High-fluidity ethylene-tetrafluoroethylene copolymer composition and preparation method thereof

A technology of tetrafluoroethylene and copolymer, which is applied in the field of preparation of the ethylene-tetrafluoroethylene copolymer resin, and can solve the problems that the high-speed molding ability of the resin cannot be taken into account.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

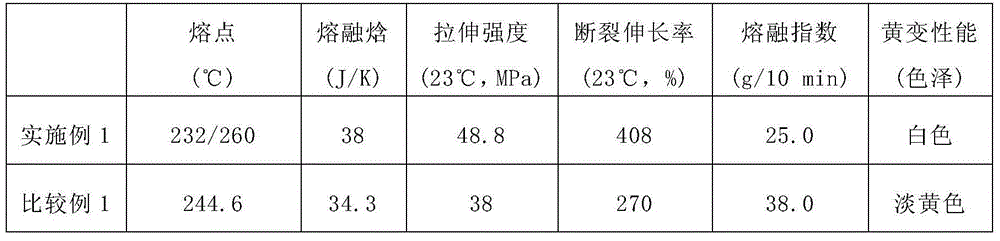

Embodiment 1

[0079] Add 6L of 1,1,1,3,3-pentafluorobutane, 50g of perfluorobutylethylene and 10ml of methanol into a 10L stainless steel autoclave that has undergone oxygen removal treatment, raise the temperature to 40°C while stirring, and add tetrafluoroethylene / Ethylene=75 / 25 (mol%) mixed gas to pressure is 0.800MPa, the concentration that adds 40ml is 0.040mol / L (C 3 f 7 OC 2 f 4 CO 2 ) 2 solution of 1,1,1,3,3-pentafluorobutane to start polymerization. When the pressure drops by 0.005MPa, it means there is a reaction. At this moment, continuously add the mixed gas of tetrafluoroethylene / ethylene (mol%)=55 / 45, make the pressure constant at 0.8MPa; 3 f 7 OC 2 f 4 CO 2 ) 2 1,1,1,3,3-Pentafluorobutane solution. After 120 minutes, the addition of the initiator was stopped, and the mixed gas of tetrafluoroethylene / ethylene (mol%)=55 / 45 was continuously added, and the gas pressure in the reactor was still kept constant at 0.8 MPa. After continuing to react for 30 min, the polym...

Embodiment 2

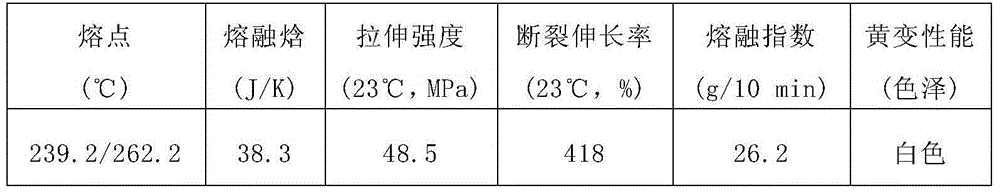

[0088] Except that the time of continuously adding initiator is 100min, other conditions are identical with embodiment 1. The obtained product was named ETFE-3 and weighed 560 g. The unit composition of the ETFE-3 copolymer was such that the molar ratio of repeating units based on TFE / repeating units based on E / repeating units based on PFBE was 54.6 / 42.8 / 2.6. The properties of ETFE-3 are shown in Table 2.

[0089] Table 2 Physical properties of ETFE-3

[0090]

Embodiment 3

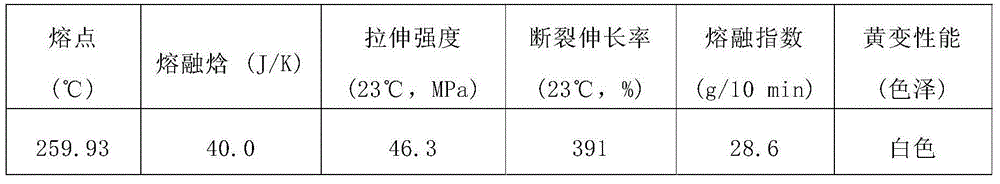

[0092] Except that the post-reaction time is 20min, other conditions are exactly the same as Example 1. The obtained product was named ETFE-4 and weighed 560 g. The unit composition of the ETFE-4 copolymer was such that the molar ratio of repeating units based on TFE / repeating units based on E / repeating units based on PFBE was 54.4 / 43.1 / 2.5. The properties of ETFE-4 are listed in Table 3.

[0093] Table 3 Physical properties of ETFE-4

[0094]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap