Pressure buffer device and regenerative combustion type exhaust gas treatment device including the pressure buffer device

A technology of processing device and buffer device, applied in the direction of pipes/pipe joints/pipe fittings, mechanical equipment, pipe components, etc., can solve the problems of overall large-scale equipment, increased processing capacity, increased power consumption, etc., to reduce operating costs. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

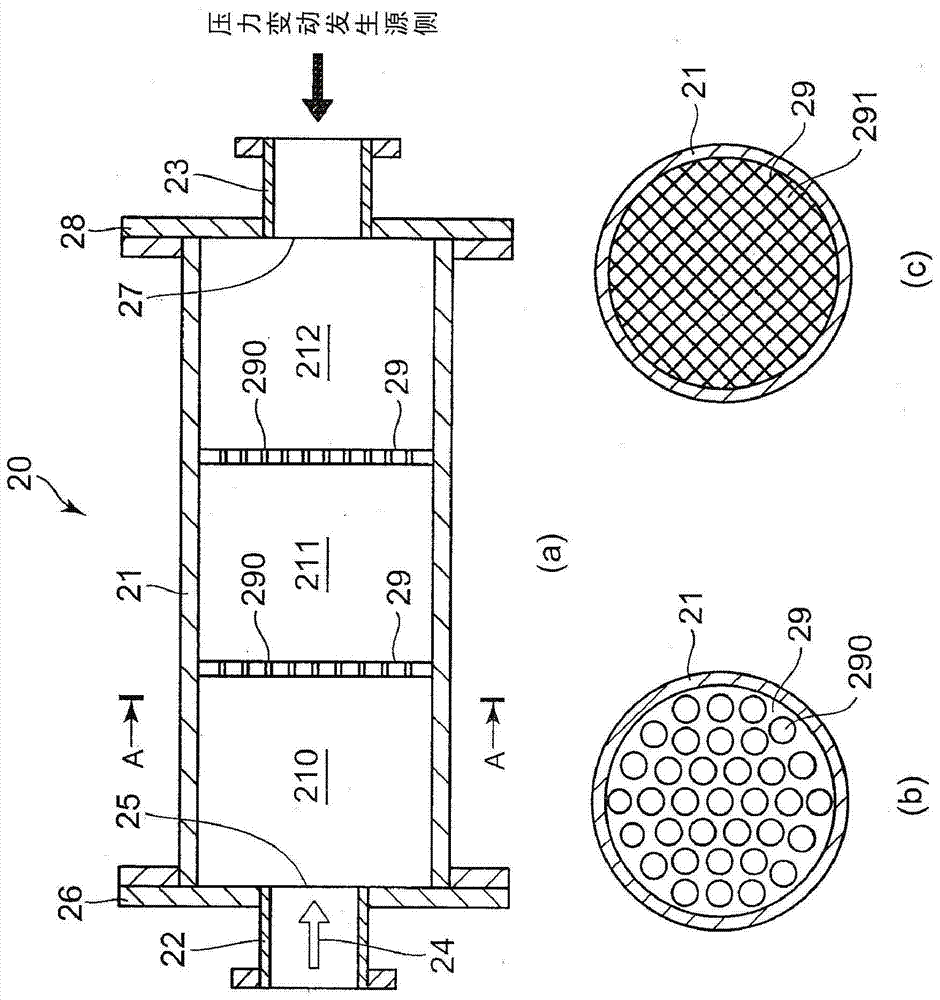

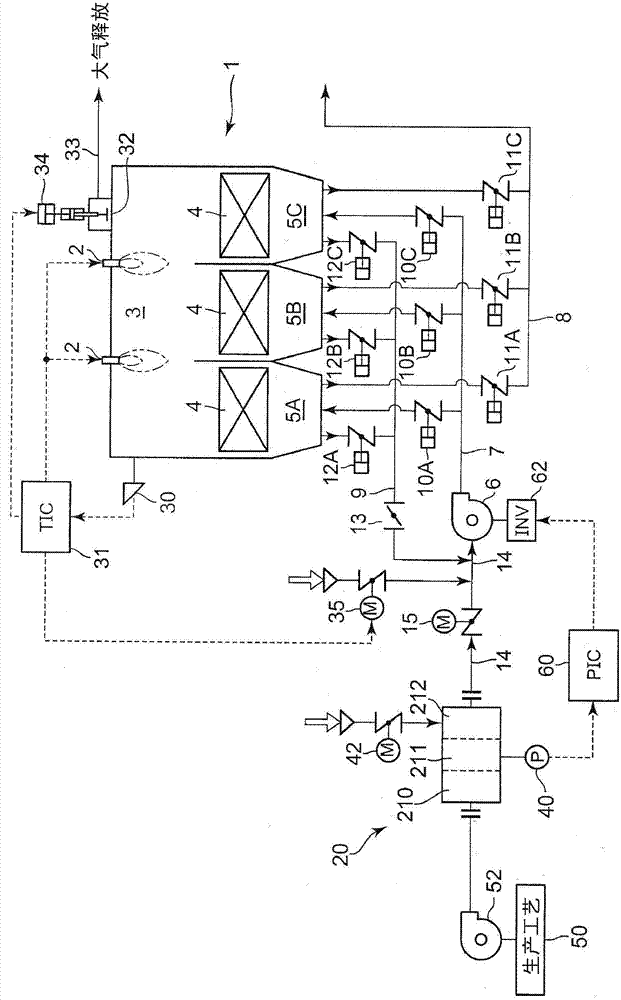

[0054] Hereinafter, a pressure buffer device according to an embodiment of the present invention will be described with reference to the drawings. In the following description, words indicating directions and positions (such as "upstream" or "downstream") are used for convenience of description, they are used to make the invention easy to understand, and do not limit the technical scope of the present invention because of the meaning of these words. Generate restrictions. In addition, the following description is only one embodiment of the present invention, and is not intended to limit the applicable objects or uses of the present invention.

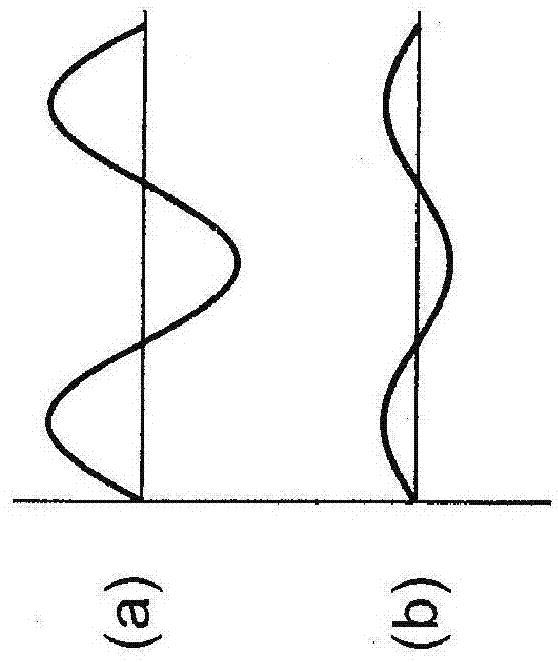

[0055] The pressure buffer device according to the embodiment of the present invention is installed between a pipe (both not shown) connecting a fluid supply source and a treatment device that processes the fluid, and compensates for fluid pressure fluctuations in the pipe due to the operation of the treatment device. to absorb.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com