Self-sorting type ball mill and application thereof

A ball mill and self-separation technology, applied in grain processing, etc., can solve problems such as easy full grinding and over-grinding, and achieve the effects of reducing potential energy, controlling yield, and saving production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

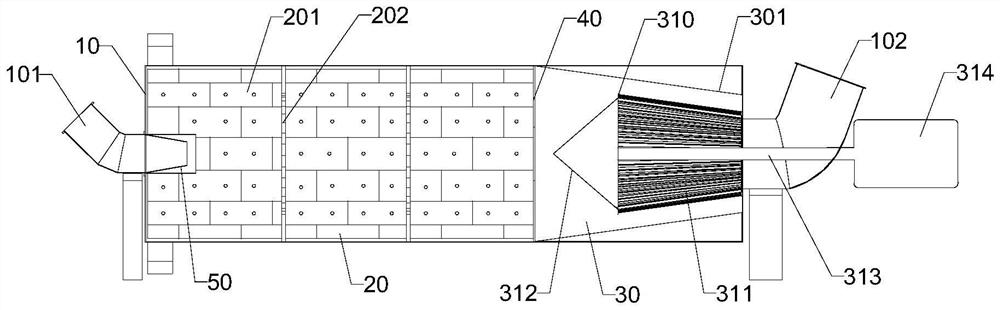

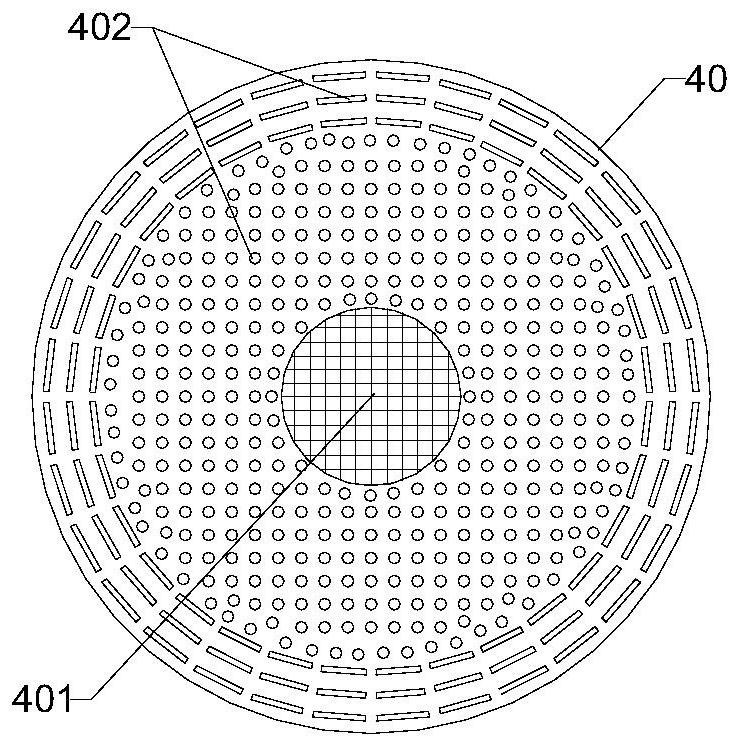

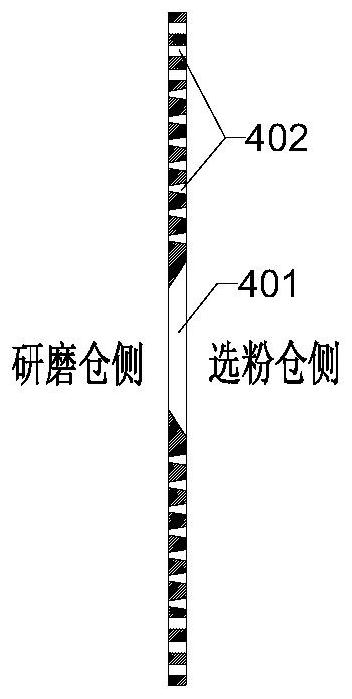

[0061] see Figure 1-5 , the present embodiment provides a self-sorting ball mill, including a cylinder body 10, a material inlet 101, and a material outlet 102. The cylinder body 10 is inclined upward from the side of the material inlet 101 to the side of the material outlet 102, and the inclination angle is 2 to 5°; the cylinder 10 is driven to rotate by the mill (not shown in the mill driving figure, specifically, the cylinder 10 can be driven to rotate by gear transmission or other means), and the cylinder 10 is driven by the feed port From 101 to the discharge port 102, a grinding bin 20 and a powder selecting bin 30 are arranged in sequence.

[0062] A grinding liner 201 is arranged on the inner wall of the cylinder 10 of the grinding chamber 20, and the grinding lining 201 is parallel to the axis of the cylinder 10; several activation rings 202 are arranged in the grinding chamber 20, which can increase the residence time of the material and prolong the time of the mate...

Embodiment 2

[0070] see Figure 6-8 , different from Embodiment 1, the powder selection bin 30 of this embodiment is also provided with a static powder selection machine 320, and the static powder selection machine 320 is located between the main compartment plate 40 and the dynamic powder selection machine 310 between.

[0071]The static powder separator 320 includes static blades 321, which are arranged in a conical shape. The angle between the static blades 321 and the axis of the cylinder body 10 is 45-65°. The side of the bin 30 gradually increases. One end of the static vane 321 close to the grinding bin 20 is fixed on the main compartment plate 40, and the other end is fixed on the cylinder body 10. Specifically, the other end is fixed on the inclined lining in the powder selection bin 30. On the plate 301, the joints are all connected by welding. The ratio of the length of the static vanes 321 in the axial direction to the length of the powder bin 30 is 15-25%, the width of each ...

Embodiment 3

[0076] see Figures 9 to 11 , different from Example 1, a drying bin 60 is also provided between the feed port 101 and the grinding bin 20 in this embodiment, and it is not necessary to make the feed port 101 and the grinding bin 20 as described in Embodiment 1. The included angle of the axis of the cylinder 10 is greater than 45° and an anti-scouring device 50 is set at the feed port 101. In this embodiment, a feed conveying reamer 601 is provided at the feed port 101, and the wet material passes through the feed conveying reamer 601 is conveyed into the drying bin 60 by screw.

[0077] A plurality of dispersing devices 602 are arranged in the drying bin 60 to fully disperse the materials so that the wet materials are dried in the drying bin 60; 25%, and the gap between two adjacent dispersing devices 602 is 100-400 mm.

[0078] A second main compartment plate 70 is arranged between the drying compartment 60 and the grinding compartment 20, and the thickness of the second m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com