Prefabricated hollow staircase

A stair and hollow technology, which is applied in the directions of stairs, treads and vertical plate units, can solve the problems that prefabricated stair products cannot be popularized and used, the production cost of prefabricated stairs is high, and the loading and unloading and installation are complicated. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

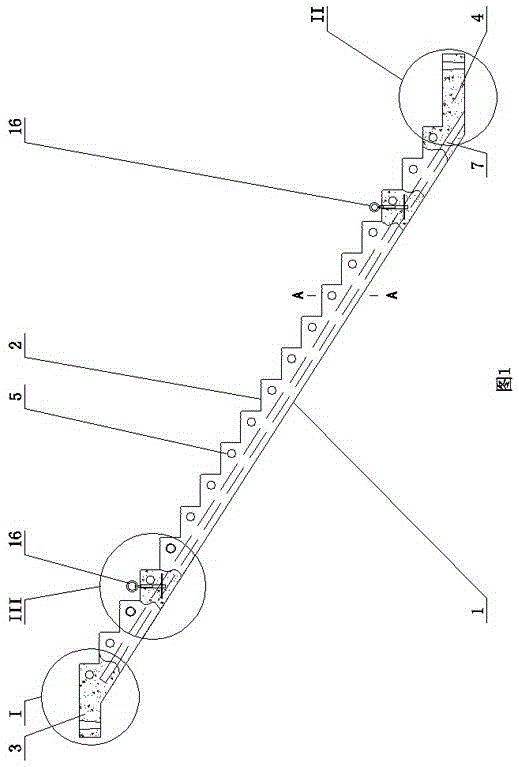

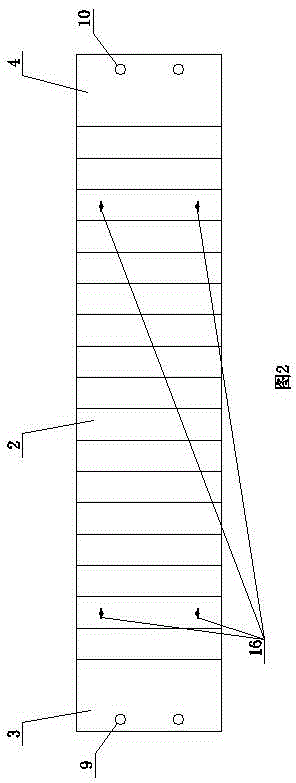

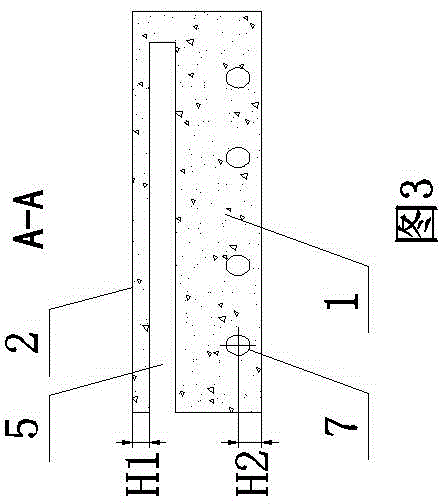

[0007] The present invention will be further described with reference to the accompanying drawings.

[0008] 1 in the figure is a stair plate, a step 2 is arranged on the stair plate 1, a transverse blind hole 5 is arranged on one side of the step 2, a longitudinal blind hole 7 is arranged in the length direction of the stair plate 1, and the opening of the blind hole 7 is arranged at the bottom of the stair plate 1 At the end part, at least two sling devices are installed in the length direction of the stairs. The sling devices are arranged on the steps, and the two sling devices are evenly distributed in the length direction of the stairs. In the same direction as the width direction of the steps, the positioning pin 14 passes through the through hole 13 provided on the lower end of the screw sleeve 11. The height of the screw sleeve 11 is connected in a T-shape with the length of the positioning pin 14. The upper part of the screw sleeve 11 is provided with a threaded hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com