Plating film manufacturing method

A manufacturing method and coating technology, applied in the direction of electrical components, current conduction devices, electric solid devices, etc., can solve problems such as productivity decline, yield decline, and workpiece damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] In the present example, a plated film was produced on the surface of the workpiece in the following procedure.

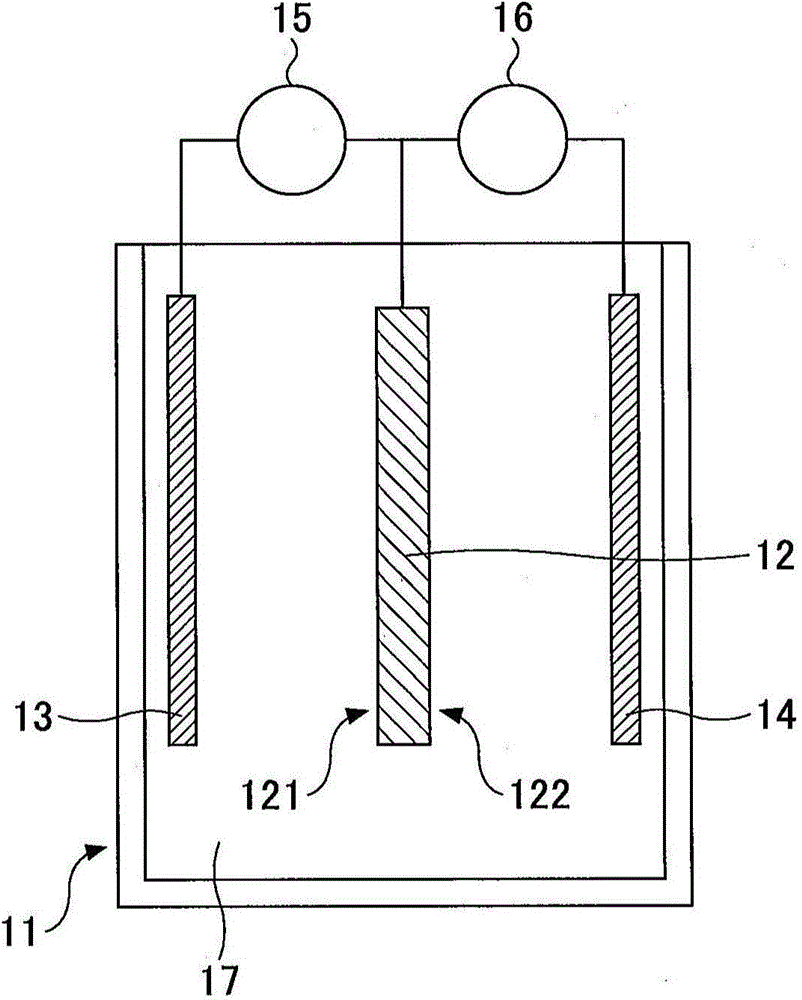

[0061] like figure 1 As shown, by connecting a polarity inversion power supply 15 between the workpiece 12 and the electrode 13 and connecting a DC power supply 16 between the workpiece 12 and the electrode 14, the coating film was produced.

[0062] At this time, as the workpiece 12, a metal plate composed of a copper alloy (C194) was used. In addition, as the composition of the plating solution, copper sulfate containing 200g / L, sulfuric acid of 100g / L, chlorine gas of 50ppm, brightener of 2ml / L (manufactured by Rohm&Hass Co., trade name: MICROFILL TM EVF BRIGHTER), 10 ml / L leveler (manufactured by Rohm & Hass Co., trade name: MICROFILL TM EVF LEVELER), and 20 ml / L polymer (manufactured by Rohm & Hass Co., trade name: MICROFILL TM EVF C2) plating solution.

[0063] After producing the coating film under the above-mentioned conditions, it can be confi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com