:

[0018] Use Ф145mm high-density nylon rods to process according to the pulley shaft diameter and width: outer diameter×inner diameter×thickness: Ф145×95×50mm, a total of 16 pieces, which are respectively installed in the inner hole of the pulley. To prevent and reduce sediment from entering the bearing, install Ф95×Ф145×14 skeleton oil seals on both sides, put the main shaft in the middle and install it, and finally assemble it on the grab bucket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com