Direct-injection type flame detector with self-checking light source and flame detection method

A flame detector and light source technology, applied in photometry, photometry using electric radiation detectors, optical radiation measurement, etc., can solve the problems of poor consistency and repeatability, inability to realize real-time monitoring, low detection efficiency, etc. problems, to achieve the effect of improving the ability to resist false alarms, improving environmental adaptability, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with accompanying drawing.

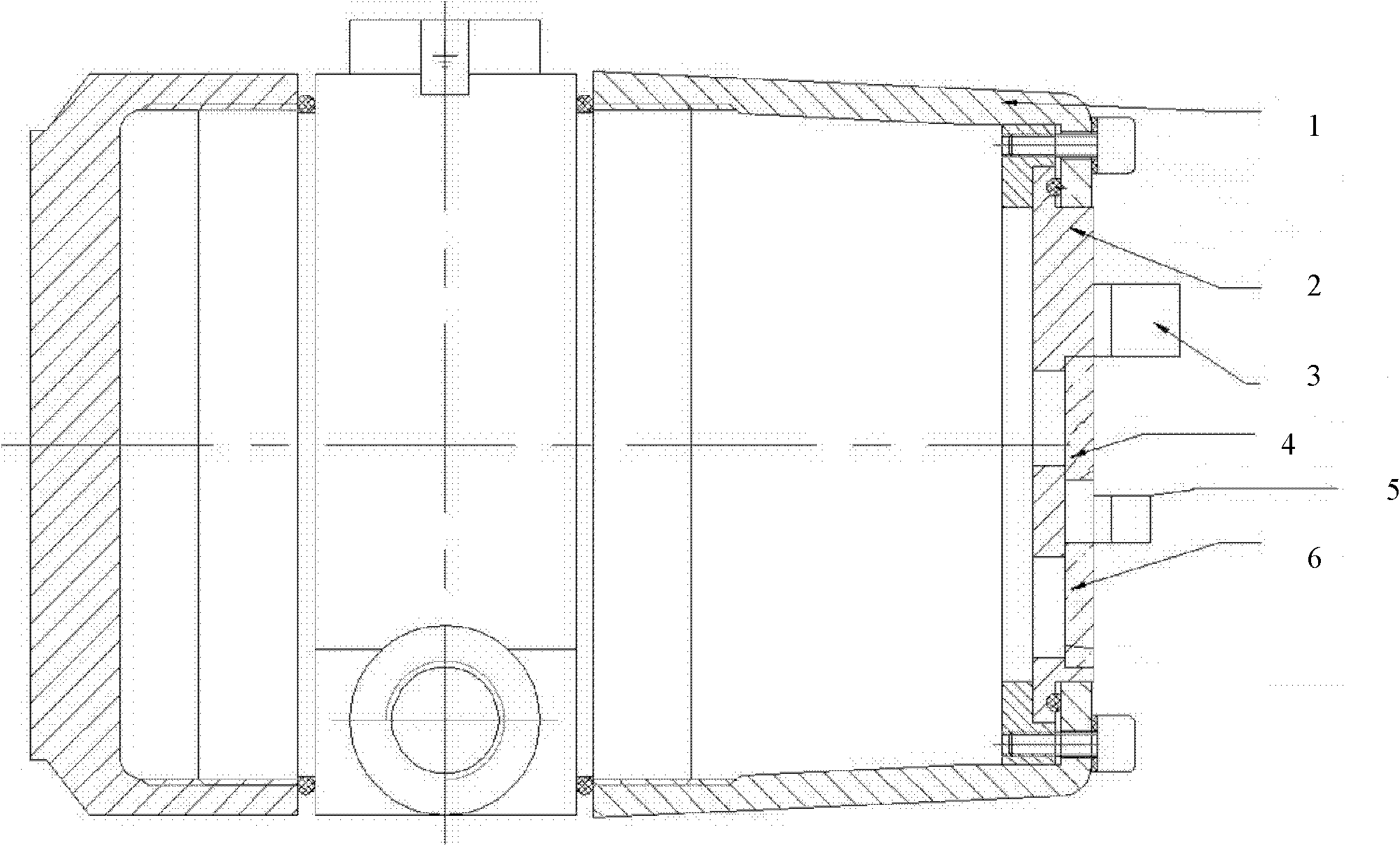

[0059] Such as figure 1 As shown, the shell of the self-inspection light source direct flame detector includes a housing 1, a panel 2, an ultraviolet self-inspection lamp holder 3, an ultraviolet window 4, an infrared self-inspection lamp holder 5 and an infrared window 6; The board is fixed on the panel, the power conversion and signal output interface board is fixed at the rear of the housing, and the ultraviolet and infrared detection boards are connected with the power conversion and signal output interface board through signal lines.

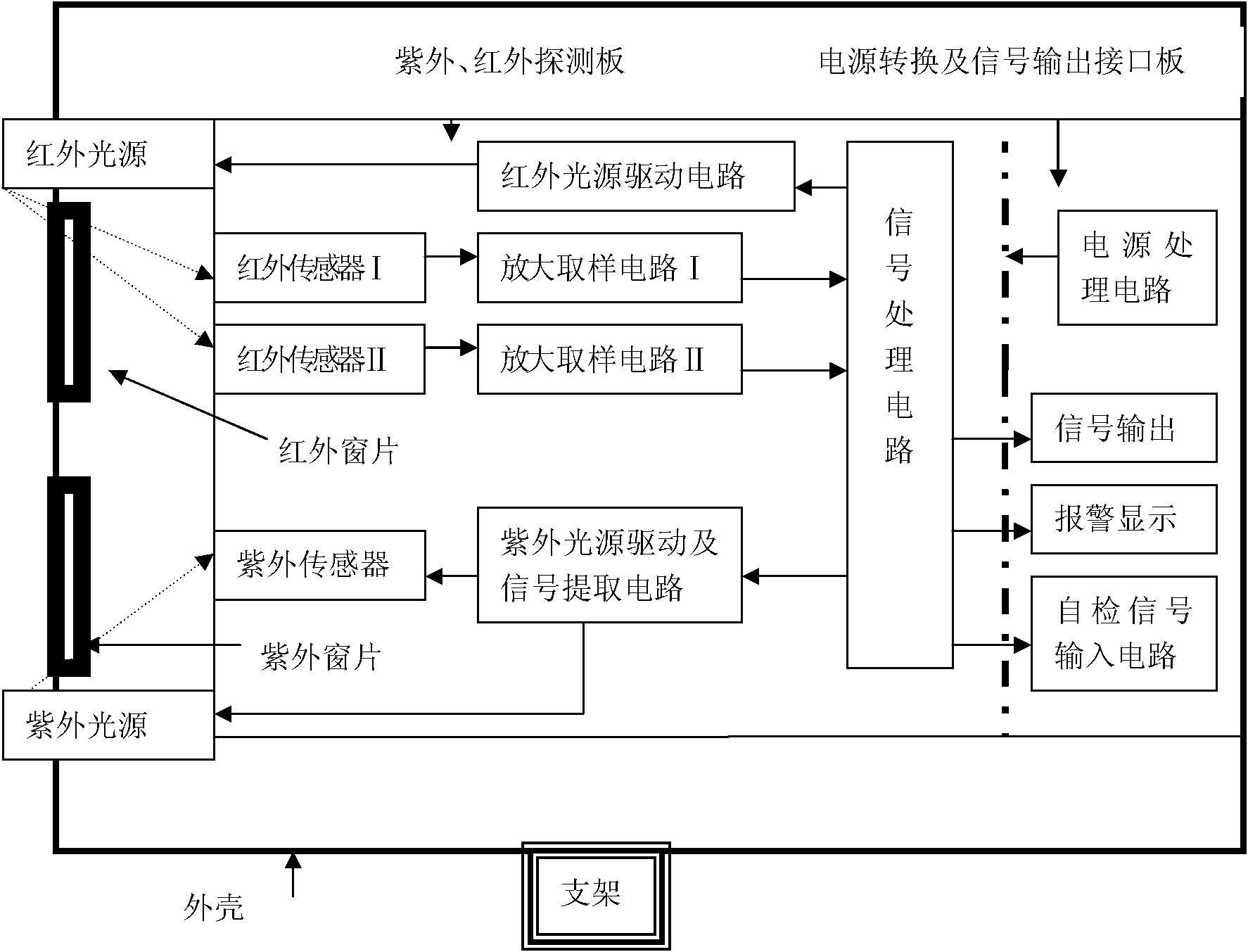

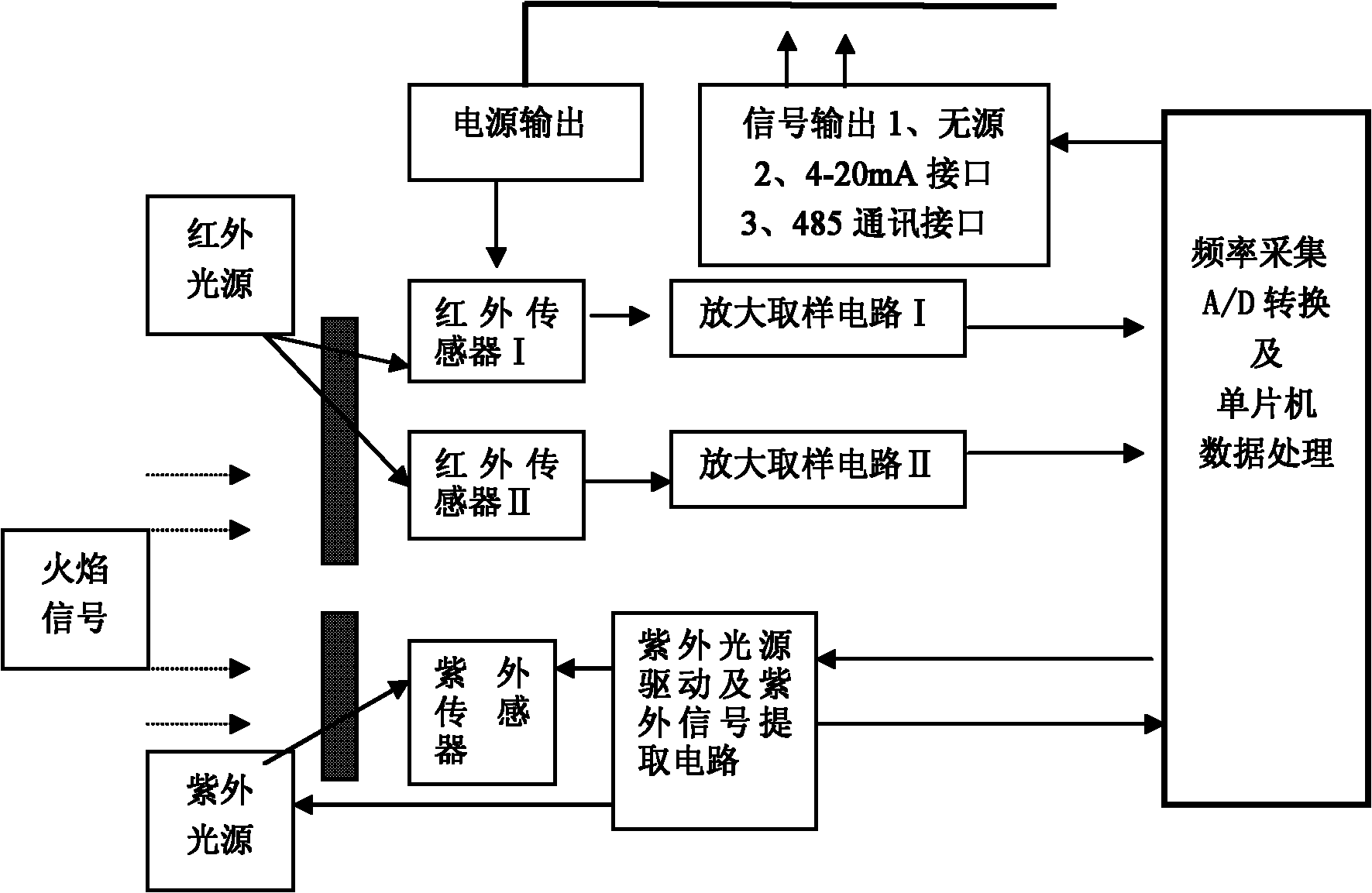

[0060] The self-inspection light source direct-ray flame detector of the present invention includes a housing, an infrared light source, an ultraviolet light source, an infrared window, an ultraviolet window, an infrared sensor I, an infrared sensor II, an ultraviolet sensor, an infrared light source driving circuit, an ultraviolet light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com