Wire Rod Online Cold Heading Test Recording Method and System

A recording system and recording method technology, applied in the direction of testing metals, material inspection products, and preparation of test samples, can solve the problems of high false detection rate, time-consuming and labor-intensive, low work efficiency, etc., to ensure reliability and accuracy, The system is simple and reliable, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

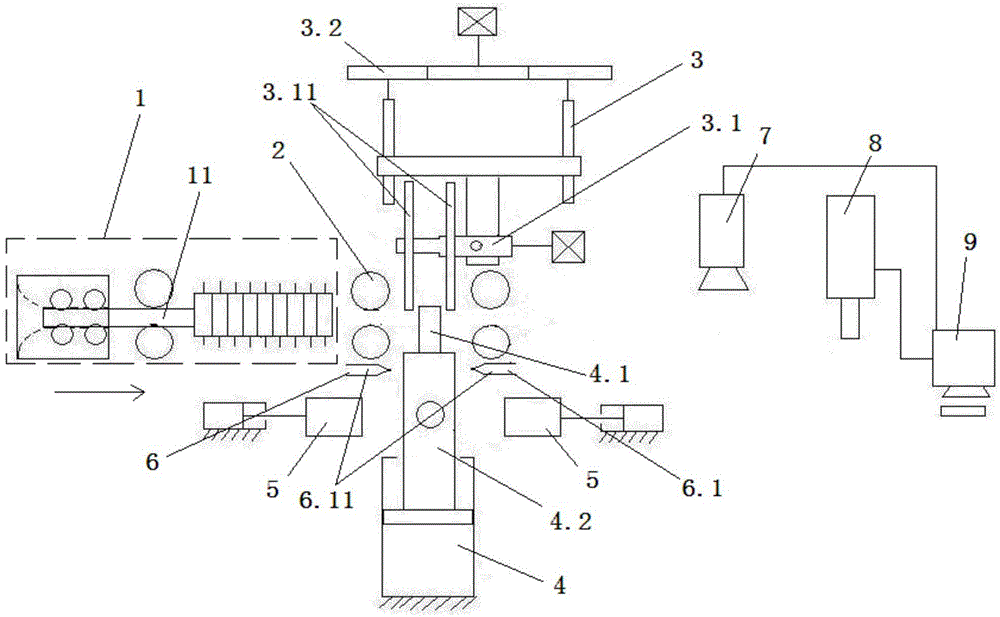

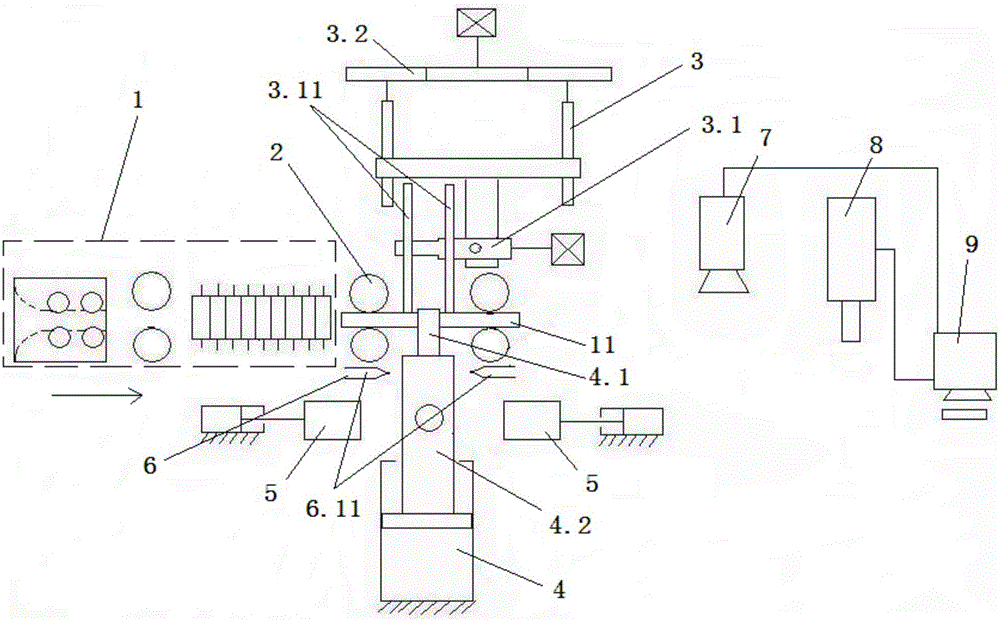

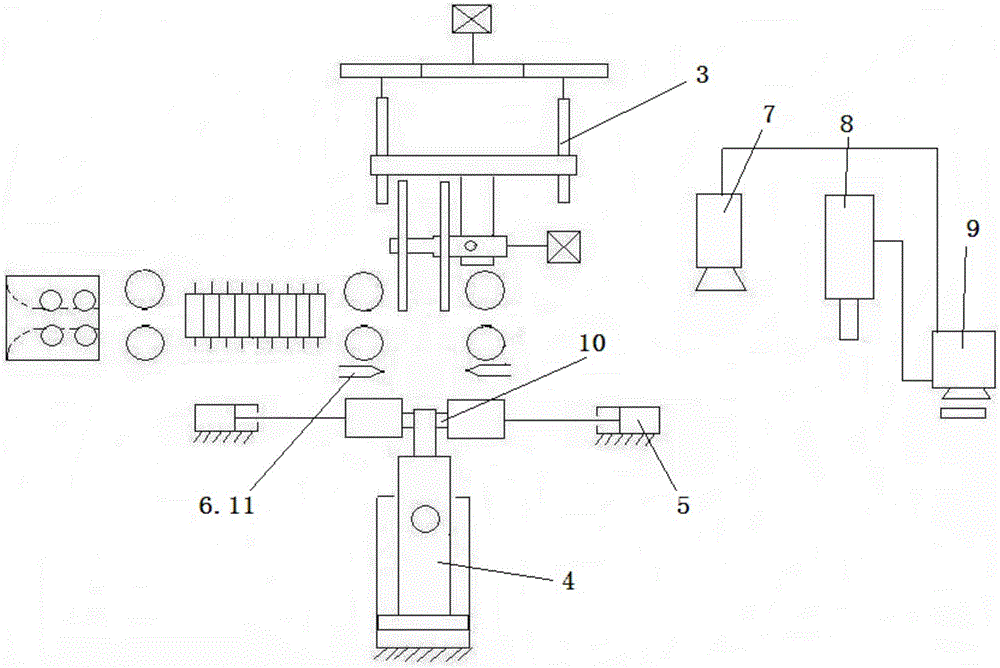

[0052] see Figure 1-Figure 6 , taking the cold heading steel wire rod of φ5.5mm as an example, the method of the present invention is further explained.

[0053] 1) The 300mm wire rod 11 intercepted from the wire rod production line is sent to the straightening system 1 for straightening, and the straightening system 1 includes a rough leveler and a fine leveler;

[0054] 2) Send the straightened wire rod 11 to the first clamping device 4 through the conveying system 2 (in this embodiment, pinch rollers are used);

[0055] 3) The first clamping device 4 includes a first driving device 4.2 and a first sample holder 4.1, and drives the two U-shaped chucks 4.11 of the first sample holder 4.1 under the drive of the first driving device 5.2 by radial clamping Tighten the wire rod 11;

[0056] 4) After the first sample holder 4.1 clamps the wire rod, the cutting system 3 is started, and the third driving device 3.2 of the cutting system 3 drives the two cutting wheels 3.11 of the...

Embodiment 2

[0063] see Figure 1-Figure 6 , taking the cold heading steel wire rod of φ6.5mm as an example, the method of the present invention is further explained.

[0064] 1) The 300mm wire rod 11 intercepted from the wire rod production line is sent to the straightening system 1 for straightening, and the straightening system 1 includes a rough leveler and a fine leveler;

[0065] 2) Send the straightened wire rod 11 to the first clamping device 4 through the conveying system 2 (in this embodiment, pinch rollers are used);

[0066] 3) The first clamping device 4 includes a first driving device 4.2 and a first sample holder 4.1, and drives the two U-shaped chucks 4.11 of the first sample holder 4.1 under the drive of the first driving device 5.2 by radial clamping Tighten the wire rod 11;

[0067] 4) After the first sample holder 4.1 clamps the wire rod, the cutting system 3 is started, and the third driving device 3.2 of the cutting system 3 drives the two cutting wheels 3.11 of the...

Embodiment 3

[0074] see Figure 1-Figure 6 , taking the cold heading steel wire rod of φ8.5mm as an example, the method of the present invention is further explained.

[0075] 1) The 300mm wire rod 11 intercepted from the wire rod production line is sent to the straightening system 1 for straightening, and the straightening system 1 includes a rough leveler and a fine leveler;

[0076] 2) Send the straightened wire rod 11 to the first clamping device 4 through the conveying system 2 (in this embodiment, pinch rollers are used);

[0077] 3) The first clamping device 4 includes a first driving device 4.2 and a first sample holder 4.1, and drives the two U-shaped chucks 4.11 of the first sample holder 4.1 under the drive of the first driving device 5.2 by radial clamping Tighten the wire rod 11;

[0078] 4) After the first sample holder 4.1 clamps the wire rod, the cutting system 3 is started, and the third driving device 3.2 of the cutting system 3 drives the two cutting wheels 3.11 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com