Method for adjusting clearance of four-single-raceway outer ring four-row tapered roller bearing

An adjustment method and clearance technology, applied in the direction of bearing components, shafts and bearings, mechanical clearance measurement, etc., can solve the problems of large measurement error, poor operability, difficulty in platform manufacturing and verification, etc., and achieve high accuracy and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] A method for adjusting the clearance of a four-row tapered roller bearing with four single-race outer rings, comprising the following steps:

[0043] Step 1 Preparation before adjustment

[0044] (1) The finished bearing parts should be cleaned after passing the inspection;

[0045] (2) Clearance adjustment is carried out on a workbench, a flat plate or a set of 6 support blocks. The height difference of the same group of support blocks should be less than 50% of the parallel difference between the two ends of the inner ring of the tested bearing;

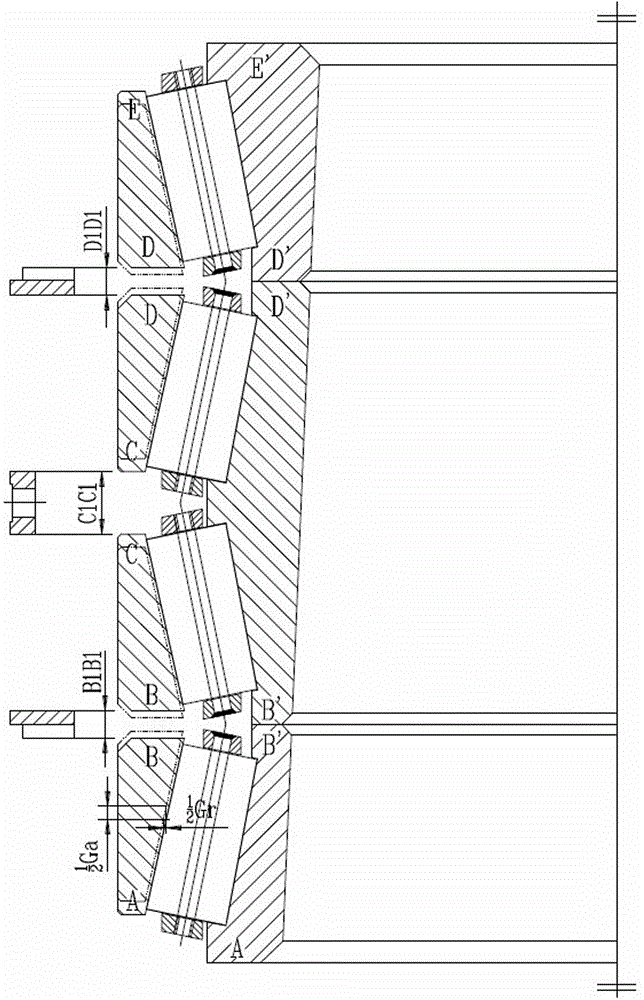

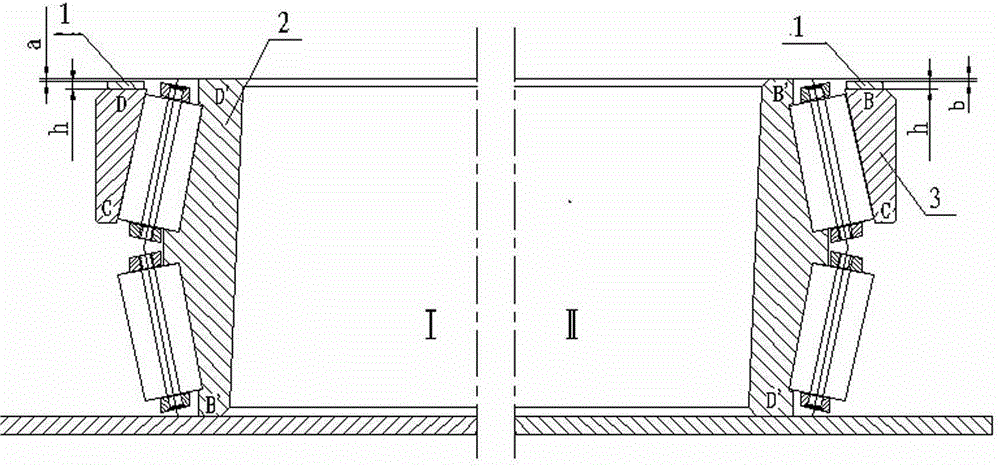

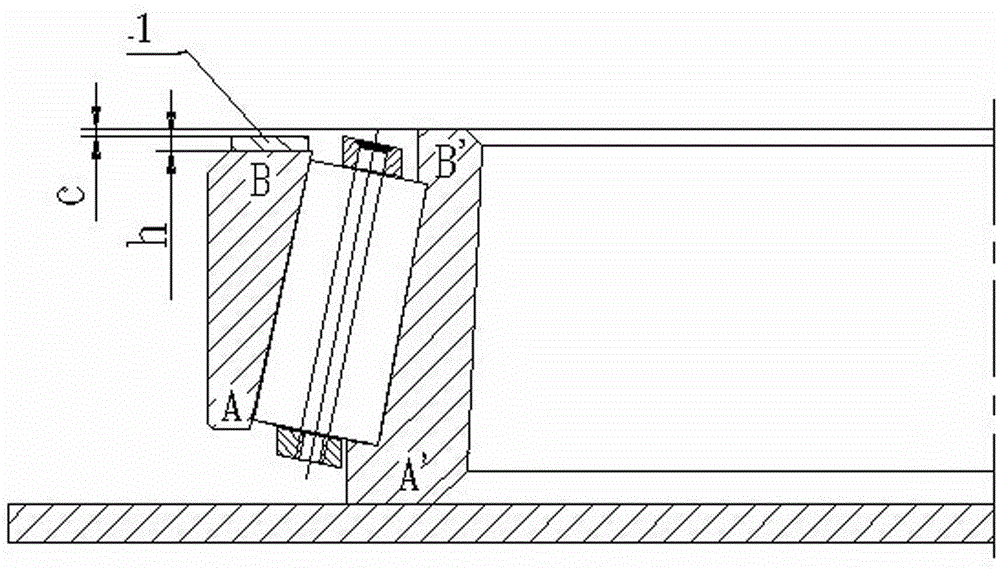

[0046] (3) According to the letters shown in the clearance adjustment specification pattern, see figure 1 , Mark with an electric pen on the end faces of all rings and the outer diameter surface of the spacer, and mark the bearing sequence number at the same time.

[0047] Step 2 Adjustment requirements

[0048] (1) Before the measurement, the positioning end face of the inner ring assembled at the lower part should be i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com