Light guide plate torsion test method

A technology of torsion testing and light guide plate, which is applied in the direction of applying stable torsion to test the strength of materials, etc., which can solve the problems of no test method, staying at the light guide network, and the inability to check the quality of the light guide plate, so as to achieve high quality and improve reliability. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

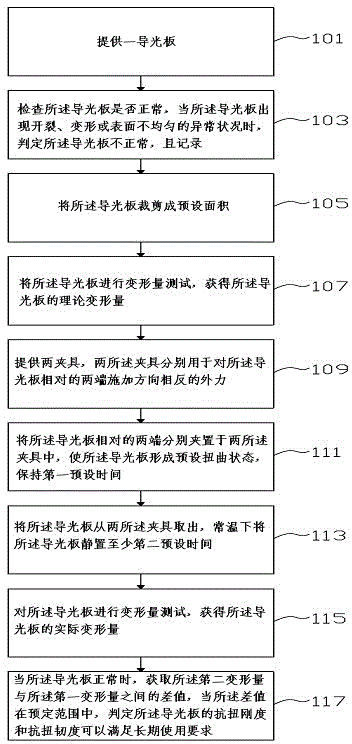

[0027] see figure 1 , a method for testing the torsion of a light guide plate provided in an embodiment of the present invention. The method includes the following steps:

[0028] Step 101: Provide a light guide plate. In this embodiment, since the light guide plate made of acrylic material is the most widely used, for more practical significance, the material of the light guide plate is acrylic. Certainly, in other embodiments, the material of the light guide plate may also be polycarbonate (pc).

[0029] Step 103: Check whether the light guide plate is normal. When the light guide plate is cracked, deformed or has an uneven surface, it is determined that the light guide plate is abnormal and recorded. In this embodiment, the light guide plate is placed in an environment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com