A kind of highly negative dielectric anisotropy liquid crystal mixture with high birefringence and low viscosity and its application

A dielectric anisotropy, high birefringence technology, applied in liquid crystal materials, nonlinear optics, instruments, etc., can solve the problem that the comprehensive performance of liquid crystal devices cannot meet the needs, achieve good mutual solubility, improve performance, and reduce driving voltage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

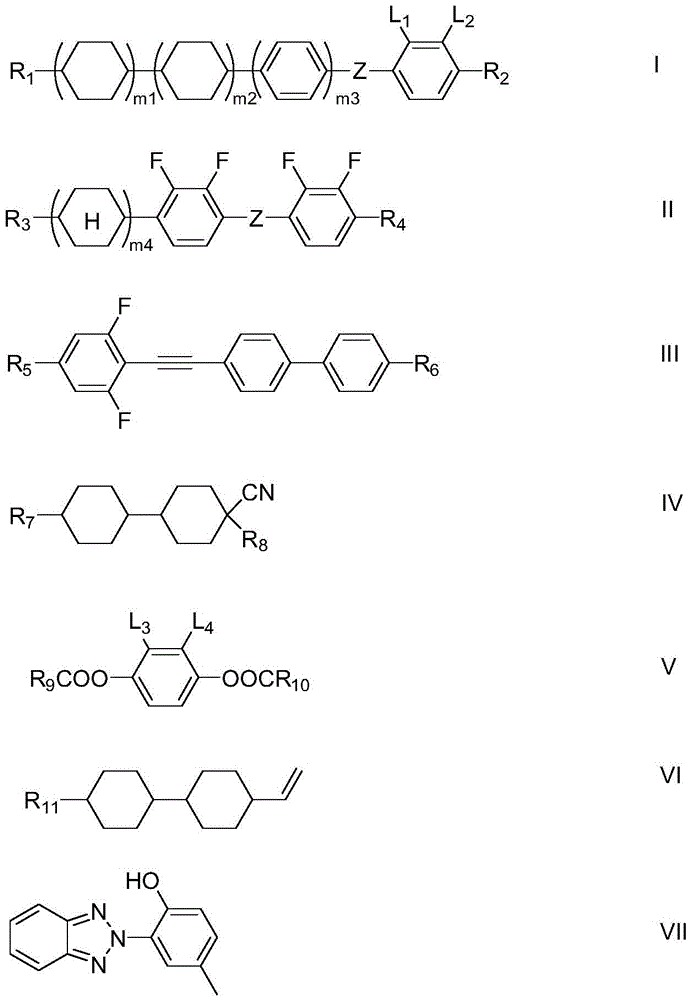

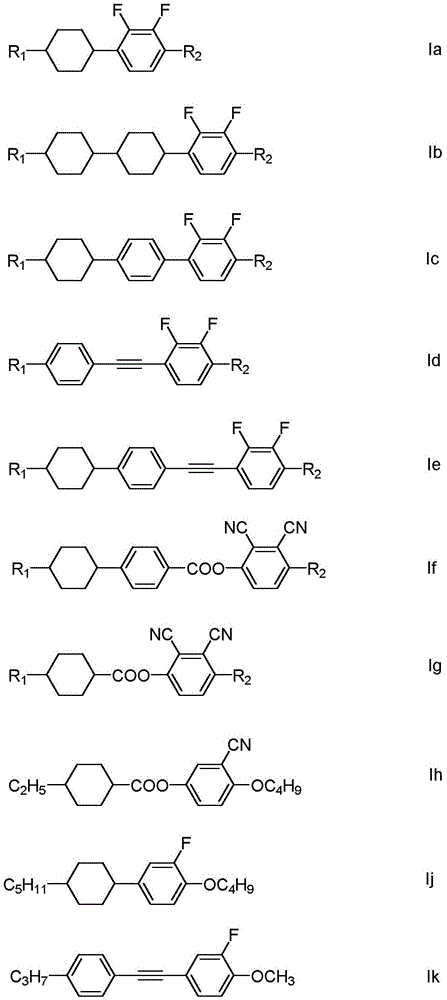

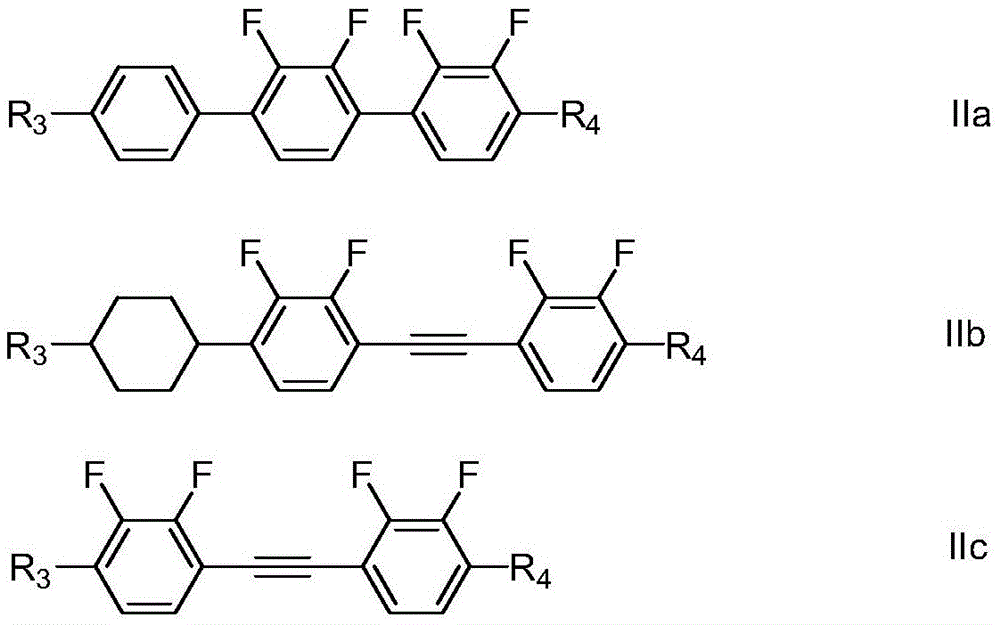

Method used

Image

Examples

Embodiment 1

[0041] The components and their proportions in the liquid crystal mixture are shown in Table 3 below:

[0042] Composition and proportioning of liquid crystal mixture in Table 3 embodiment one

[0043]

[0044]

[0045] The performance test parameters of the liquid crystal mixture of embodiment one are as shown in table 4:

[0046] The performance test data of the liquid crystal mixture of table 4 embodiment one

[0047] Performance parameters

[0048] no o (589nm,25℃)

Embodiment 2

[0050] The components and their proportions in the liquid crystal mixture are shown in Table 5 below:

[0051] Composition and proportioning ratio of liquid crystal mixture in Table 5 embodiment two

[0052]

[0053]

[0054] The performance test parameters of the liquid crystal mixture of embodiment two are as shown in table 6:

[0055] Table 6 embodiment two performance test data

[0056] Performance parameters

Embodiment 3

[0058] The components and their proportions in the liquid crystal mixture are shown in Table 7 below:

[0059] Composition and proportioning ratio of liquid crystal mixture in Table 7 embodiment three

[0060]

[0061]

[0062] The performance test parameters of the liquid crystal mixture of embodiment three are as shown in table 8:

[0063] Table 8 embodiment three performance test data

[0064] Performance parameters

[0065] Clearing Point(°C)

PUM

| Property | Measurement | Unit |

|---|---|---|

| isotropization temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com