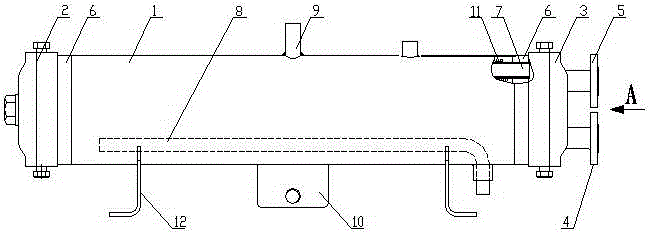

Horizontal compact shell-and-tube condenser

A compact, shell-and-tube technology, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of wasting space and shell materials, poor heat exchange effect, and large gaps between tubes. Achieve space saving, improve cooling effect and good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings:

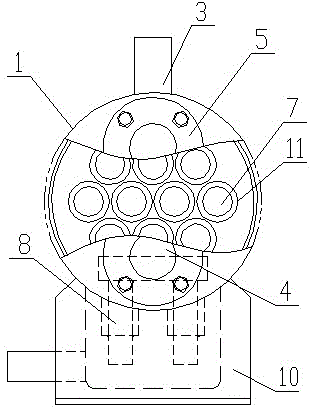

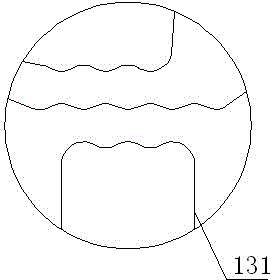

[0021] As shown in the figure, the horizontal compact shell-and-tube condenser includes a cylindrical horizontal cylinder 1. The top of the cylinder 1 is provided with a refrigerant inlet 9, and the bottom of the cylinder 1 is provided with a refrigerant outlet 10 and a saddle 12. , The two sides of the cylinder 1 are provided with a left end cover 2 and a right end cover 3, the right end cover is provided with a cooling liquid inlet 4 and a cooling liquid outlet 5, and a tube plate is provided between the left and right end covers and the end surface of the cylinder 1 6. The end cap and the tube plate 6 are connected with the end surface of the cylinder body through the threaded part. The inner sides of the left end cover 2 and the right end cover 3 are respectively provided with a plurality of curved baffle plates 13, 13...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap