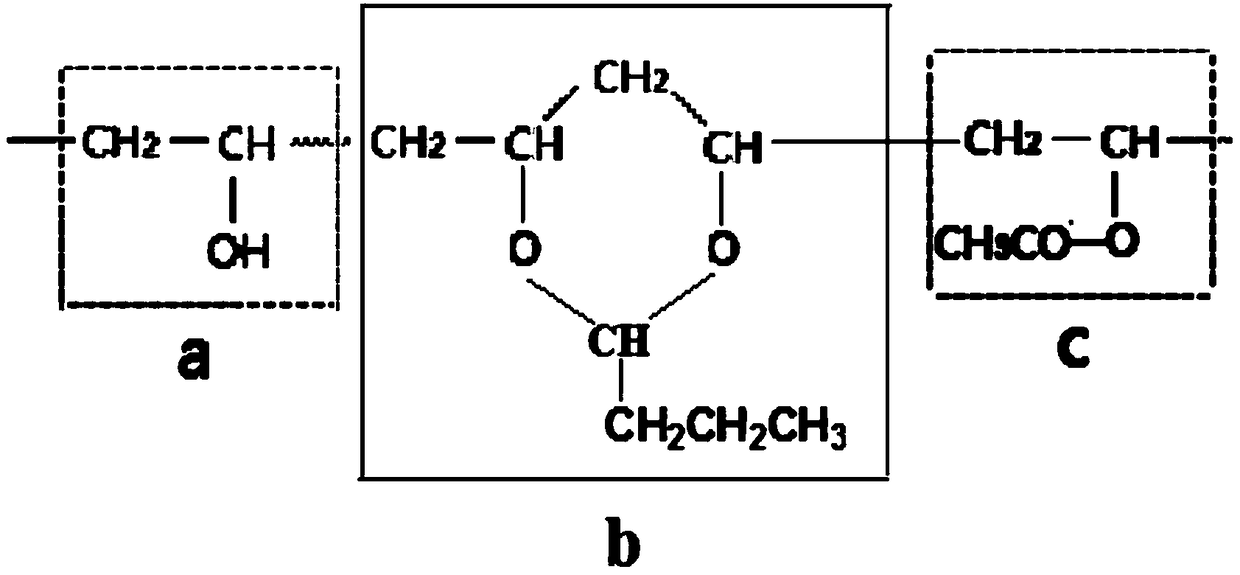

A kind of preparation method of high bulk density polyvinyl butyral resin

A technology of polyvinyl butyral resin and bulk density, which is applied in the field of polymer compound preparation, can solve the problems of uncontrollable speed and degree, coarse PVB particles, and difficult drying process, so as to reduce equipment investment cost and facilitate processing Excellent performance and yellowing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

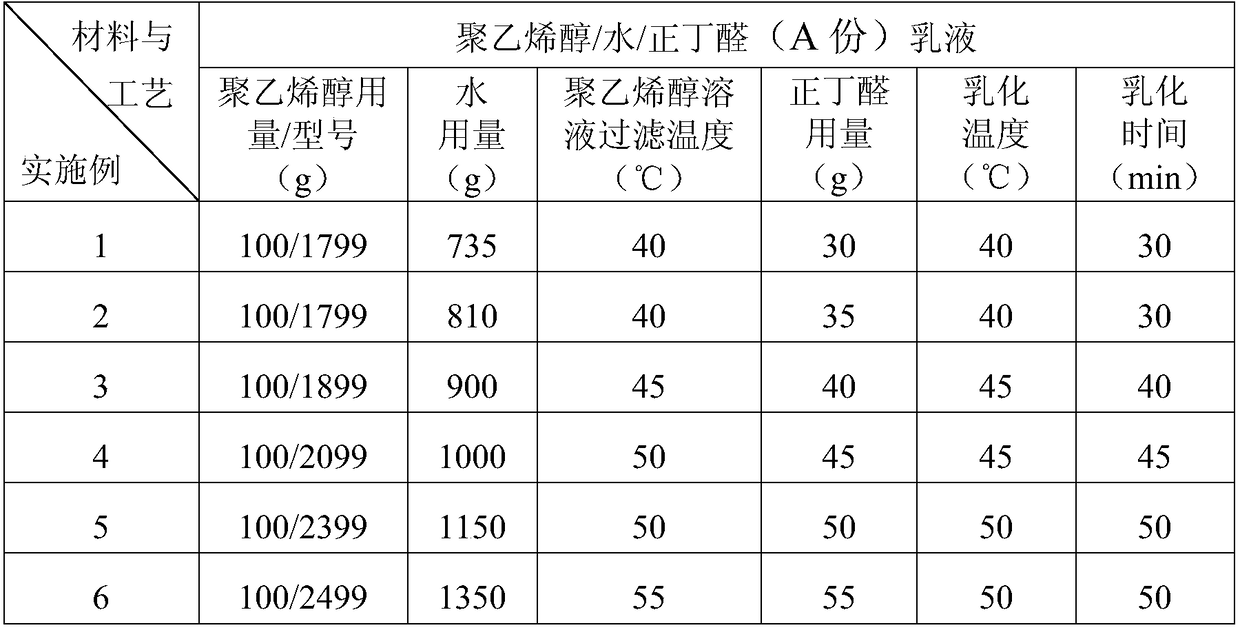

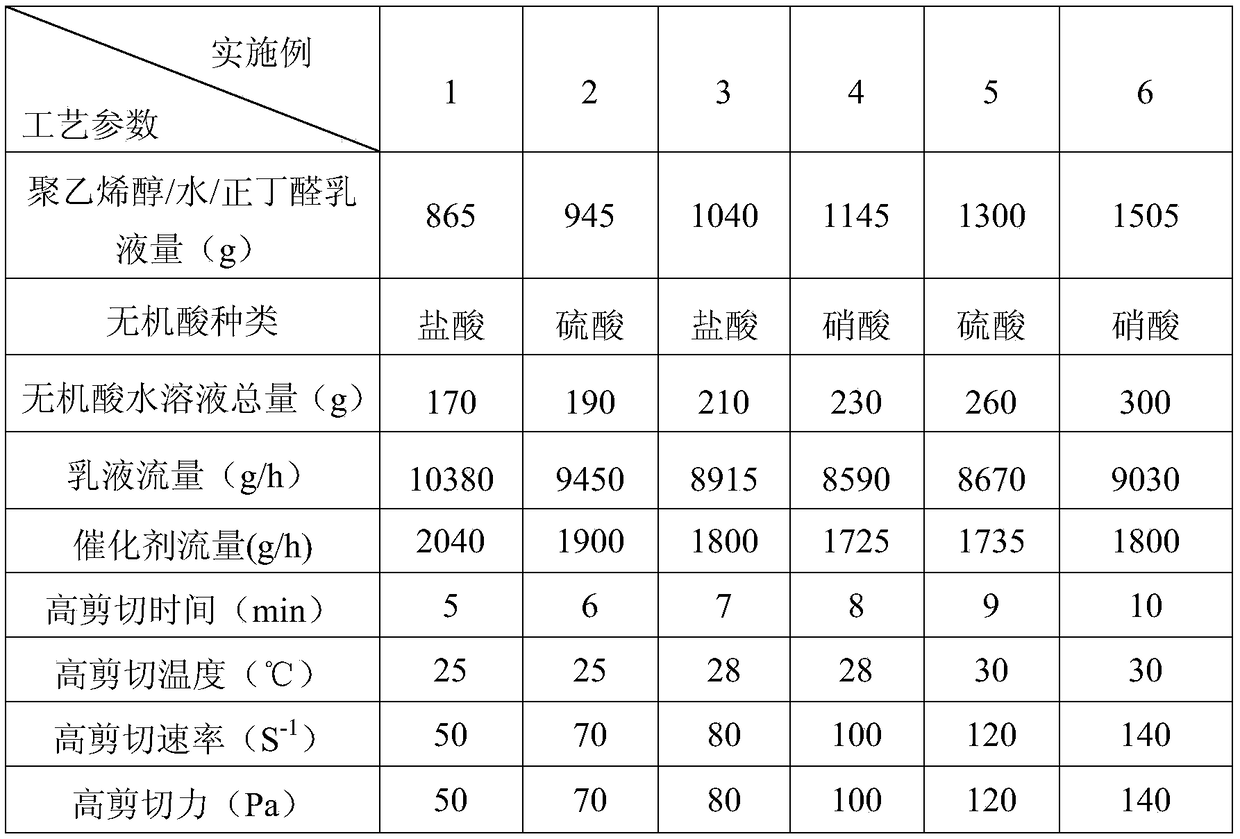

Embodiment 1~6

[0037] The basic reaction synthesis process of Examples 1 to 6:

[0038] 1. Preparation of polyvinyl alcohol / n-butyraldehyde water emulsion:

[0039] Add 735 to 1550 parts by mass of water into the dissolving kettle, add 100 parts by mass of polyvinyl alcohol under stirring, keep it at a temperature of 58~62℃ for 1h, heat up to 93~97℃ and keep it for 2h (to make the polyvinyl alcohol complete Dissolve), cool to 50-60℃ and filter to obtain (835-1650 parts by mass) polyvinyl alcohol aqueous solution, and then combine the polyvinyl alcohol aqueous solution and the filtered 30-55 parts by mass n-butyraldehyde (part A) Add 0.5 to 0.8% of the amount of n-butyraldehyde (antioxidant) in an emulsifier at a temperature of 40-50°C and stir for 30-60 minutes (to make the polyvinyl alcohol and n-butyraldehyde fully mixed) to prepare polyvinyl alcohol / n-butyraldehyde water Emulsion, cool the emulsion to below 30℃ for later use;

[0040] 2. Preparation of polyvinyl butyral resin:

[0041] Take 500...

Embodiment 7

[0066] A preparation method of high bulk density polyvinyl butyral resin, the steps are:

[0067] a. Preparation of polyvinyl alcohol / n-butyraldehyde water emulsion:

[0068] Add 735 parts by mass of water into the dissolving kettle, add 100 parts by mass of polyvinyl alcohol under stirring, keep it at a temperature of 58°C for 1h, heat up to 93°C and keep it for 2h, so that the polyvinyl alcohol is completely dissolved, and the temperature is reduced to 50°C After filtering to obtain an aqueous solution of polyvinyl alcohol, the aqueous solution of polyvinyl alcohol and (preferably filtered) 30 parts by mass of n-butyraldehyde (part A) are mixed, and stirred by an emulsifier at a temperature of 40°C for 30 minutes to make Fully mix polyvinyl alcohol and n-butyraldehyde to prepare polyvinyl alcohol / n-butyraldehyde water emulsion, and cool the temperature of the polyvinyl alcohol / n-butyraldehyde water emulsion to below 30°C for use;

[0069] The n-butyraldehyde (Part A) is also added...

Embodiment 8

[0078] A preparation method of high bulk density polyvinyl butyral resin, the steps are:

[0079] a. Preparation of polyvinyl alcohol / n-butyraldehyde water emulsion:

[0080] Add 1550 parts by mass of water into the dissolving kettle, add 100 parts by mass of polyvinyl alcohol under stirring, keep at a temperature of 62°C for 1h, heat up to 97°C and keep for 2h, so that the polyvinyl alcohol is completely dissolved, and the temperature is reduced to 60°C After filtering to obtain an aqueous solution of polyvinyl alcohol, the aqueous solution of polyvinyl alcohol and (preferably filtered) 55 parts by mass of n-butyraldehyde (part A) are mixed, and stirred by an emulsifier at a temperature of 50°C for 60 minutes, so that Fully mix polyvinyl alcohol and n-butyraldehyde to prepare polyvinyl alcohol / n-butyraldehyde water emulsion, and cool the temperature of the polyvinyl alcohol / n-butyraldehyde water emulsion to below 30°C for use;

[0081] An antioxidant with 0.8% of the total mass of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com