A gasifier start-up ignition method and start-up flue gas generation system

A flue gas generation and gasification furnace technology, which is applied in the chemical industry, petroleum industry, and the manufacture of combustible gas, etc., can solve the problems of uneven flue gas, easy burning of burners, etc., and achieve long service life, stable and smooth combustion warming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the drawings and embodiments.

[0020] In order to ensure the stable starting and ignition process of the conveying bed gasifier, the ignition burner and the starting burner will not be burnt during the start of the furnace, this embodiment provides a starting ignition method of the conveying bed gasifier. The middle start burner and ignition are not directly fixed on the gasifier body, but are set on the start-up flue gas generation system connected to the gasifier body. The start-up flue gas generation system generates flue gas with the required temperature, and then the smoke The gas passes into the gasifier body through the flue, so that the temperature and pressure in the gasifier body rise to the state required for feeding, thereby completing the ignition of the transport bed gasifier.

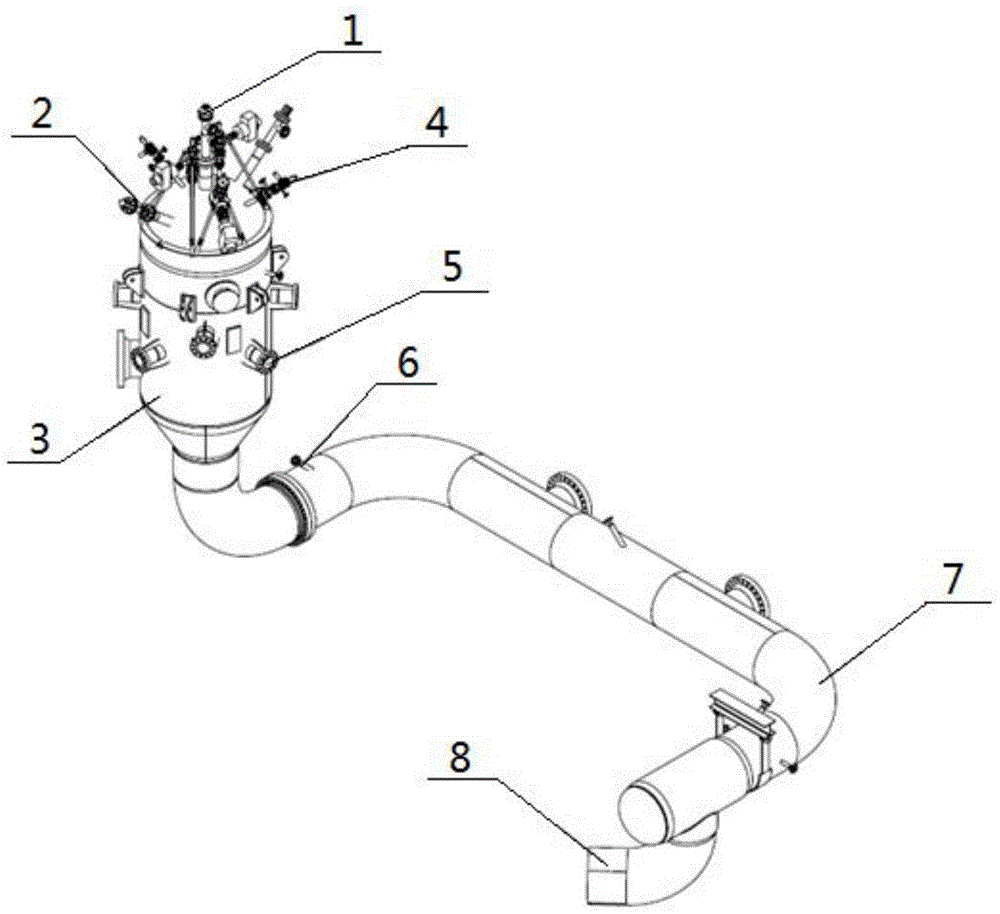

[0021] The structure of the start-up smoke generation system used in this method is as follows figure 1 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com