Pig slaughtering link retrospective method based on time window

A technology of time window and live pigs, which is applied in the direction of instruments, sensing record carriers, data processing applications, etc., can solve the problems of difficult pig tracking management and meat product supply chain traceability management, etc., to reduce marking costs, easy operation, and reduce workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

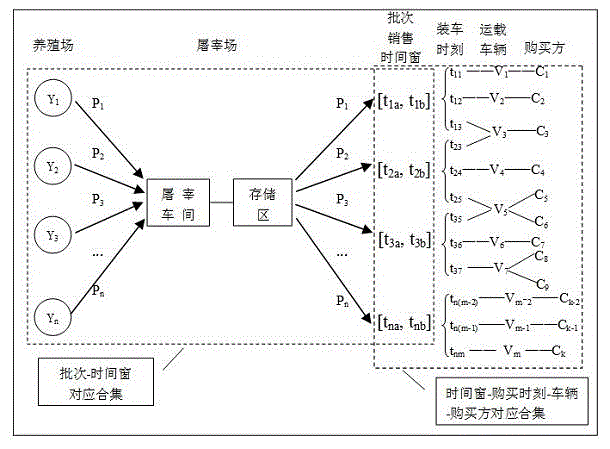

[0030] Before the method of the present invention is described in detail, the application background of the present invention is first given: (a) the slaughterhouse purchases live pigs from multiple farms every day, and the live pigs purchased from the same farm at the same time are one batch; (b) ) Live pigs are slaughtered in batches and distributed to corresponding storage areas after slaughter; (c) The application of the present invention needs to be realized with the help of the slaughterhouse information system.

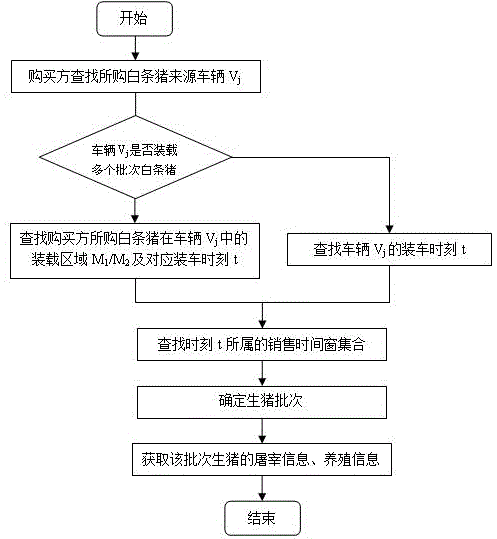

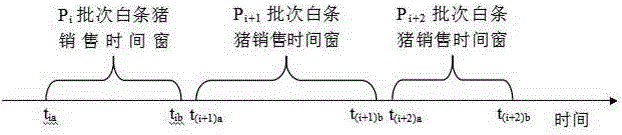

[0031] like figure 1 As shown, the traceability method of the present invention comprises the following steps:

[0032] (1) for P i The first pig of a batch of live pigs shall be identified as a batch, and the batch information and ear tag information shall be stored in the slaughterhouse information system, where P i is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com