Horizontal paper lapping machine

A paper-wrapped, horizontal technology, applied in the field of copper-aluminum electromagnetic wire wrapping production equipment, can solve the problems of felt fans sticking into the wire, easy to fall off paper strips when the machine is stopped, and the length of the fuselage occupies a large space, so as to save equipment manufacturing. Cost, shorten the distance of occupied equipment, and save the effect of area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

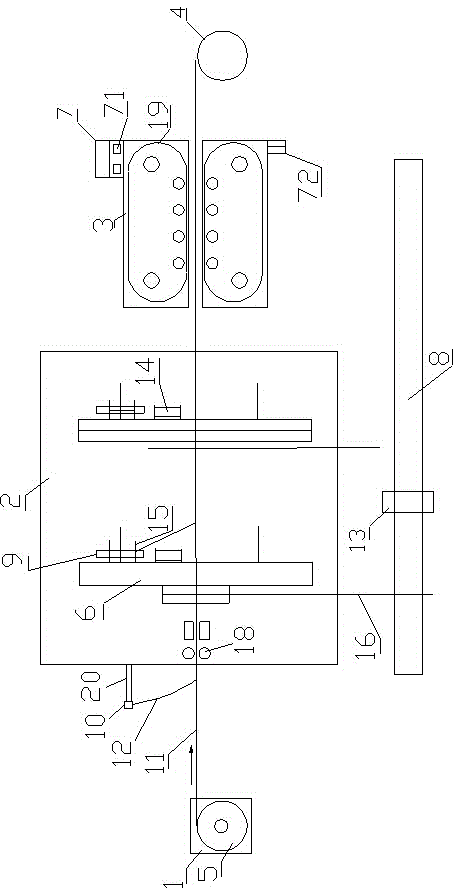

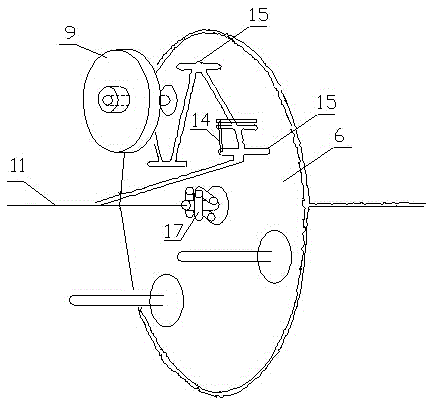

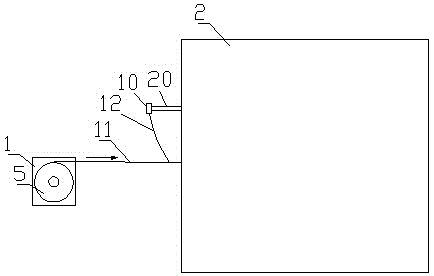

[0020] Such as figure 1 A horizontal paper wrapping machine is shown, comprising a pay-off device 1, a straightening combination wheel 18, a double-head wrapping device 2, a traction device 3, a meter counting device 7, and a take-up device 4; the pay-off device 1 includes a pay-off Frame 5, double-head wrapping device 2 is provided with six paper trays 9. The double-head wrapping device 2 is arranged longitudinally as a whole; there is also an automatic stop device for burrs before the line inlet of the paper wrapping machine. Wrapping device 2 comprises two vertically installed iron pans 6, such as figure 2 As shown, each iron plate 6 is provided with three paper trays 9, and each paper plate 9 is mounted on the iron plate 6 with three screws, and each iron plate 6 is also provided with three Paper break stop switch 14 and a plurality of paper guide wheels 15, the paper guide wheels 15 can also adopt the paper guide rod according to the tension requirements, and each wrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com