Wellhead device for self-seepage, reverse filtration, and back-injection wells

A technology for wellhead devices and reinjection wells, applied in water supply devices, drinking water devices, buildings, etc., can solve the problems of concrete manhole covers affecting reinjection volume, washing out, and consuming large building materials, and solve the problem of rapid reinjection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

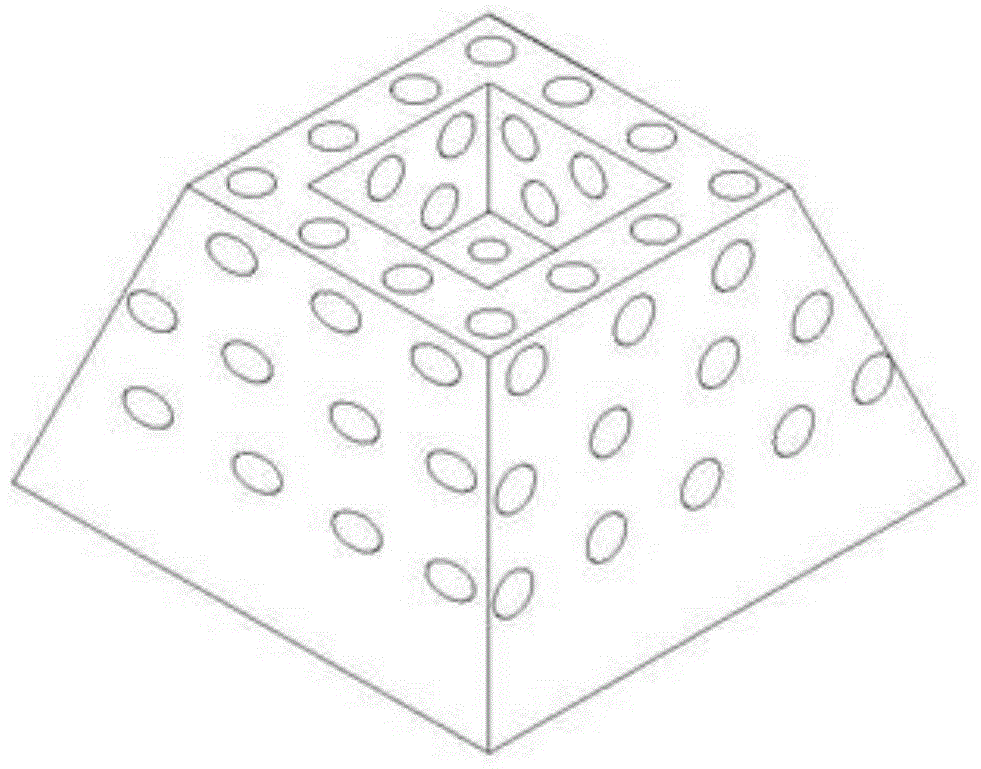

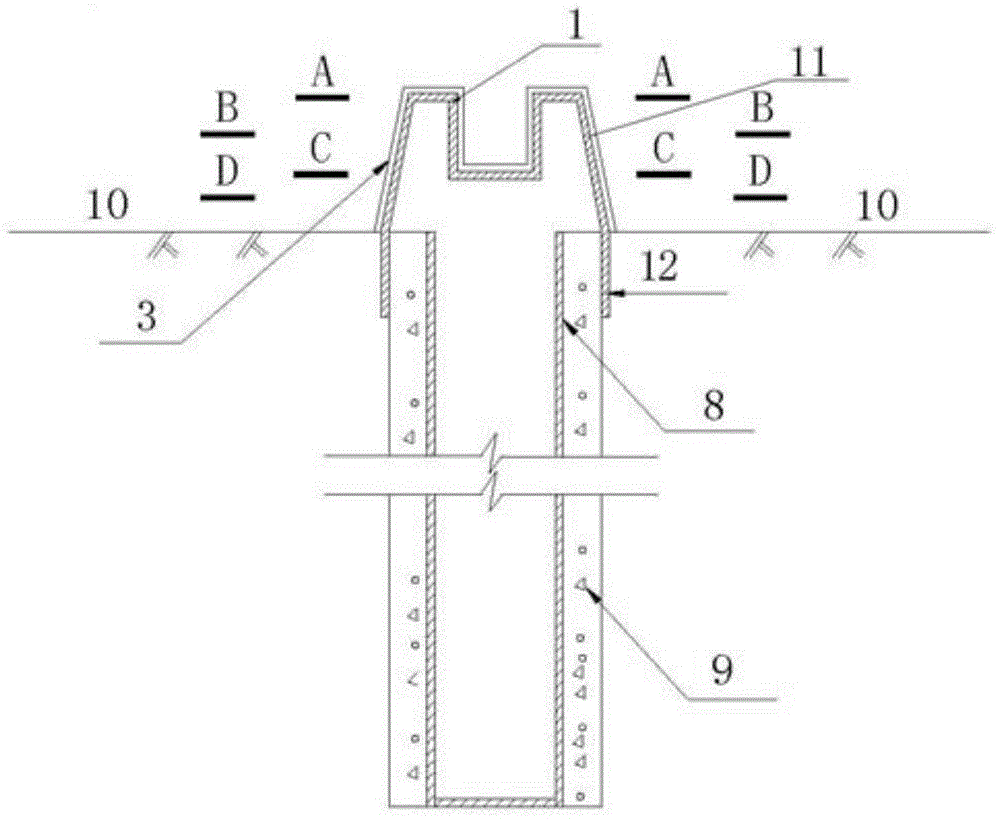

[0031] exist Figure 1-8 Among them, the wellhead device of the platform-shaped internal and external water inflow self-infiltration reverse filtration reinjection well relates to the reinjection well 8 and its wellhead device. The filter material 9, the recharge well 8 is located below the ground 10 at the bottom of the river or at the bottom of the canal.

[0032] The wellhead device includes a well cover 1 and a geotextile filter layer 3 .

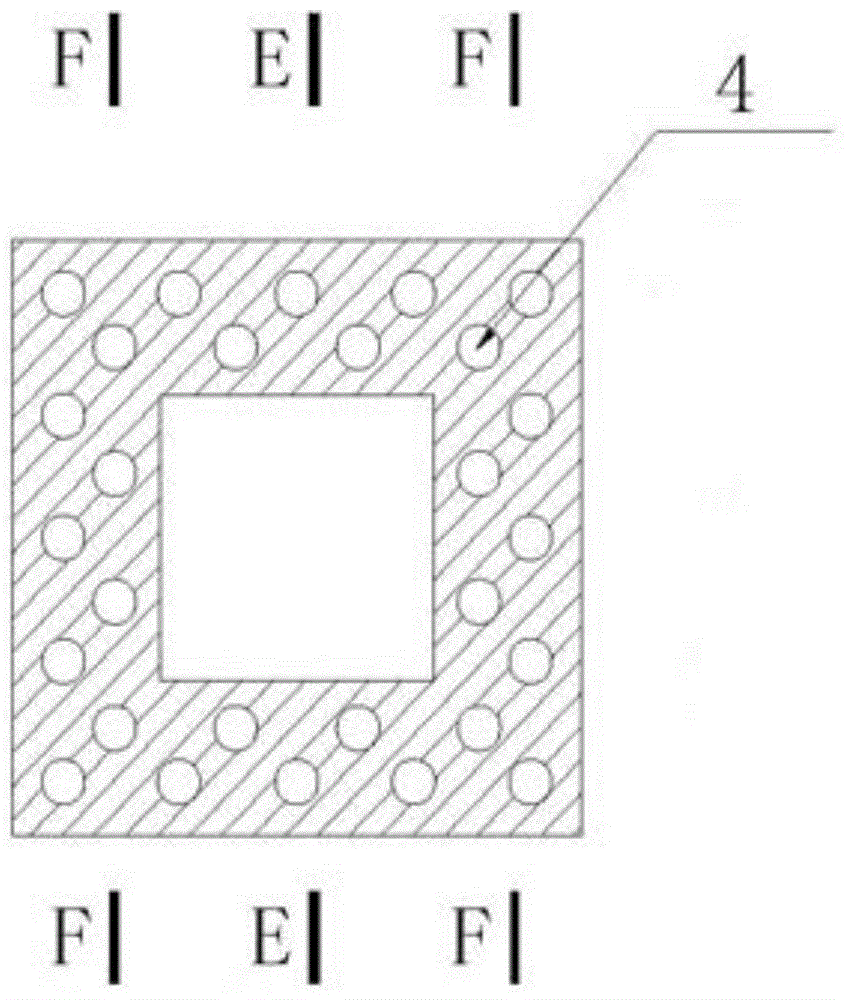

[0033]The manhole cover 1 is composed of the upper part 11 of the manhole cover with the water inlet and the lower part 12 of the manhole cover buried under the ground of the river bottom or the canal bottom, and the manhole cover 1 as a whole is a hollow bottomless frustum. The center of the upper part of the well cover 1 is provided with a hollow annular groove (cube groove) with a groove bottom, and a circular water inlet hole is arranged on the outer side of the upper part of the well cover, that is, the water inlet hole 4 on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com