Patents

Literature

38 results about "Batch Identifier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

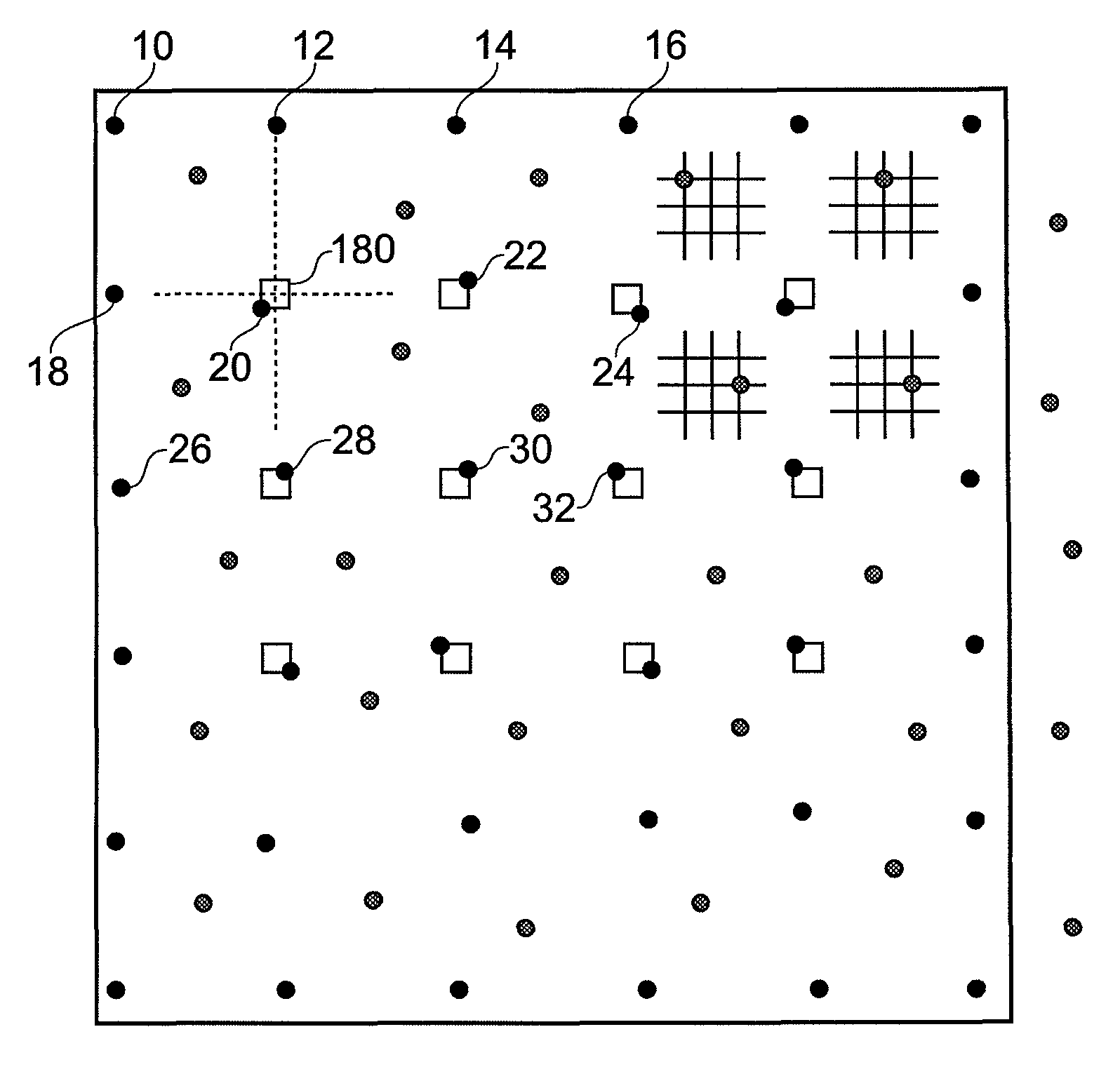

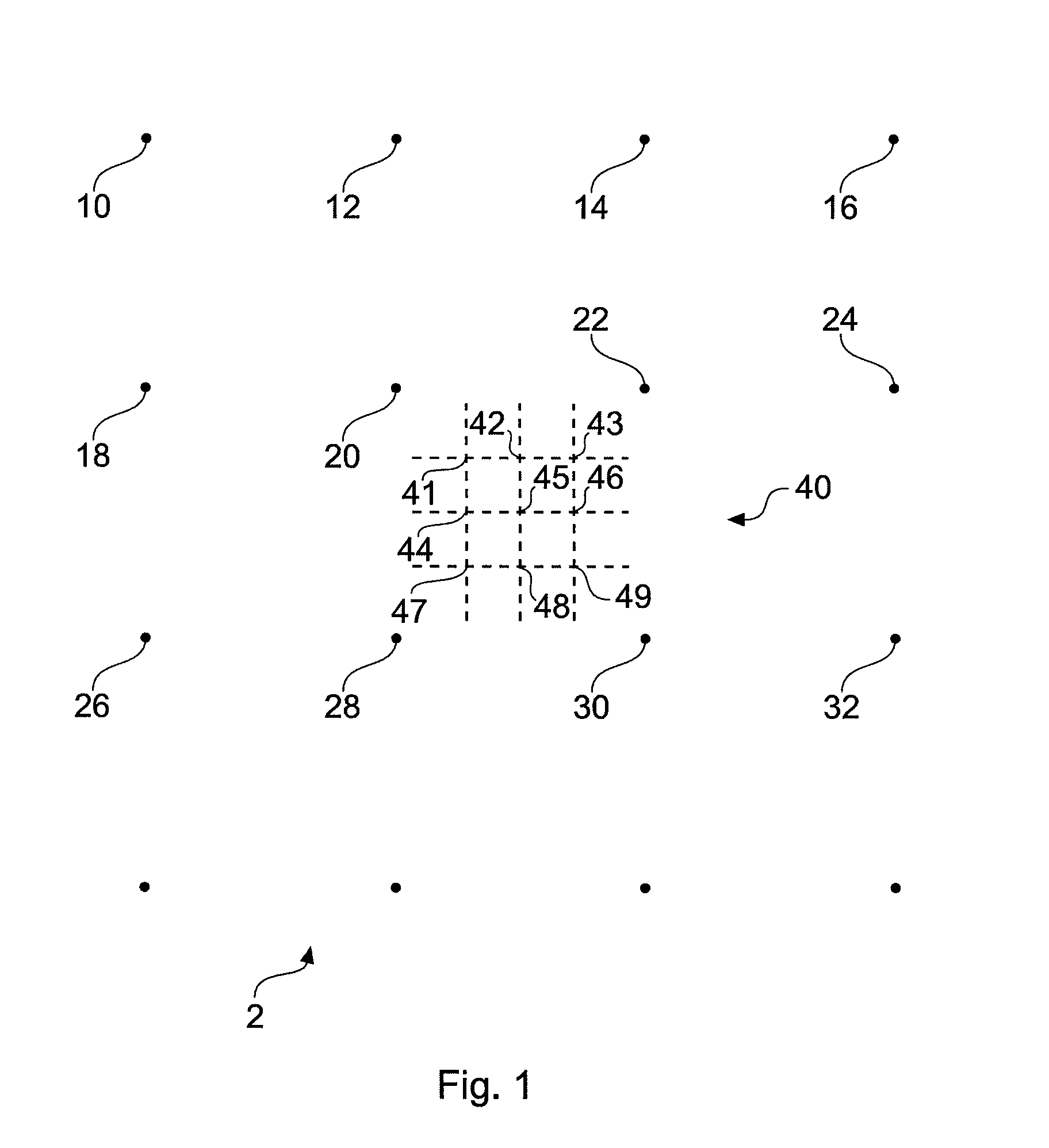

Method of and System for Authenticating An Item

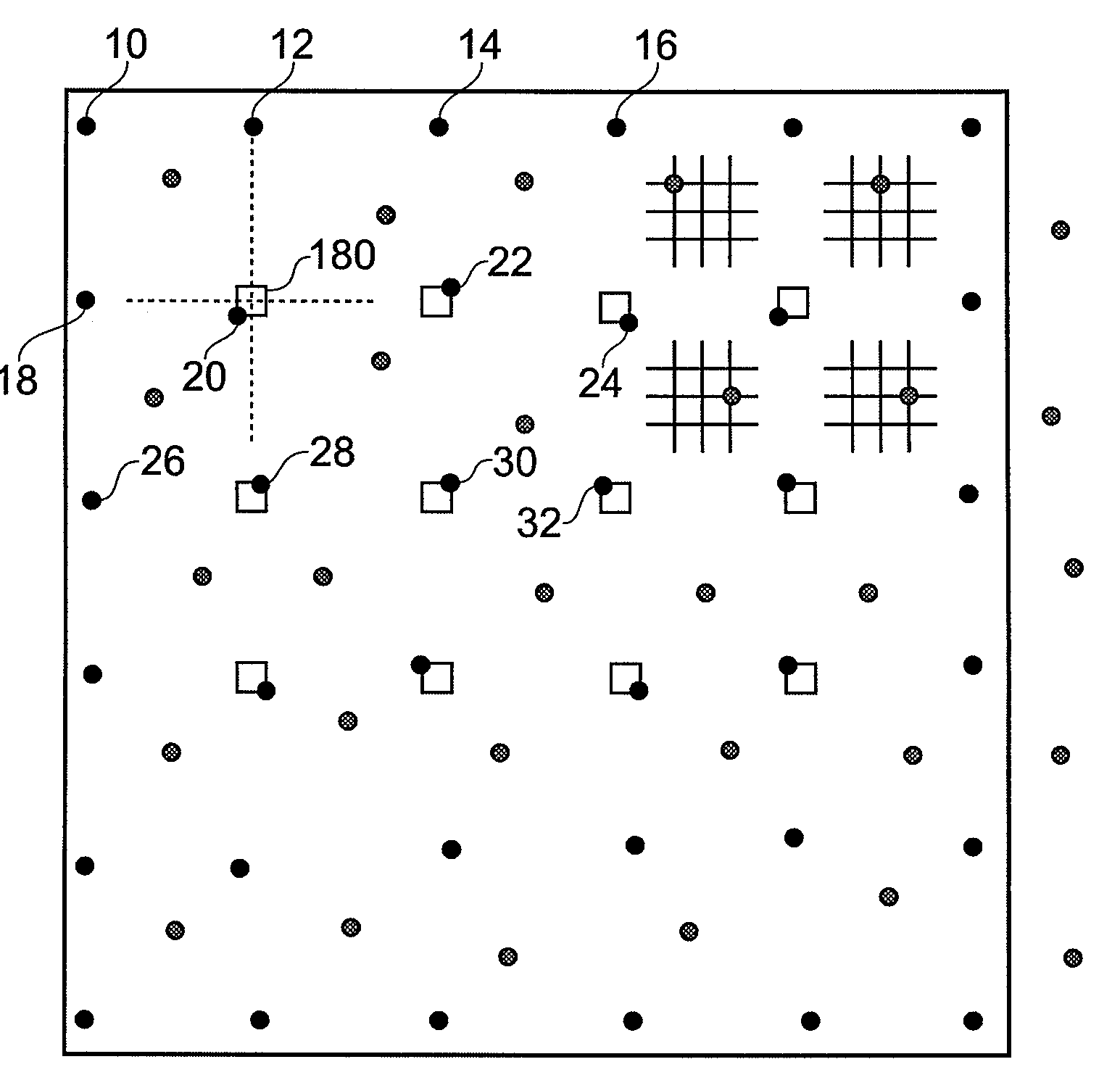

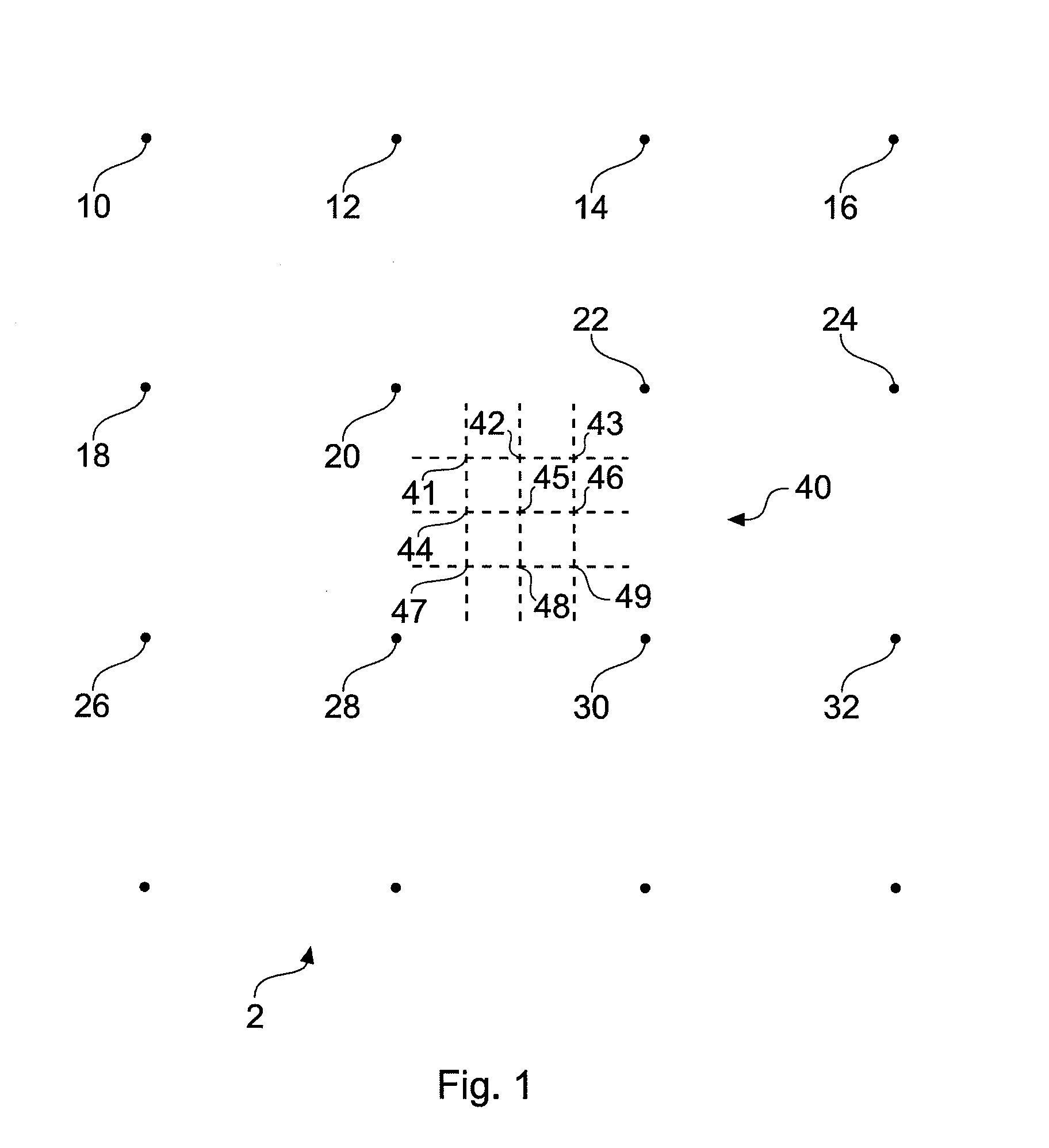

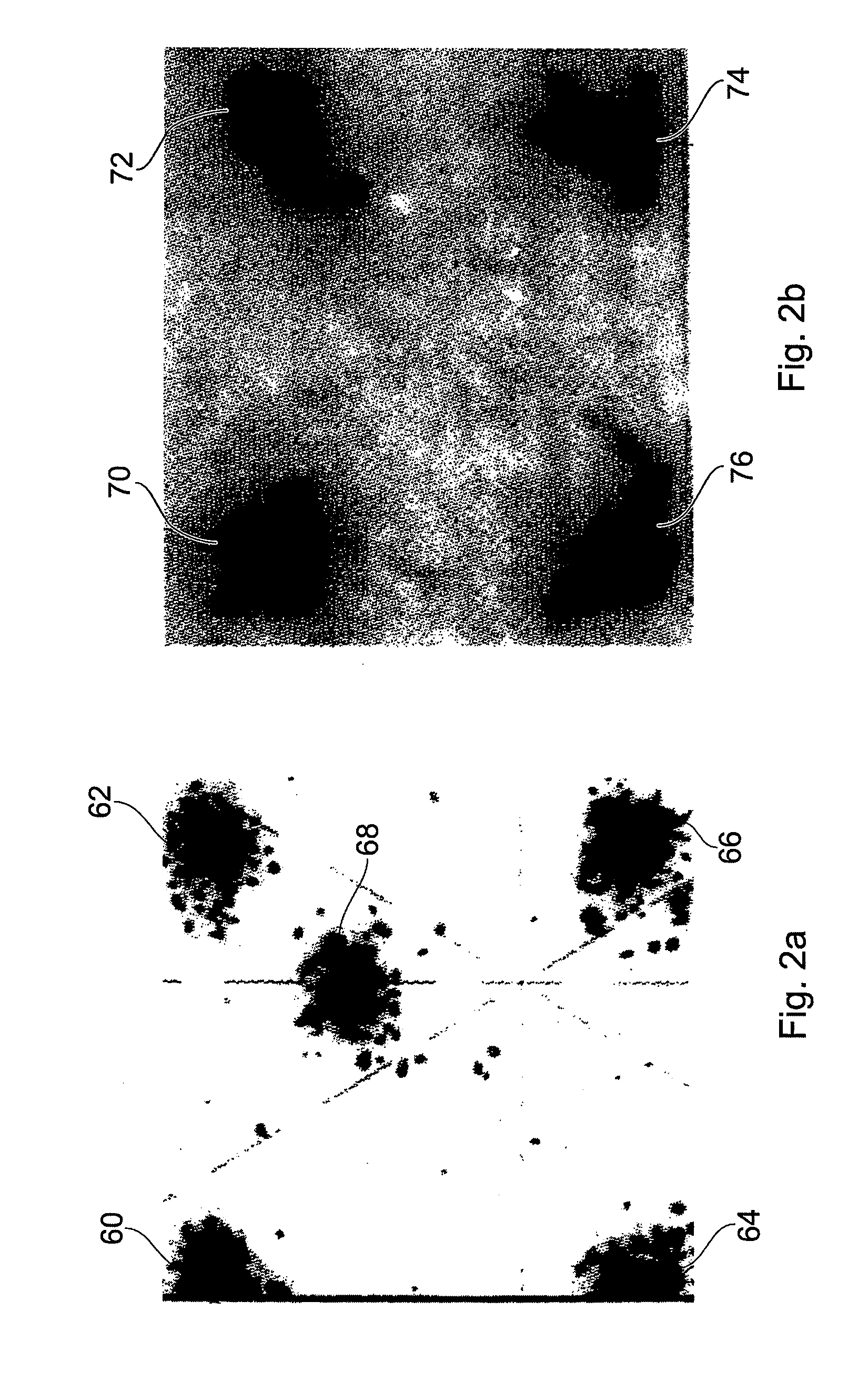

A method of authenticating the identity of an item bearing or associated with a printed security marker, the method comprising:a. printing the security marker with a pattern that encodes at least one of a unique product identifier, a batch identifier, and positional information about a portion of the marker;b. scanning and storing an image of the security marker as printed, said image being taken at sufficiently high resolution to capture artefacts of the printing process;and authentication steps comprising:c. imaging a portion of the marker at sufficiently high resolution to capture the artefacts, andd. querying a data store by providing the image of the portion of the marker or a compressed or parameterised version of the image and data derived from the pattern.

Owner:HEWLETT PACKARD DEV CO LP

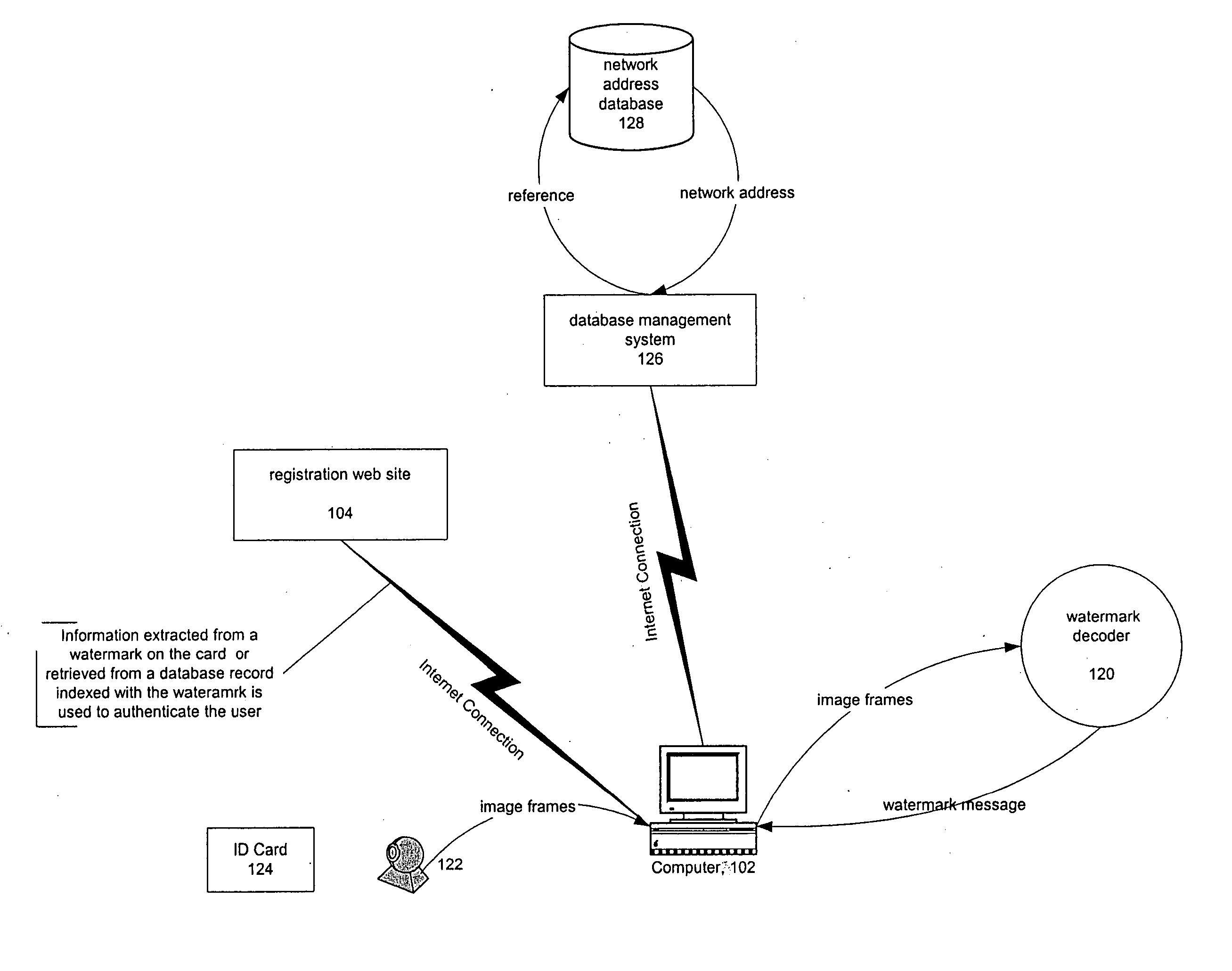

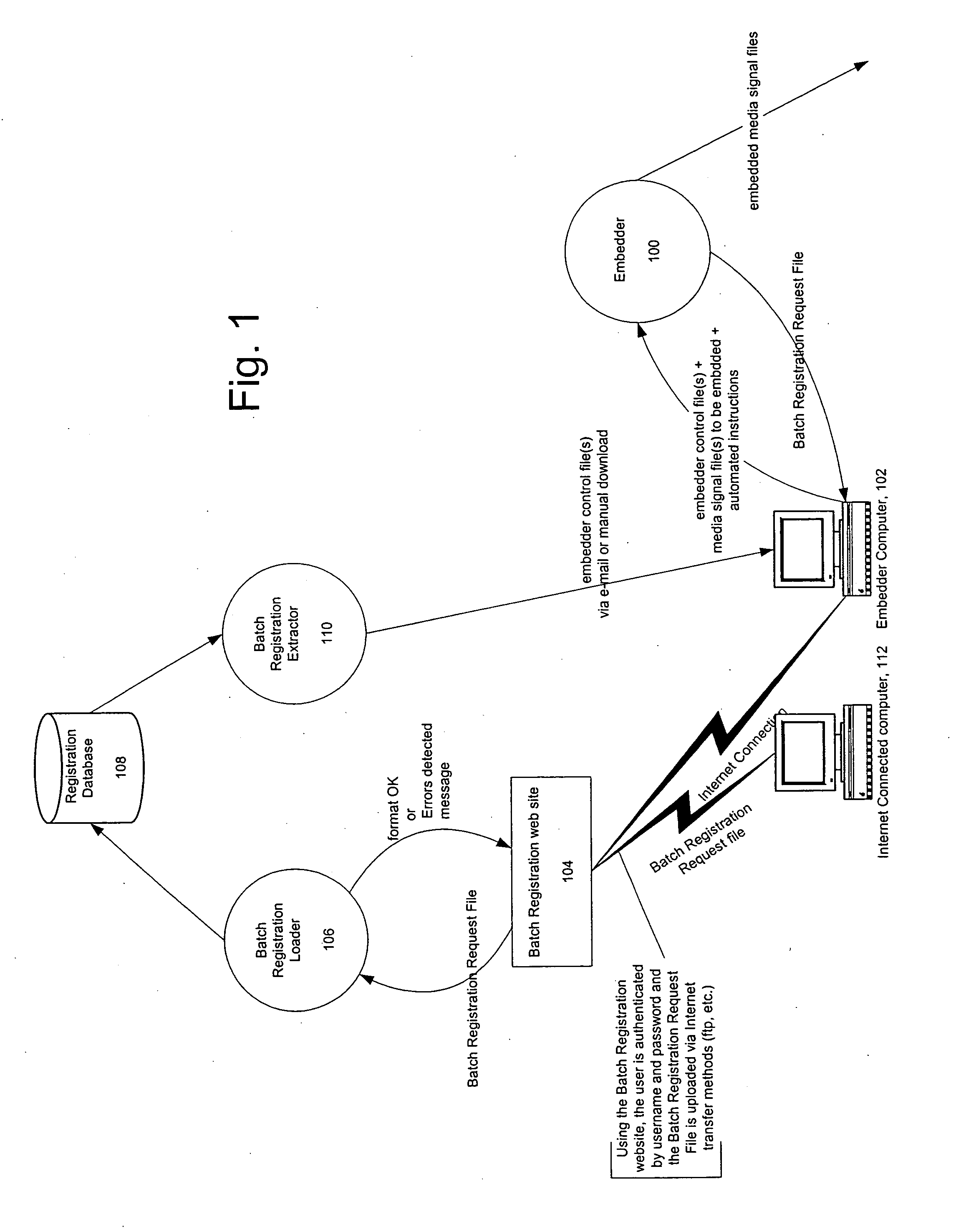

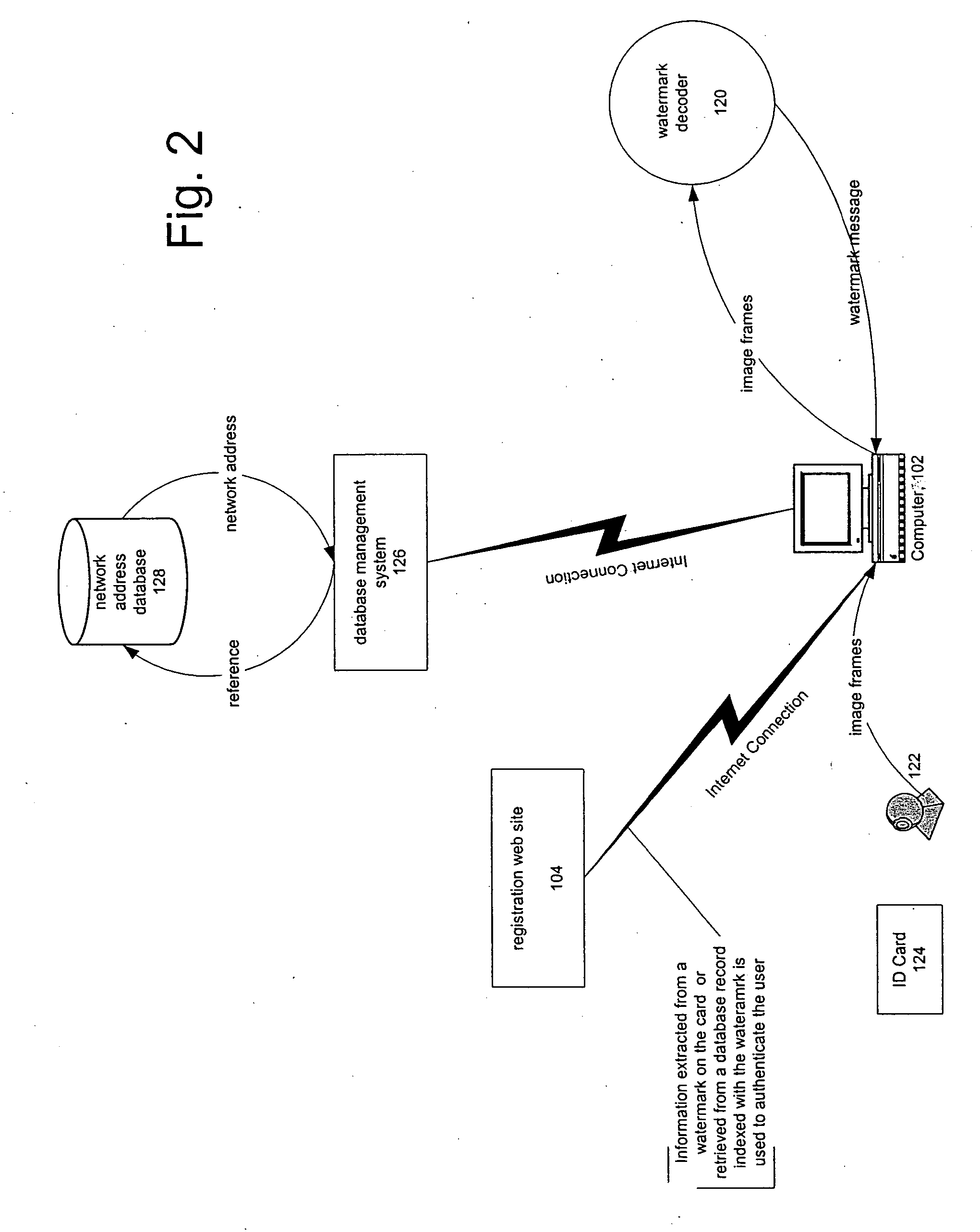

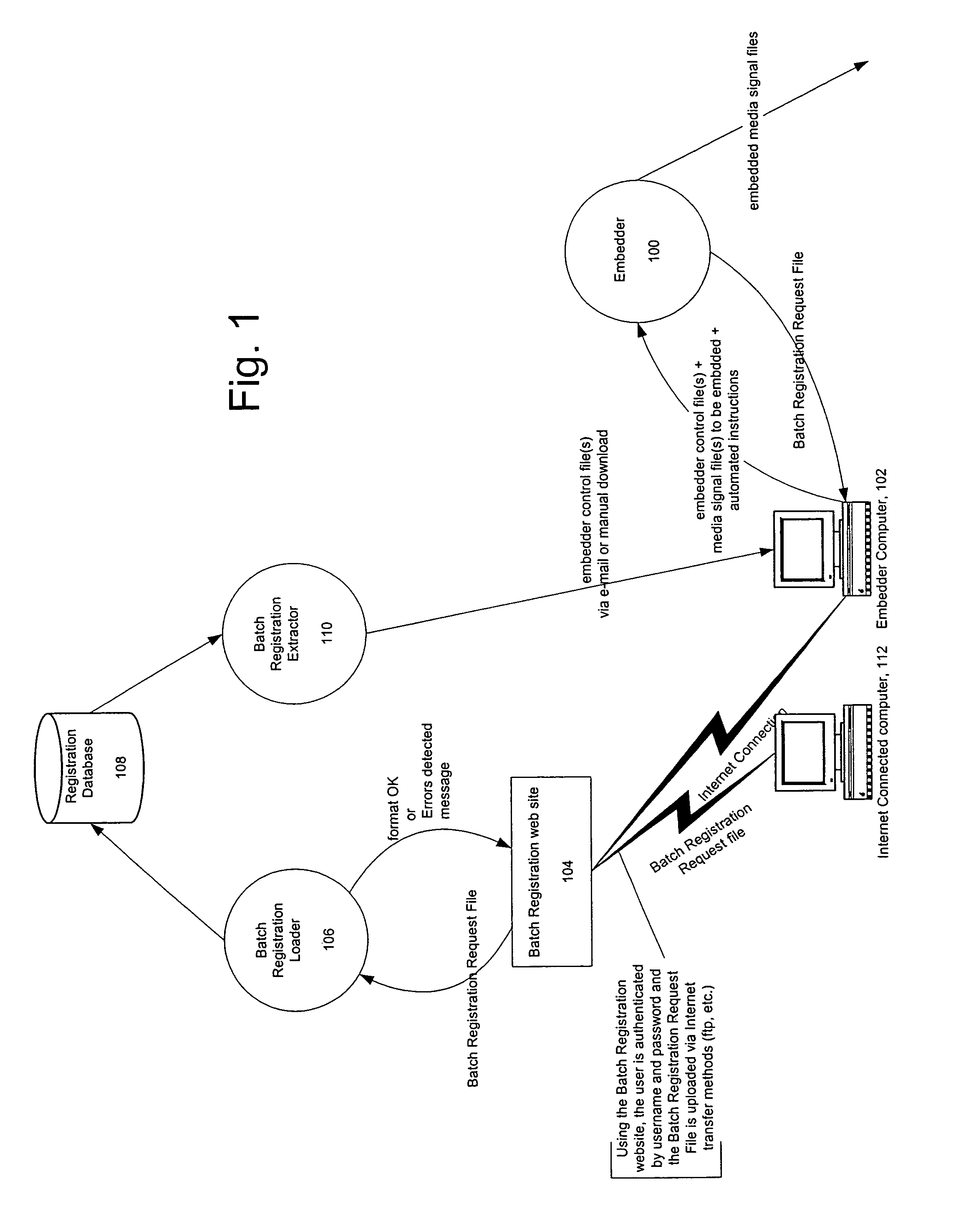

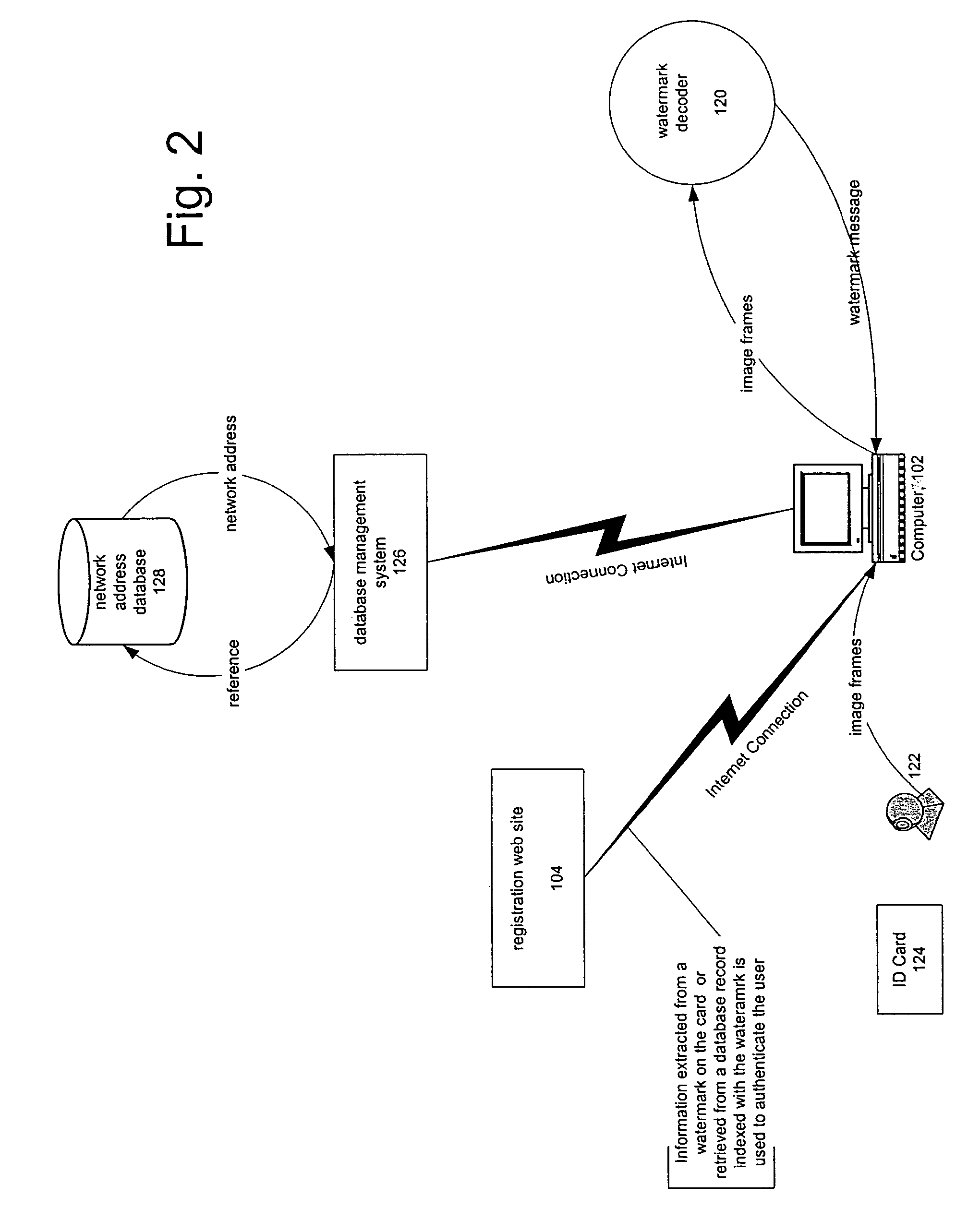

Batch identifier registration and embedding in media signals

ActiveUS20070070429A1Efficient and accurateCharacter and pattern recognitionVisual presentationUnique identifierOperating system

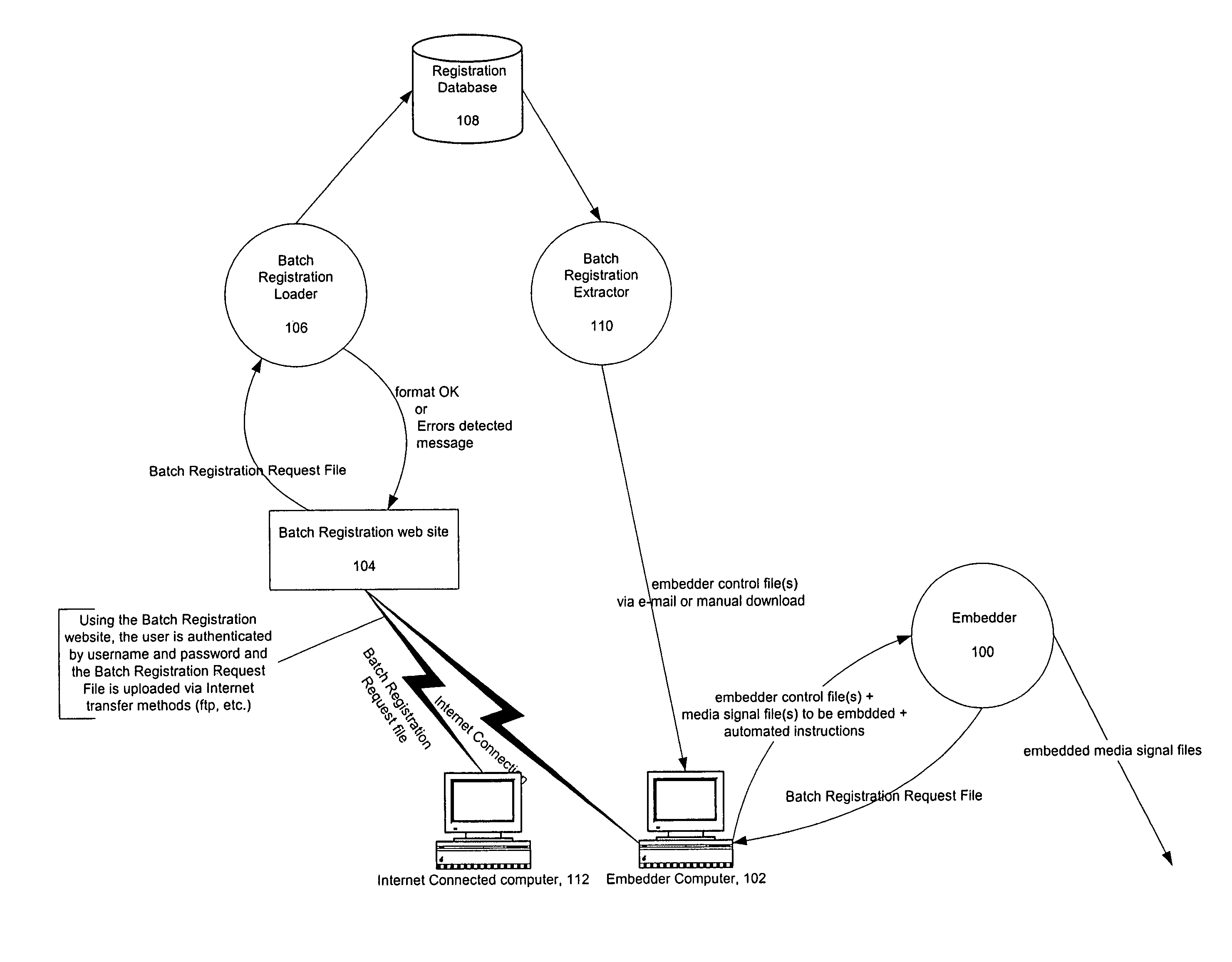

An automated batch identifier registration and embedding system for media signals, such as image, video and audio files. A batch identifier registration system enables a user to submit a request for a batch of unique identifiers to be embedded in media signals. The user submits a request for a batch of IDs. The batch registration system verifies the accuracy of the request, sends a confirmation, allocates IDs, creates corresponding entries in a registration database, and creates embedder files used in a batch embedding process. The user may then submit a request for embedder files. To perform automated batch embedding, a watermark embedder takes the embedder files and corresponding list of media signal files as input and automatically embeds identifiers supplied in the embedder files into corresponding media signal files.

Owner:DIGIMARC CORP

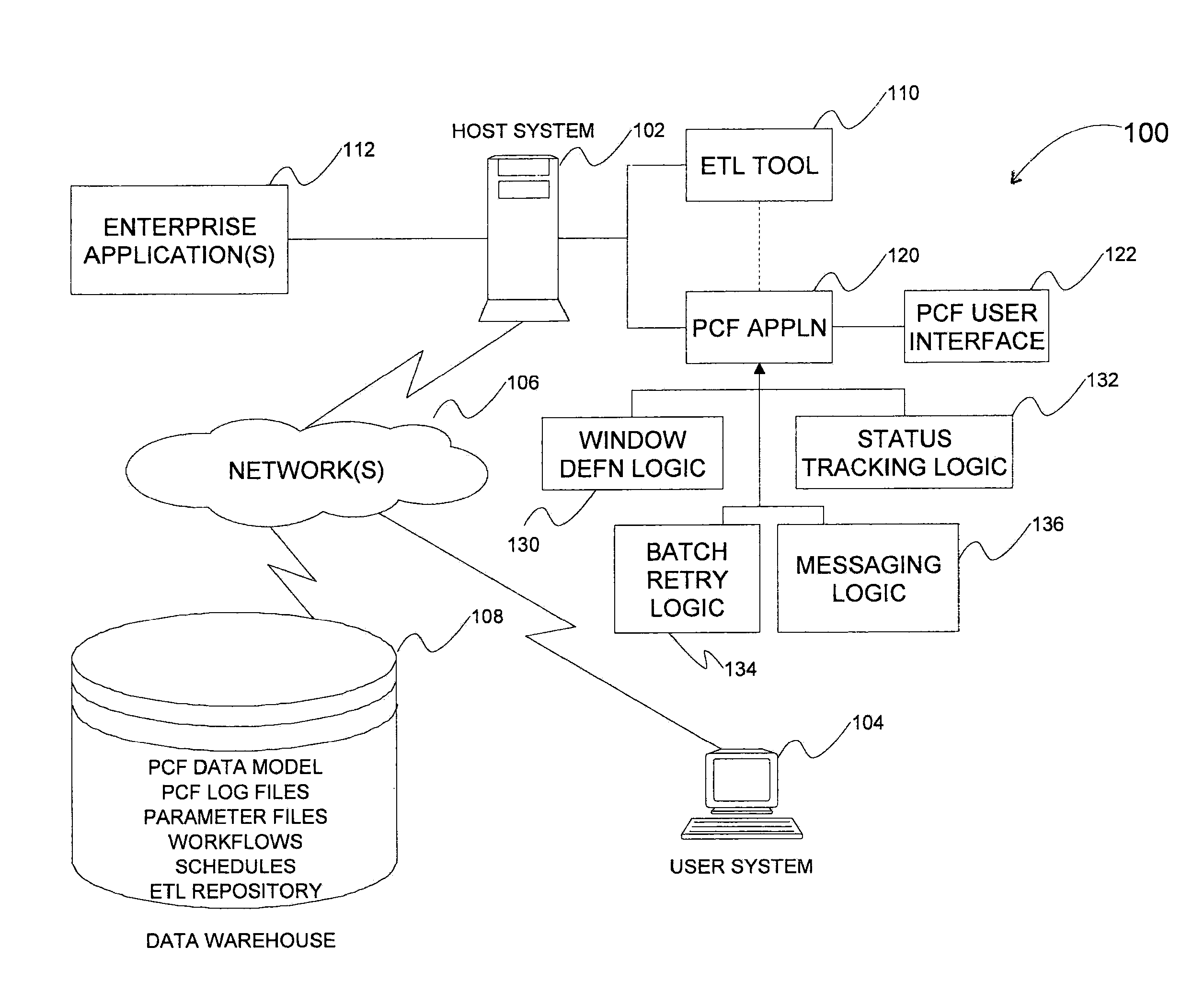

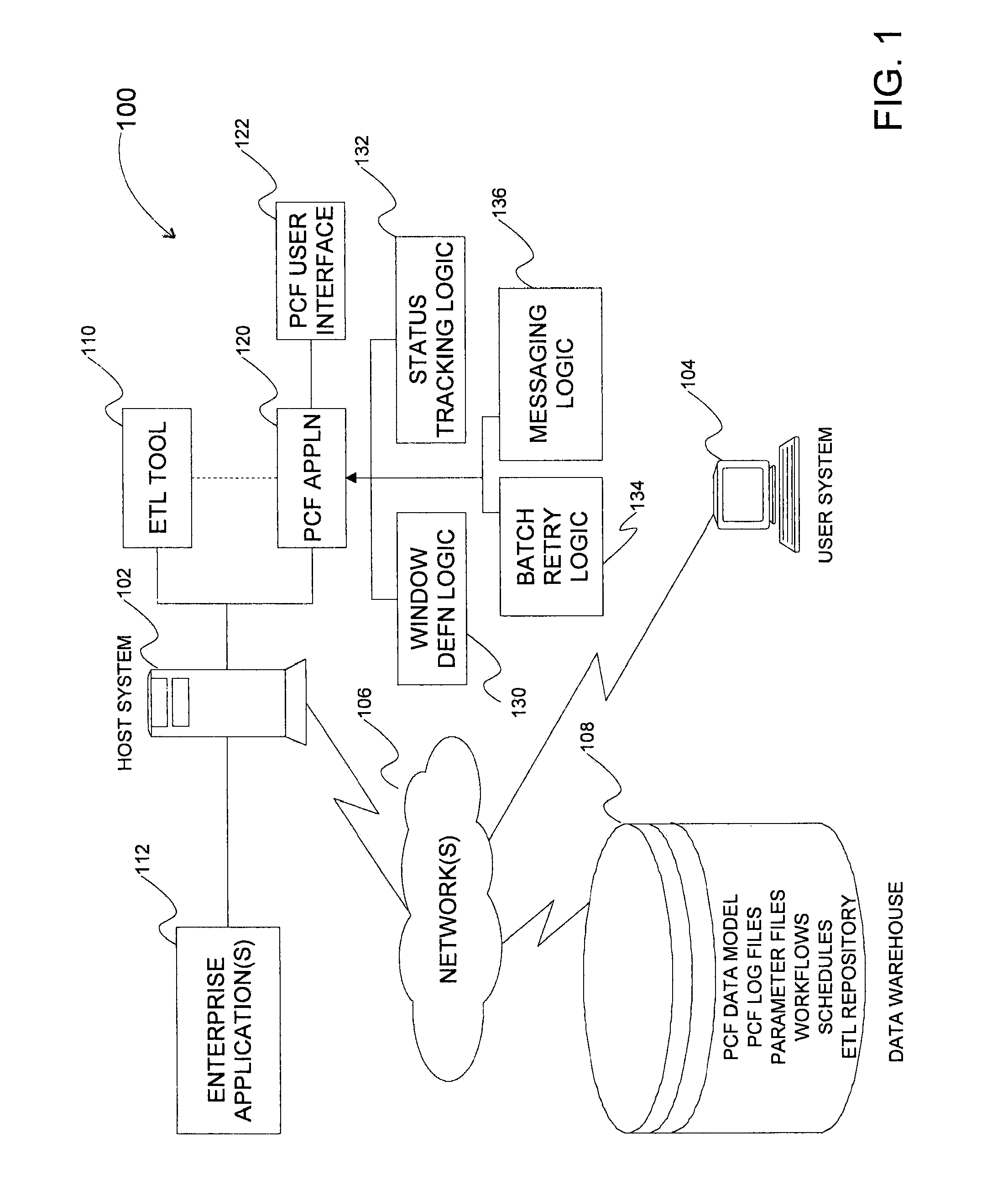

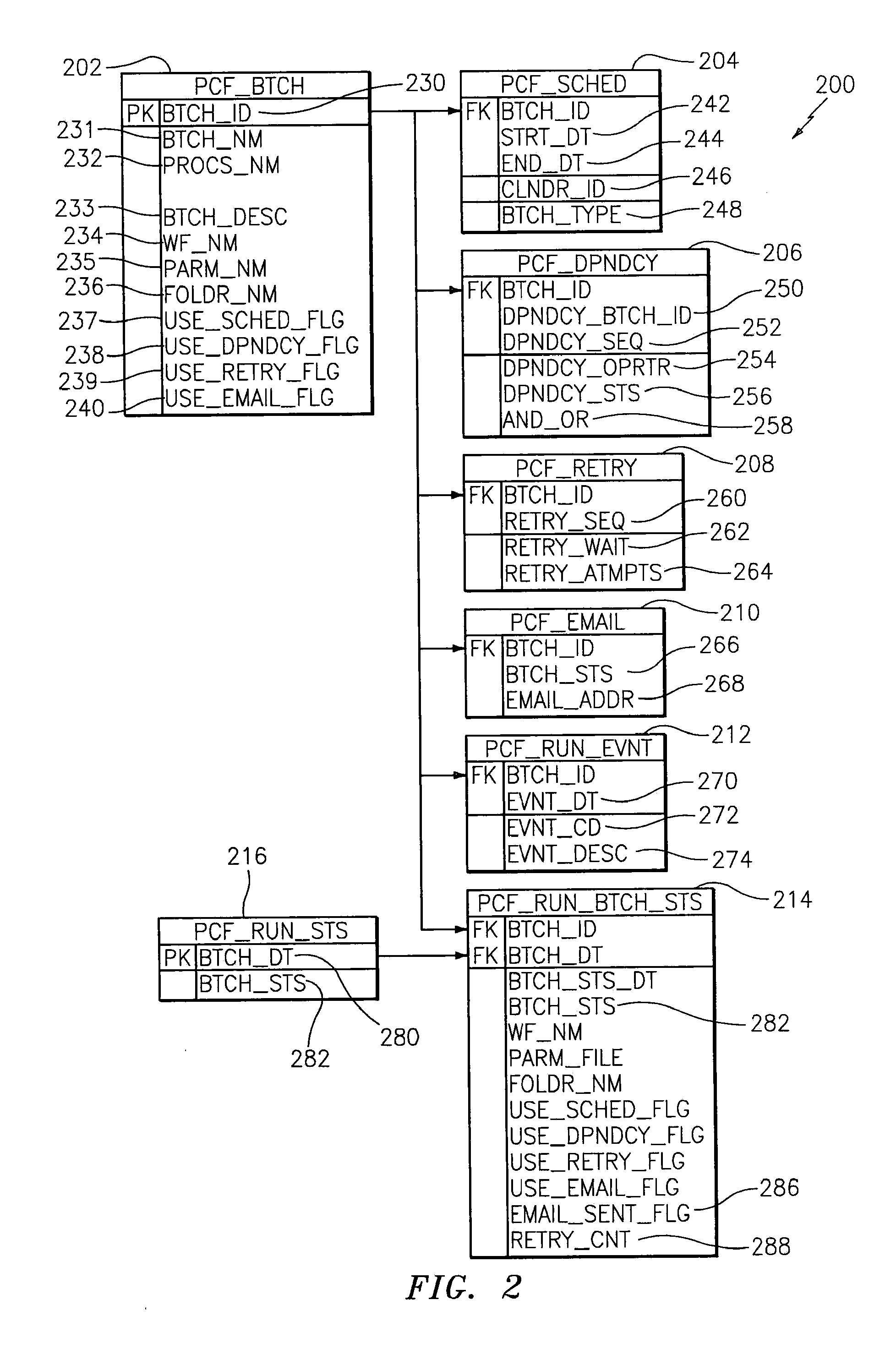

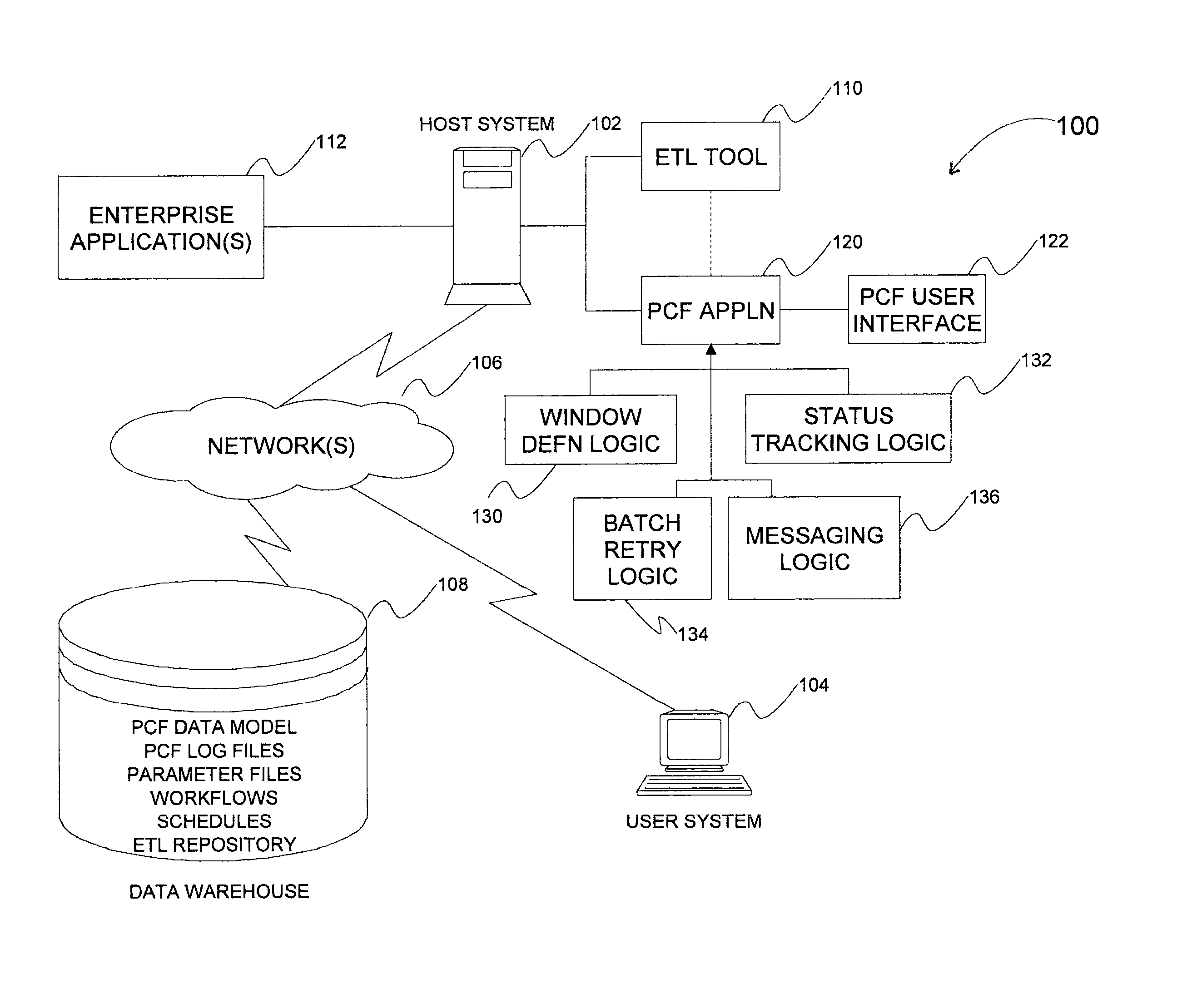

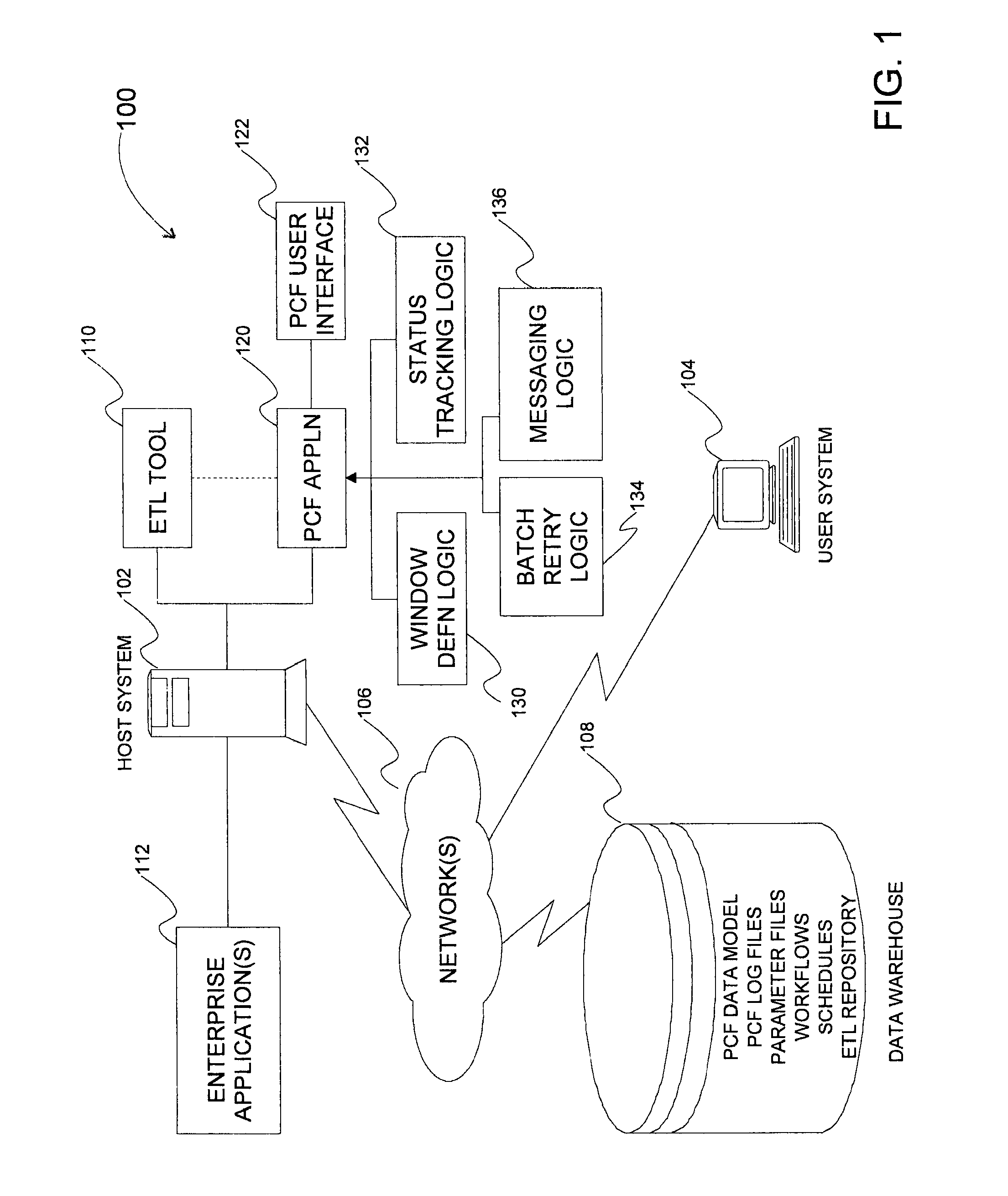

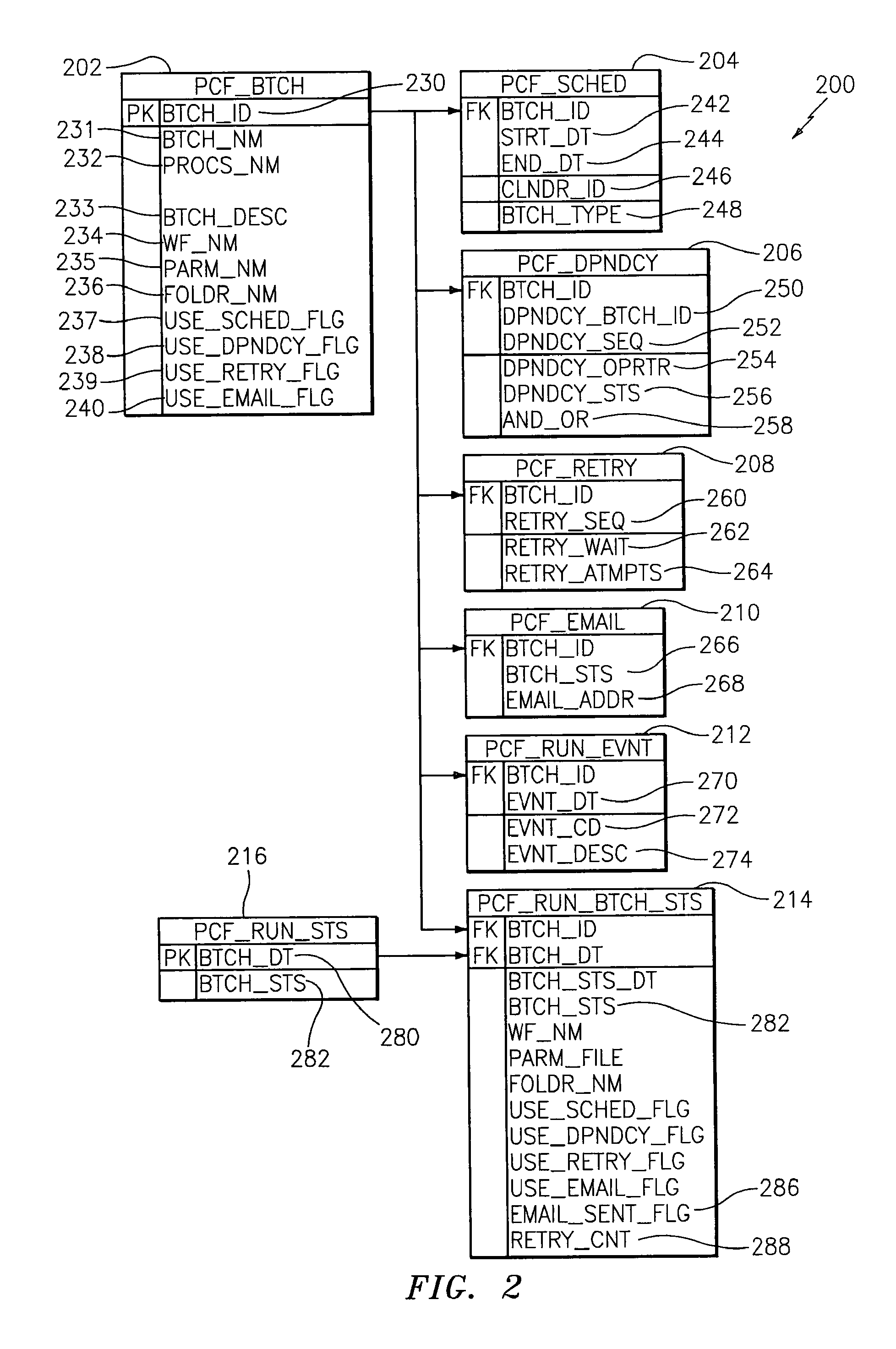

Methods, systems, and computer program products for managing batch operations in an enterprise data integration platform environment

InactiveUS20100153952A1Multiprogramming arrangementsOffice automationBatch processingBatch operation

Methods, system, and computer program products for managing batch operations are provided. A method includes defining a window of time in which a batch will run by entering a batch identifier into a batch table, the batch identifier specifying a primary key of the batch table and is configured as a foreign key to a batch schedule table. The time is entered into the batch schedule table. The method further includes entering extract-transform-load (ETL) information into the batch table. The ETL information includes a workflow identifier, a parameter file identifier, and a location in which the workflow resides. The method includes retrieving the workflow from memory via the workflow identifier and location, retrieving the parameter file, and processing the batch, according to the process, workflow, and parameter file.

Owner:AT&T INTPROP I L P

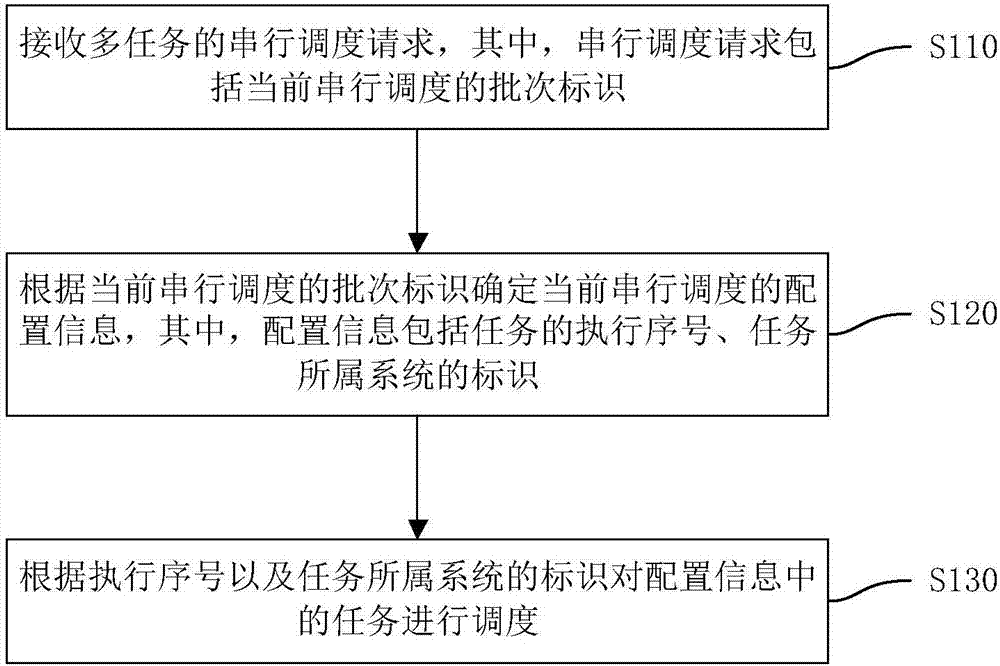

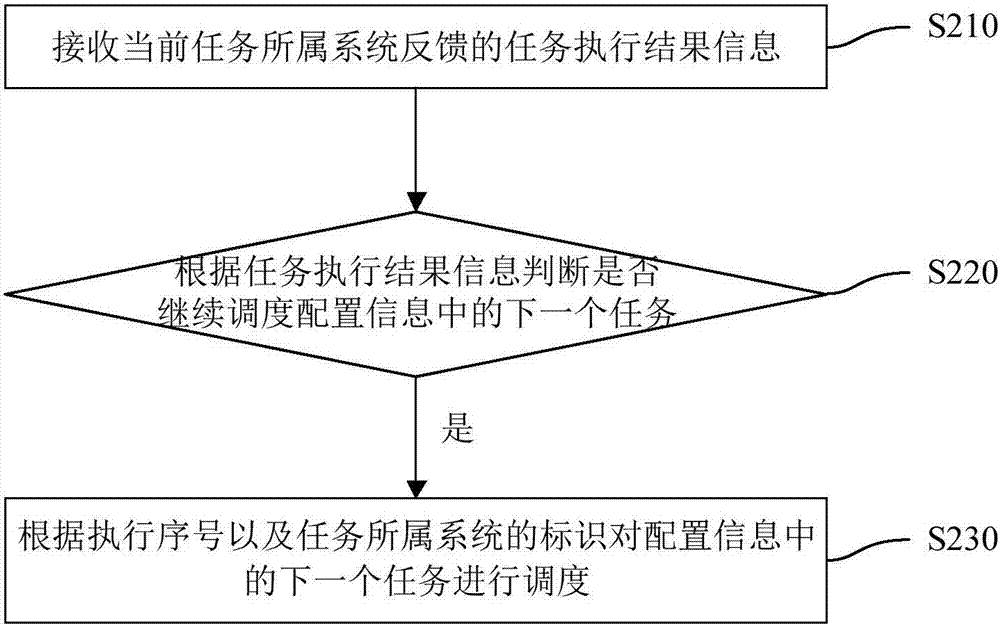

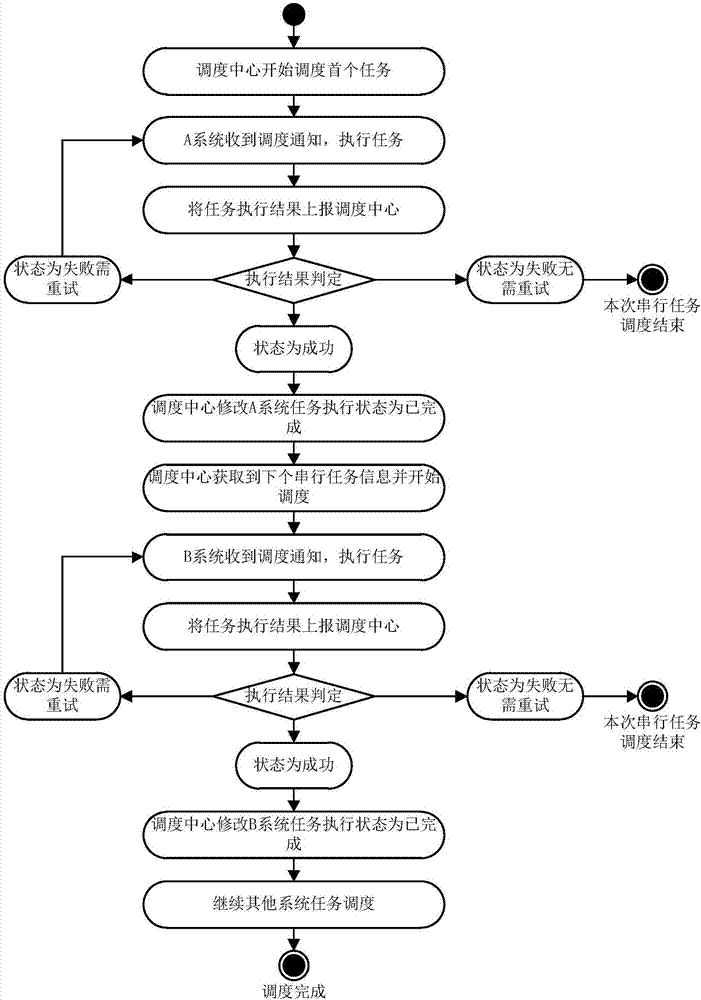

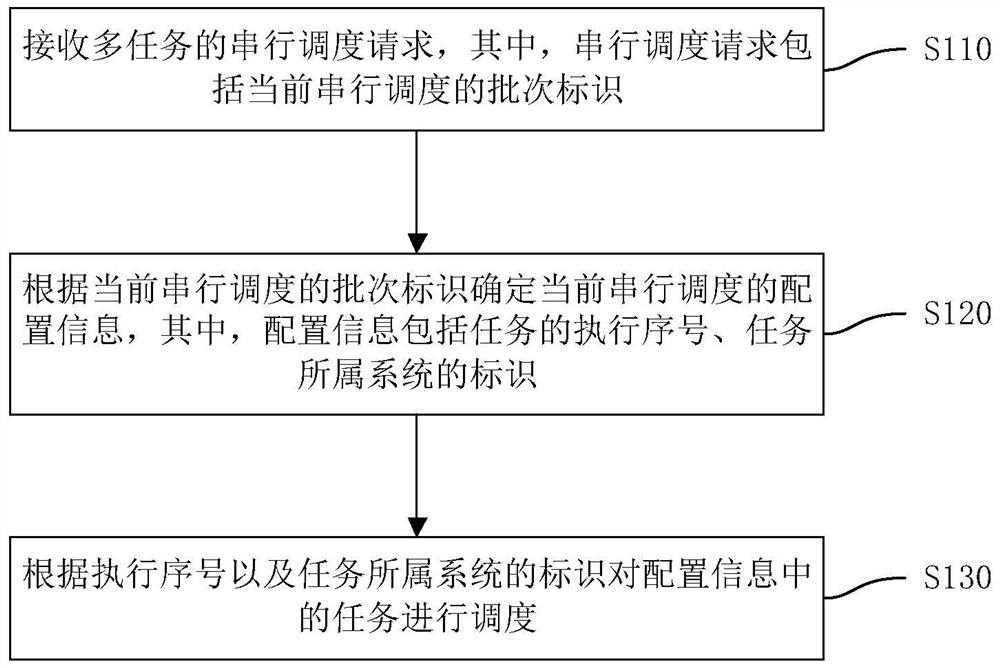

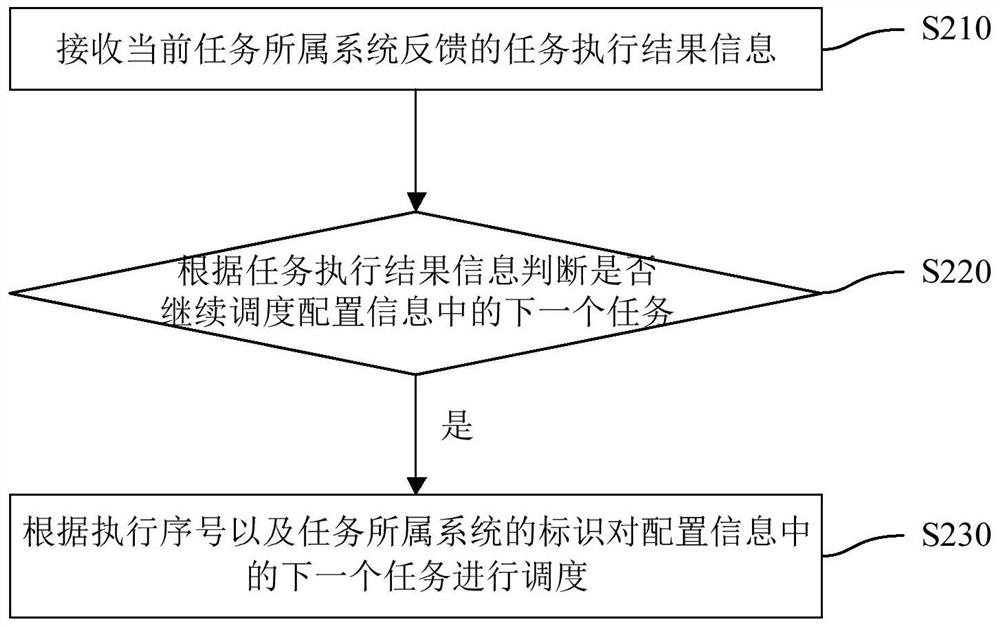

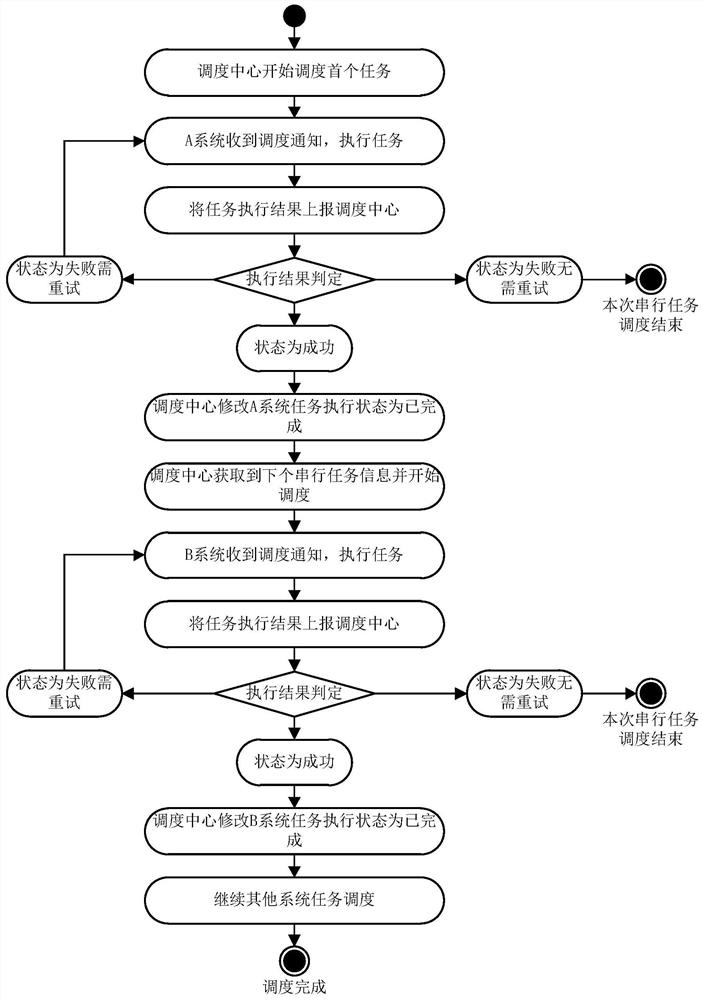

Serial scheduling method and device for multiple tasks

ActiveCN107168789AFlexibly change the order of task executionFlexibility to change the number of tasksResource allocationOperating systemBatch Identifier

The invention discloses a serial scheduling method and device for multiple tasks. The method comprises the steps that a serial scheduling request for multiple tasks is received, wherein the serial scheduling request comprises a batch identifier of current serial scheduling; configuration information of the current serial scheduling is determined according to the batch identifier of the current serial scheduling, wherein the configuration information comprises execution numbers of the tasks and an identifier of a system which the tasks belong to; and the tasks in the configuration information are scheduled according to the execution numbers and the identifier of the system which the tasks belong to. Through the method, the current problem that serial scheduling processing is needed for multiple tasks is solved, the task execution order and the number of the tasks can be flexibly changed just by changing task information in the configuration information, it can be guaranteed that the tasks are serially scheduled and executed, and the method can better adapt to task alteration.

Owner:ADVANCED NEW TECH CO LTD

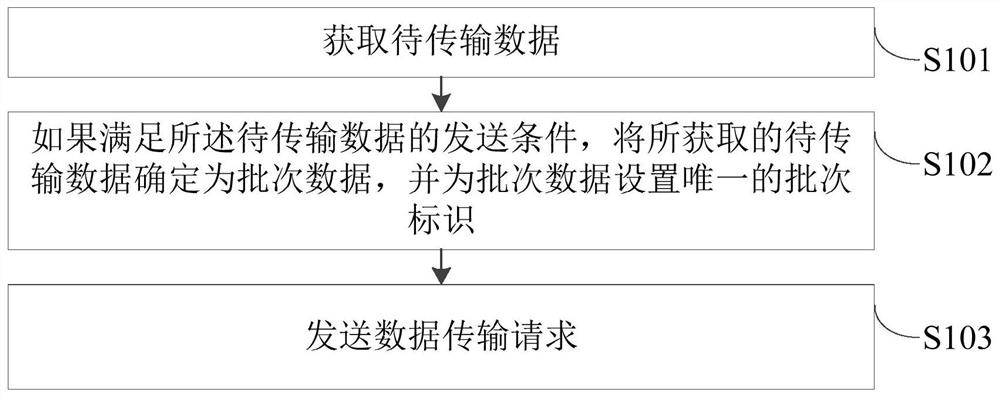

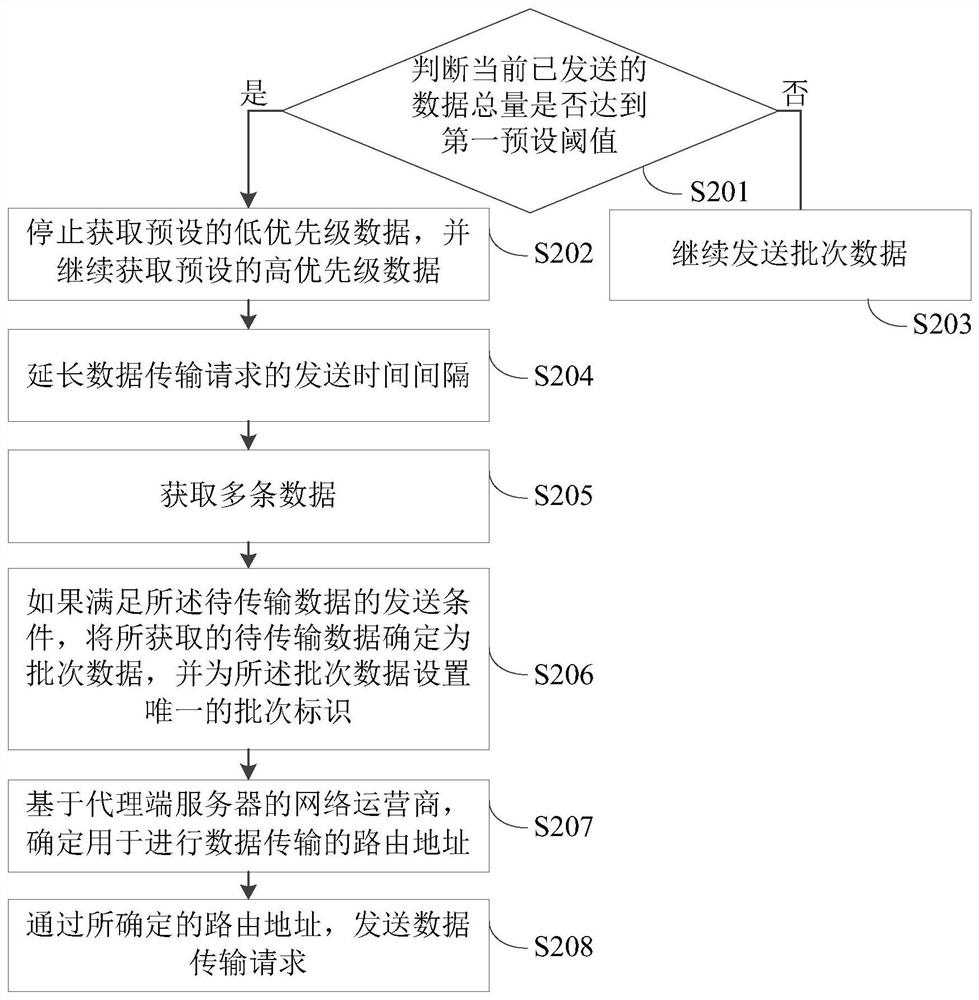

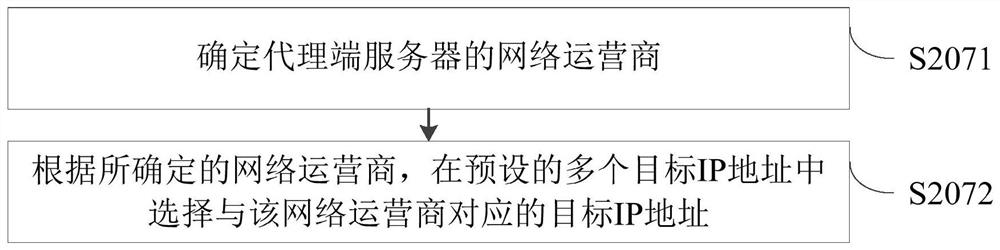

Data transmission method and apparatus, data storage method and apparatus, server and storage medium

ActiveCN109639811AImprove accuracyAvoid duplicate transmissionTransmissionData transmission circuitOperating system

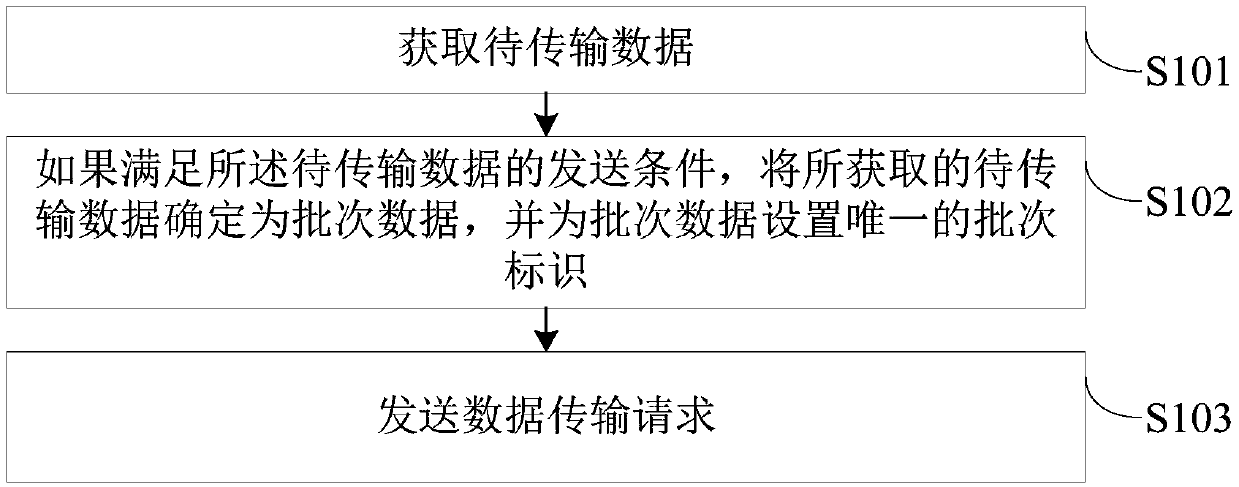

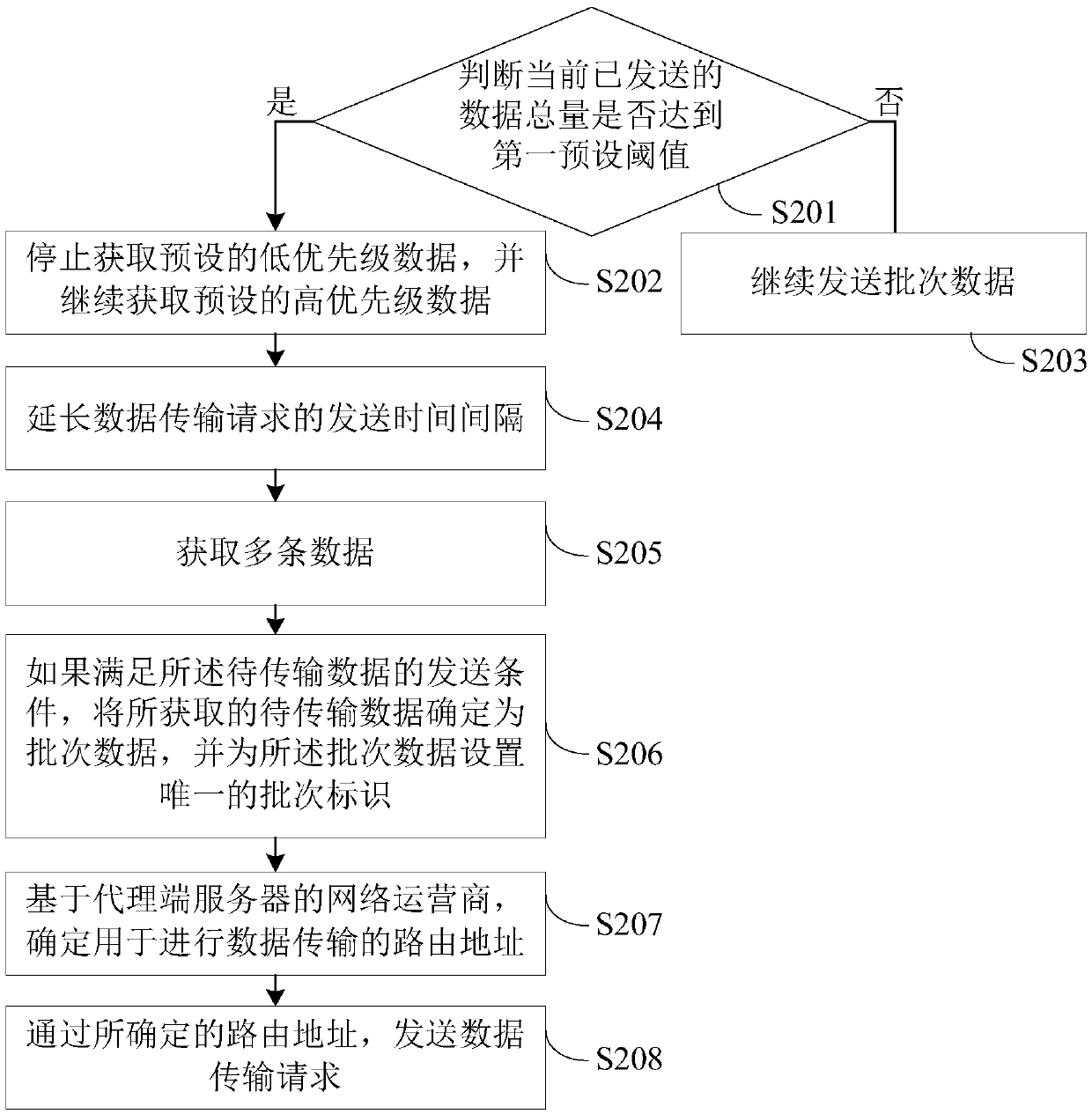

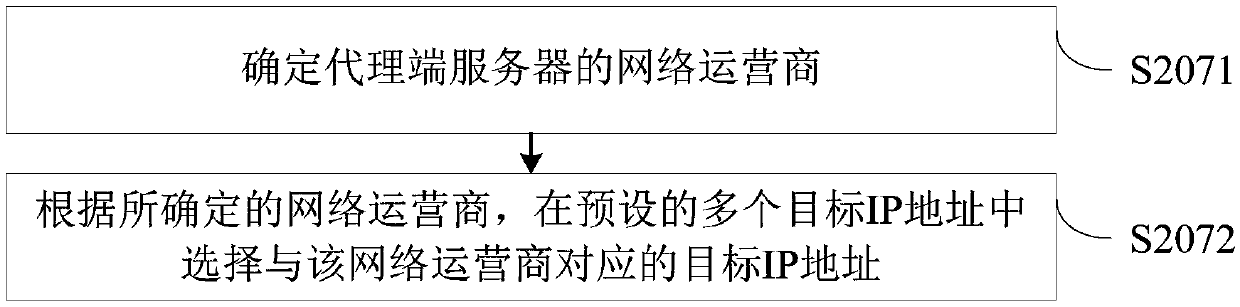

The embodiment of the invention provides a data transmission method and apparatus, a data storage method and apparatus, a server and a storage medium. The transmission method comprises the following steps: acquiring data to be transmitted, if sending conditions of the data to be transmitted are satisfied, determining the acquired data to be transmitted as batch data, and setting a unique batch identifier for the batch data; and sending a data transmission request. The storage method comprises the following steps: receiving a data transmission request; judging whether a stored identifier of a batch identifier exists locally; when the stored identifier of the batch identifier exists, determining that the batch data have been, wherein the data transmission request is a repeated transmission request; and when the stored identifier of the batch identifier does not exist, determining that the batch data are not stored; and storing the batch data, and adding the stored identifier for the batch identifier. By adoption of the data transmission method and the data storage method provided by the embodiment of the invention, the data transmission accuracy during large data size transmission can be improved.

Owner:BEIJING KINGSOFT CLOUD NETWORK TECH CO LTD +1

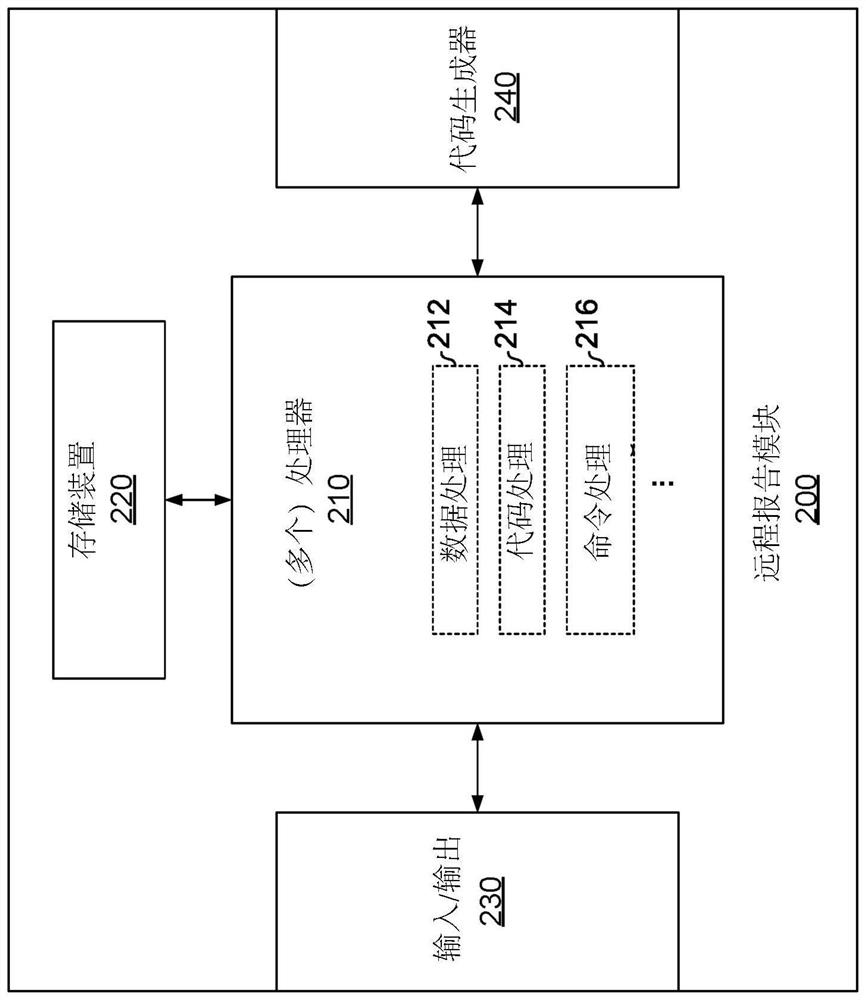

Batch identifier registration and embedding in media signals

An automated batch identifier registration and embedding system for media signals, such as image, video and audio files. A batch identifier registration system enables a user to submit a request for a batch of unique identifiers to be embedded in media signals. The user submits a request for a batch of IDs. The batch registration system verifies the accuracy of the request, sends a confirmation, allocates IDs, creates corresponding entries in a registration database, and creates embedder files used in a batch embedding process. The user may then submit a request for embedder files. To perform automated batch embedding, a watermark embedder takes the embedder files and corresponding list of media signal files as input and automatically embeds identifiers supplied in the embedder files into corresponding media signal files.

Owner:DIGIMARC CORP

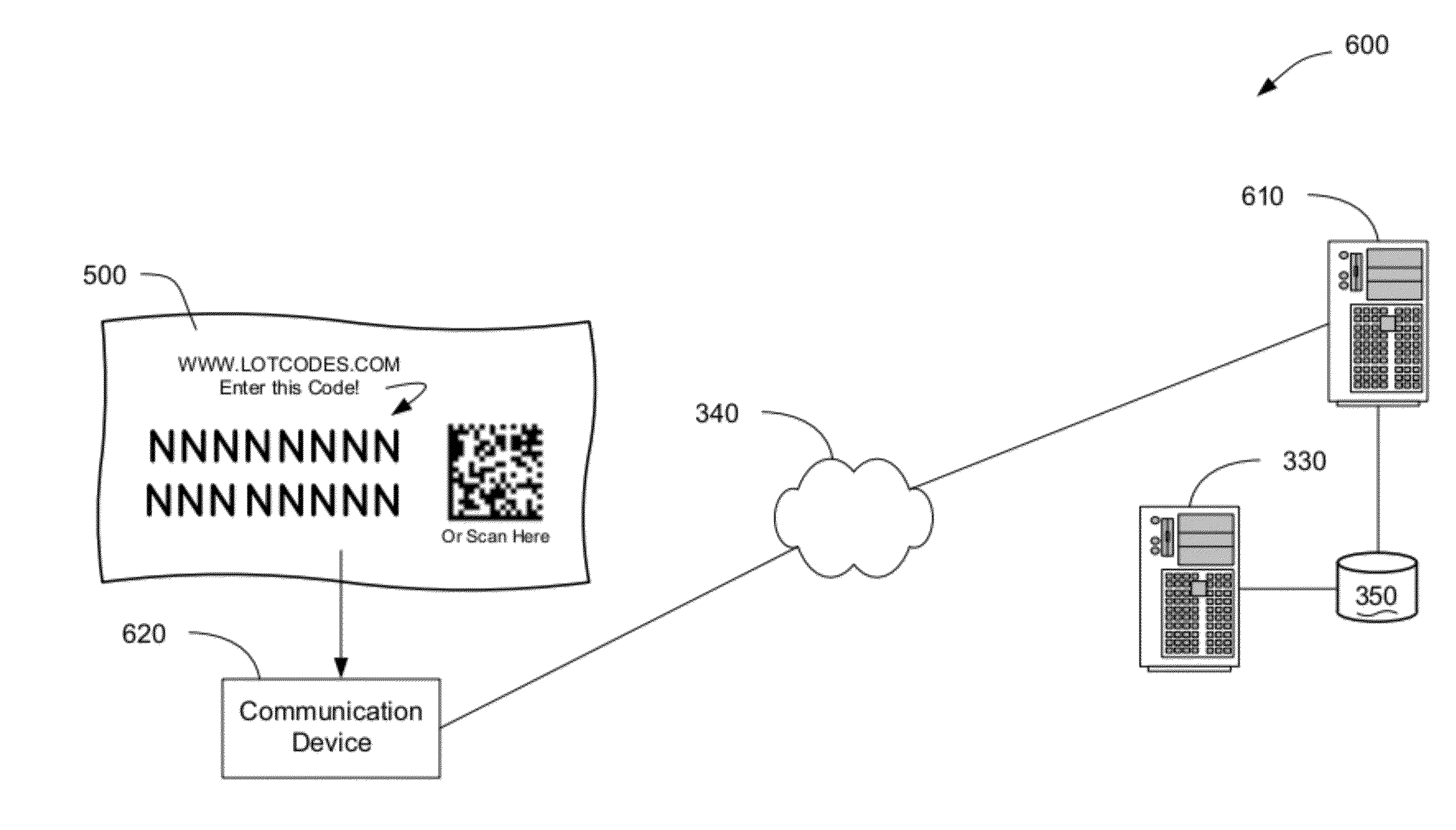

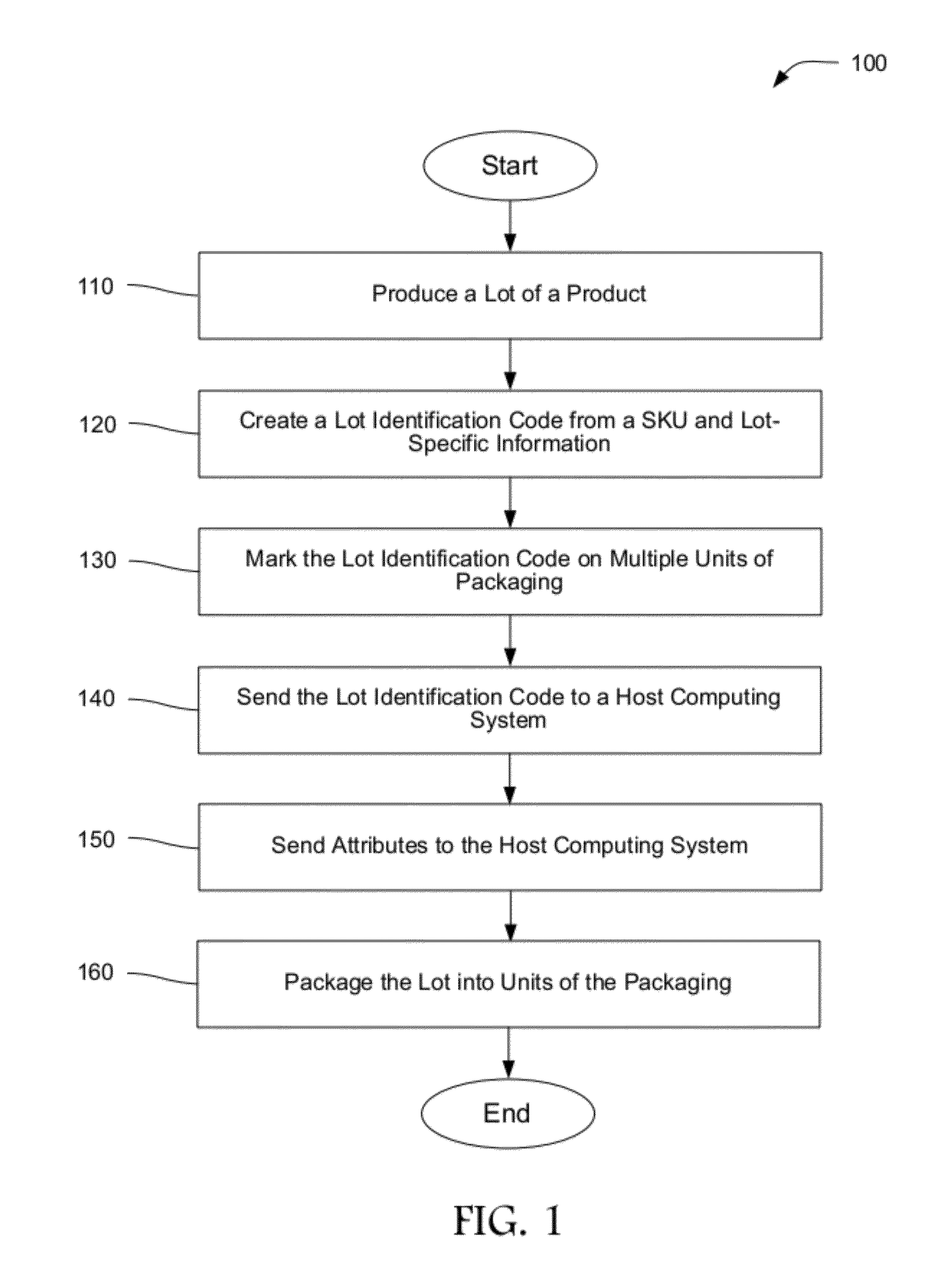

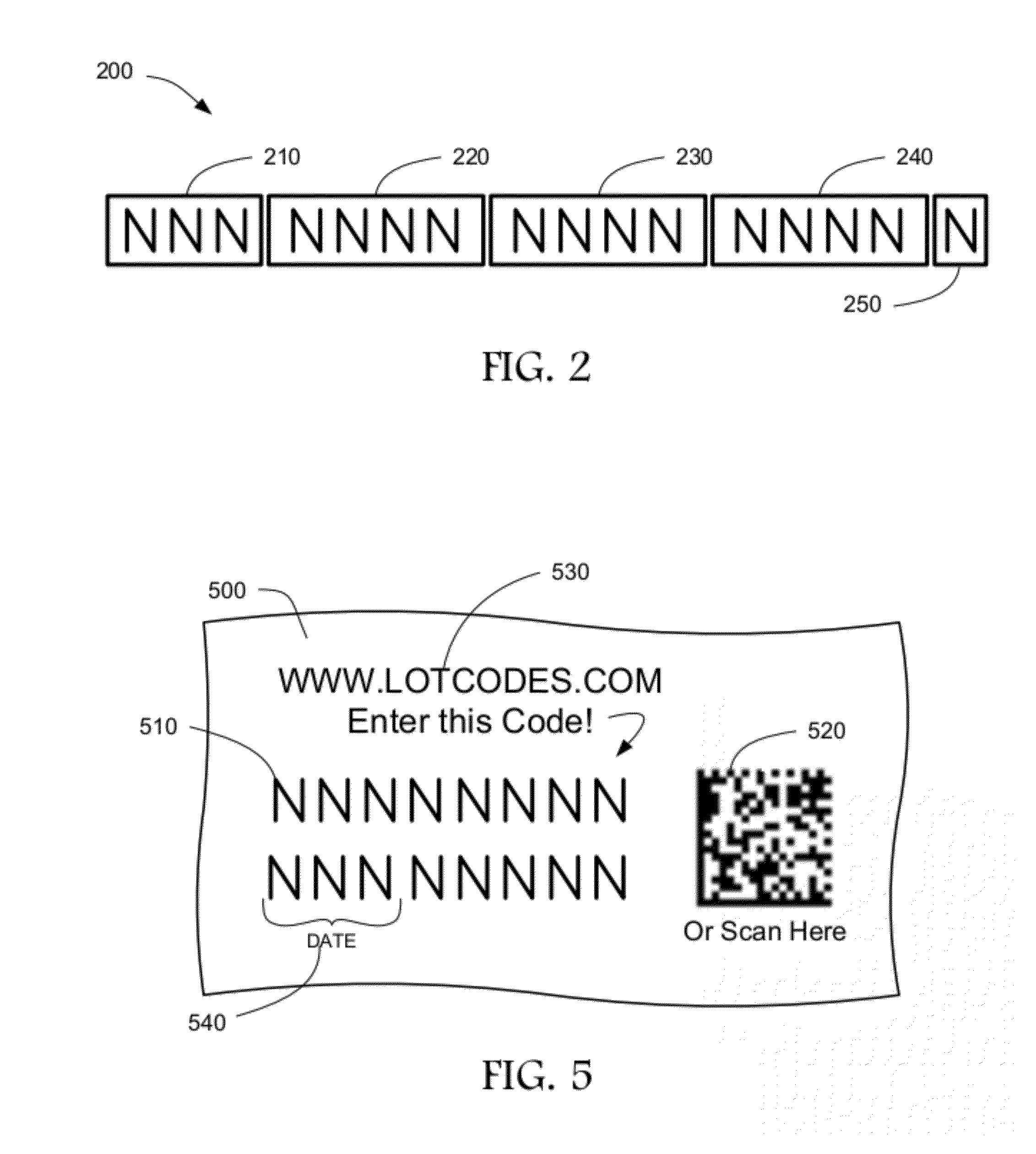

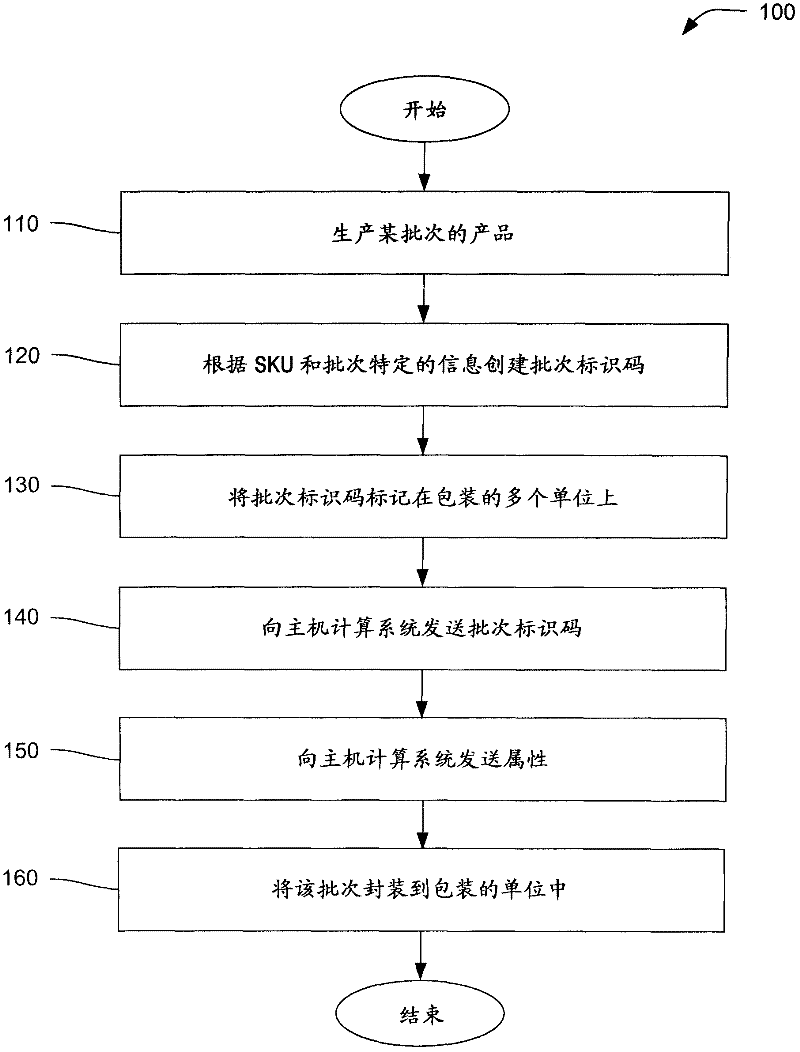

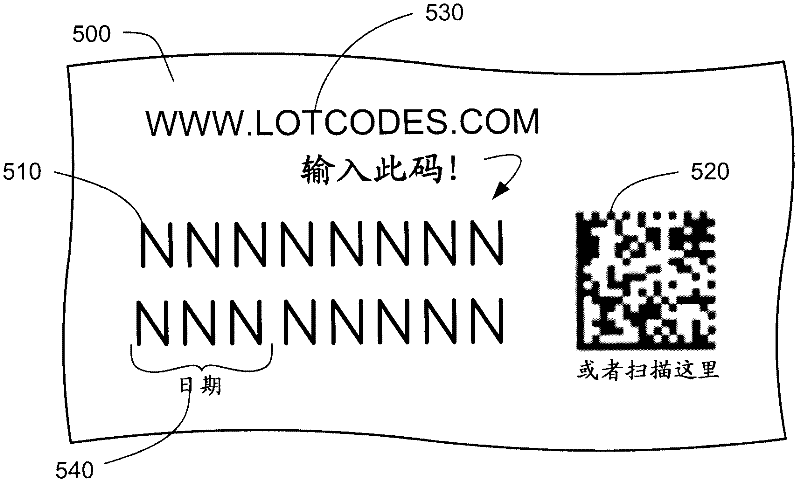

Lot Identification Codes for Packaging

InactiveUS20120059660A1Data processing applicationsDigital data processing detailsChecksumComputer science

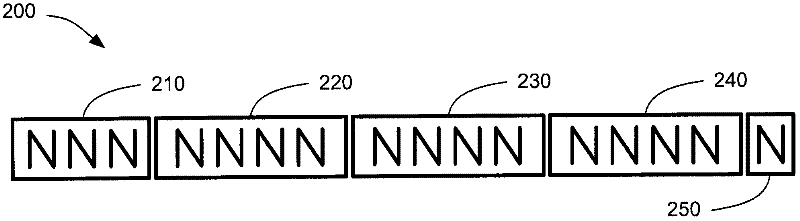

Lot identification codes marked on packaging comprise a fixed number of digits with substrings representing each of a date, a SKU, a lot number, and optionally a line and a checksum. The same fixed number of digits is used for the lot identification codes employed by multiple producers across an industry, or across multiple industries. The lot identification codes are therefore readily recognizable by search engines and otherwise reduce the number of steps required for consumers and others along the supply chain to obtain lot-specific information about packaged goods. Additionally, whenever an individual submits a lot identification code, it provides an opportunity to collect information about the product at that point along the supply chain. The information can link the quality of the product at the time and place of the request to the time and place of the packaging.

Owner:YOTTAMARK

Method of and system for authenticating an item

A method of authenticating the identity of an item bearing or associated with a printed security marker, the method comprising:a. printing the security marker with a pattern that encodes at least one of a unique product identifier, a batch identifier, and positional information about a portion of the marker;b. scanning and storing an image of the security marker as printed, said image being taken at sufficiently high resolution to capture artifacts of the printing process;and authentication steps comprising:c. imaging a portion of the marker at sufficiently high resolution to capture the artifacts, andd. querying a data store by providing the image of the portion of the marker or a compressed or parameterized version of the image and data derived from the pattern.

Owner:HEWLETT PACKARD DEV CO LP

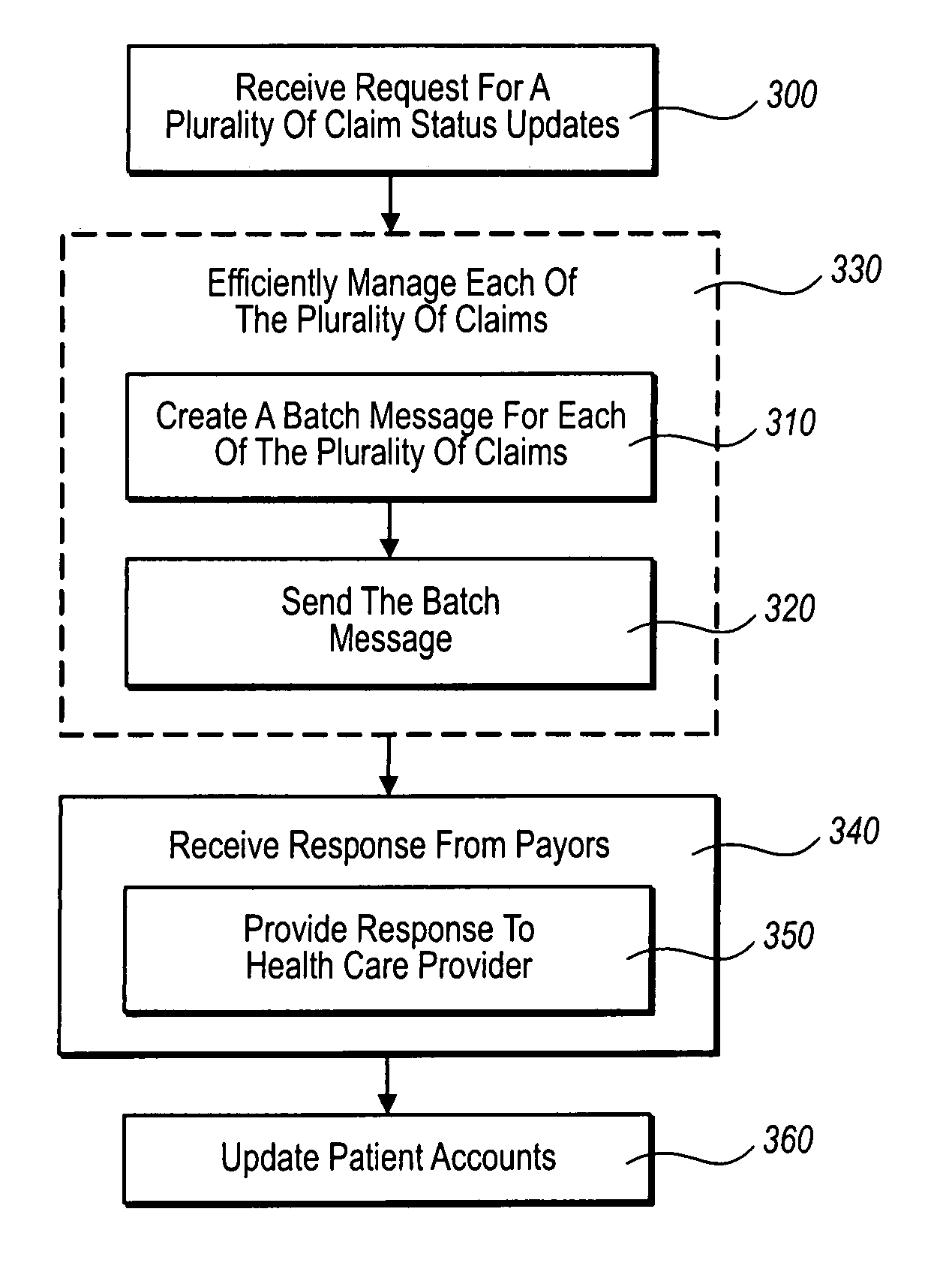

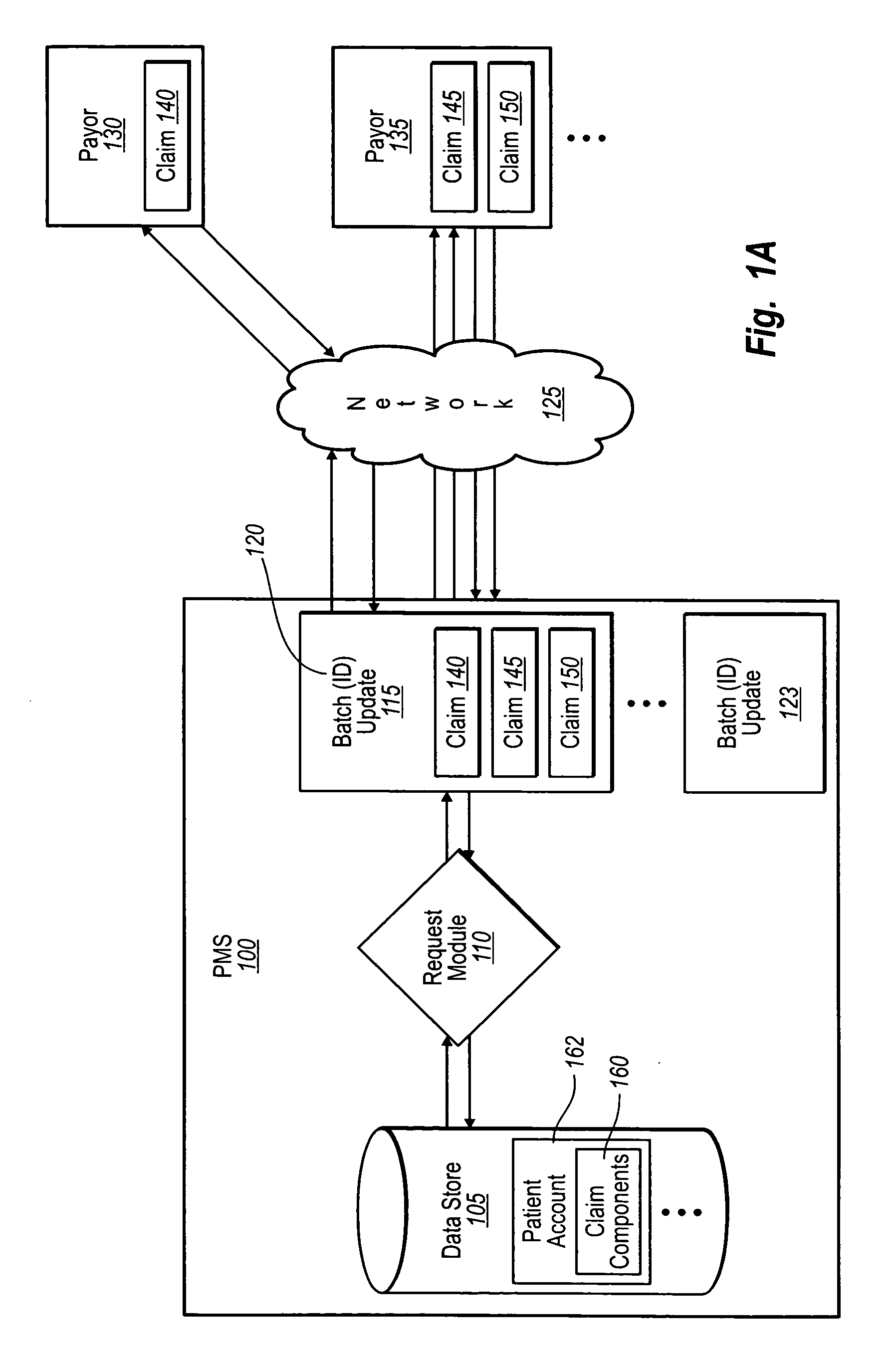

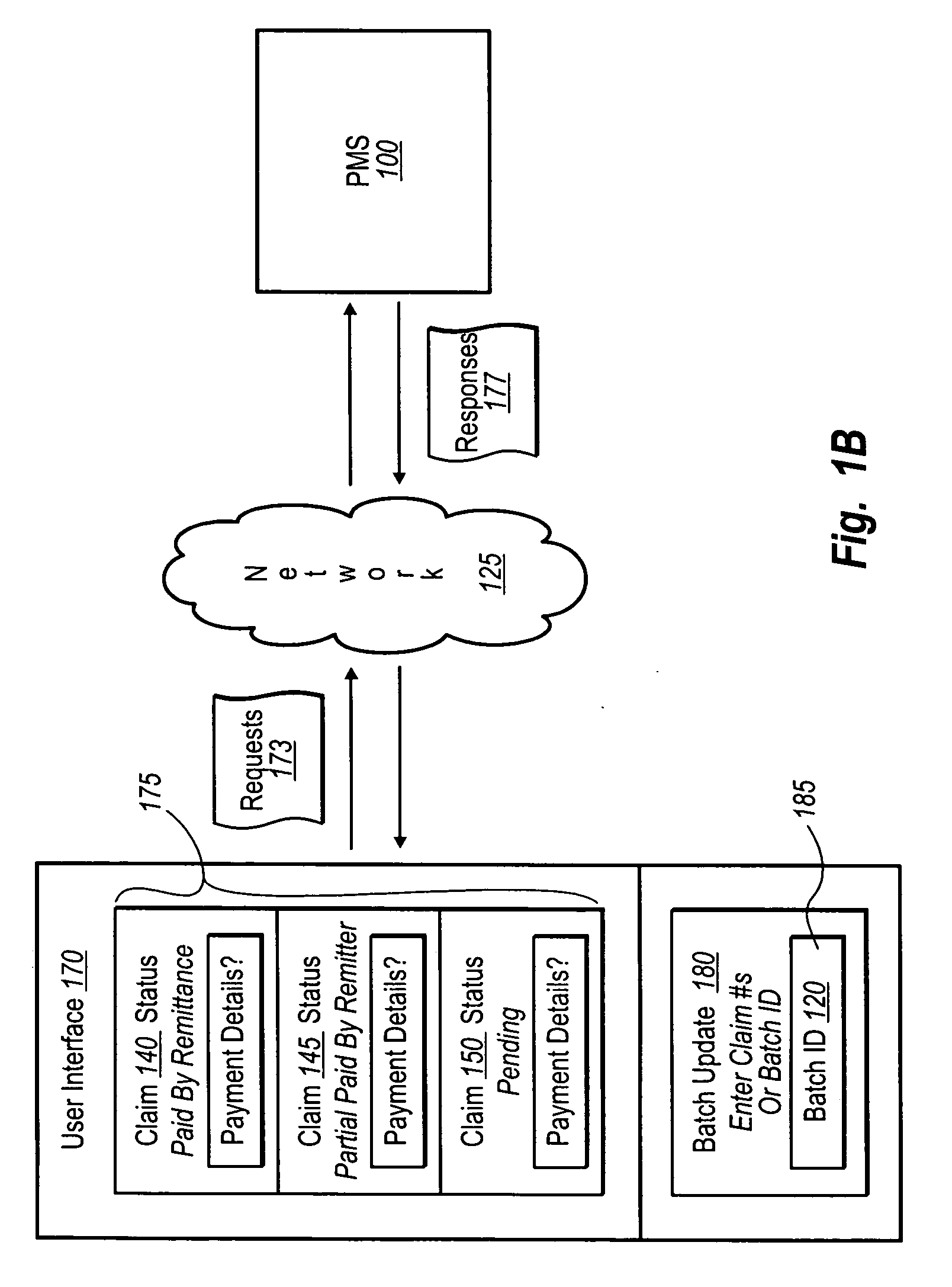

Multiple account updates in a practice management system

An electronic practice management system can be configured to send batch update requests to one or more payors (e.g., insurers) of one or more pending claims for healthcare service. In one implementation, a practice management system responds to a request for an update to one or more claims. The system then generates a batch update request message that has a batch identifier, and may be directed to one or more payors. Responses to the batch update message are then processed by the practice management system, and then provided as appropriate upon request to the healthcare provider. The healthcare provider can request the updates automatically from multiple payors in future batch requests based on a predetermined time interval. The system can also communicate with one or more banks to identify specific information regarding claim payment.

Owner:NETDEPOSIT

Lot identification codes for packaging

InactiveCN102402705ASensing record carriersRecord carriers used with machinesChecksumComputer science

Owner:YOTTAMARK

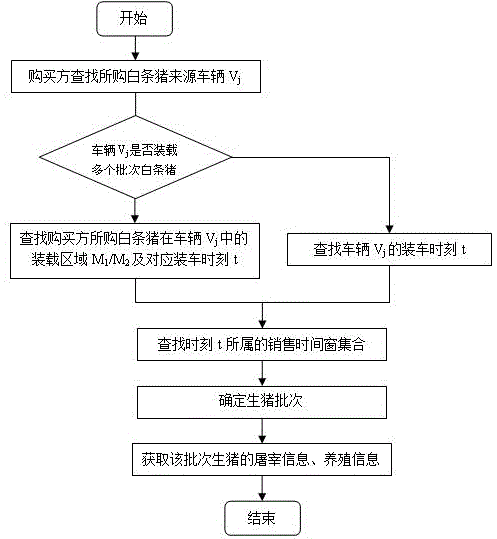

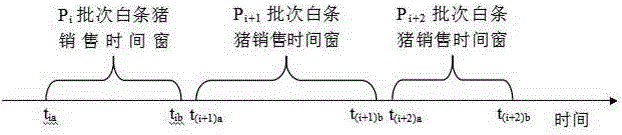

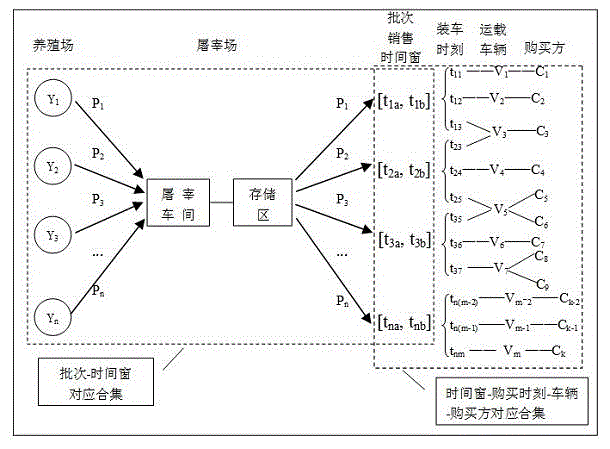

Pig slaughtering link retrospective method based on time window

InactiveCN104156838ALow costReduce workloadSensing record carriersLogisticsDatabaseIndustrial engineering

The invention discloses a pig slaughtering link retrospective method based on a time window. The method comprises the steps of allocating batch identifiers for a new batch of pigs in a slaughterhouse, reading out ear tag information on pigs in each batch, and making an identifier for the first pig in each batch of pigs; storing relevant quarantine information into a slaughterhouse information system in the slaughtering process; sending unprocessed pork after pig slaughtering to a storage area for acid discharge and to be sold; when the unprocessed pork is put on the market, recording a sale start time and a sale close time of the unprocessed pork of each batch, obtaining a sale time window of the unprocessed port of each batch, meanwhile recording the loading time and vehicle information of each carrier vehicle, and storing the above information into the slaughterhouse information system; and delivering the unprocessed pork to different purchasers through the carrier vehicles, and recording and feeding back purchaser information to the slaughterhouse. The pig slaughtering link retrospective method based on the time window can be used for the slaughterhouse to track down the flow direction of the unprocessed pork of each batch, and for the purchasers to trace back to the source of slaughtering information and breeding information on the purchased unprocessed pork.

Owner:SOUTHEAST UNIV

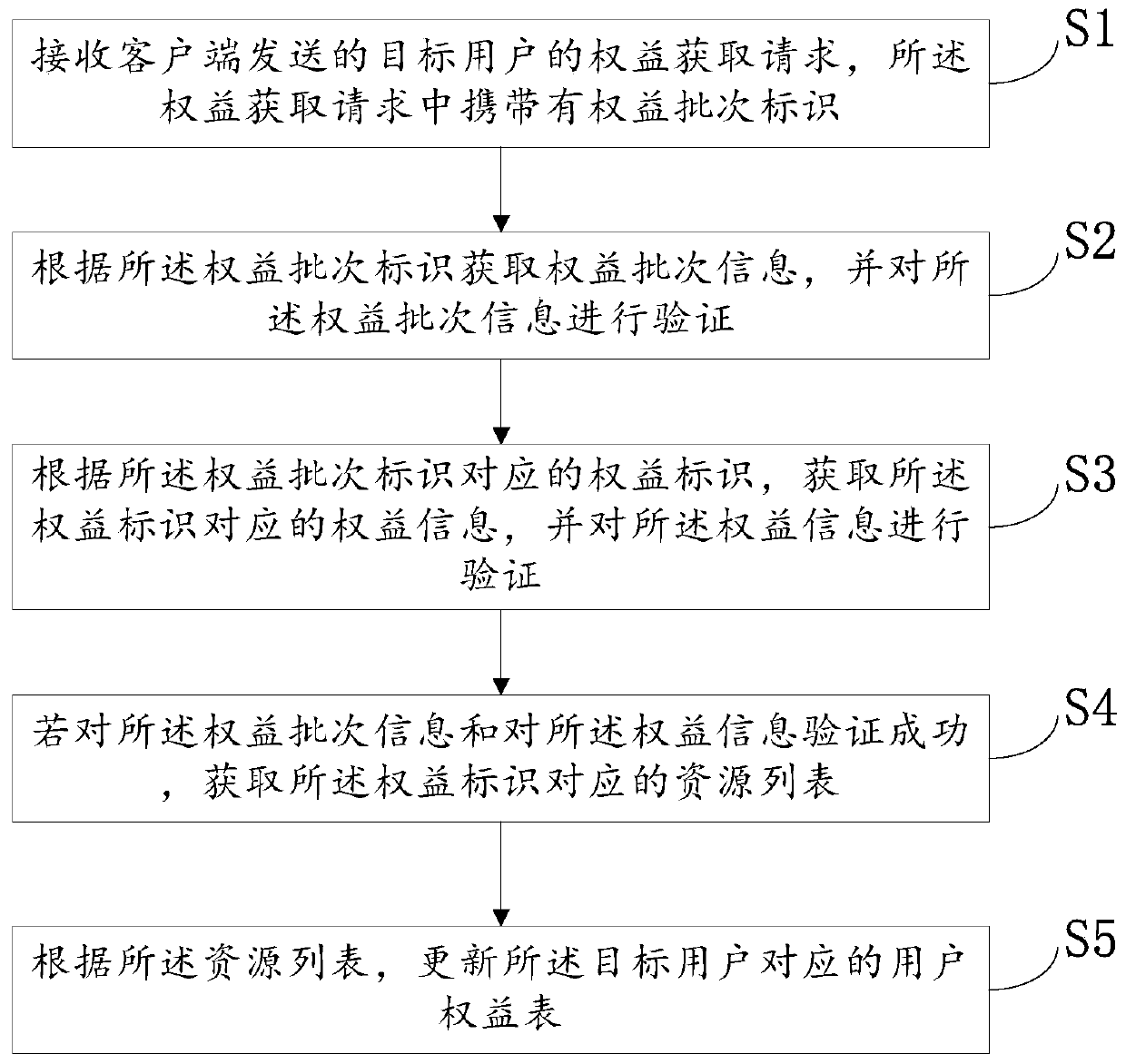

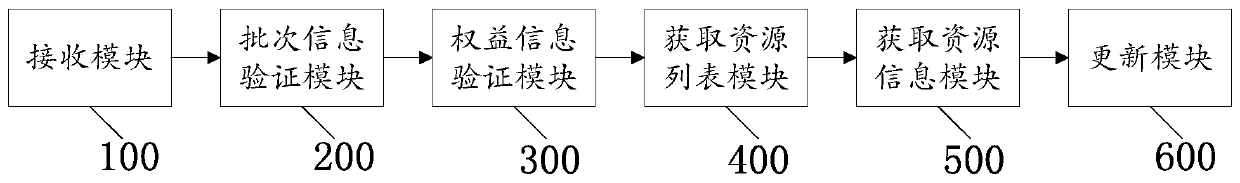

Right and interest information management method and device

InactiveCN110163504ASolve management problemsDatabase management systemsResourcesResource informationButt joint

The invention provides a right and interest information management method, which is used for right and interest management software, and the right and interest management software comprises an interface in butt joint with at least one external resource database; the method comprises the following steps: receiving a right and interest acquisition request of a target user sent by a client, wherein the right and interest acquisition request carries a right and interest batch identifier; obtaining right and interest batch information according to the right and interest batch identifier, and verifying the right and interest batch information; obtaining right and interest information corresponding to the right and interest identification according to the right and interest identification corresponding to the right and interest batch identification, and verifying the right and interest information; if the right and interest batch information and the right and interest information are verifiedsuccessfully, obtaining a resource list corresponding to the right and interest identifier; acquiring resource information corresponding to the resource list by using the interface butted with the atleast one external resource database; and updating a user right table corresponding to the target user according to the resource information.

Owner:北京思特奇信息技术股份有限公司

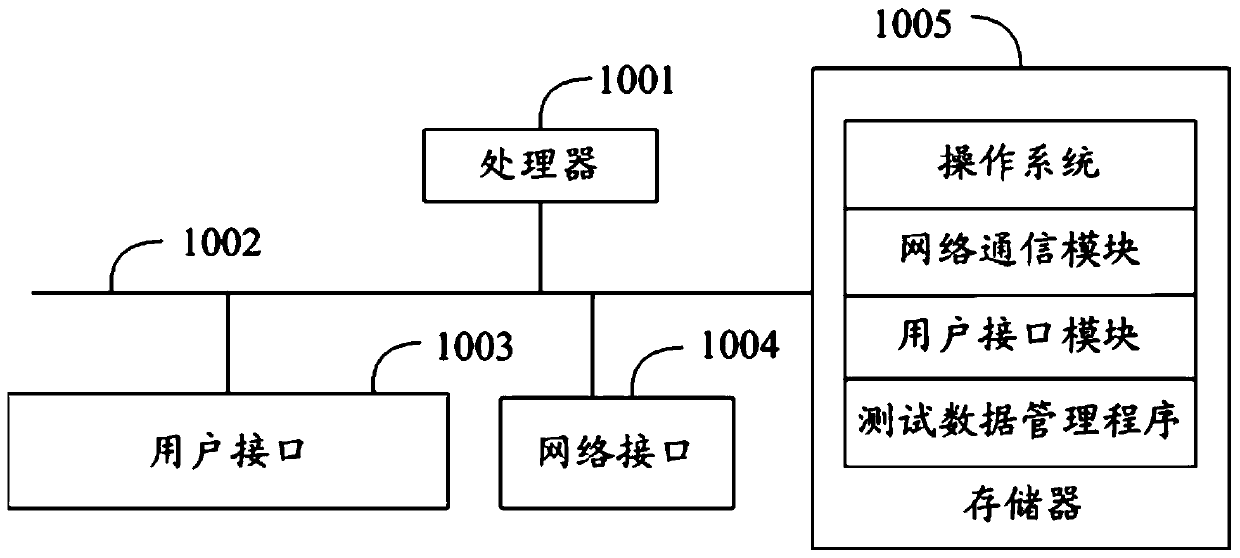

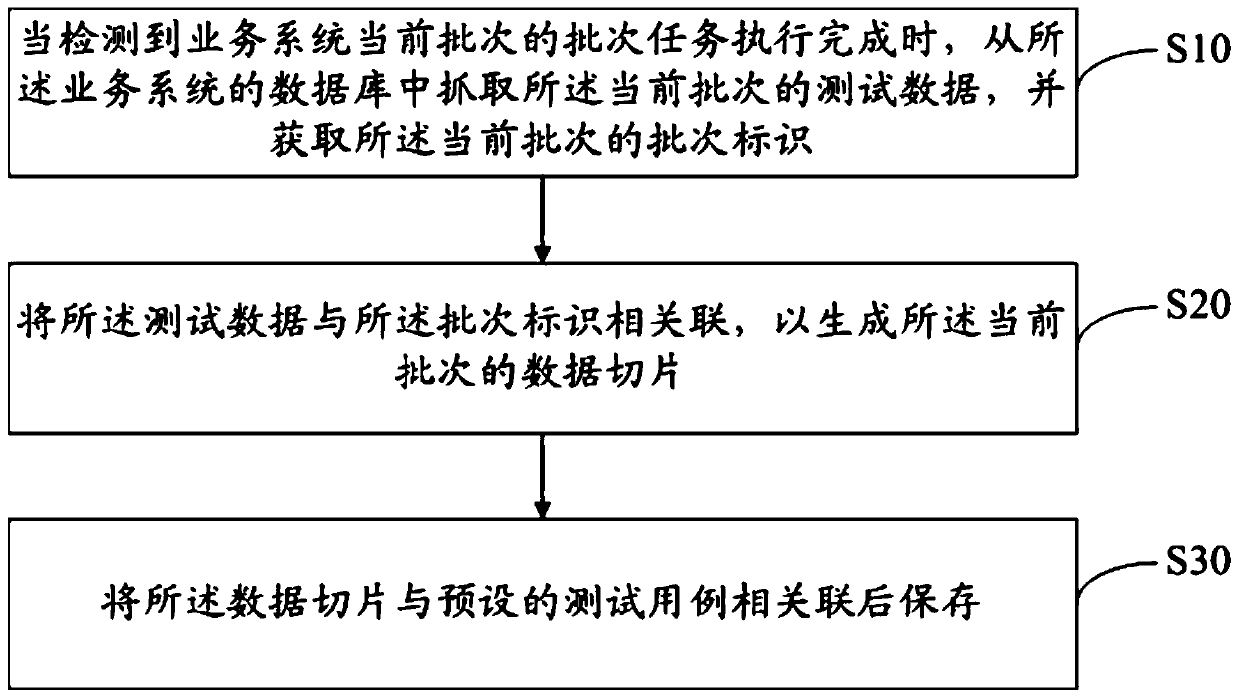

Test data management method and device, apparatus and computer readable storage medium

PendingCN110262975ARealize automatic crawlingAchieve preservationSoftware testing/debuggingTime costComputer science

The invention relates to the field of financial technology, and discloses a test data management method which comprises the following steps of when detecting that a batch task of a current batch of a business system is executed completely, capturing the test data of the current batch from a database of the business system, and obtaining a batch identifier of the current batch; associating the test data with the batch identifier to generate a data slice of the current batch; and associating the data slice with a preset test case and then storing the data slice. The invention also discloses a test data management device, an apparatus and a computer readable storage medium. According to the invention, the technical problem that the existing version iteration test or regression test needs to generate numbers again, so that the time cost and the labor cost consumption are higher, is solved.

Owner:WEBANK (CHINA)

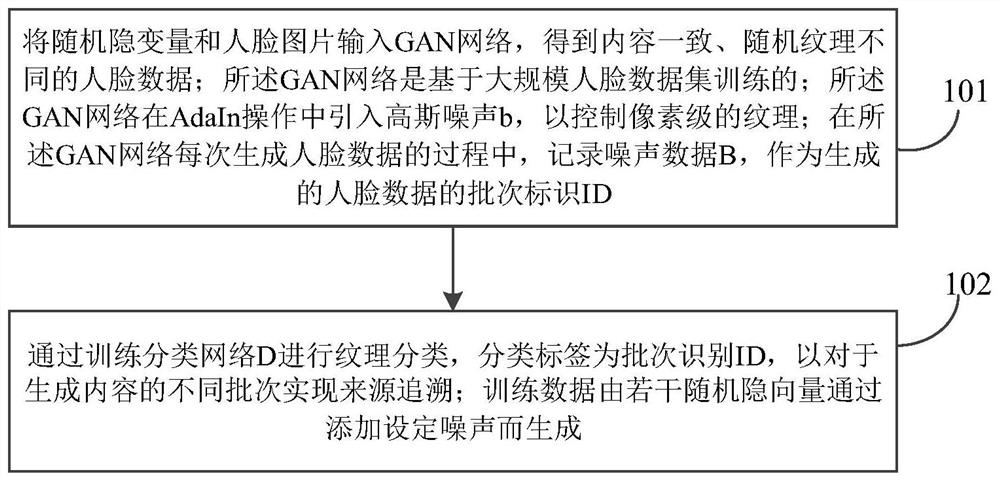

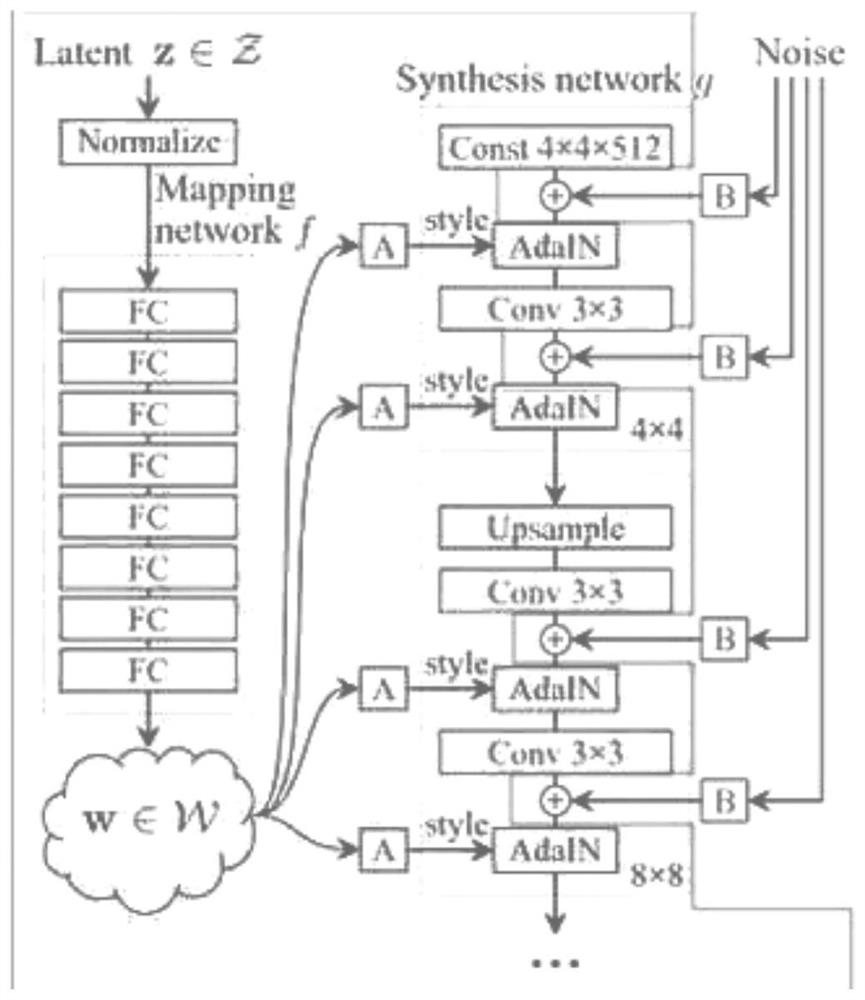

Image steganography method and system based on random texture

PendingCN113902671AFast and accurate source traceabilityImage enhancementImage analysisPattern recognitionData set

The embodiment of the invention discloses an image steganography method and system based on random textures, and the method comprises the steps: inputting a random hidden variable and a face image into a GAN network, and obtaining face data with consistent contents and different random textures, wherein the GAN network is trained based on a large-scale face data set, and Gaussian noise b is introduced into AdaIn operation by the GAN network so as to control pixel-level textures; recording noise data B as a batch identifier ID of the generated face data in the process that the GAN generates the face data each time; carrying out the texture classification by training a classification network D, wherein a classification label is a batch identification ID, so that source tracing is realized for different batches of generated contents; wherein the training data is generated by adding set noise to a plurality of random implicit vectors. Source tracing can be quickly and accurately realized for different distribution batches of generated contents.

Owner:BEIJING YINGPU TECH CO LTD

Methods, systems, and computer program products for managing batch operations in an enterprise data integration platform environment

InactiveUS8639653B2Digital data processing detailsMultiprogramming arrangementsProgram planningBatch operation

Methods, system, and computer program products for managing batch operations are provided. A method includes defining a window of time in which a batch will run by entering a batch identifier into a batch table, the batch identifier specifying a primary key of the batch table and is configured as a foreign key to a batch schedule table. The time is entered into the batch schedule table. The method further includes entering extract-transform-load (ETL) information into the batch table. The ETL information includes a workflow identifier, a parameter file identifier, and a location in which the workflow resides. The method includes retrieving the workflow from memory via the workflow identifier and location, retrieving the parameter file, and processing the batch, according to the process, workflow, and parameter file.

Owner:AT&T INTPROP I L P

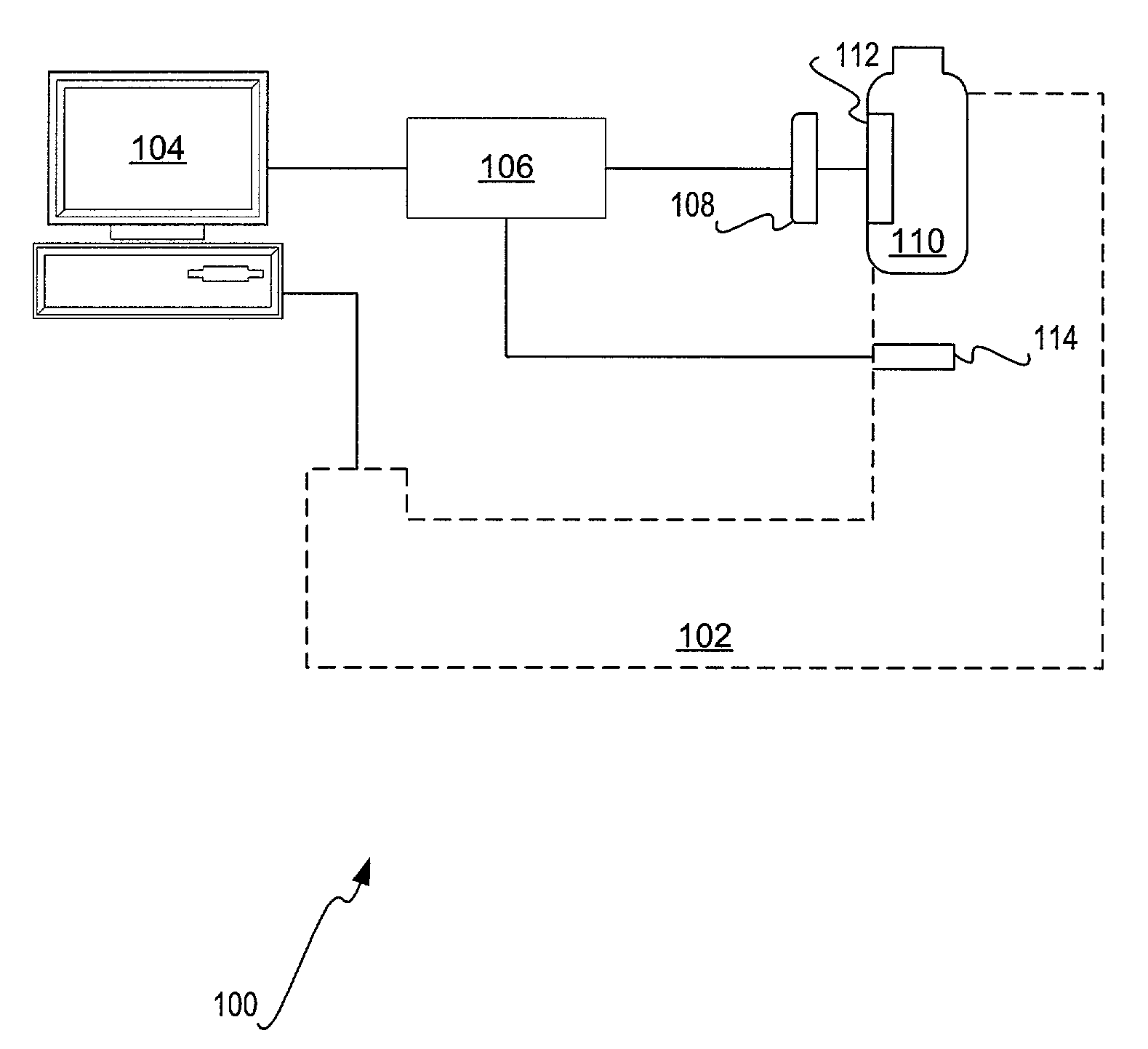

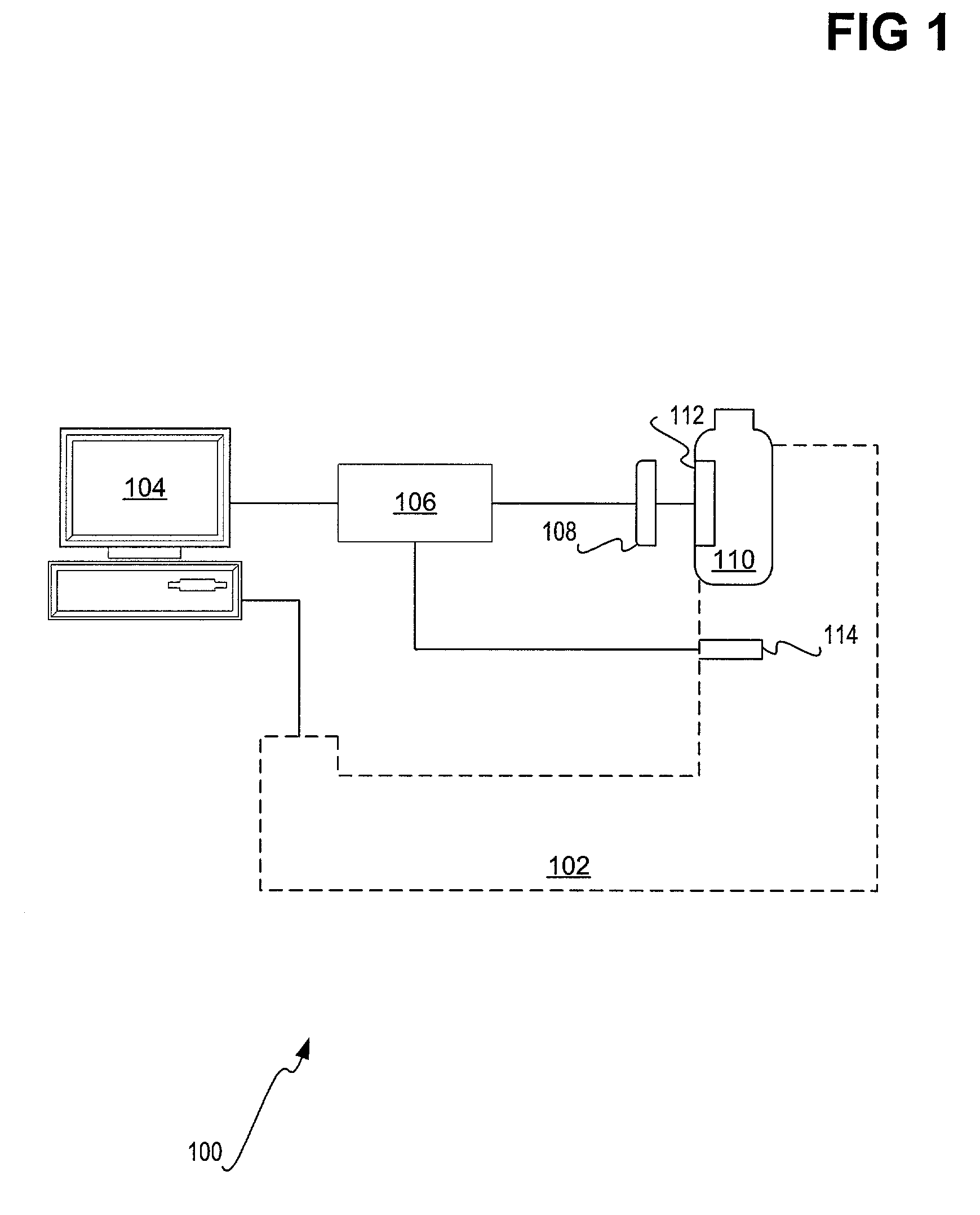

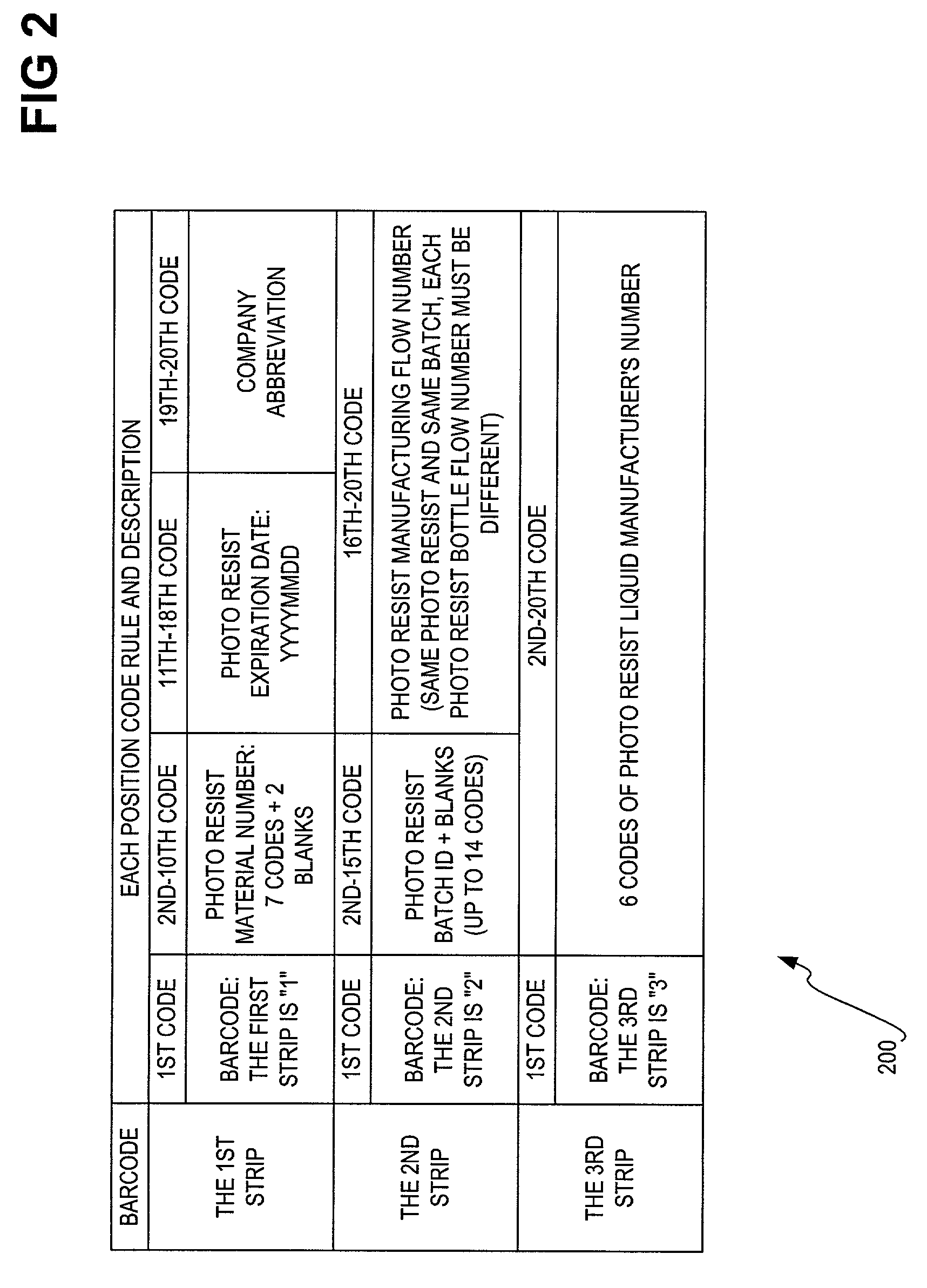

Photoresist system

A photoresist system is disclosed. A graphical user interface of the system allows an operator to initiate a bottle switching operation, among other operations. Barcode data of a photoresist bottle is obtained by an equipment server from a controller. Photoresist data relating to the bottle is obtained by the equipment server from a database through a constraint server. The equipment server, preferably with assistance from the constraint server, determines whether the bottle contains appropriate photoresist for the semiconductor processing to be performed on semiconductor wafers. If the bottle contains appropriate photoresist, the equipment server, through the constraint server, stores the expiration date of the bottle and the batch identifier of the bottle, as indicated by the barcode data, in the database. If the bottle contains inappropriate photoresist, then the system acts to prevent the semiconductor processing of the semiconductor wafers with the inappropriate photoresist contained in the bottle.

Owner:TAIWAN SEMICON MFG CO LTD

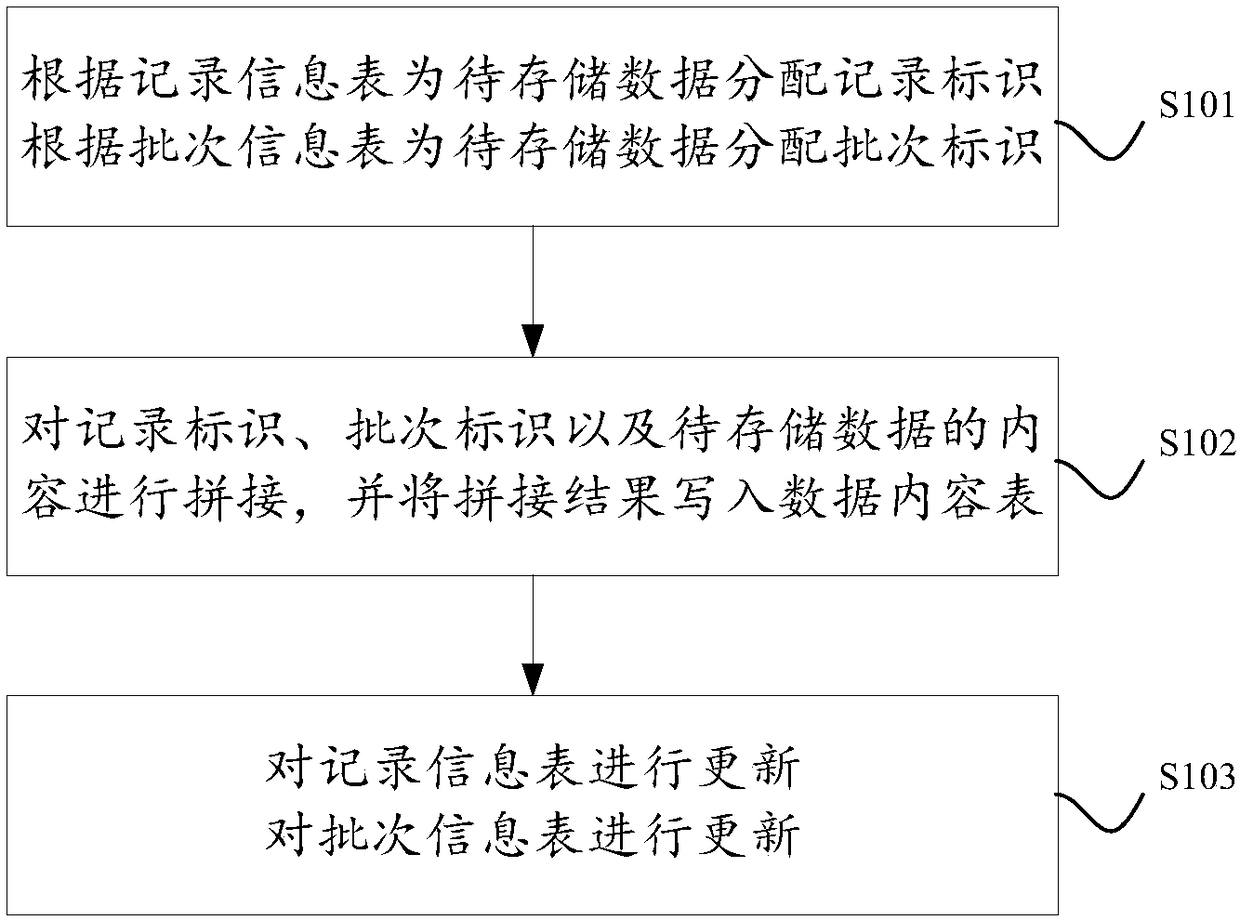

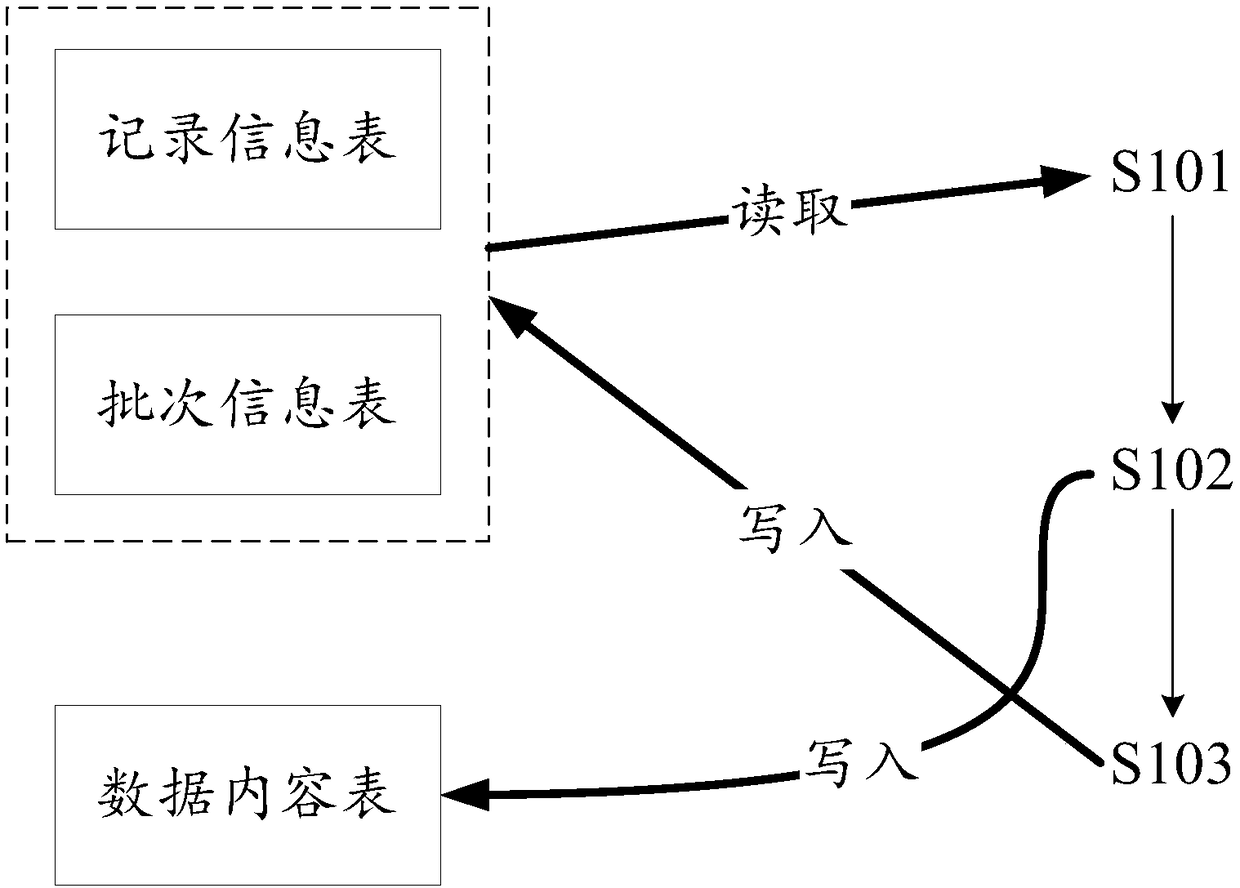

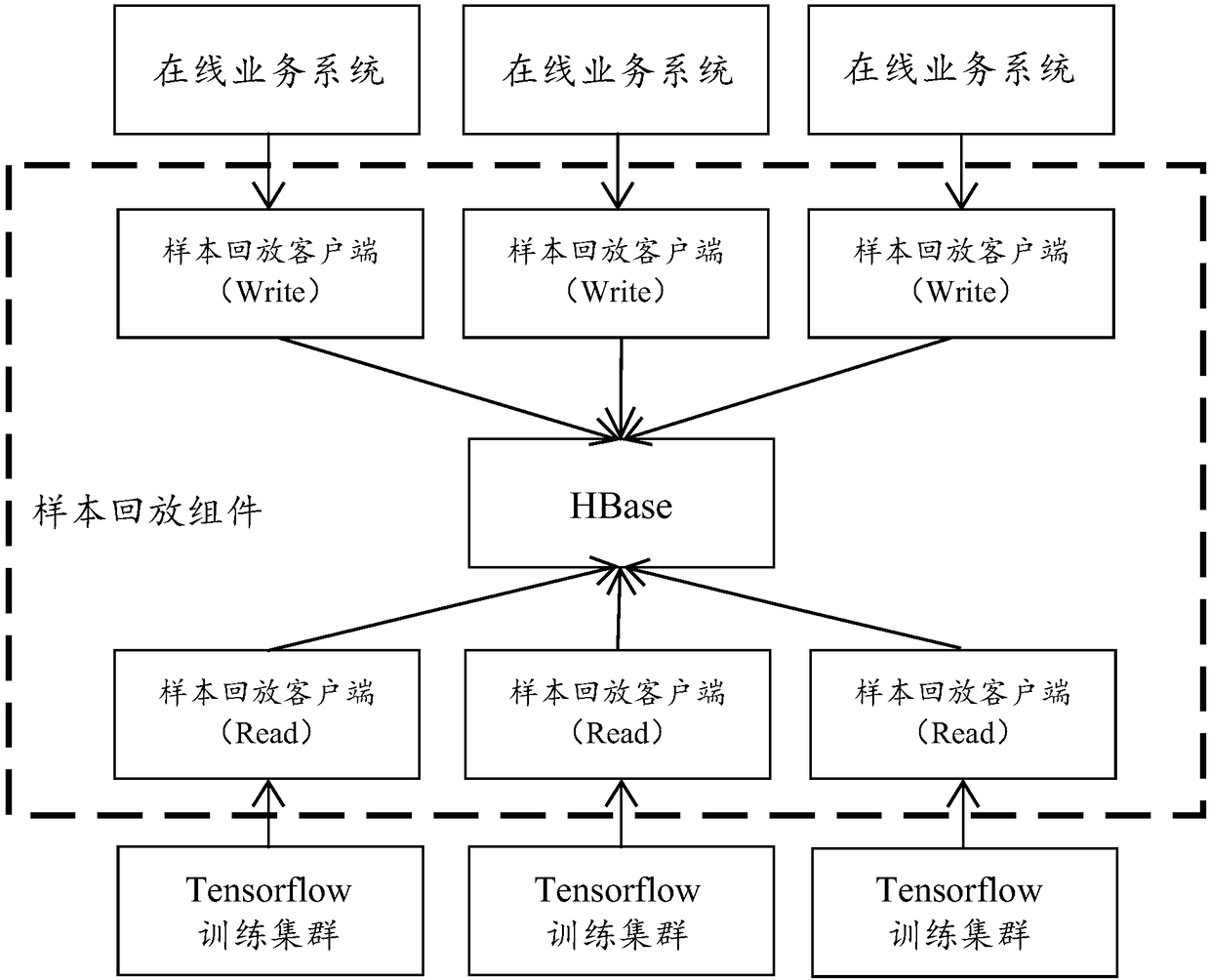

Data access method and device for sample playback

ActiveCN108536759AImplement the playback strategyMeet the needs of actual business applicationsSpecial data processing applicationsAccess methodData access

The invention discloses a data access method and device for sample playback; a record information table, a batch information table, and a data content table are configured; for any data to be stored,the following storage operation is performed: allocating a record identifier to the data to be stored according to the record information table; allocating a batch identifier to the data to be storedaccording to the batch information table; splicing the allocated record identifier, the batch identifier and the content of the data to be stored according to a storage structure of the data content table, and writing a splicing result into the data content table; and updating the record information table and the batch information table.

Owner:ADVANCED NEW TECH CO LTD

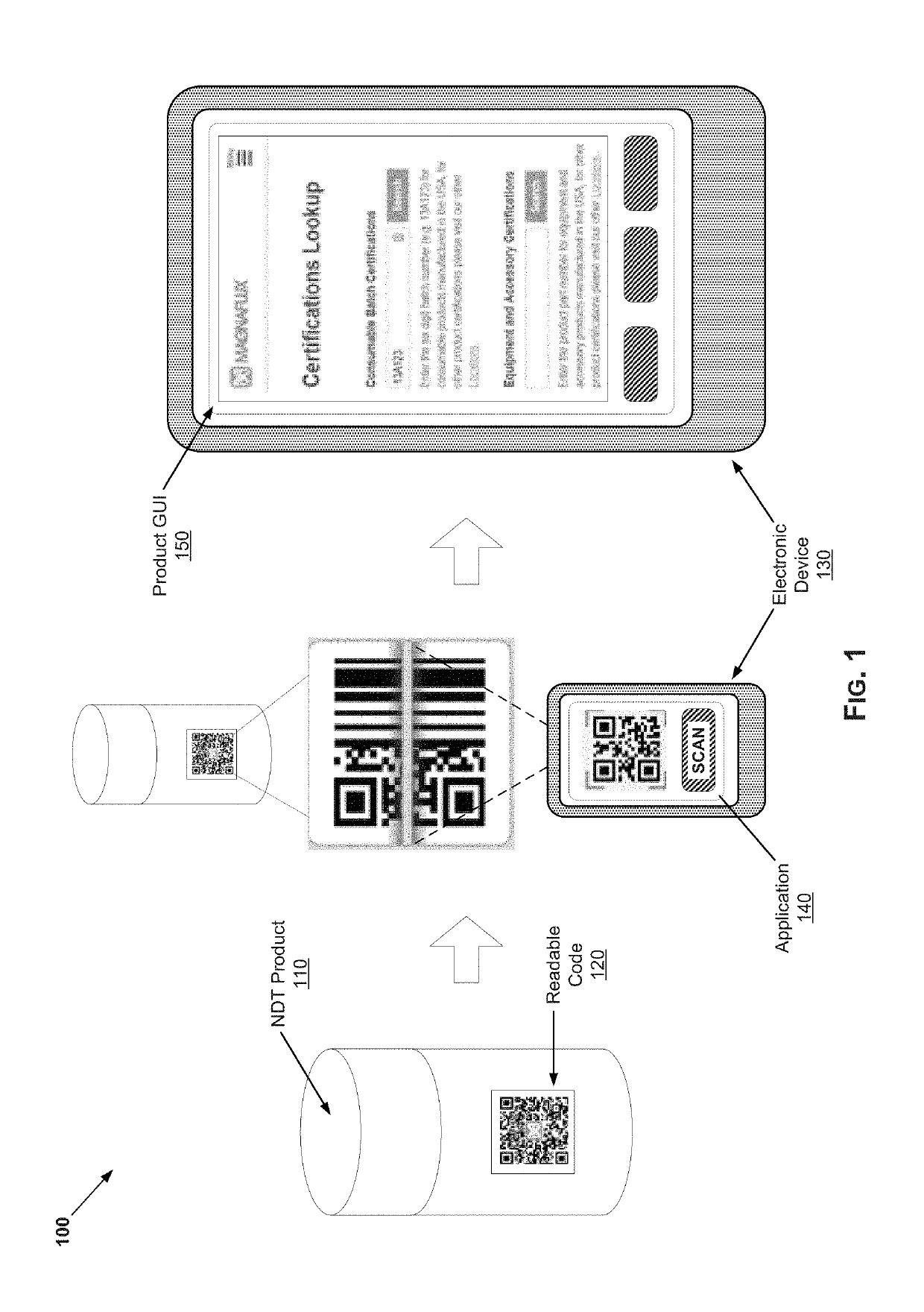

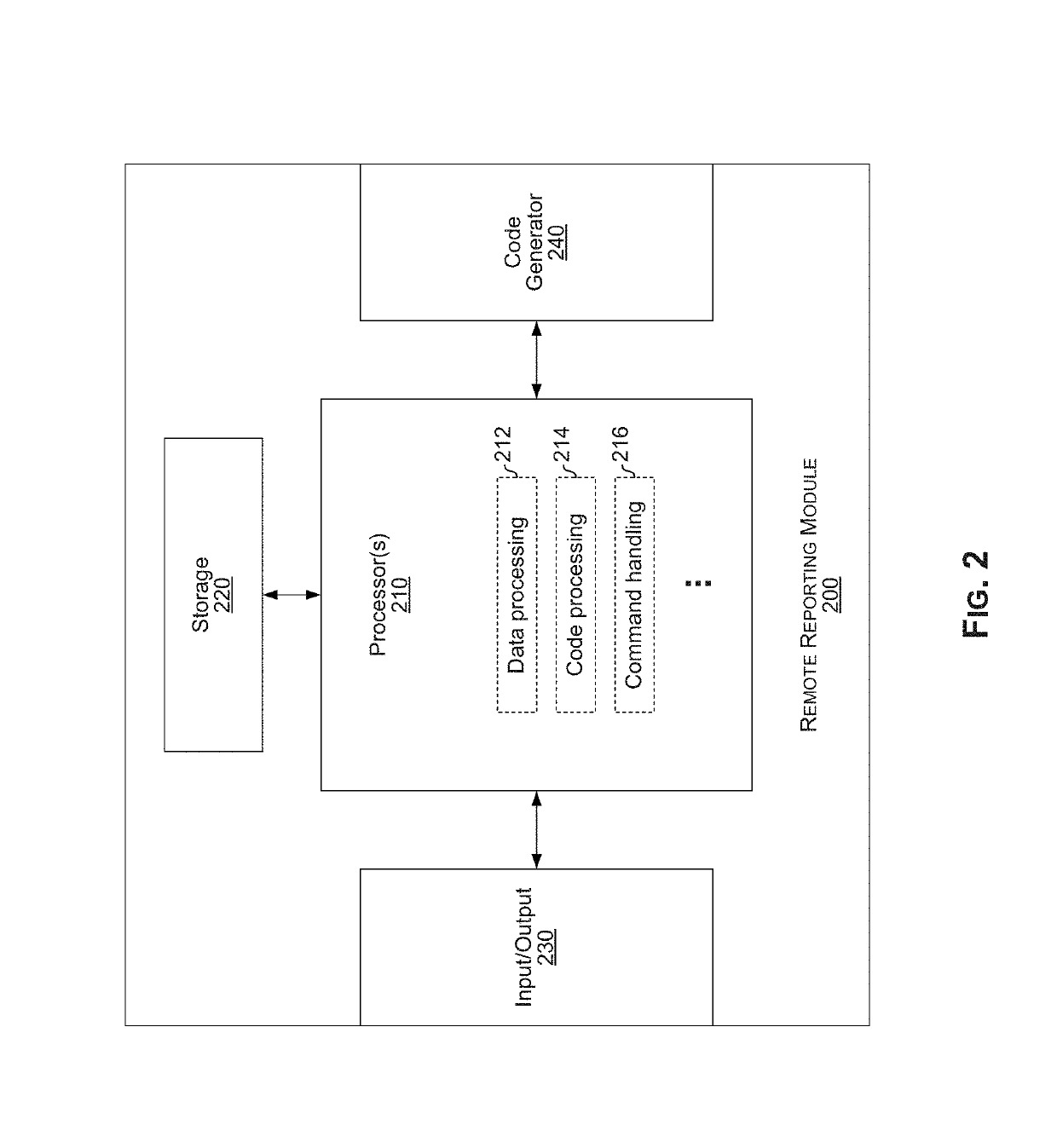

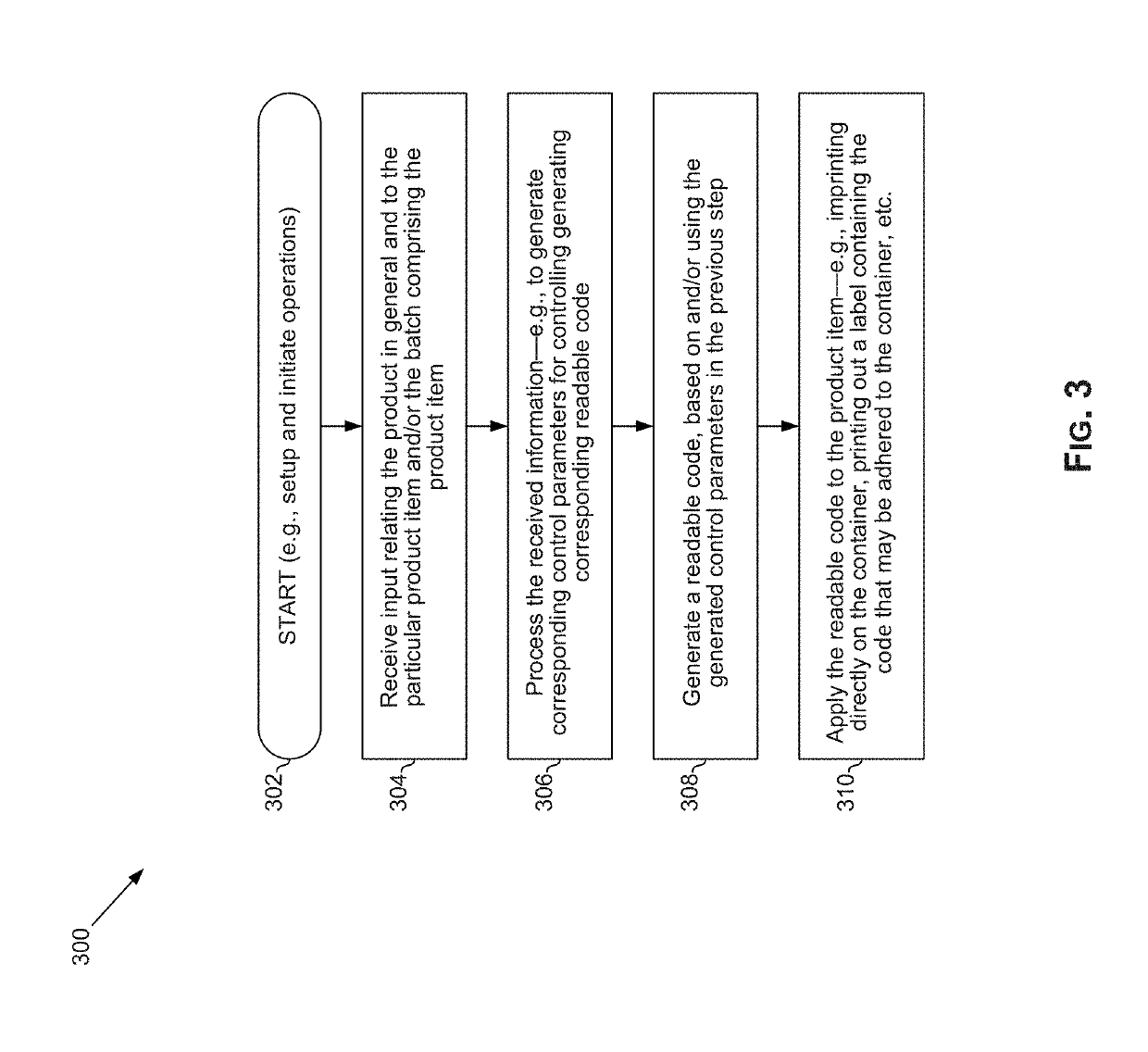

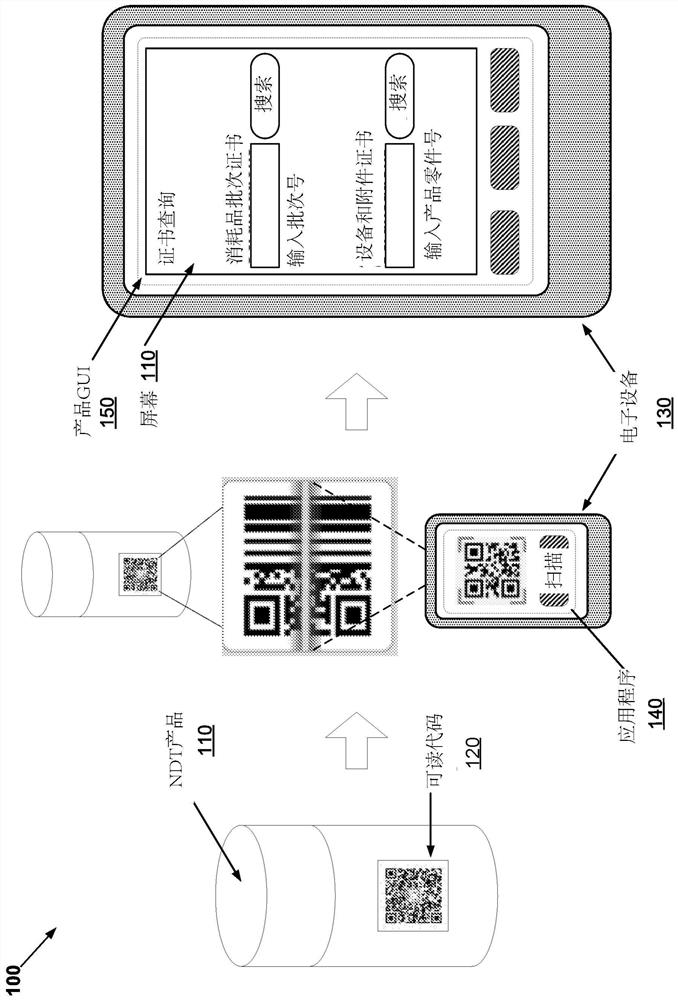

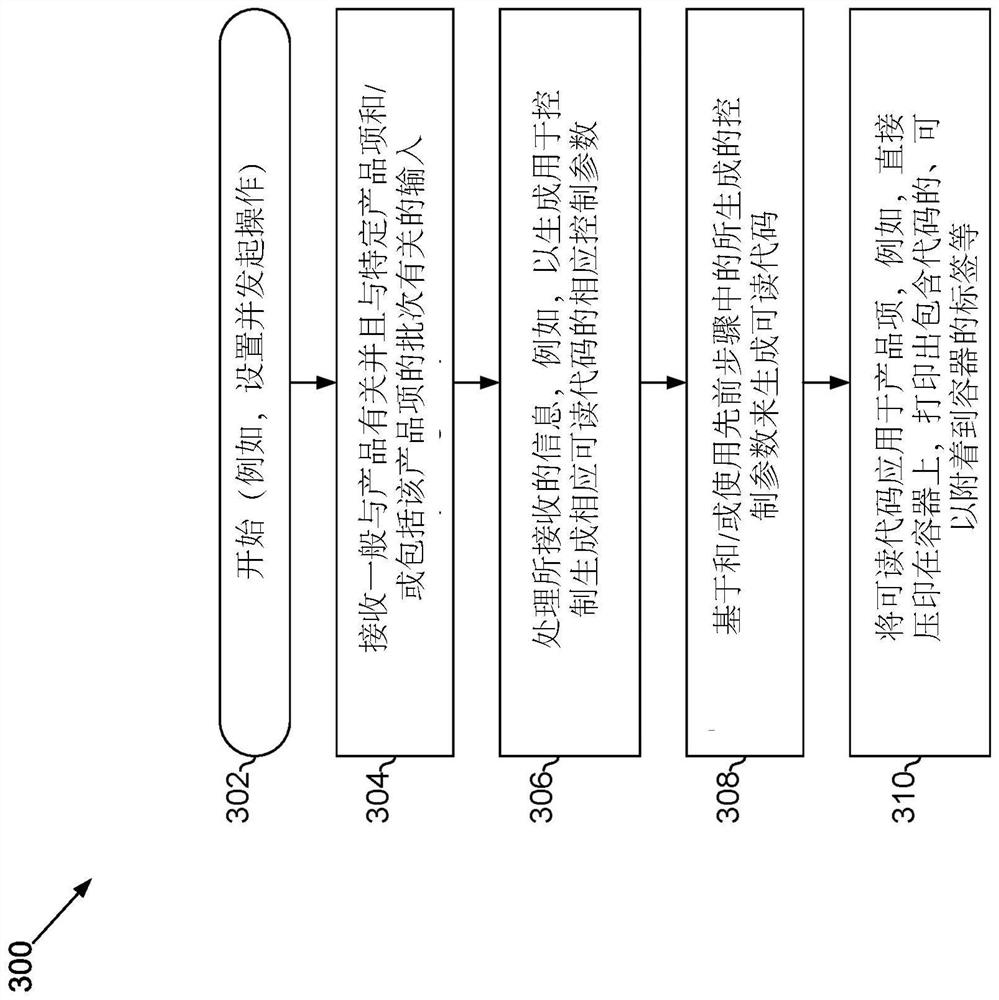

Methods and systems for enhanced non-destructive testing (NDT) product labels and use thereof

InactiveUS20190266209A1Easy to testRecord carriers used with machinesSpecial data processing applicationsNon destructiveProduct Identifier

Systems and methods are provided for enhanced non-destructive testing (NDT) product labels and use thereof. An example label may be configured for application to non-destructive testing (NDT) products, with the label including a readable code that incorporates information relating to a particular NDT product sample. The information uniquely identifies the NDT product sample and / or a batch that includes the NDT product sample. An example system may include a reader configured for reading machine-readable code incorporated into a label applied to an NDT product, and circuitry configured for processing data obtained from the machine-readable code. The circuitry may extract based on the processing, information relating to the NDT product, the information including a unique product identifier and / or a unique batch identifier. The circuitry may then trigger based on the unique product identifier and / or the unique batch identifier, actions associated with the NDT product and / or use of the NDT product.

Owner:ILLINOIS TOOL WORKS INC

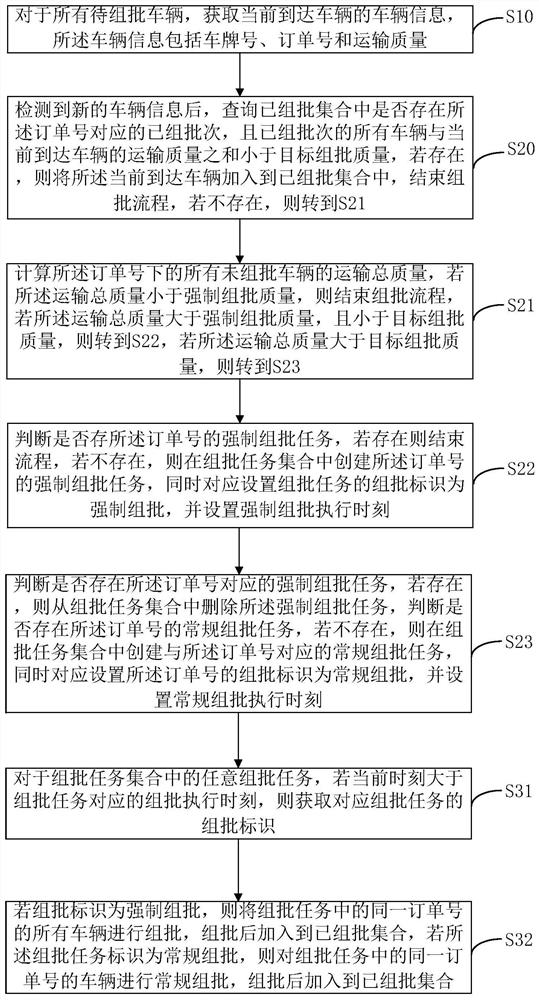

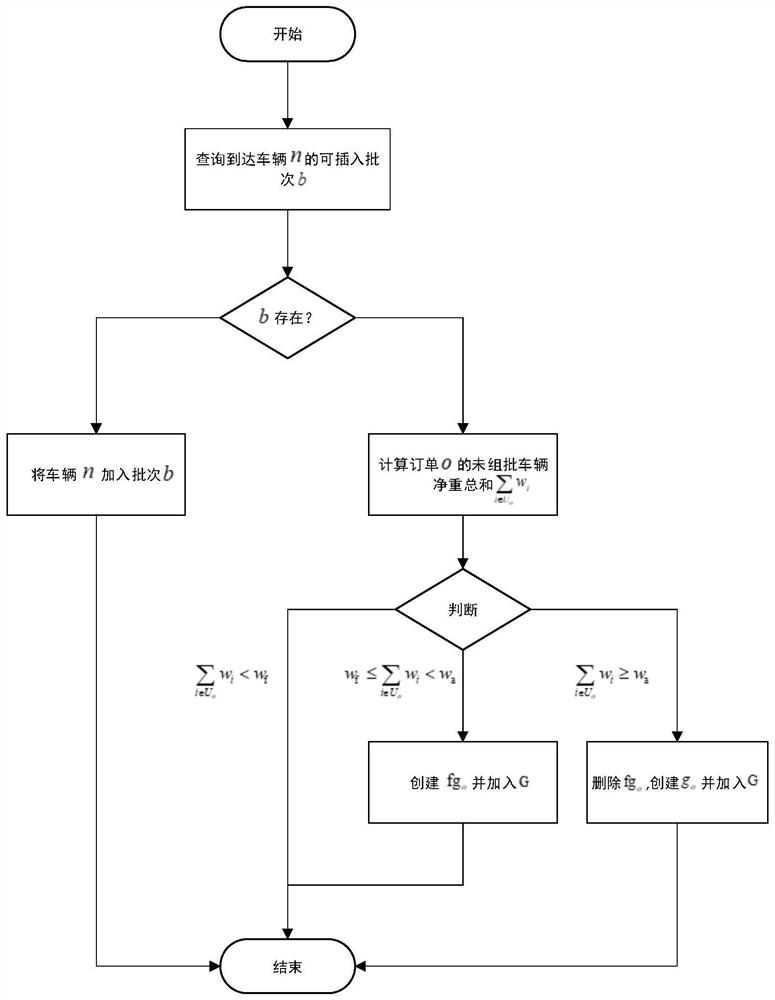

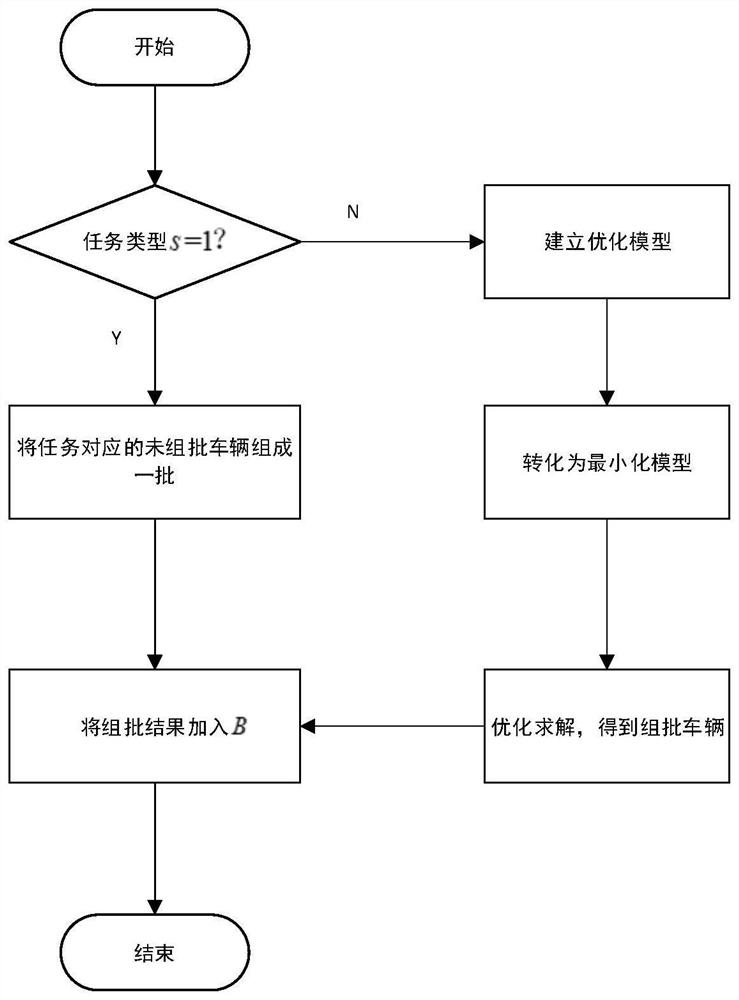

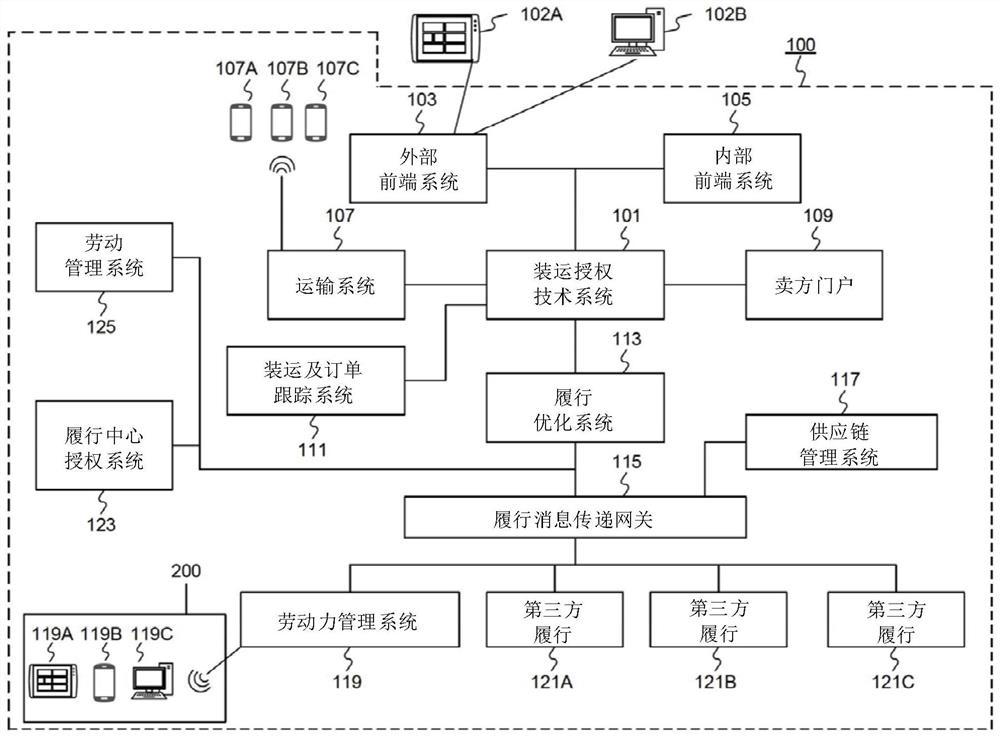

Automatic batch grouping method for automobile transportation material sampling in bulk cargo yard

ActiveCN112232539ASave testing costsAvoid waiting too long for batchingForecastingResourcesBulk cargoCar parking

The embodiment of the invention discloses an automatic batch grouping method for automobile transportation material sampling in a bulk cargo yard. The method comprises steps that a forced batch grouping task and a conventional batch grouping task are created according to the relation between the total transportation mass of vehicles which are not grouped and the forced batch grouping mass and thetarget batch grouping mass respectively; for any group batch task, if the current moment is greater than the group batch execution moment corresponding to the group batch task, a group batch identifier is obtained corresponding to the group batch task; if the grouping identifier is forced grouping, the vehicles with the same order number are grouped in the grouping task, and if the grouping task identifier is conventional grouping, the vehicles with the same order number in the grouping task are conventionally grouped; and after batch grouping, the data are added into a group batch set. According to the method, the optimal vehicle combination can be obtained, so inspection and test cost is saved, and meanwhile, the forced grouping quality is set for the vehicles with insufficient vehicle transportation quality and target quality, so the situation that the vehicles wait for grouping for a long time in a parking lot is avoided.

Owner:WISDRI ENG & RES INC LTD

Computerized systems and methods for assisted picking processes

Owner:COUPANG CORP

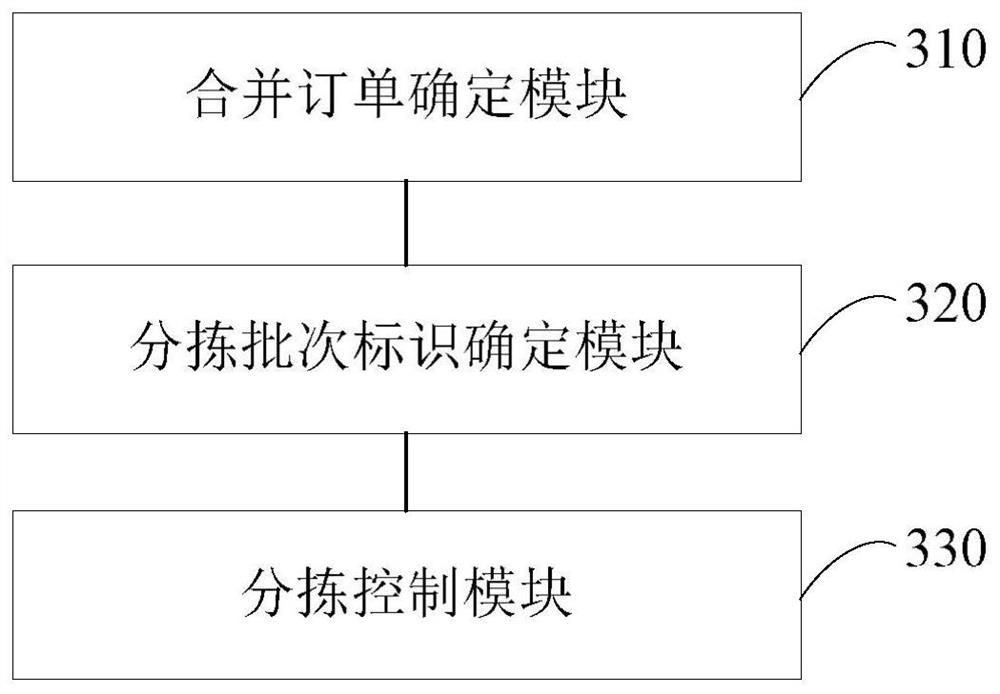

Processing method, device, system, equipment and storage medium for logistics sorting information

ActiveCN109823755BSimplify the sorting processImprove sorting efficiencyStorage devicesLogistics managementProcess engineering

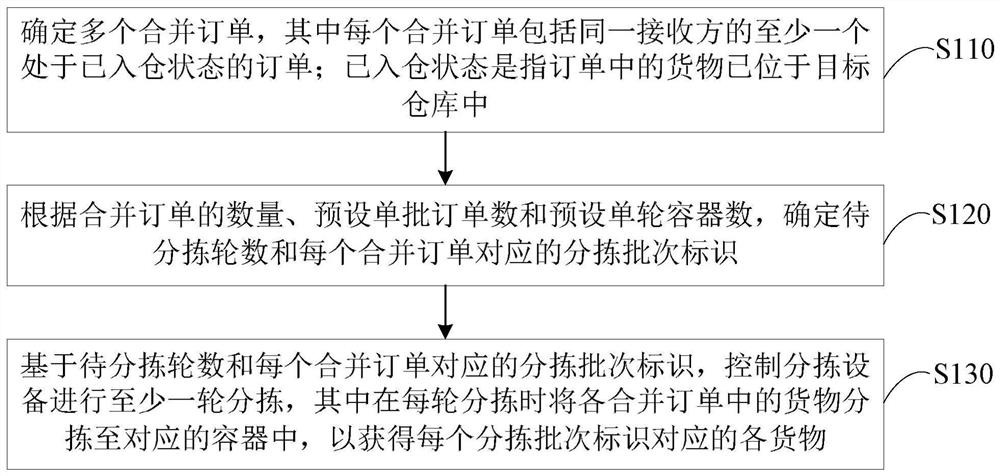

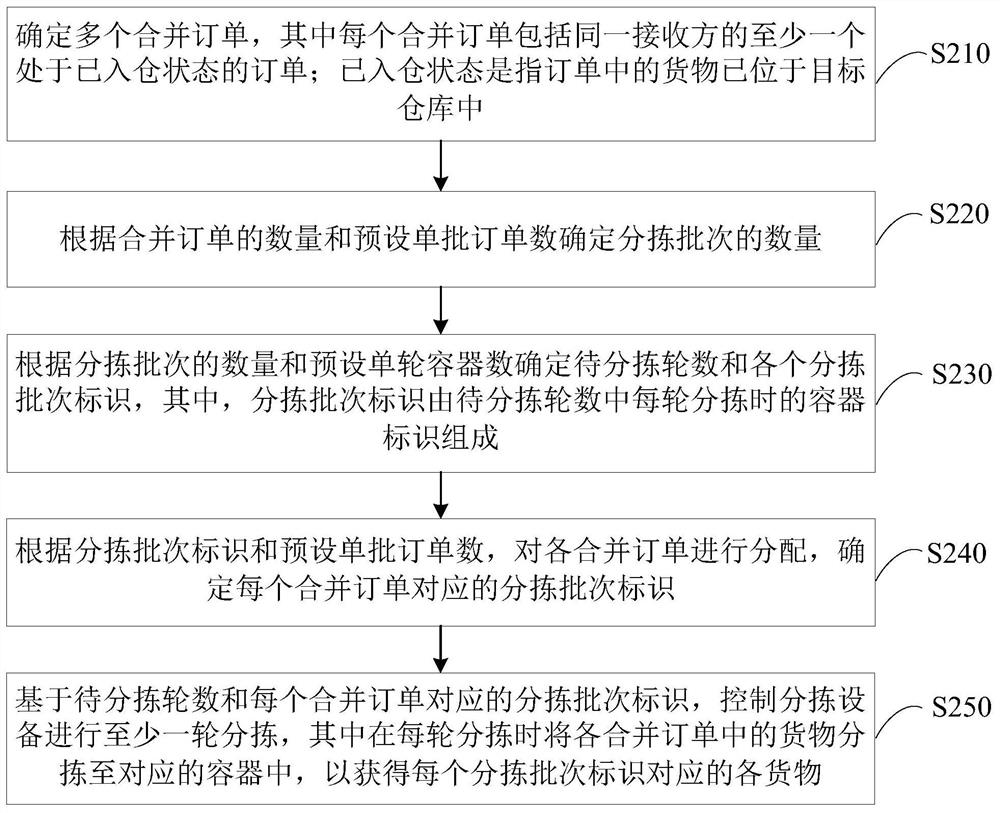

The embodiment of the present invention discloses a processing method, device, system, equipment and storage medium for logistics sorting information. The method includes: determining multiple consolidated orders, wherein each consolidated order includes at least one Orders in the warehouse state; according to the number of combined orders, the number of preset single-batch orders and the preset number of single-round containers, determine the number of rounds to be sorted and the sorting batch identification corresponding to each combined order. Among them, the sorting batch The identification is determined according to the container identification corresponding to the combined order in each round of sorting rounds to be sorted; based on the number of rounds to be sorted and the sorting batch identification corresponding to each combined order, the sorting equipment is controlled to perform at least one round Sorting, wherein in each round of sorting, the goods in each combined order are sorted into corresponding containers, so as to obtain the goods corresponding to each sorting batch identification. Through the technical solutions of the embodiments of the present invention, the sorting process can be simplified and the sorting efficiency can be improved.

Owner:深圳威狮物流网络科技有限公司 +1

Multi-task serial scheduling method and device

ActiveCN107168789BGuaranteed to be scheduledProblems with adapting to task changesResource allocationParallel computingOperating system

Owner:ADVANCED NEW TECH CO LTD

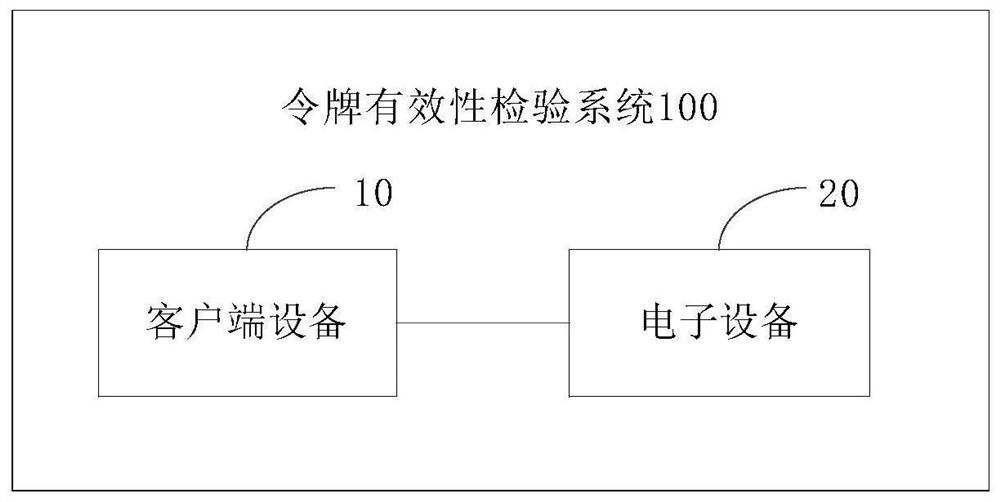

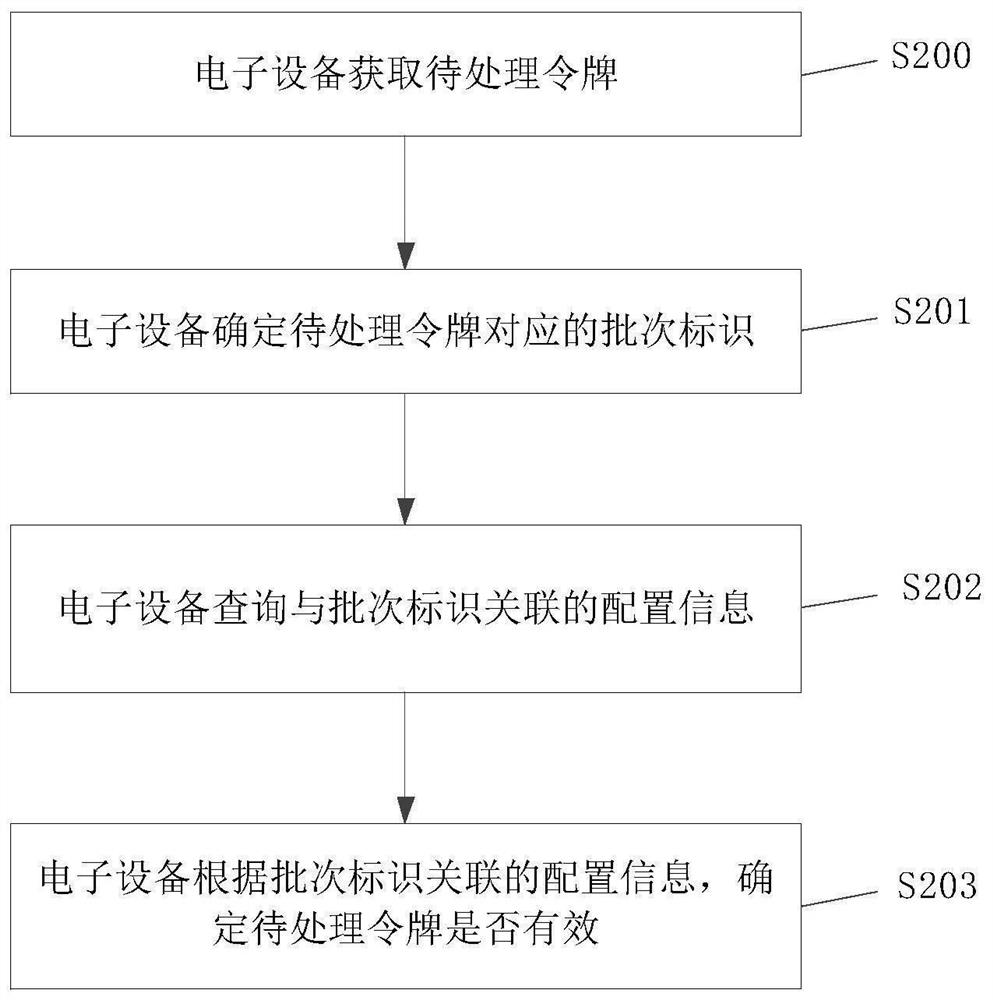

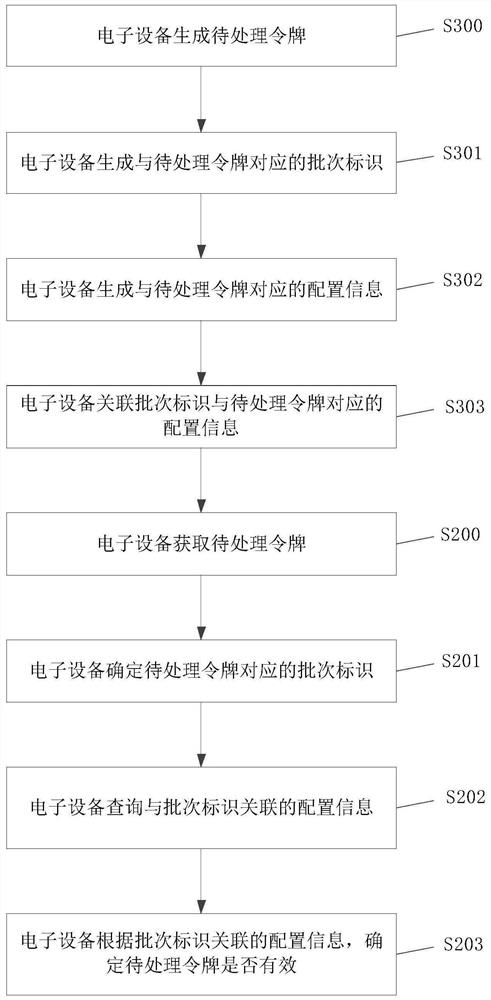

Token validity test method, device and equipment and storage medium

PendingCN114168450AImprove securityReduce occupancySoftware testing/debuggingDigital data authenticationReliability engineeringElectronic equipment

The invention relates to a token validity test method and device, equipment and a storage medium, and relates to the field of data processing. The problem of data security caused by token leakage in the prior art is solved. The method comprises the following steps: acquiring a token to be processed; determining a batch identifier corresponding to the token to be processed; querying configuration information associated with the batch identifier; the configuration information is used for representing the effective access authority of the token to be processed; and determining whether the token to be processed is valid or not according to the configuration information associated with the batch identifier. On the basis, the electronic equipment can set the leaked token as the invalid token by adjusting the validity configuration of the token, so that other equipment is prevented from applying for accessing the electronic equipment by using the tokens, and the safety of the electronic equipment is further improved.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

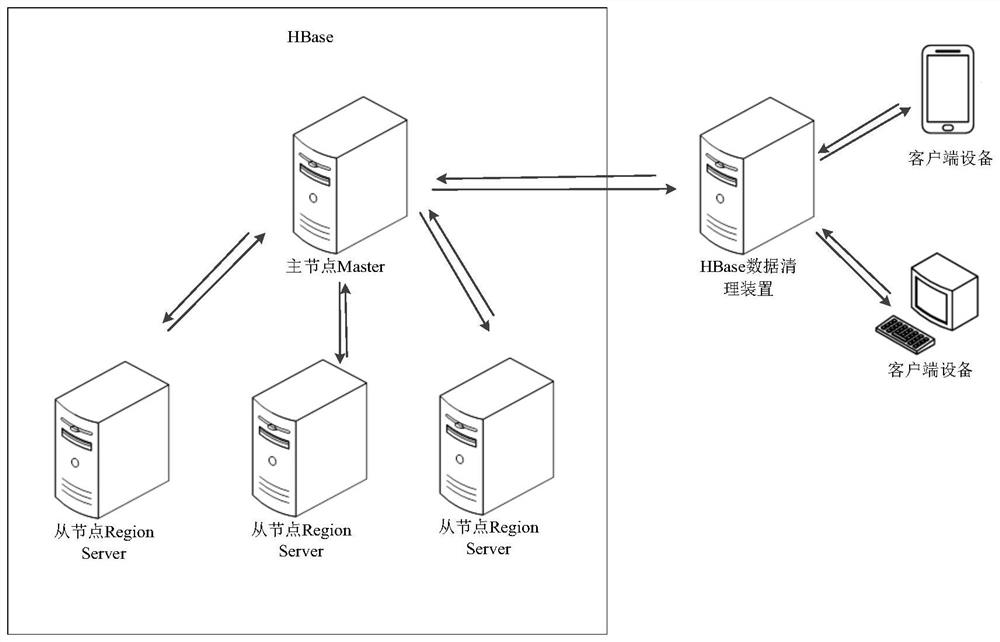

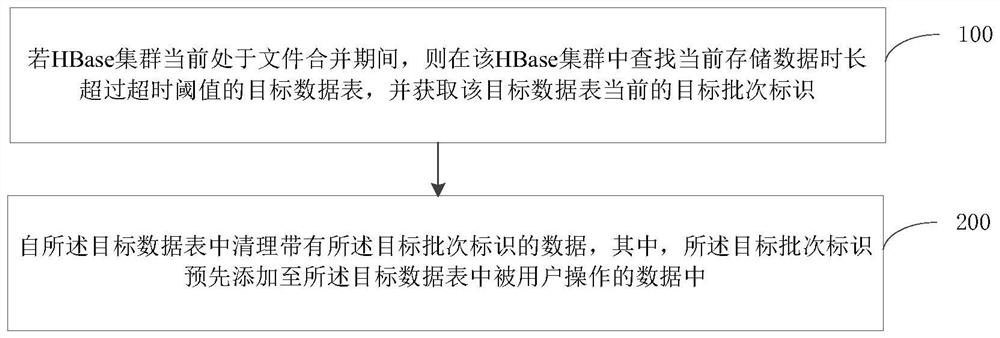

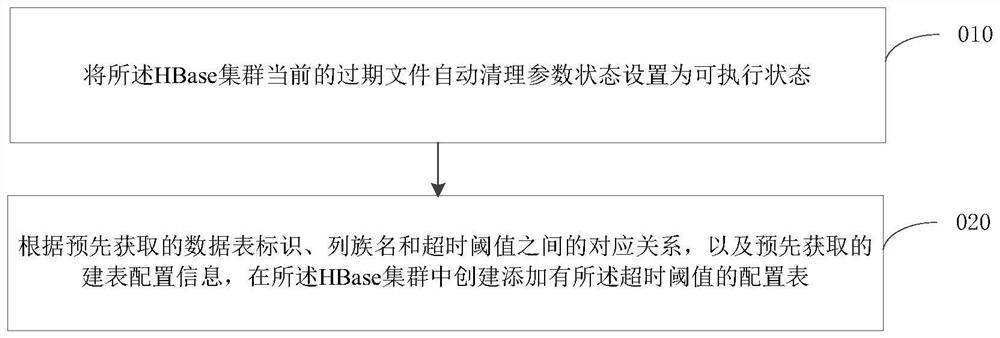

HBase data cleaning method and device

PendingCN113515509AImprove performanceImprove running stabilityDatabase distribution/replicationSpecial data processing applicationsDatasheetDatabase

The embodiment of the invention provides an HBase data cleaning method and device, which can be used in the technical field of big data, and the method comprises the following steps: if an HBase cluster is currently in a file merging period, searching a target data table of which the current data storage duration exceeds an overtime threshold in the HBase cluster, and obtaining a current target batch identifier of the target data table; and clearing the data with the target batch identification from the target data table, and adding the target batch identification into the data operated by the user in the target data table in advance. According to the method and the device, the operation pressure of the main node in the HBase cluster can be effectively reduced, the reliability and the efficiency of the HBase data cleaning process can be improved, and the overall performance and the operation stability of the HBase cluster are improved.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

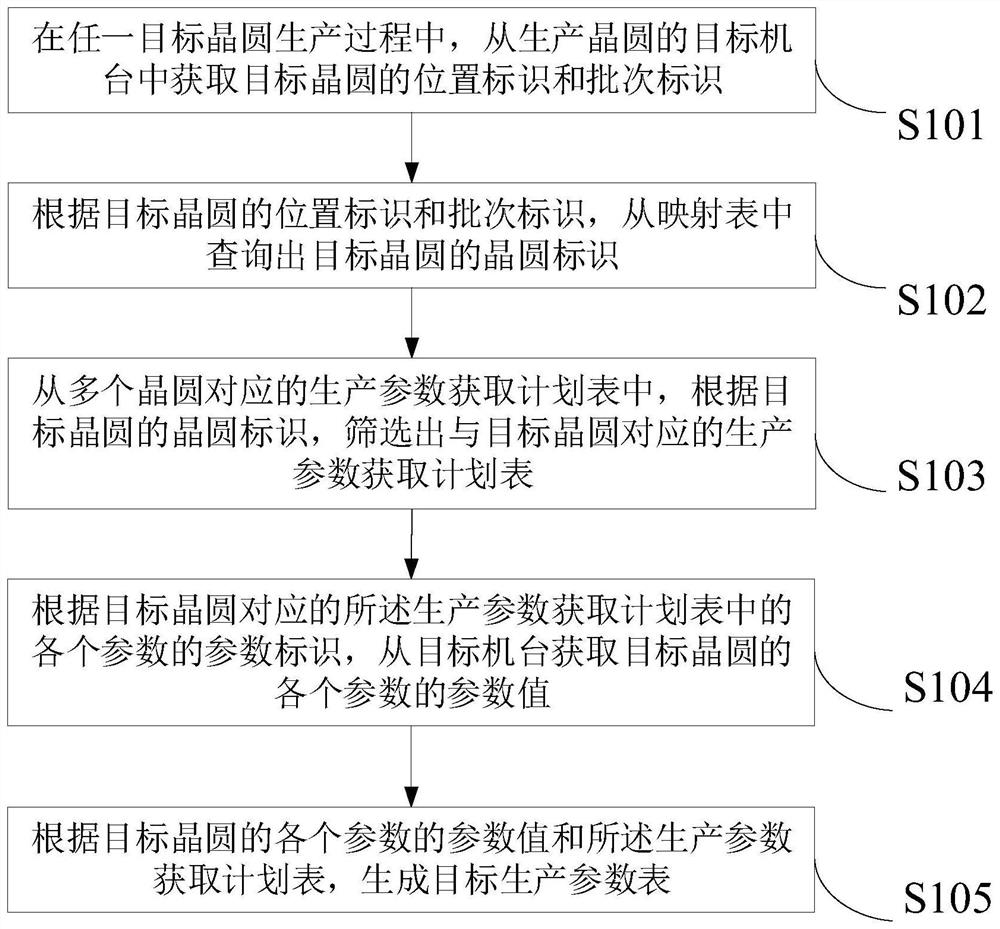

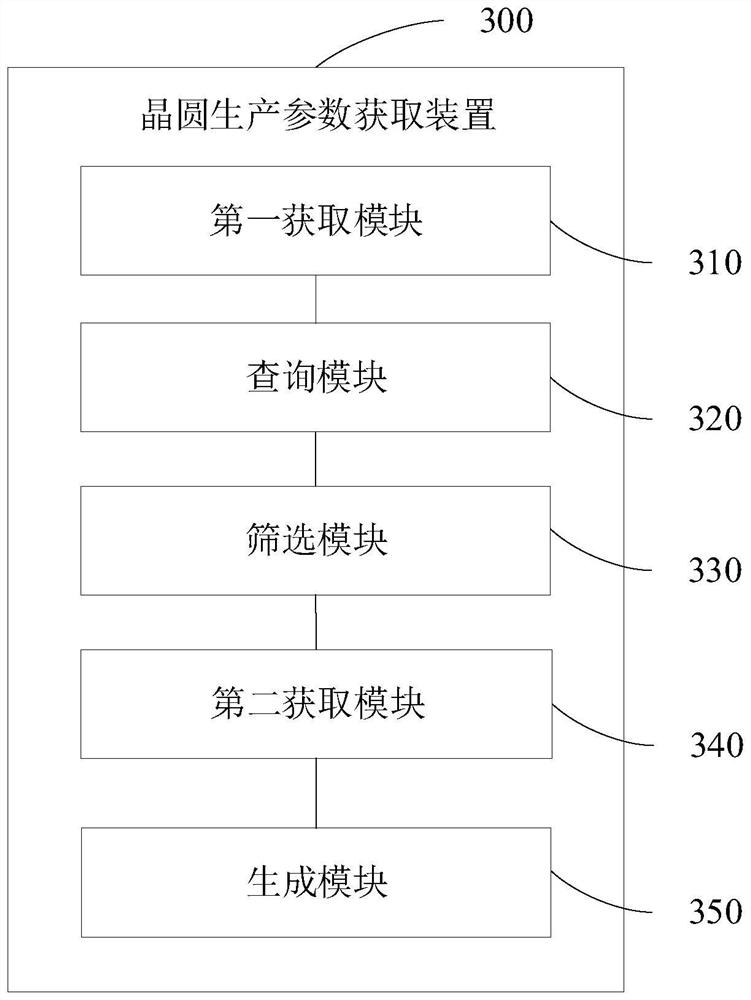

Wafer production parameter acquisition method and device, equipment and storage medium

PendingCN114300392AImprove accuracyHigh speedSemiconductor/solid-state device manufacturingWaferProcess engineering

The invention provides a wafer production parameter acquisition method and device, equipment and a storage medium, and the method comprises the steps: querying a wafer identifier of a target wafer in a mapping table according to a position identifier and a batch identifier of a wafer in a machine, finding a corresponding production parameter according to the wafer identifier, and obtaining a schedule, and obtaining parameter identifiers of the parameters in the schedule according to the production parameters, obtaining parameter values of the target wafer corresponding to the parameter identifiers from the machine, obtaining the schedule according to the obtained parameter values and the production parameters, and generating a target production parameter table. In this way, the production parameter acquisition schedule matched with the target wafer in the current machine can be quickly determined, and the accuracy and speed of acquiring the production parameters corresponding to the wafers can be improved.

Owner:赛美特科技有限公司

Data transmission method, data storage method, device, server and storage medium

ActiveCN109639811BImprove accuracyAvoid duplicate transmissionSecuring communicationEngineeringData transmission

An embodiment of the present invention provides a data transmission method, data storage method, device, server, and storage medium, wherein the transmission method includes: obtaining the data to be transmitted and if the transmission condition of the data to be transmitted is met, the acquired data to be transmitted is Determine it as batch data, and set a unique batch identifier for the batch data; send a data transmission request. The storage method includes: receiving a data transmission request; judging whether there is a stored mark of the batch identification locally; when there is a stored mark of the batch identification, determining that the batch data has been stored, and the data transmission request is a repeated transmission request; When there is no stored flag of the batch identifier, it is determined that the batch data is not stored; the batch data is stored, and the stored flag is added to the batch identifier. The embodiment of the present invention can improve the accuracy of data transmission when large amount of data is transmitted.

Owner:BEIJING KINGSOFT CLOUD NETWORK TECH CO LTD +1

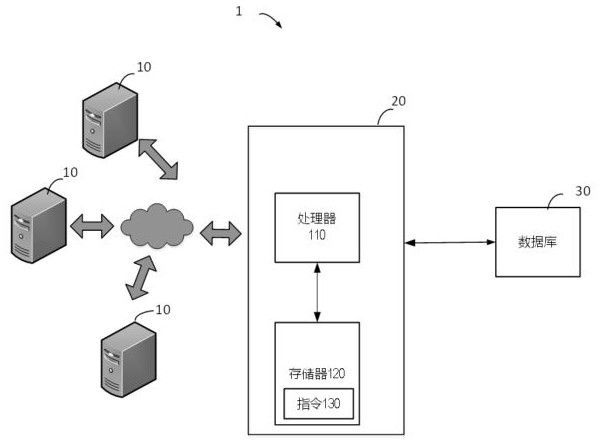

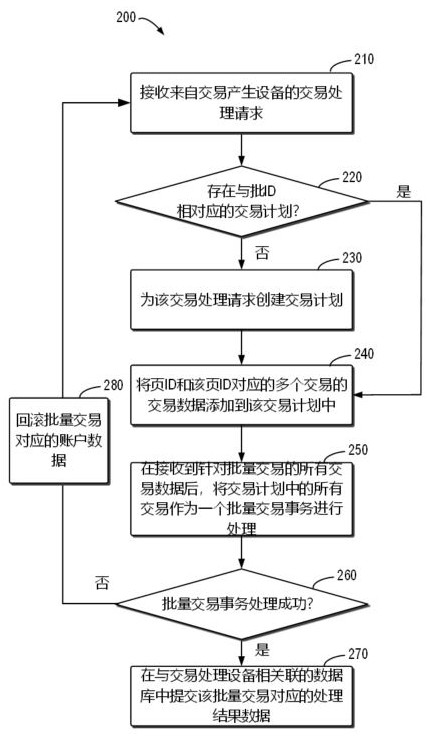

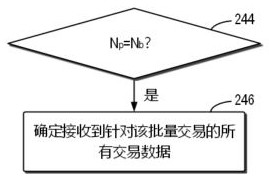

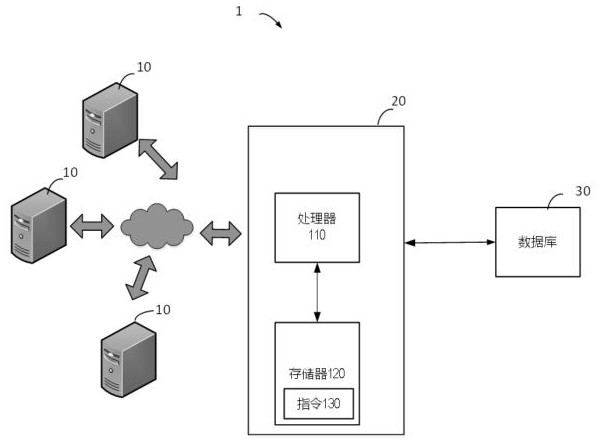

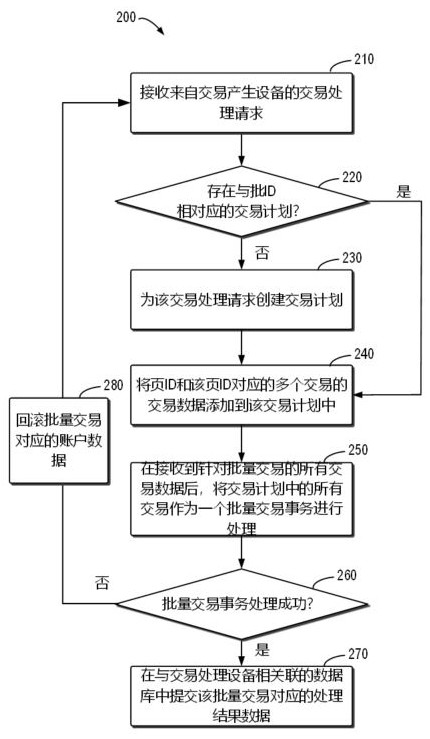

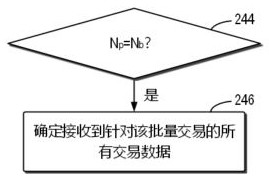

Method, computing device and storage medium for processing batch transactions

The present invention provides a method, computing device and computer-readable storage medium for processing batch transactions. The method includes: in a transaction processing device: receiving a transaction processing request from a transaction generating device; determining whether a transaction plan corresponding to the batch identifier exists in the transaction processing device; in response to determining that there is no transaction plan corresponding to the batch identifier A transaction plan, creating a transaction plan for the transaction processing request and adding the page identifier and transaction data of multiple transactions corresponding to the page identifier into the transaction plan; in response to determining that there is a transaction plan corresponding to the batch identifier, adding The page identifier and the transaction data of the multiple transactions corresponding to the page identifier are added to the transaction plan; and after receiving all transaction data for the batch transaction, all transactions in the transaction plan are processed as a batch transaction transaction deal with.

Owner:南京吉拉福网络科技有限公司 +1

Methods and systems for enhanced non-destructive testing (NDT) product labels and use thereof

PendingCN112088306ASensing record carriersRecord carriers used with machinesNon destructiveSoftware engineering

Systems and methods are provided for enhanced non-destructive testing (NDT) product labels and use thereof. An example label may be configured for application to non destructive testing (NDT) products, with the label including a readable code that incorporates information relating to a particular NDT product sample. The information uniquely identifies the NDT product sample and / or a batch that includes the NDT product sample. An example system may include a reader configured for reading machine-readable code incorporated into a label applied to an NDT product, and circuitry configured for processing data obtained from the machine-readable code. The circuitry may extract based on the processing, information relating to the NDT product, the information including a unique product identifier and / or a unique batch identifier. The circuitry may then trigger based on the unique product identifier and / or the unique batch identifier, actions associated with the NDT product and / or use of the NDTproduct.

Owner:ILLINOIS TOOL WORKS INC

Batch transaction processing method, computing device and storage medium

The invention provides a method for processing batch transactions, computing equipment and a computer readable storage medium. The method comprises the following steps: in transaction processing equipment, receiving a transaction processing request from transaction generation equipment; determining whether a transaction plan corresponding to the batch identifier exists in the transaction processing equipment or not; in response to determining that the transaction plan corresponding to the batch identifier does not exist, creating a transaction plan for the transaction processing request, and adding the page identifier and transaction data of a plurality of transactions corresponding to the page identifier into the transaction plan; in response to determining that the transaction plan corresponding to the batch identifier exists, adding the page identifier and transaction data of a plurality of transactions corresponding to the page identifier into the transaction plan; and after receiving all transaction data for the batch transaction, processing all transactions in the transaction plan as a batch transaction transaction.

Owner:南京吉拉福网络科技有限公司 +1

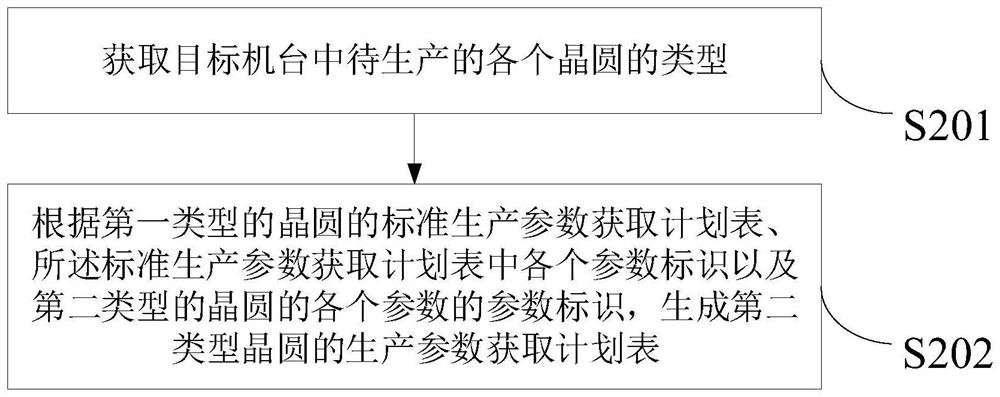

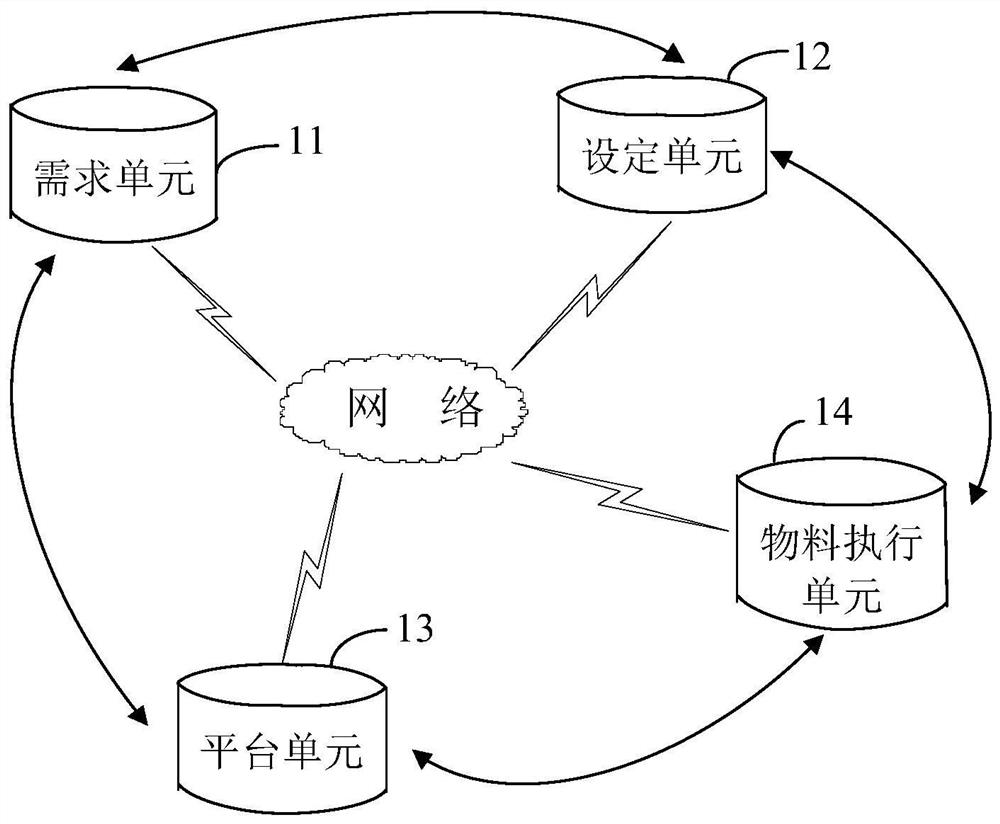

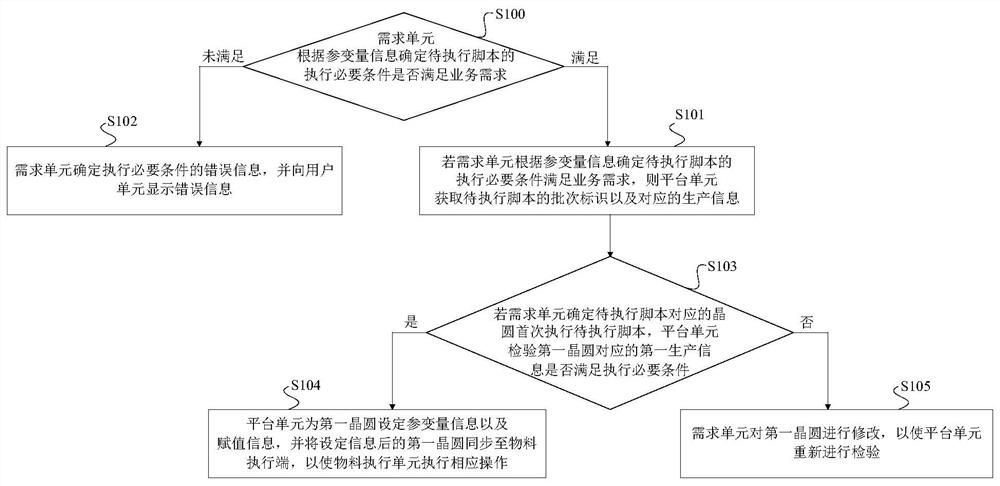

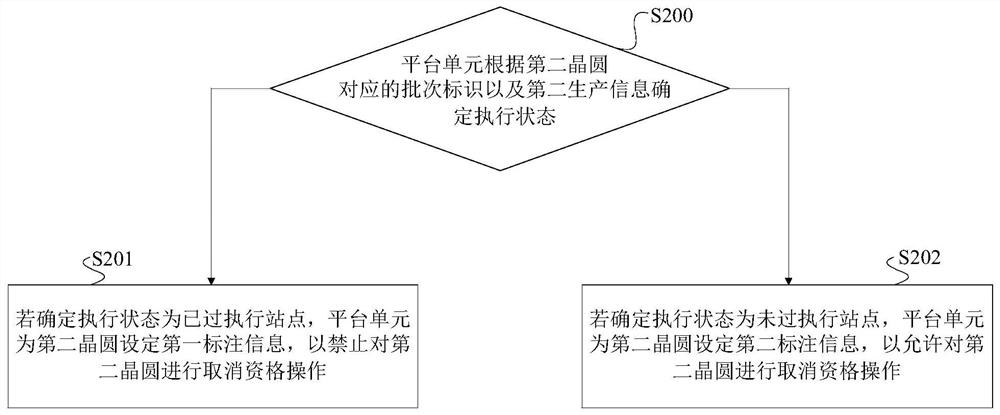

Wafer script setting method and device, equipment and storage medium

PendingCN114444432AAvoid the risk of obsolescenceRealize instant settingComputer aided designTotal factory controlWaferExecution unit

The invention provides a wafer script setting method and device, equipment and a storage medium. If the demand unit determines that the execution necessary condition of the script to be executed meets the business demand according to the parameter information, the platform unit obtains a batch identifier of the script to be executed and corresponding production information, and determines that a wafer corresponding to the script to be executed executes the script to be executed for the first time in the demand unit; and the platform unit checks whether the first production information corresponding to the first wafer meets the execution necessary condition or not, and if yes, the platform unit sets parameter information and assignment information for the first wafer and synchronizes the first wafer with the set information to the material execution unit, so that the material execution unit executes corresponding operation. According to the technical scheme, the script to be executed can be set in real time without modifying the script process, the script to be executed which does not meet the execution necessary condition is avoided from the source, the risk that wafers are scrapped in batches is avoided, the setting process is irrelevant to the batch number, and the overall production efficiency is not affected.

Owner:CHANGXIN MEMORY TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com