Patents

Literature

31results about How to "Shorten the operating distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

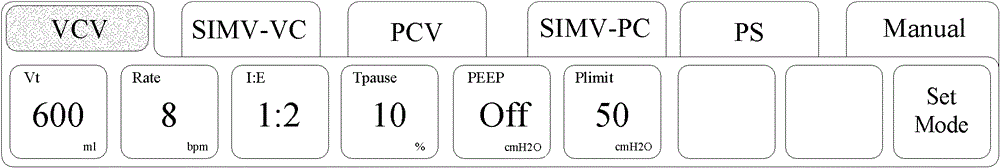

Parameter setting method and device for medical equipment and medical equipment

ActiveCN102441215AIntuitive input operationAvoid frequent operationsRespiratorsMedical equipmentInput control

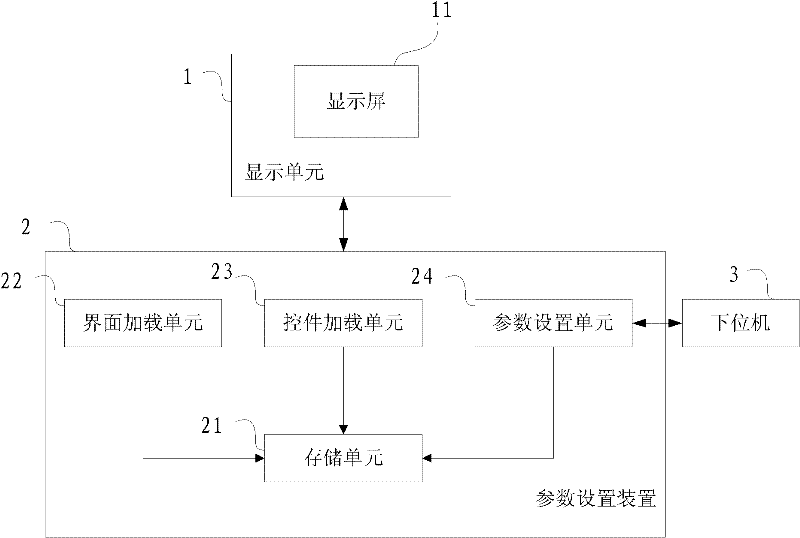

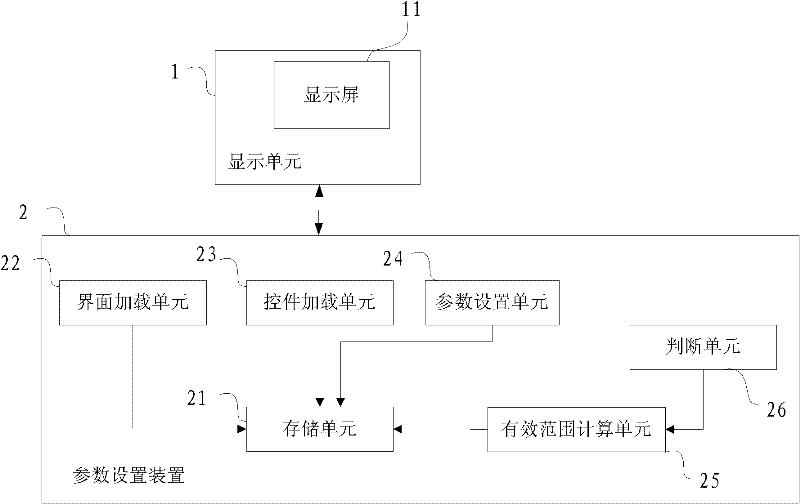

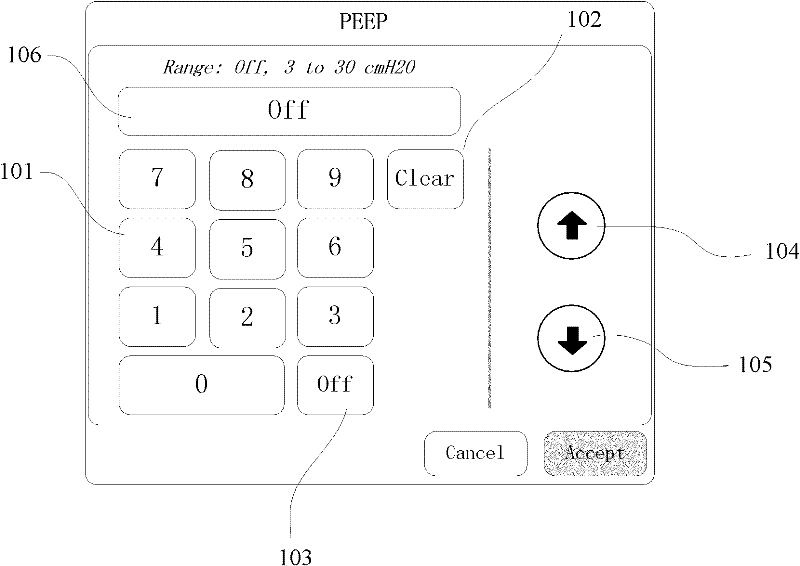

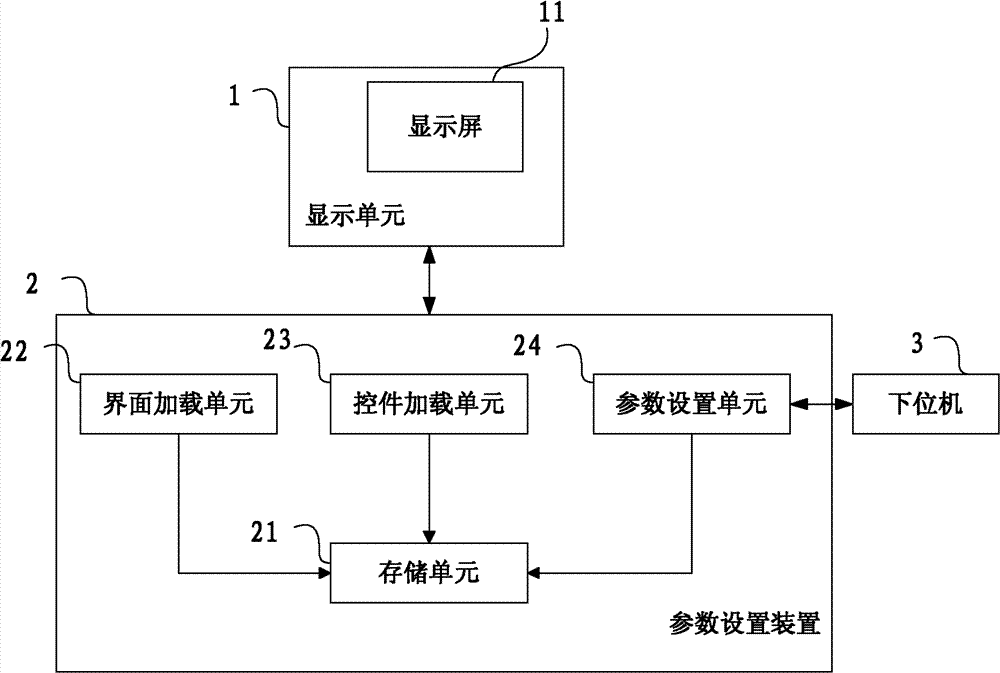

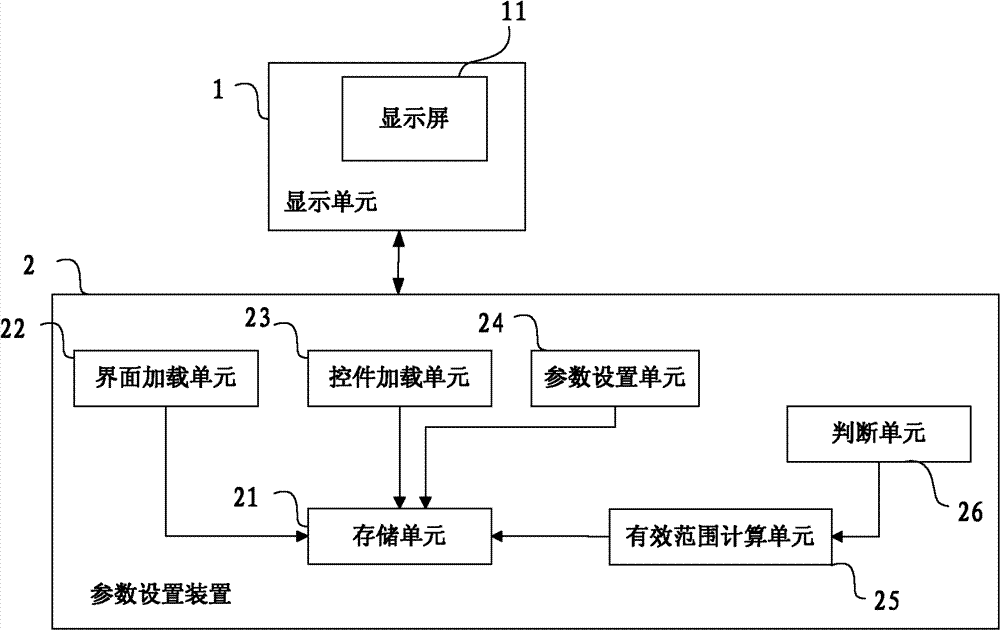

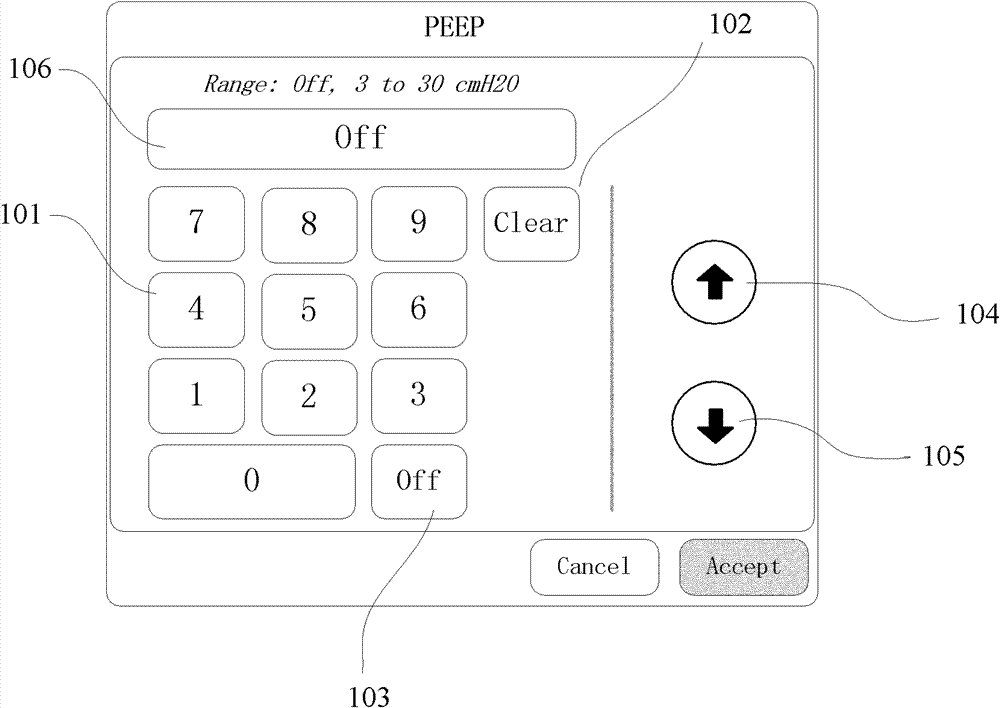

The invention discloses a parameter setting method and device for medical equipment and medical equipment. The method comprises the following steps of: presetting data input controls of parameter items, and building a first corresponding table of the parameter items and the data input controls, wherein the data input controls include basic keys for all the parameter items and additional keys dynamically appointed in the first corresponding table according to the parameter items; inquiring the first corresponding table according to the to-be-adjusted parameter items input by a user, and loading the data input controls corresponding to the to-be-adjusted parameter items; receiving novel parameter values and parameter modifying instructions input by the user through the data input controls; and sending the modified novel parameter values to a lower computer, and confirming if the parameter values are modified according to the feedback from the lower computer. According to the parameter setting method and device disclosed by the invention, the parameter setting process is more intuitive and the operating distance is shortened, so that the parameters setting process can be finished in a step; and a rotary encoder is avoided being operated frequently, so that the operator can more quickly complete the parameter setting process.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

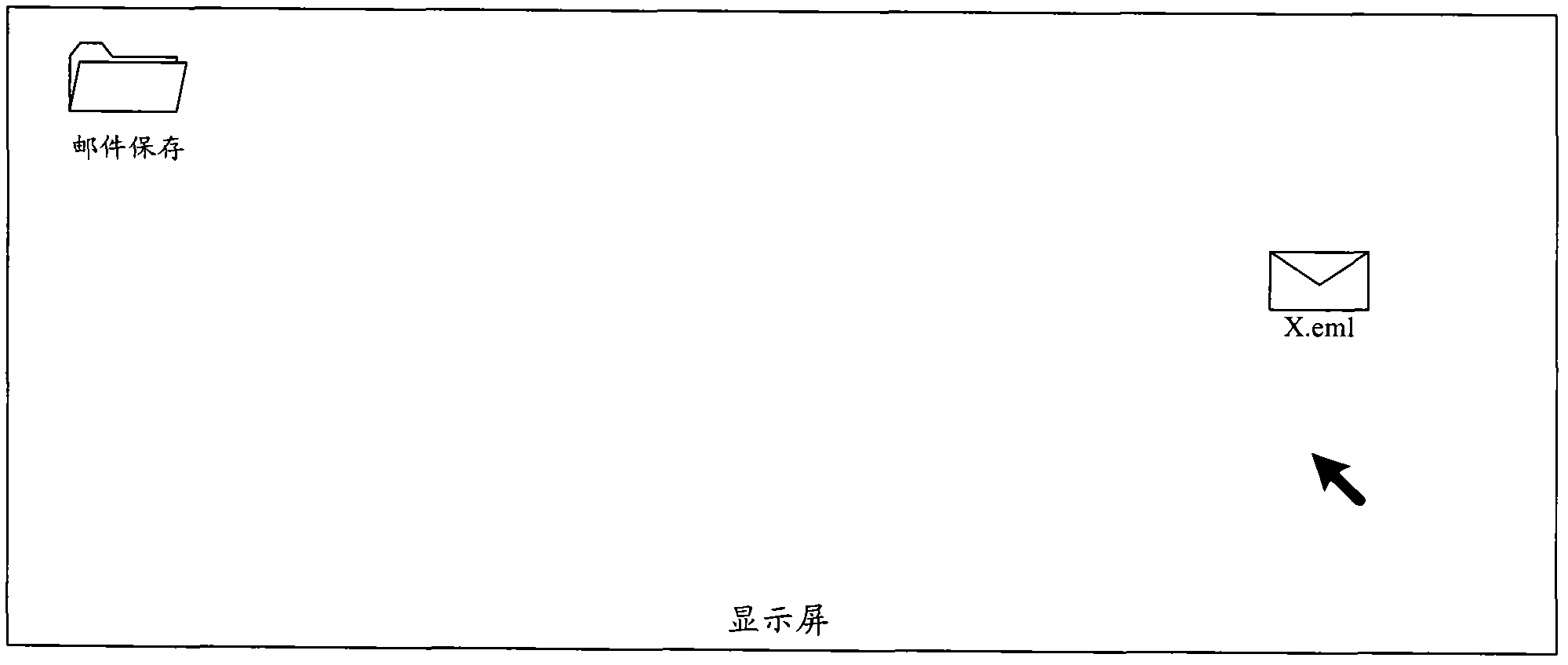

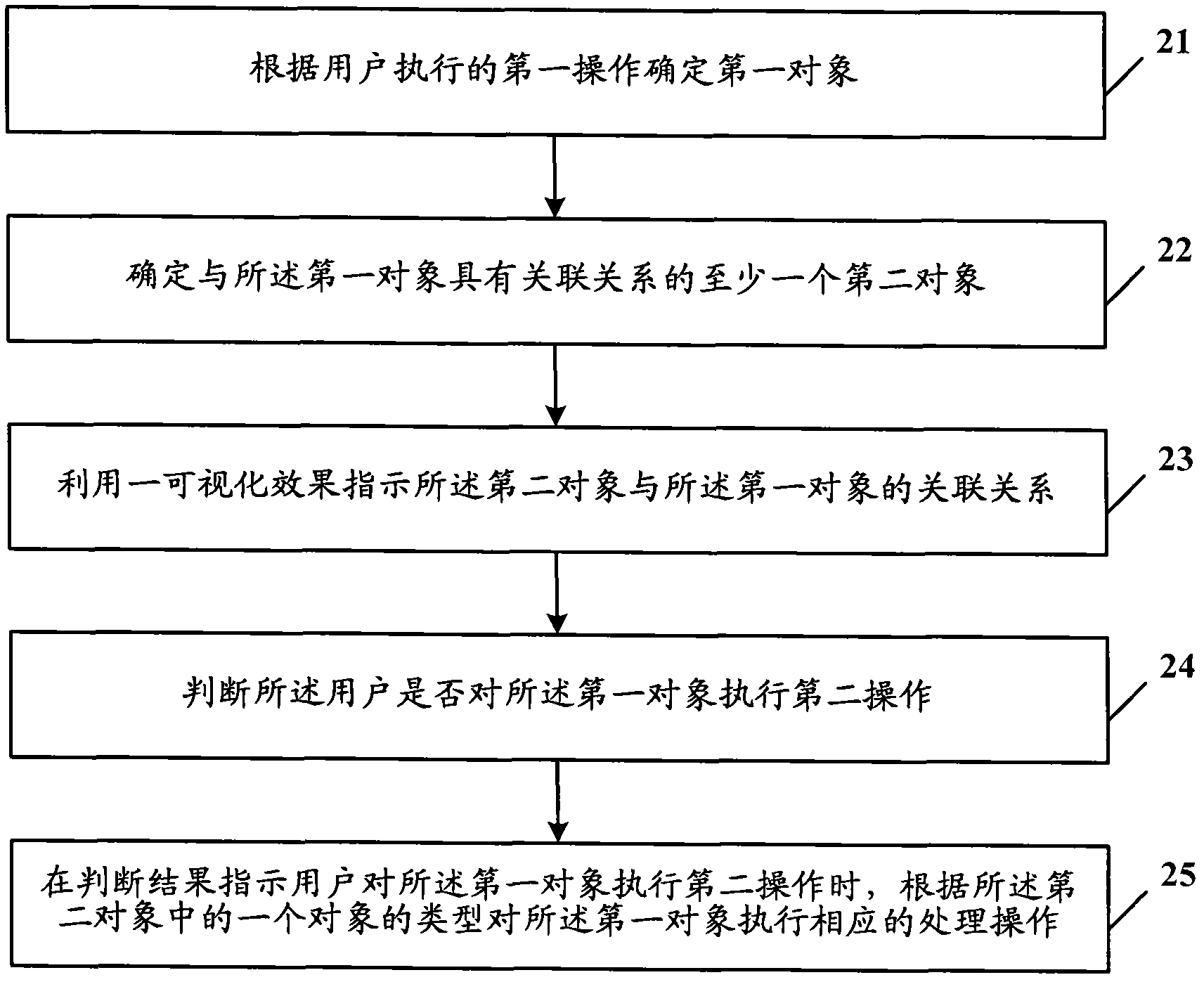

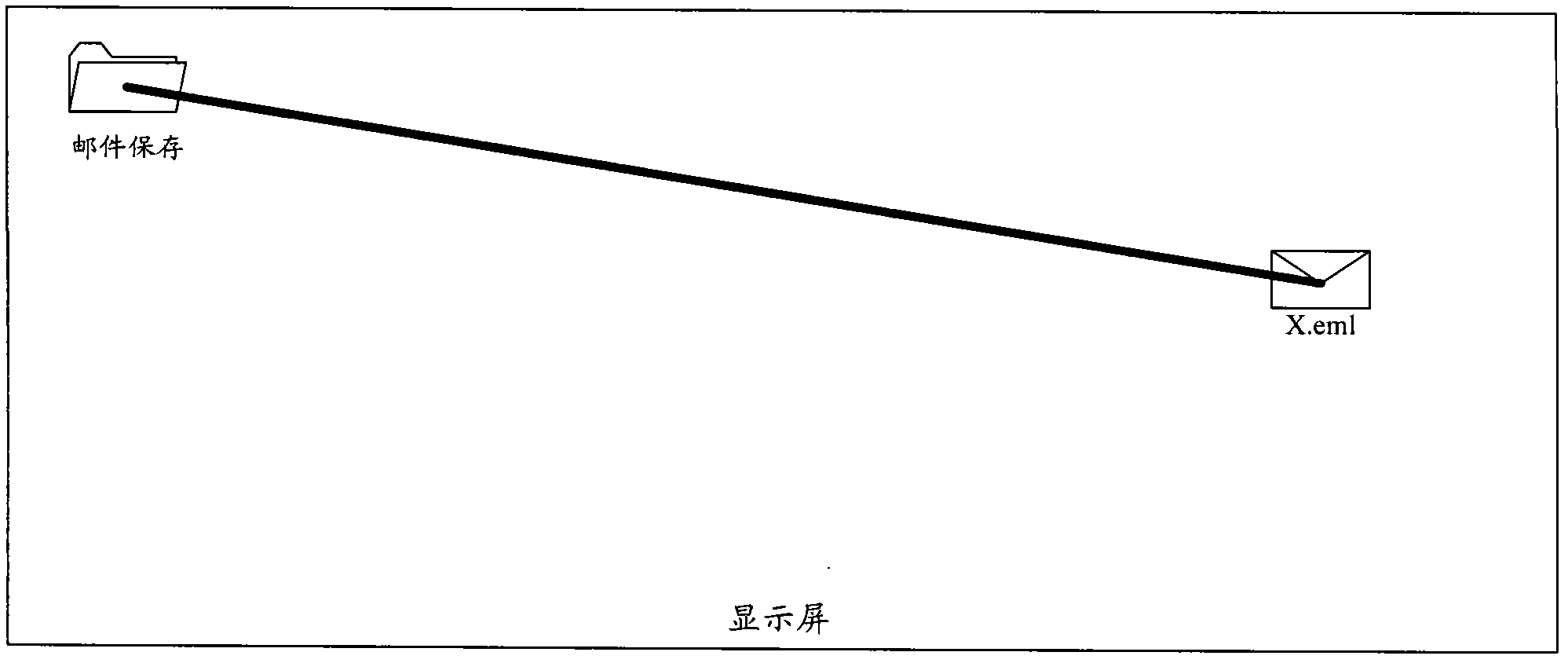

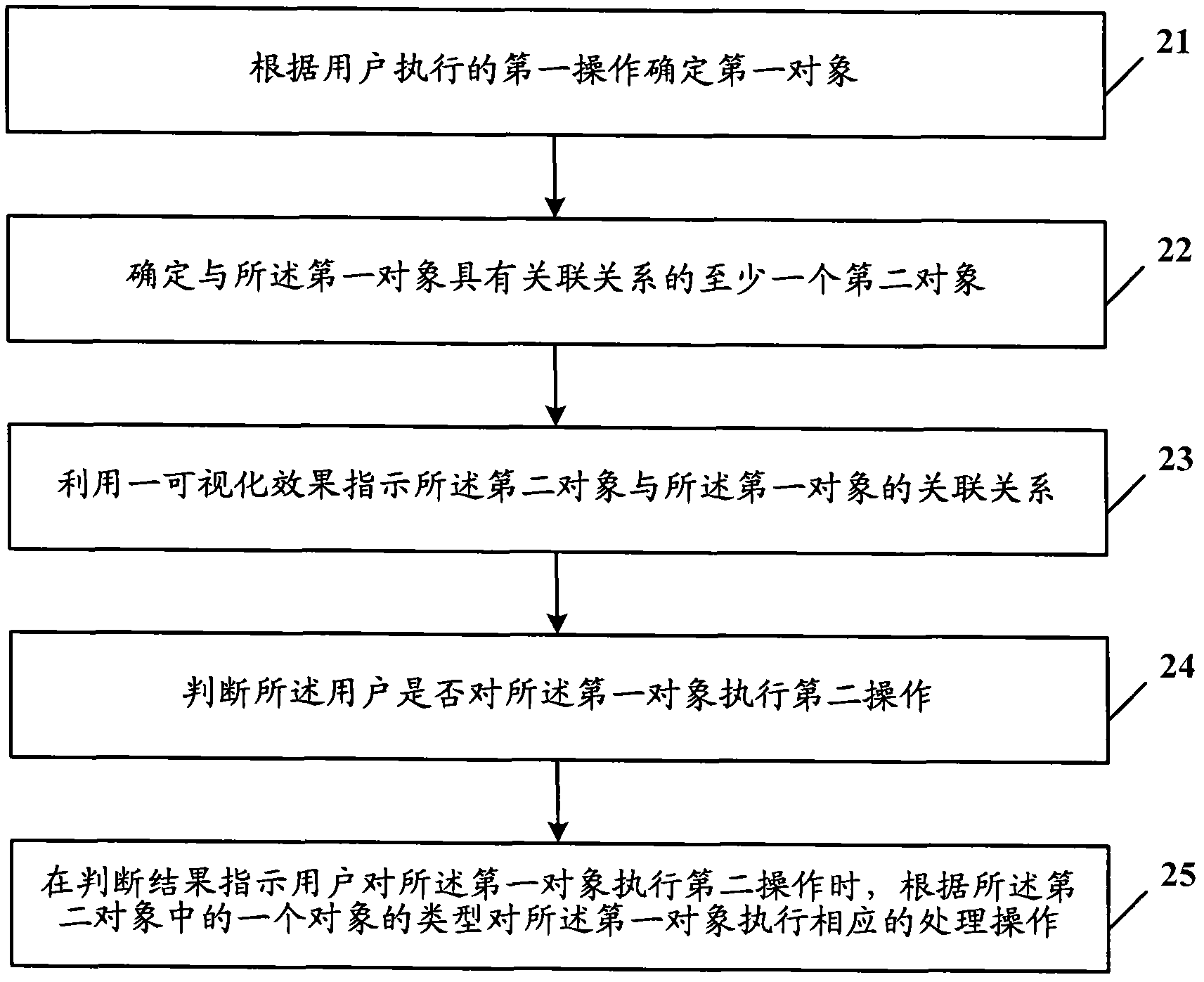

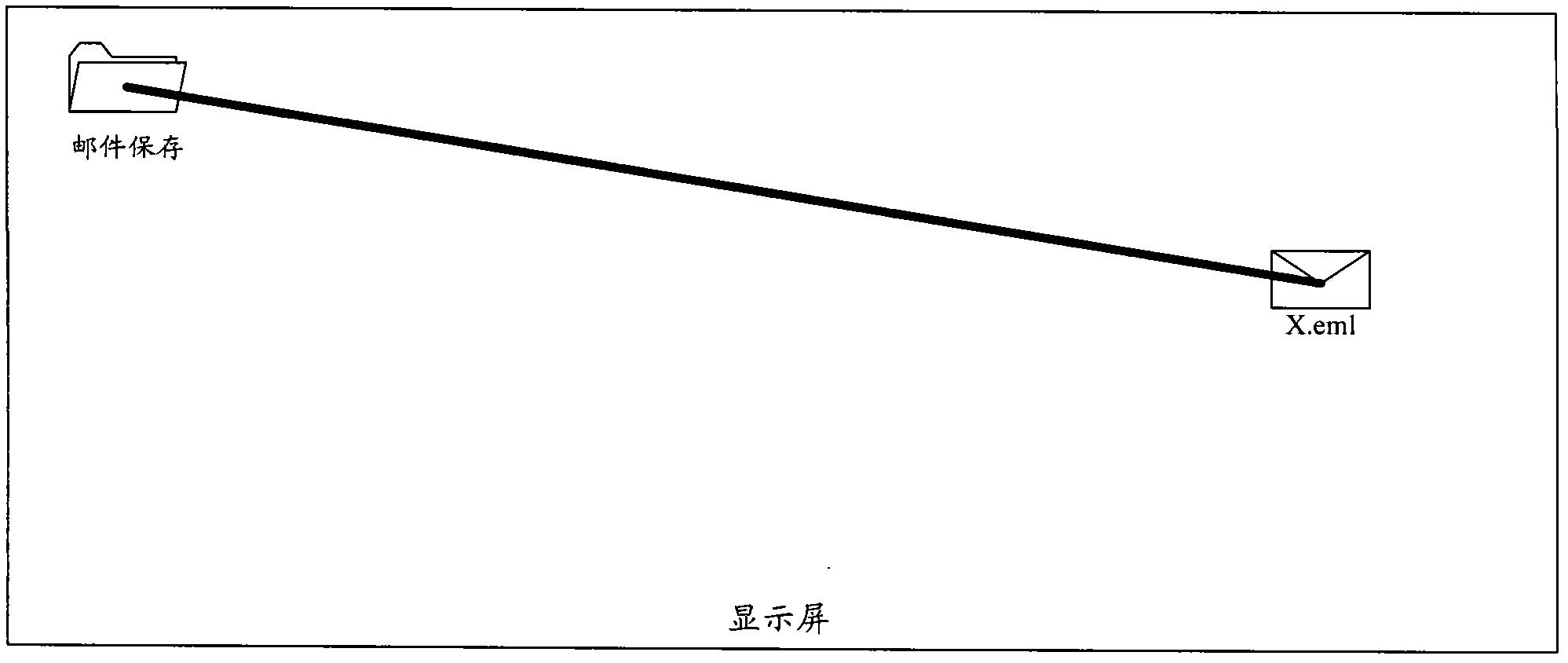

Object processing method and device as well as electronic equipment

ActiveCN102486715AImprove operational efficiencyReduce distanceInput/output processes for data processingElectric equipmentElectronic equipment

The invention provides an object processing method and device as well as electronic equipment. The object processing method comprises the following steps of: determining a first object according to a first operation executed by a user; determining at least one second object which has an incidence relation with the first object; indicating the incidence relation between the second object and the first object by utilizing a visualized effect; judging whether the user executes a second operation on the first object; executing a corresponding processing operation on the first object according to the type of one object in the second object when the judged result shows that the user executes the second operation on the first object, wherein the a result generated by the processing operation is the same as the result generated by that the first objected is selected by a pointer, dragged to the position of the second objected and released, and with the adoption of the second operation, the moved distance of the first object is less than the distance between the first object and the second object before the second operation is executed. According to the invention, the operation efficiency of the user is improved.

Owner:LENOVO (BEIJING) CO LTD

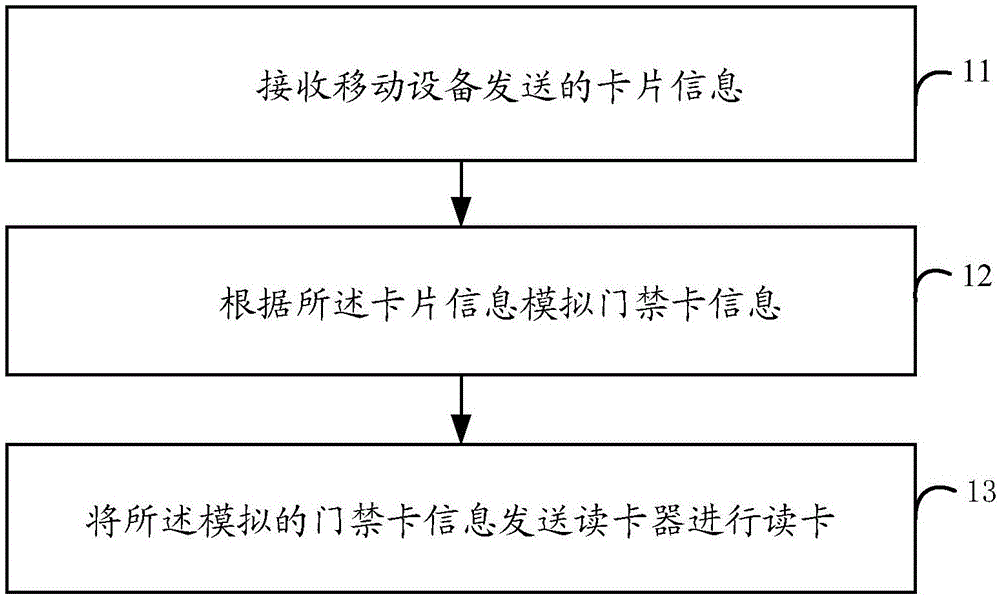

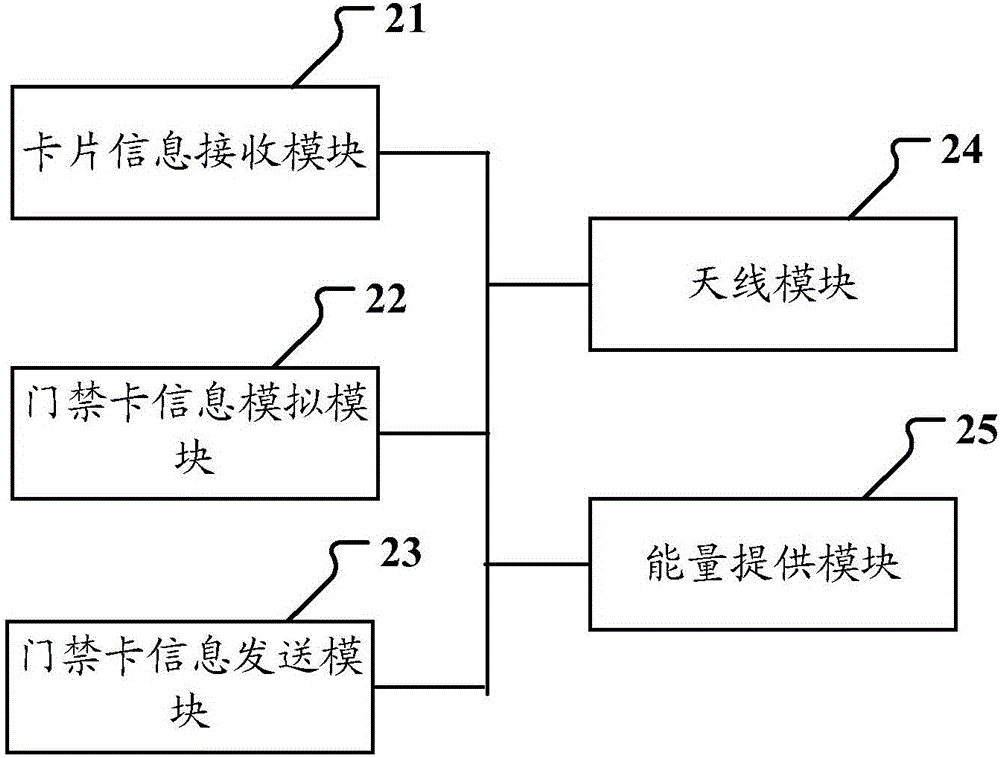

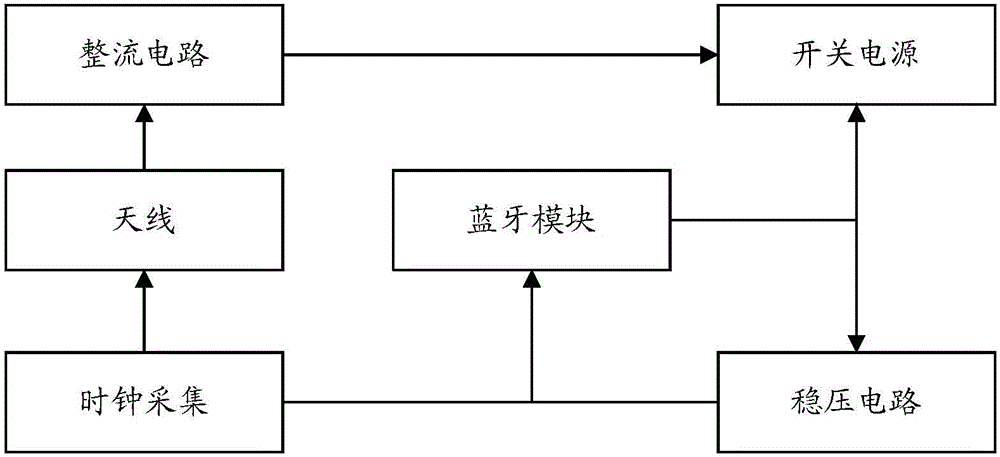

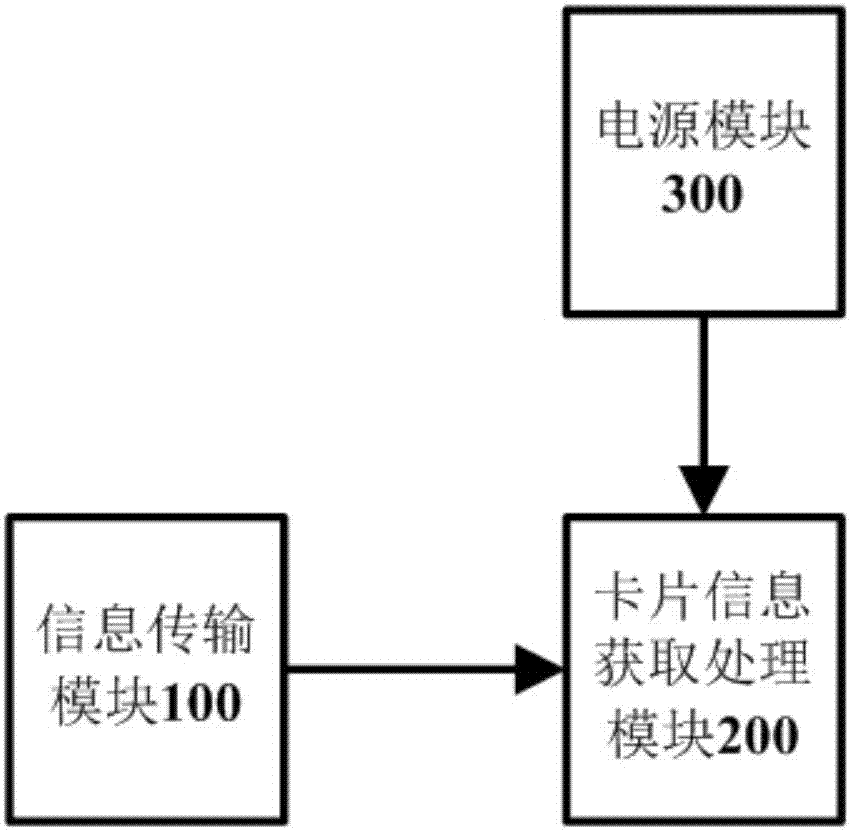

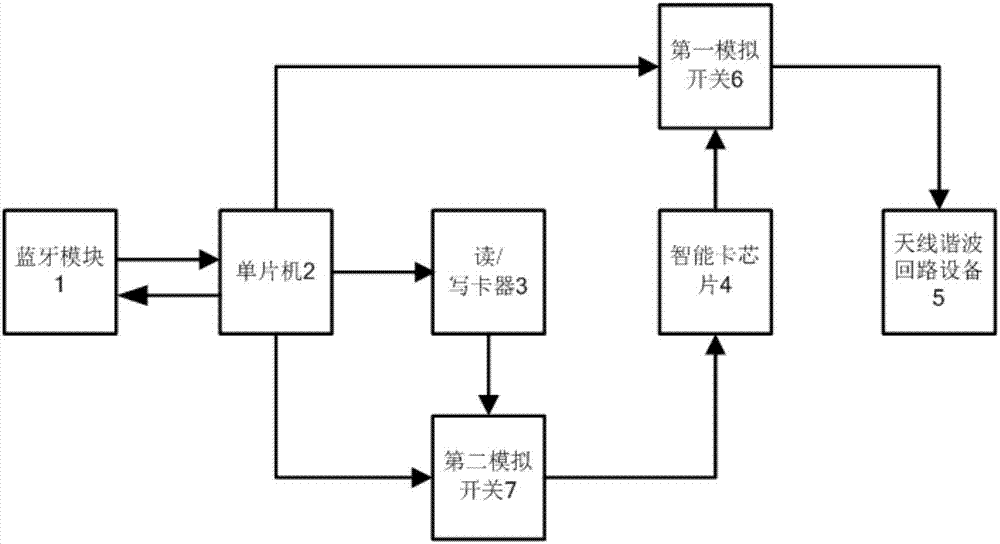

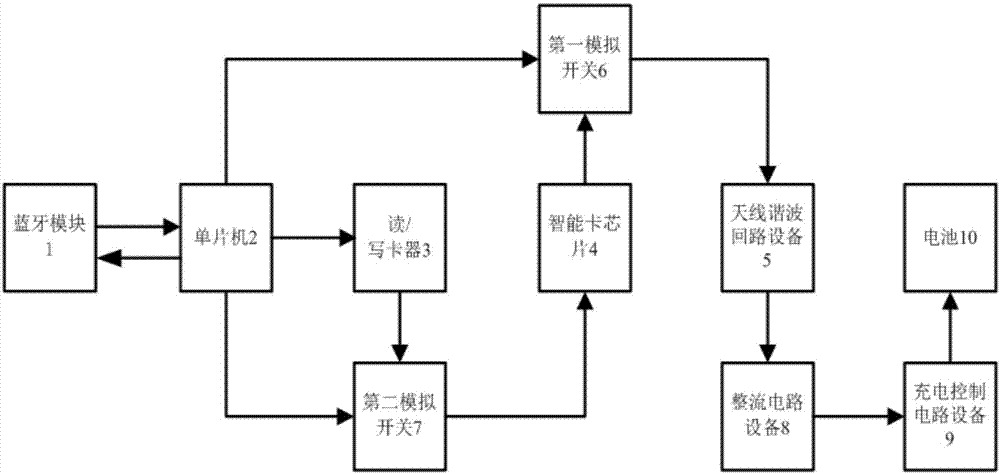

Communication adapter method, device and system

InactiveCN106373229AImprove securityEasy to retrieveIndividual entry/exit registersCard readerMobile device

The invention discloses a communication adapter method, a communication adapter device and a communication adapter system. The method comprises the following steps: receiving card information transmitted by mobile equipment; simulating entrance guard card information according to the card information; transmitting the simulated entrance guard card information to a card reader for reading the card. According to the invention, entrance guard card reading and unlocking can be realized on the basis of not changing the existing entrance guard card reading structure, and great convenience is brought to application of a user.

Owner:FREEVISION TECH CO LTD

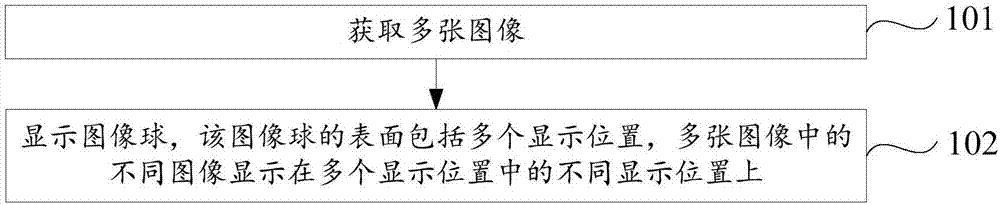

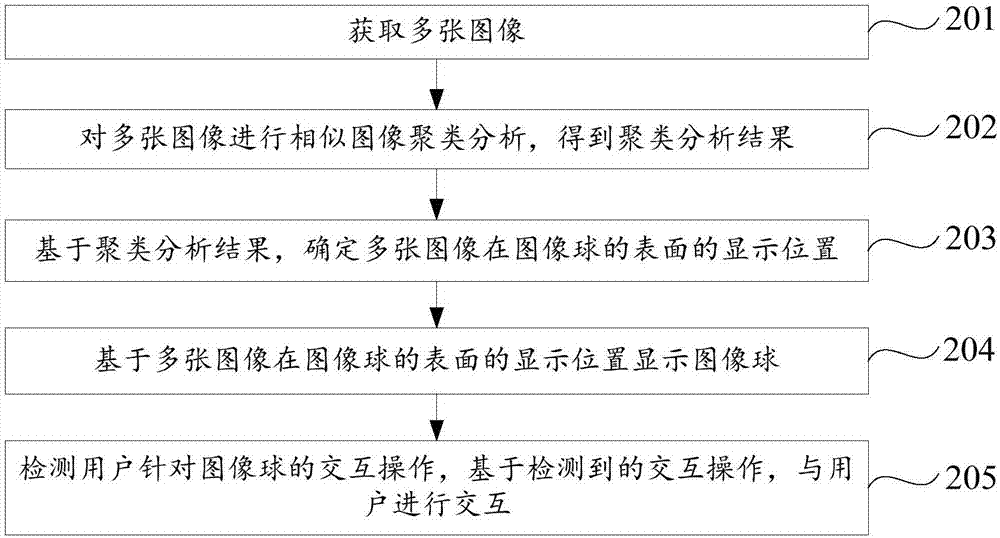

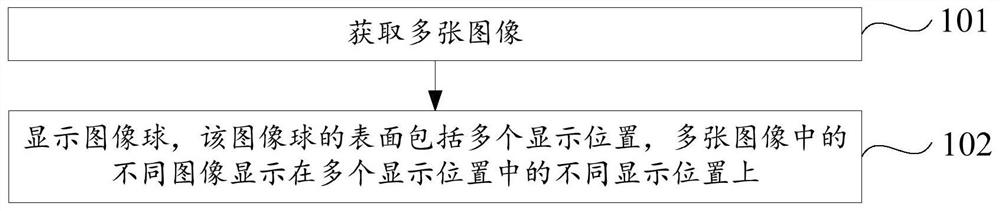

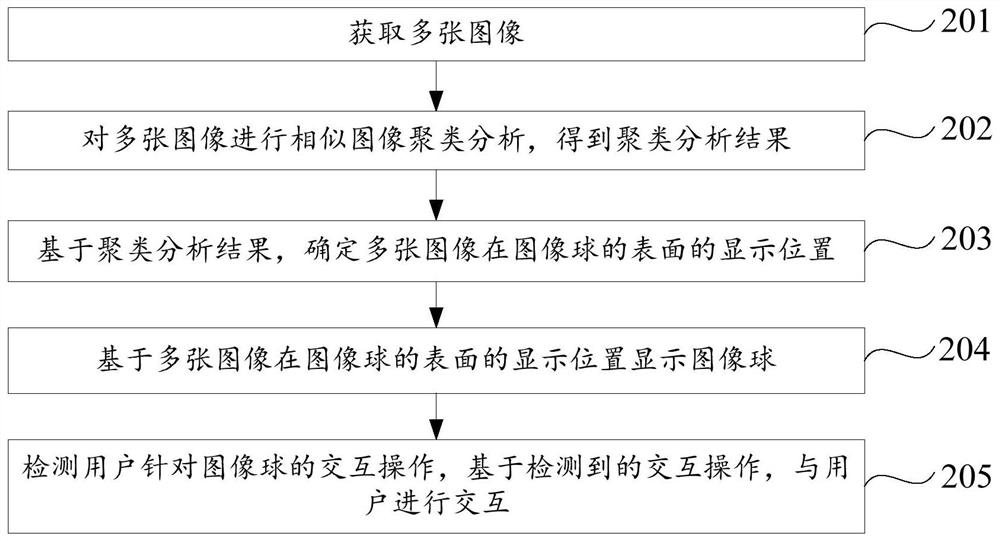

Image display method, image display devices and computer-readable storage medium

ActiveCN108009273AEasy to browseBrowse implementationStill image data browsing/visualisationSpecial data processing applicationsInformation processingDisplay device

The disclosure relates to an image display method, image display devices and a computer-readable storage medium, and relates to the field of information processing technology. The method includes: acquiring a plurality of images, wherein a surface of an image ball includes a plurality of display positions; and displaying different images in the plurality of images on different display positions inthe plurality of display positions. The different images in the plurality of images can be centrally displayed on the plurality of display positions included by the image ball, thus the plurality ofimages can be conveniently and integrally browsed through the image ball when a user browses the images, more-intuitive visual experience is brought for the user, and the user is enabled to more quickly find an image, in which the user is interested, in the plurality of images; and browsing on the plurality of images can be realized simply through image-ball operations when the user browses the images. Compared with displaying the plurality of images in a tiled manner in a plurality of display pages in the related art, the method enables the user to browse the plurality of images through up-down scrolling of a display page, and shortens operation distances.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

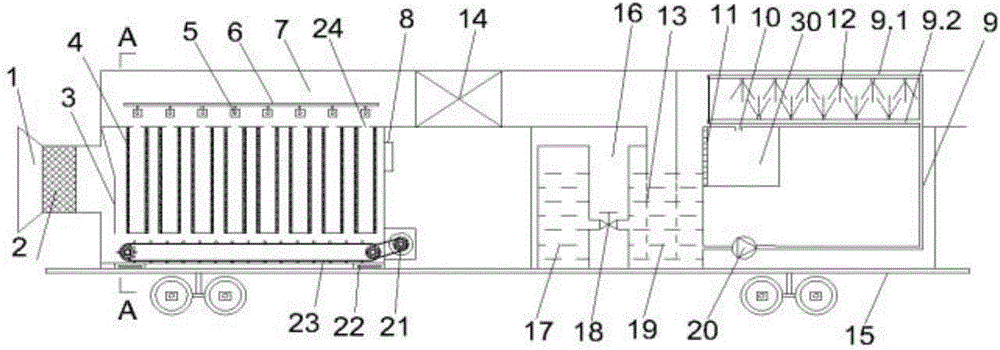

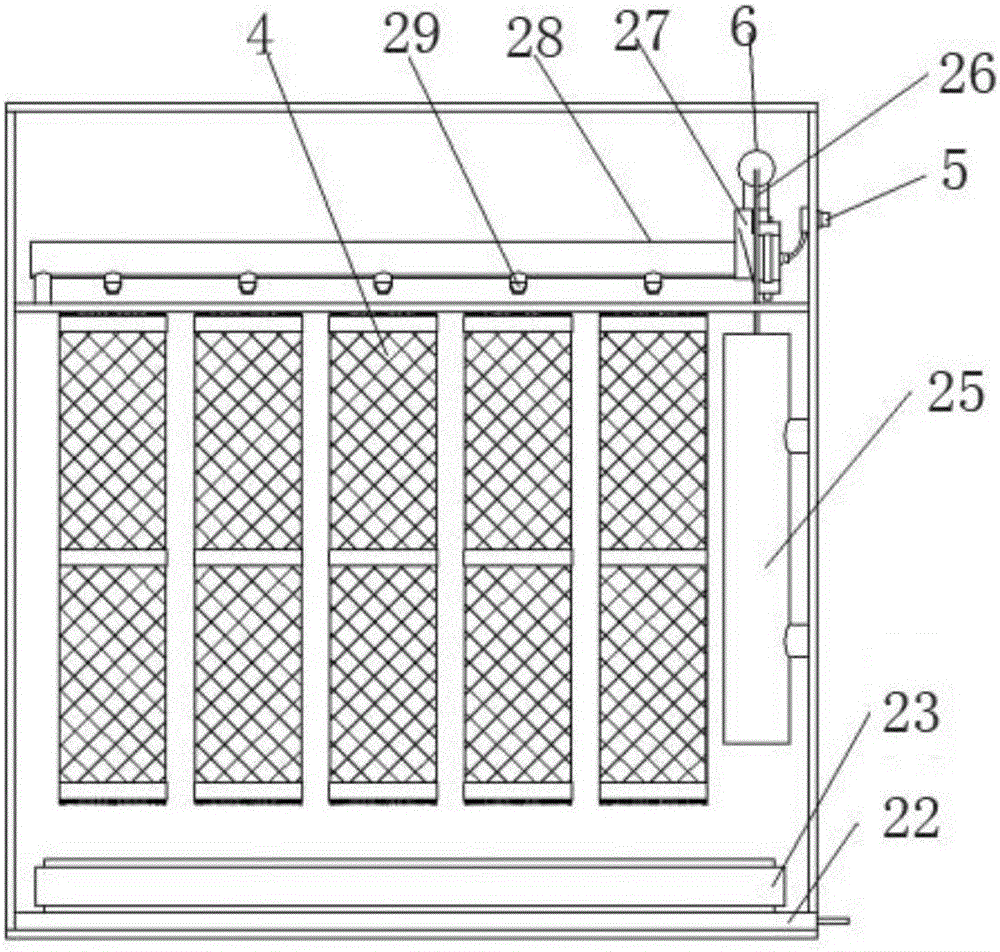

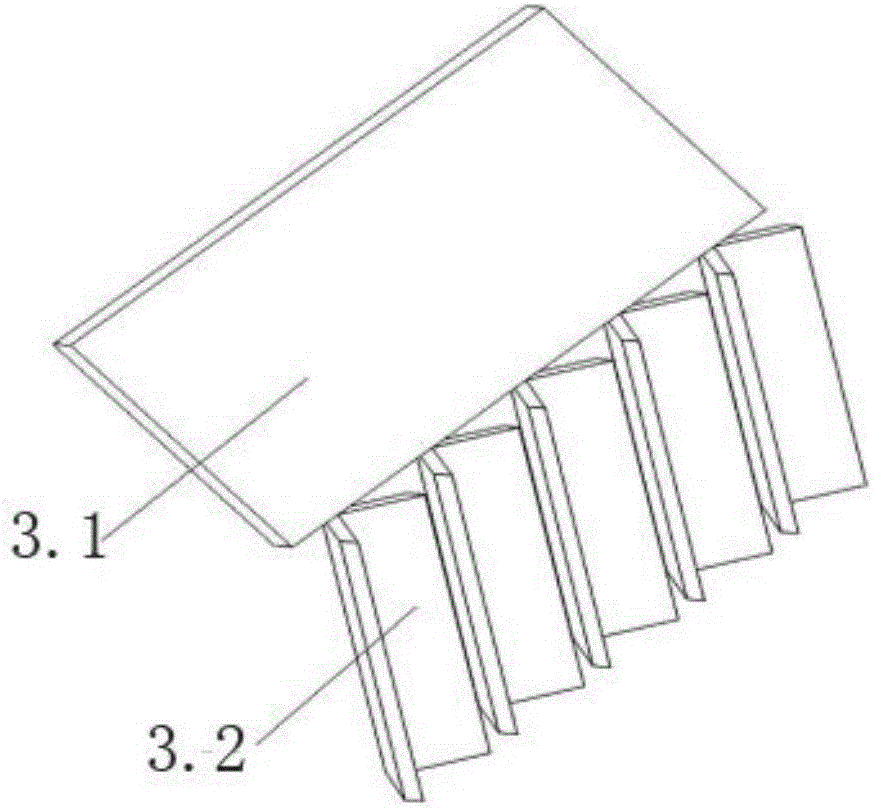

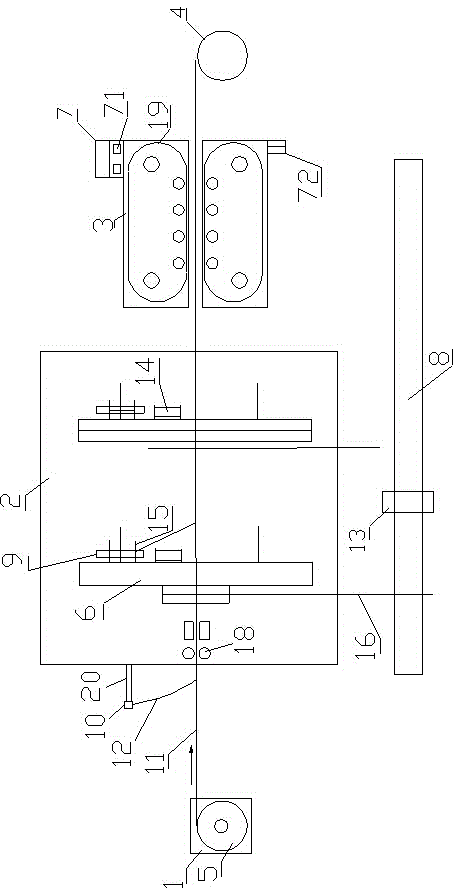

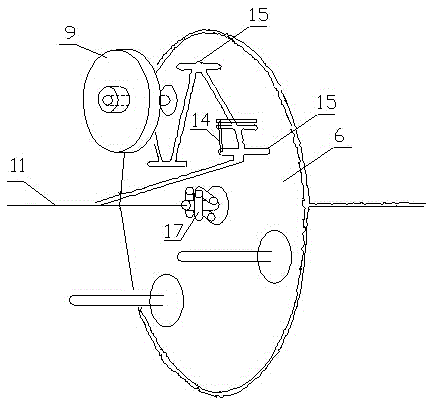

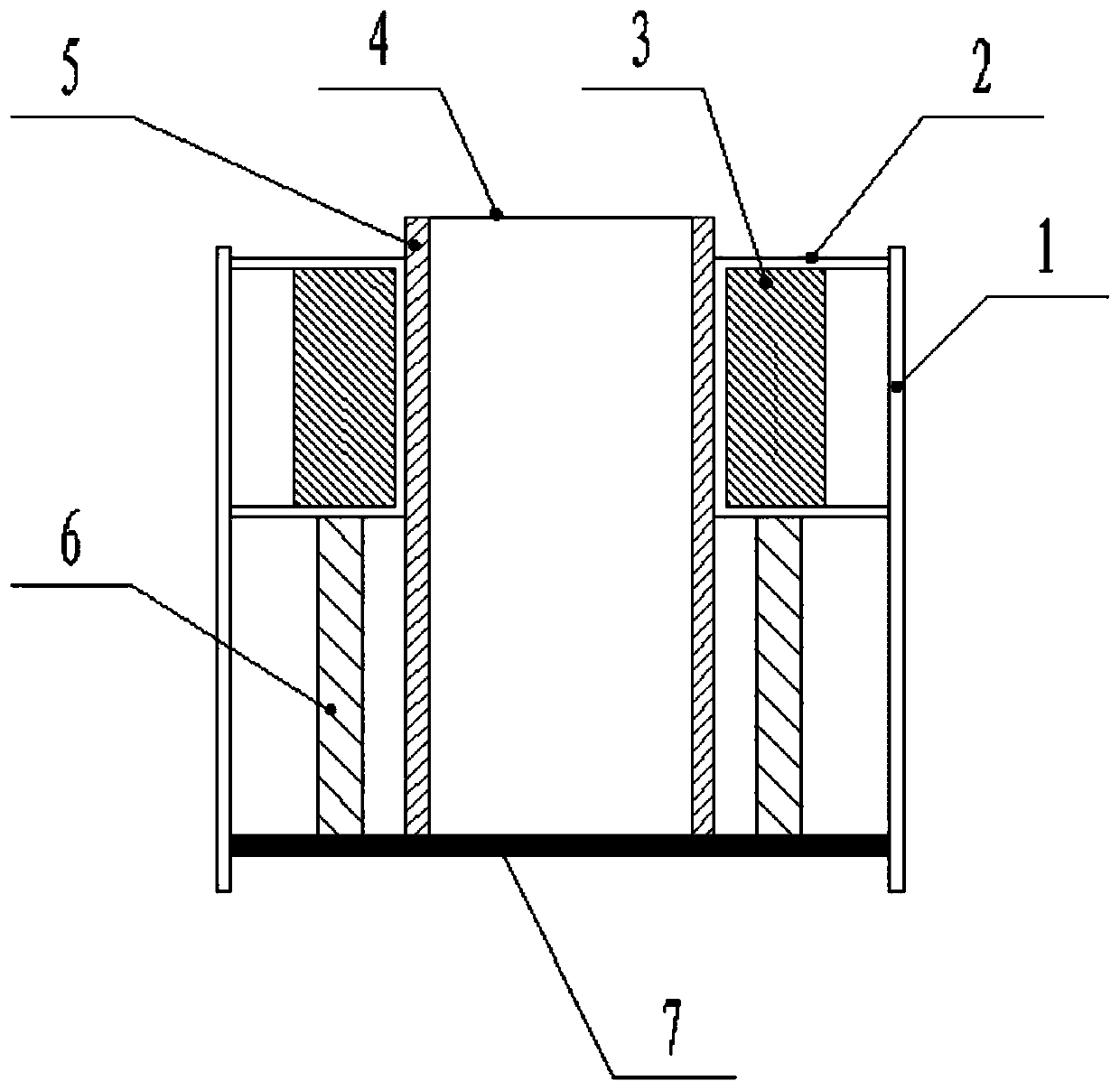

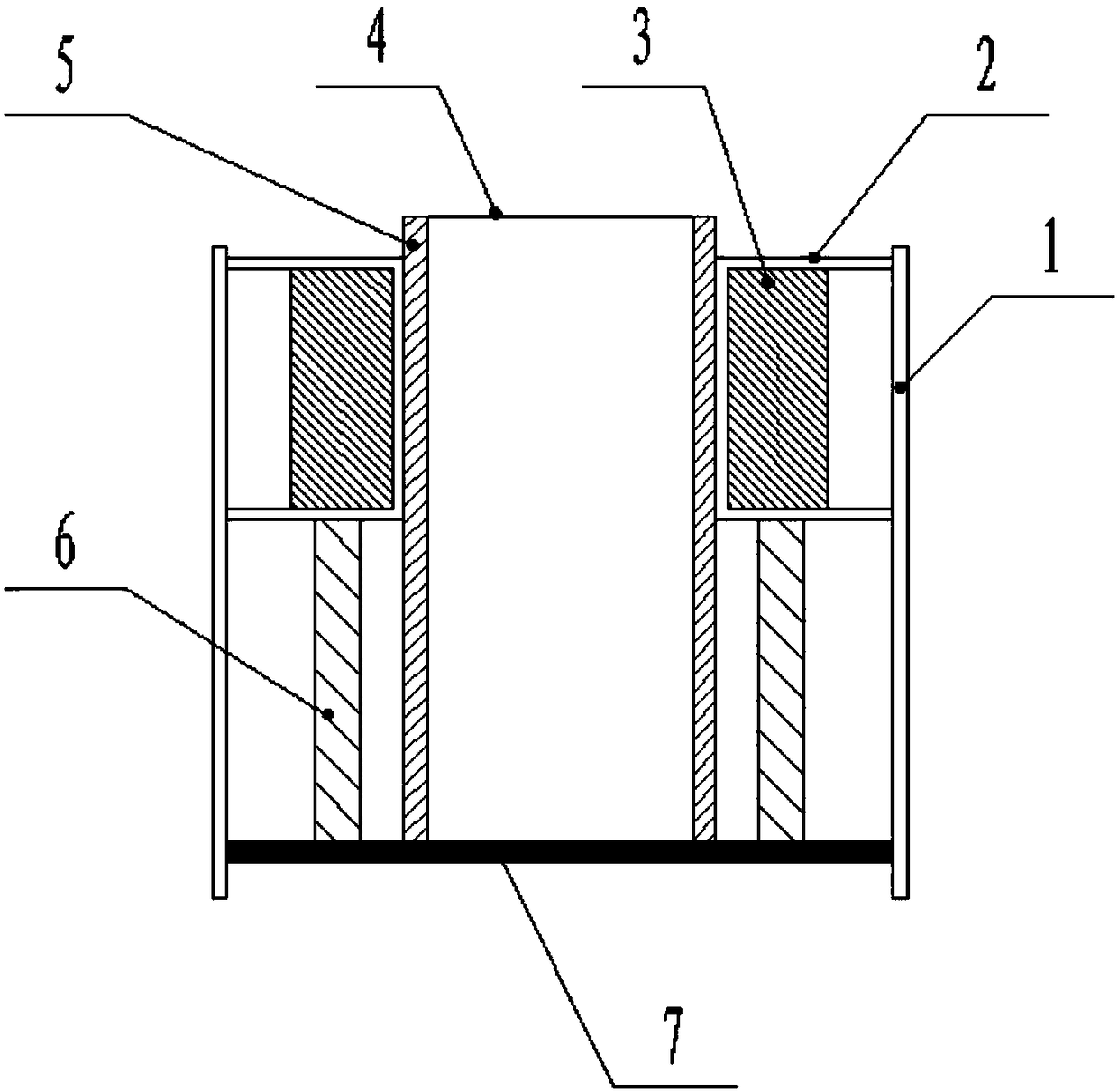

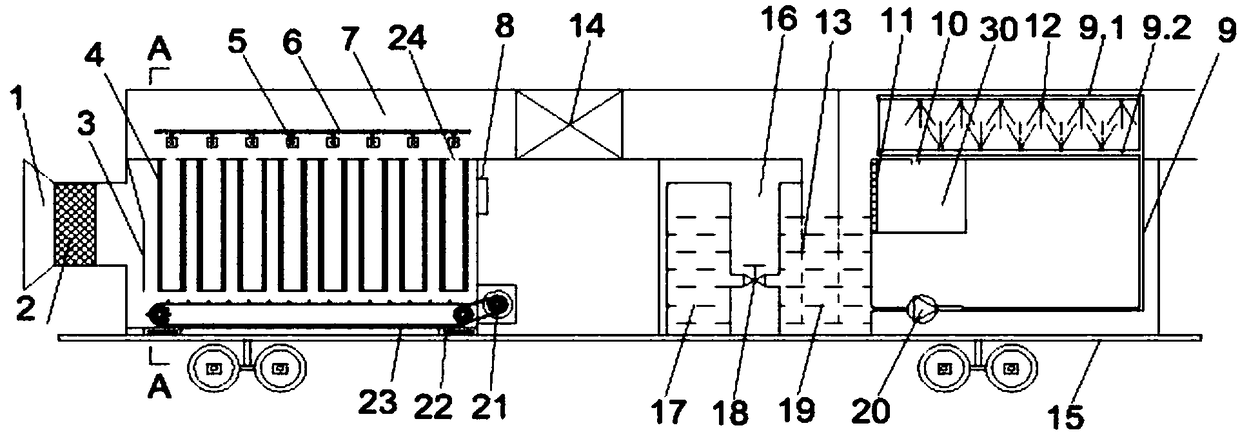

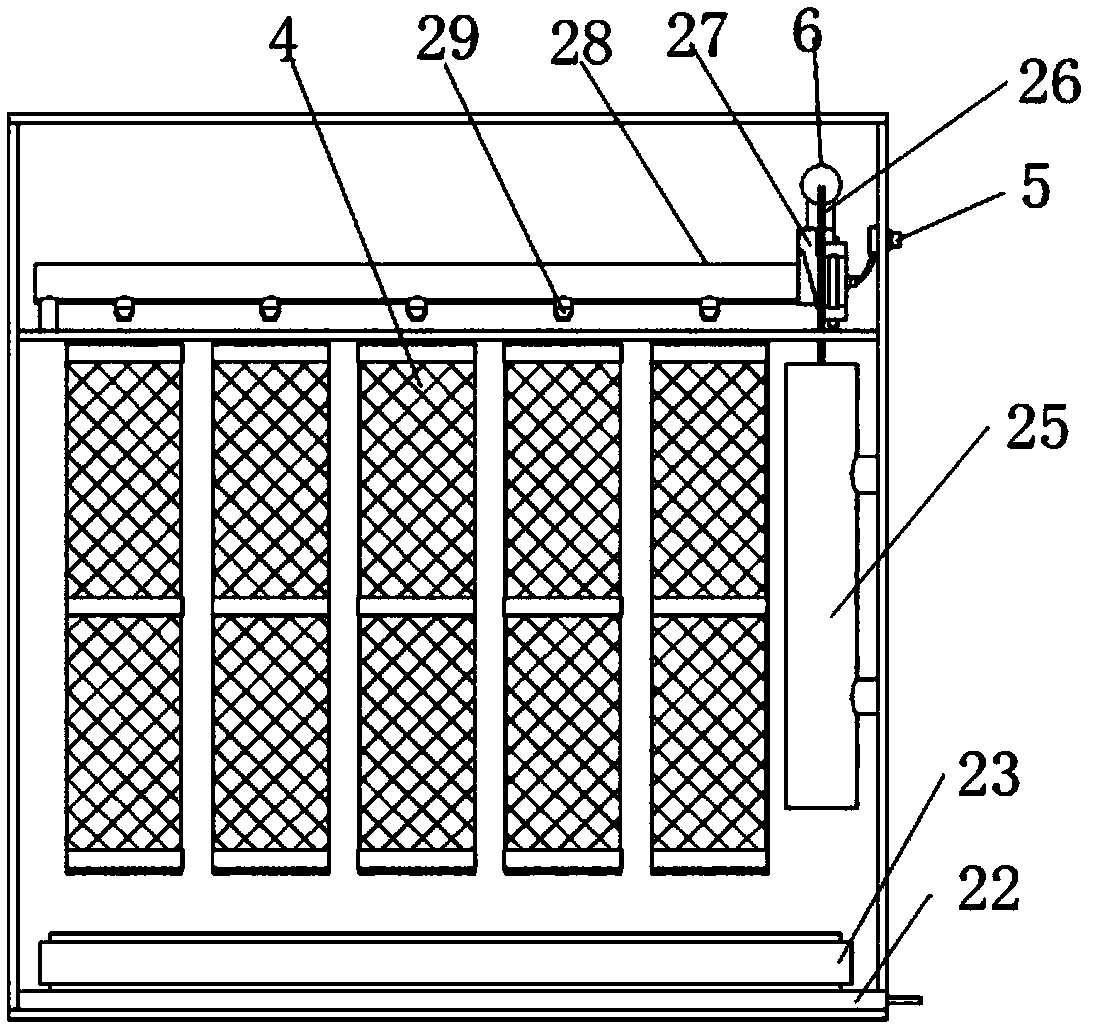

Dedusting smoke-removing assistant ventilating device for tunnel construction

ActiveCN106761890ANo pollutionShorten the operating distanceDust removalDispersed particle separationFiltrationEngineering

The invention discloses a dedusting smoke-removing assistant ventilating device for tunnel construction. One side of the inlet of a dedusting box (7) is connected with a dust hood (1), and the other side of the dedusting box is connected with the inlet of a drawing-type ventilator (14). A smoke-removing box (16) is installed at the tail part of the device, and connected with the outlet of the drawing-type ventilator. The foul air generated in the tunneling process is pumped into the dedusting box through the dust hood so as to execute the dust filtration, and the air is pumped into the smoke-removing box so as to execute the fume treatment, finally the purified air is discharged from the outlet of the drawing-type ventilator. The smoke-removing box is capable of conveying sodium hydroxide solution in a liquid inlet box to a spray pipeline (9) through a water pump (20) and spraying by an atomizer (12), sprayed alkaline solution mist executes the neutral reaction with the acid gas in the fume, so that the purification treatment of the fume is realized. The dedusting smoke-removing assistant ventilating device for the tunnel construction is capable of integrating the dust filtration, the fume treatment and the assistant ventilation, realizing the efficient purification of the foul air, and improving the ventilation condition in the tunnel.

Owner:CHINA UNIV OF MINING & TECH

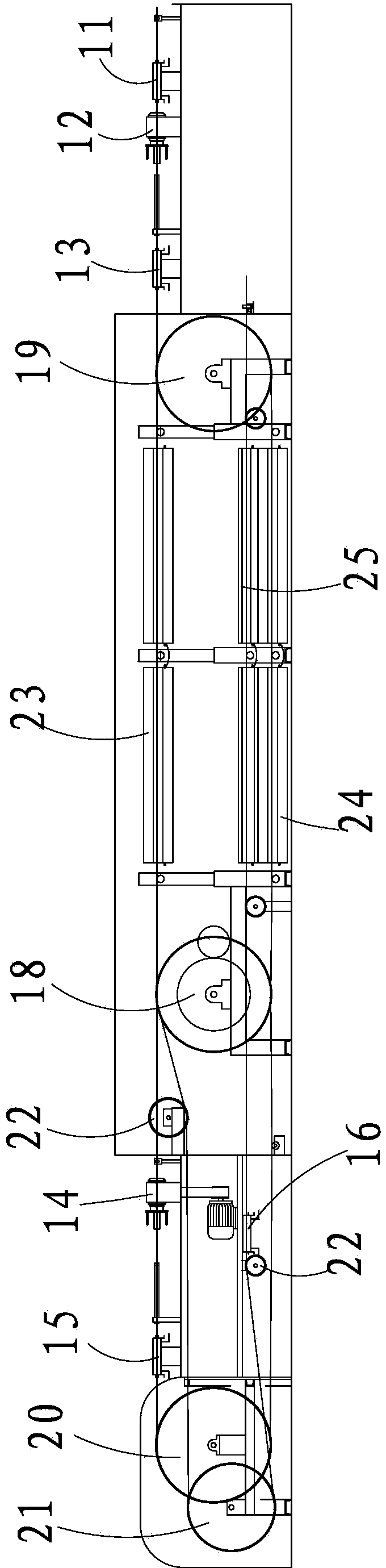

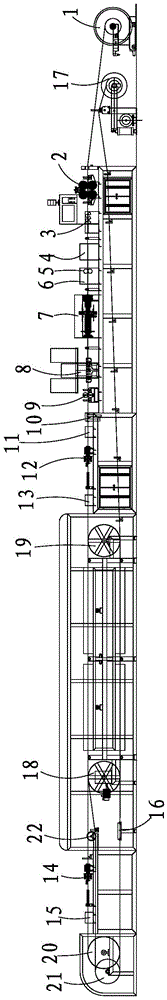

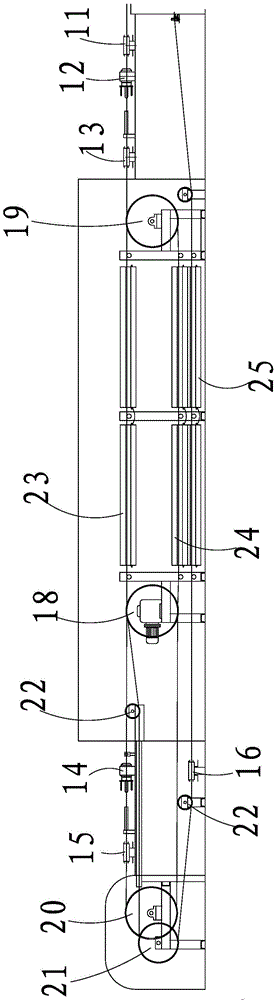

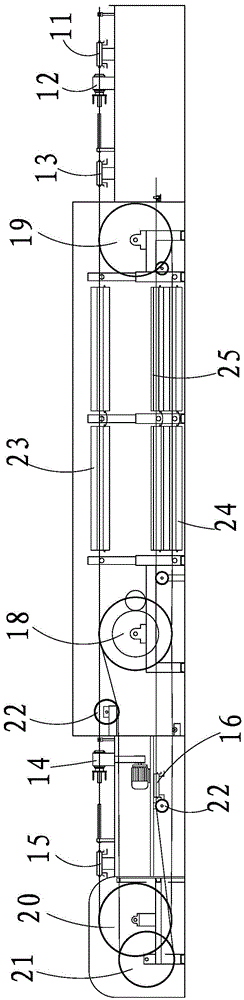

Horizontal paper lapping machine

InactiveCN104157450AWon't fall off automaticallyShorten the occupied equipment distanceCoils manufacturePulp and paper industryTraction belt

The invention relates to a horizontal paper lapping machine which comprises a pay-off unit, a straightening combination wheel, a double-end lapper, a traction apparatus, a metering unit and a take-up unit. The pay-off unit comprises a pay-off rack, three paper unwinding plates are arranged on each lapping head of the double-end lapper, a wire is paid off from the pay-off rack and passes through inner shaft holes of the lapping heads and traction belts to reach the take-up unit, the double-end lapper is arranged longitudinally integrally, and the paper unwinding plates are changed to be in longitudinal arrangement from transverse arrangement. The horizontal paper lapping machine has the advantages that air resistance and noise are low, the horizontal paper lapping machine is short relatively, has a function of automatically stopping when encountering burrs and can brake automatically during stopping, product quality s well controlled, and product yield is improved.

Owner:WUXI FEILONG ELECTROMAGNETIC WIRE

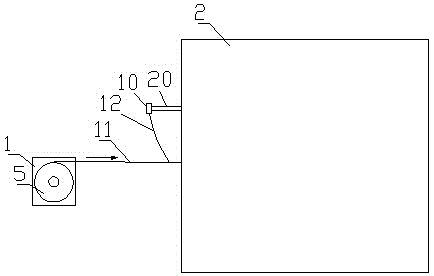

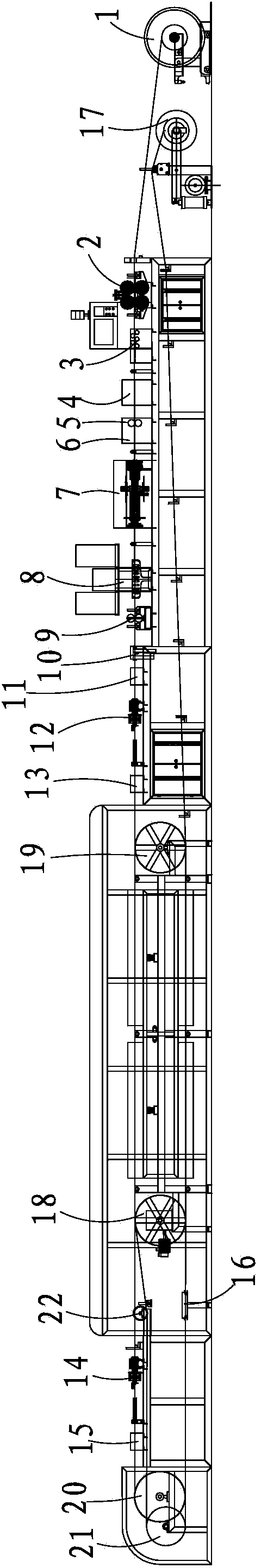

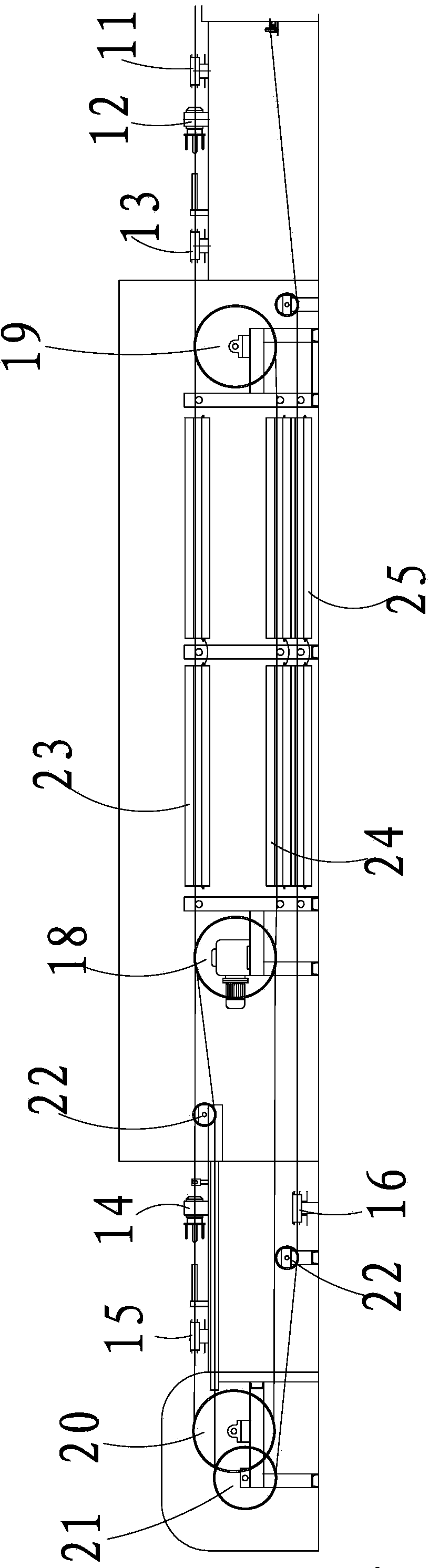

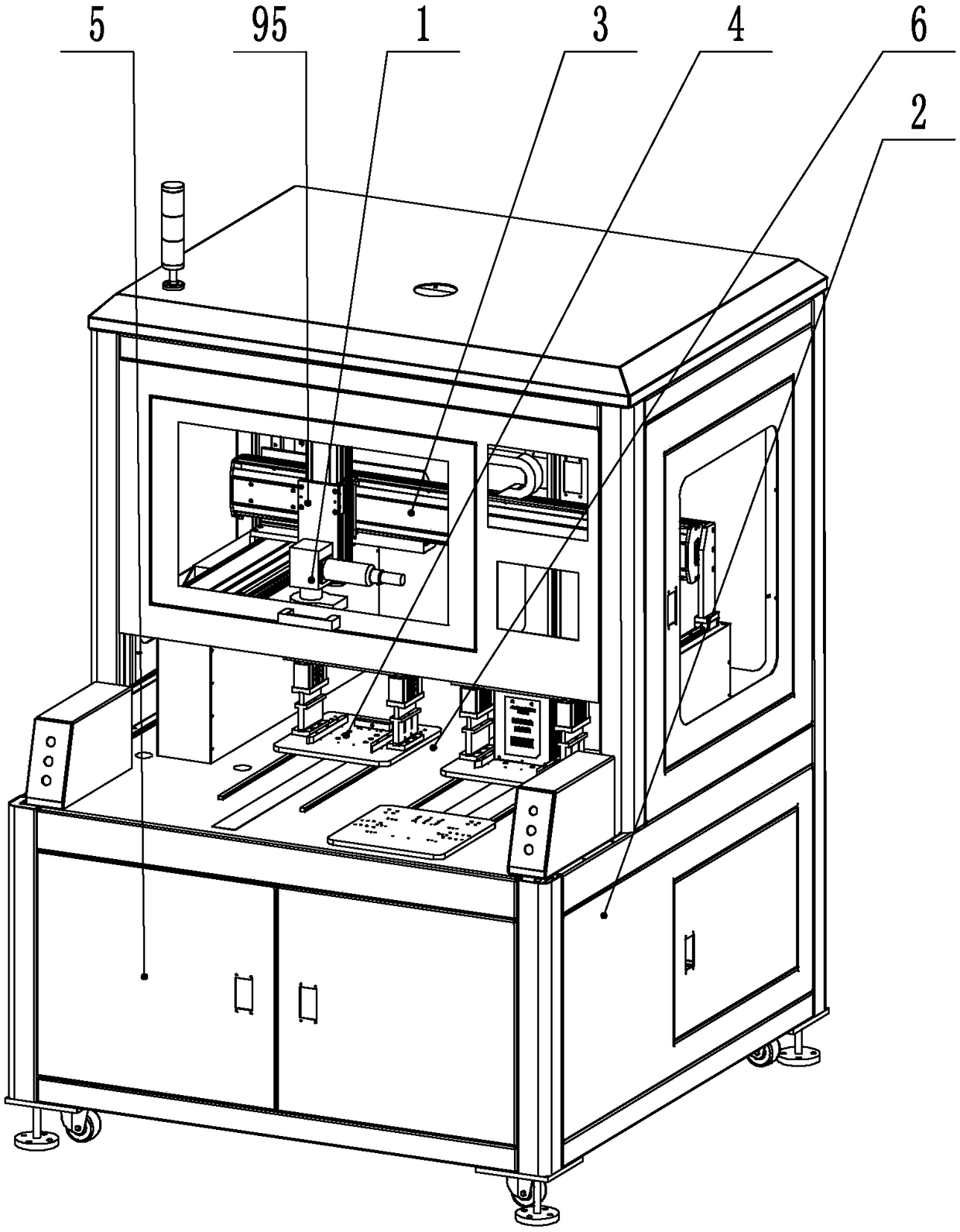

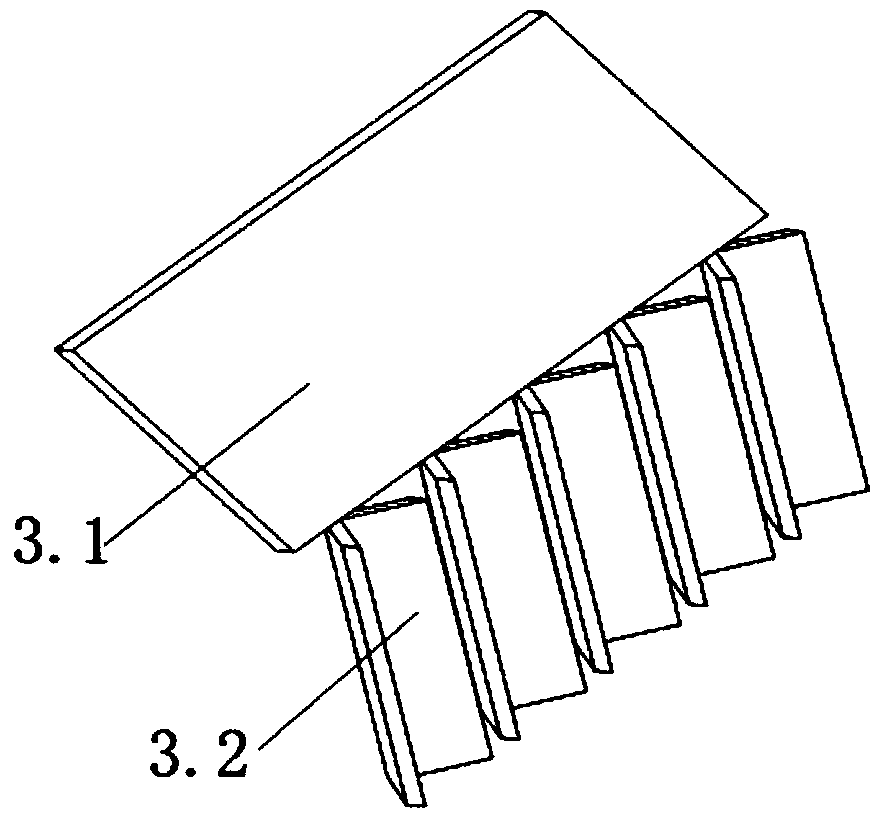

Equipment for manufacturing self-adhesive glass silk covered composite film lapping electromagnetic wires

ActiveCN103489507ACompact structureShorten the operating distanceInsulated cablesCable/conductor manufactureComposite filmQuality control

The invention relates to equipment for manufacturing self-adhesive glass silk covered composite film lapping electromagnetic wires. The equipment comprises a pay-off rack, a meter counting device, a straightening device, a polishing device, a cleaning device, an air drying device, a film lapping device, an induction heating device, a rolling device, a water cooling blow-drying device, a traction device and a take-up machine. The equipment further comprises a first paint cylinder, a first glass silk covered head, a second paint cylinder, a second glass silk covered head, a third paint cylinder, a self-adhesive coating paint cylinder and a drying oven assembly. The pay-off rack and the take-up machine are located on the same side. The equipment is compact in structure. With the cooperation with the intensive requirement, operation quality control points are relatively centralized, the operation distance is beneficially shortened, and production efficiency is improved. The self-adhesive glass silk covered composite film lapping electromagnetic wires can be formed on the production equipment at one time, and therefore production efficiency is improved.

Owner:SUZHOU GUANLONG MAGNET WIRE

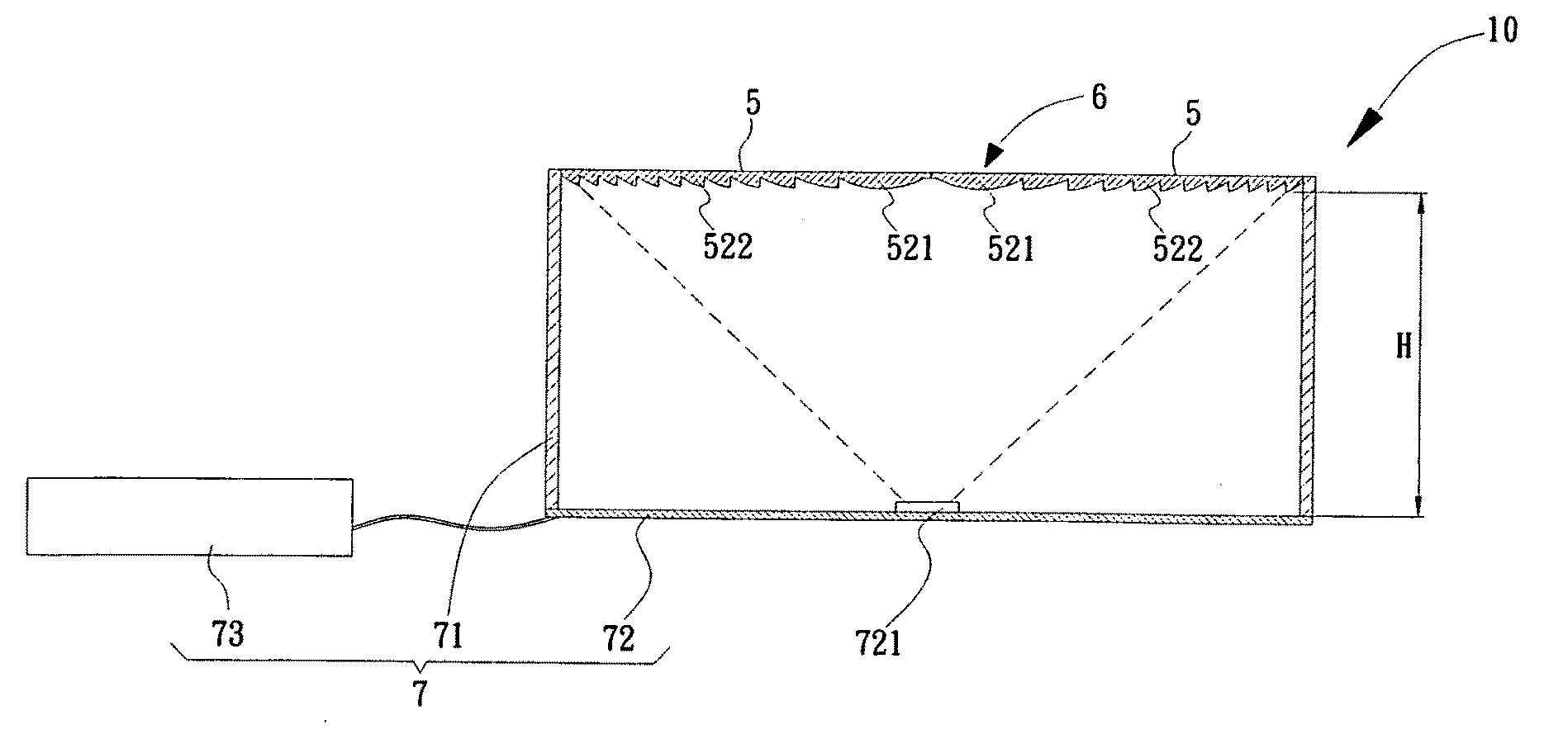

Optical structure and solar cell using the same

InactiveUS20100101640A1Lower operating temperatureImprove photoelectric conversion efficiencySolar heating energyBeam/ray focussing/reflecting arrangementsAnnular arrayConcentrator

An optical structure is characterized by improving a primary lens of a photovoltaic concentrator system. The optical structure is accomplished by properly dividing the primary lens, determining required optical operational regions, and arranging the optical operational regions basing on an identical location into an annular array, thereby forming the complete optical structure. The optical structure facilitates enhancing uniformity of light distribution throughout the optical operational regions, improving photoelectric conversion efficiency of a solar cell having the optical structure, and reducing operational distance between the primary lens and the solar cell.

Owner:HOKUANG OPTICS

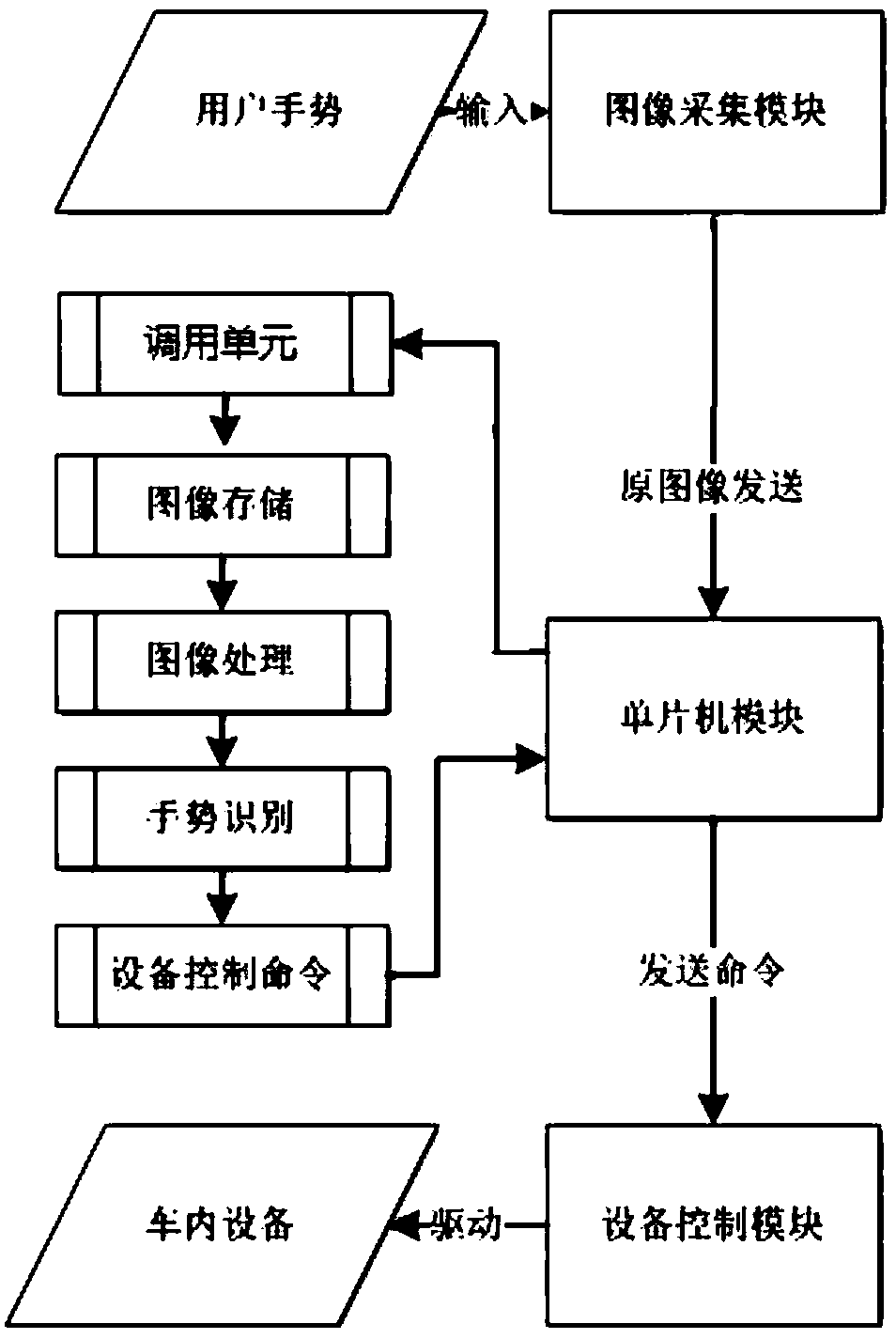

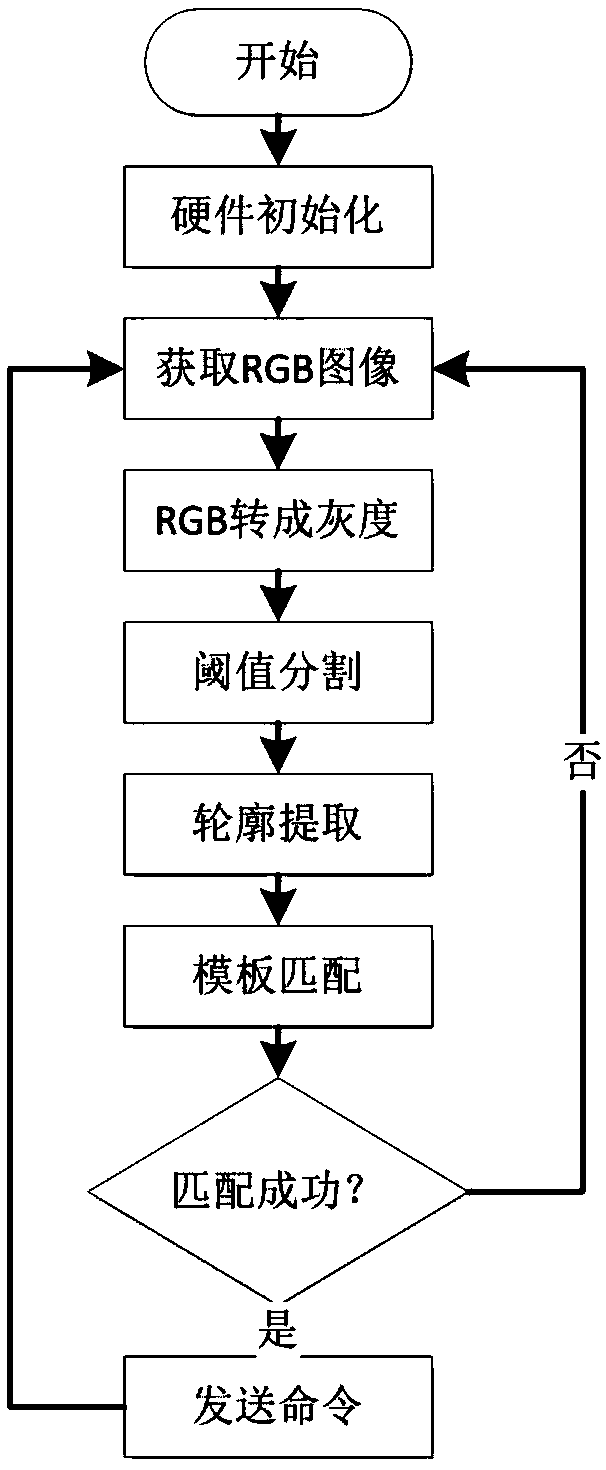

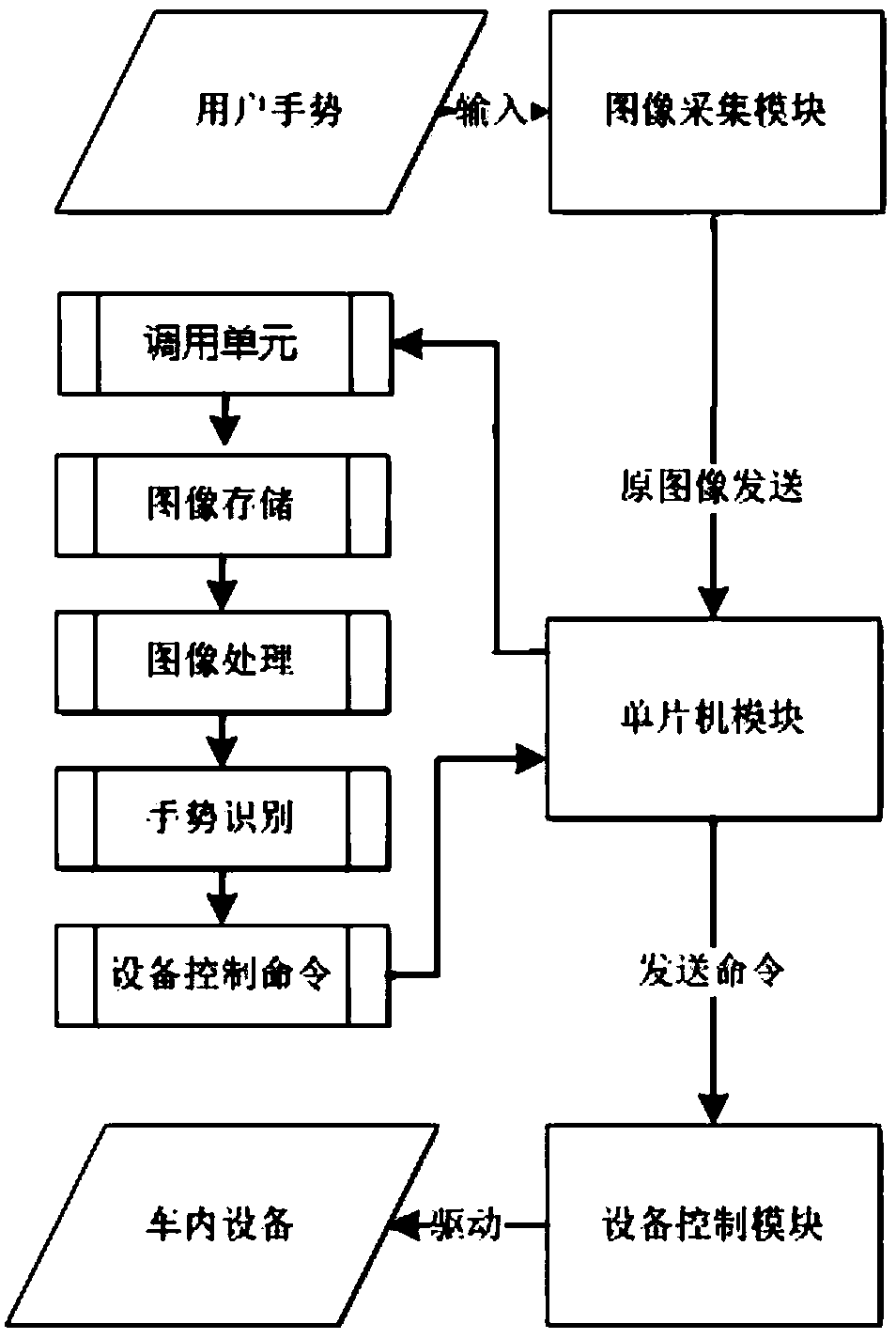

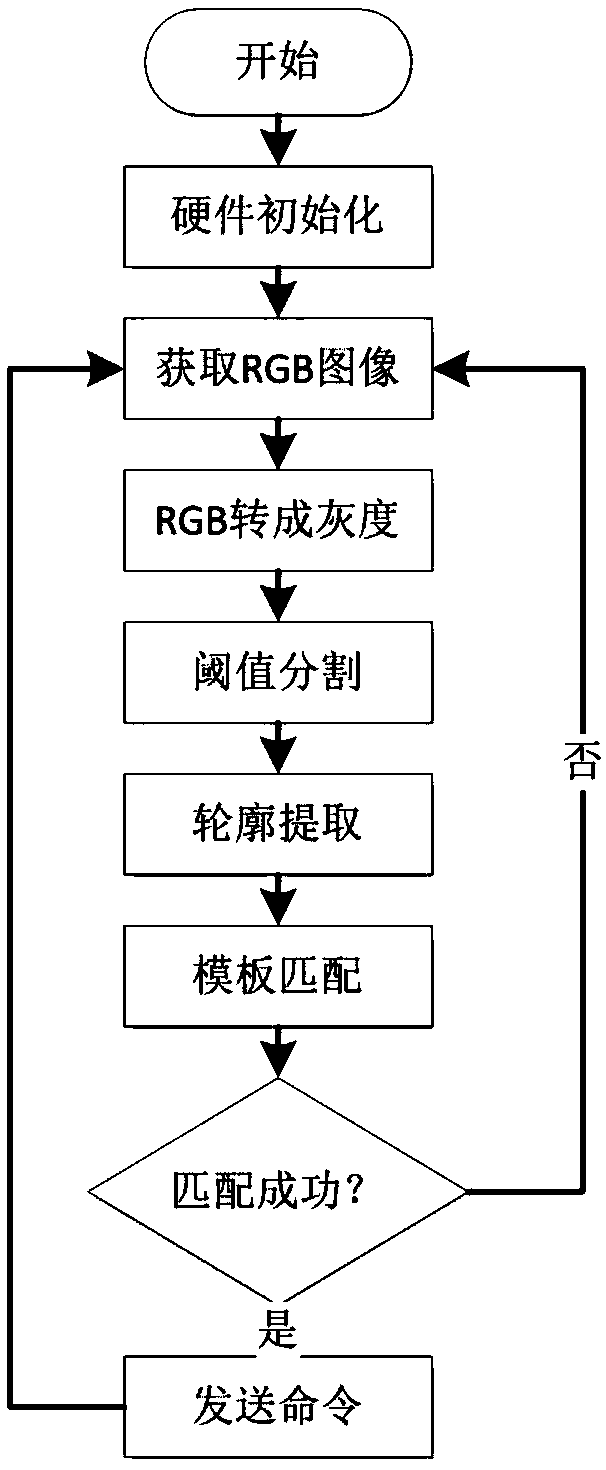

Automobile gesture control device based on single-chip microcomputer and control method thereof

ActiveCN108732969ANew control methodLong operating distanceProgramme controlInput/output for user-computer interactionIn vehicleControl equipment

The invention provides an automobile gesture control device based on a single-chip microcomputer and a control method thereof. The single-chip microcomputer serves as a main control unit, an infraredlight supplementing lamp is used for projecting infrared light, and a monocular camera with an infrared filtering piece is used for capturing user gesture images which are transmitted to the single-chip microcomputer module. The single-chip microcomputer module is used for analyzing and processing the user gesture images, and controls a device control module to operate an automobile device, so that the gesture control of the automobile device is realized. The invention is advantageous in that the single-chip microcomputer module has excellent expansibility and can be connected with different device driving modules according to actual demands, different automobile devices can be driven, and the purpose of controlling multiple in-vehicle devices by using gestures can be achieved; meanwhile,the infrared light supplementing device is adopted to be matched with the monocular camera, so that the infrared light supplementing device can be used under the condition of low illumination; the automobile gesture control device is more suitable for being applied to a vehicle, and can still be normally used when no sunlight is used for night driving.

Owner:哈尔滨拓博科技有限公司

Communication transfer device and system

PendingCN107273957AEasy to go outLow costCo-operative working arrangementsIndividual entry/exit registersInformation transmissionTransfer system

The invention provides a communication transfer device. A card information obtaining and processing module is used for obtaining original card information of a card swiping system and generating data, which can be recognized by a card reader of the card swiping system, by utilizing the card information, and meanwhile, the module transmits the original card information to an information transmission module; and the information transmission module is used for sending the original card information of the card swiping system to a user terminal and sending control information of the user terminal to the card information obtaining and processing module. The invention also provides a communication transfer system, which comprises a control system and the communication transfer device. The control system is arranged at the user terminal and is in communication connection with a bluetooth device of the communication transfer device through a bluetooth device of the user terminal. The user terminal adopts a mobile terminal. The device and system realize card reading and swiping through the mobile device on the basis of not changing an existing card-reading structure, thereby greatly facilitating use of users.

Owner:FREEVISION TECH CO LTD

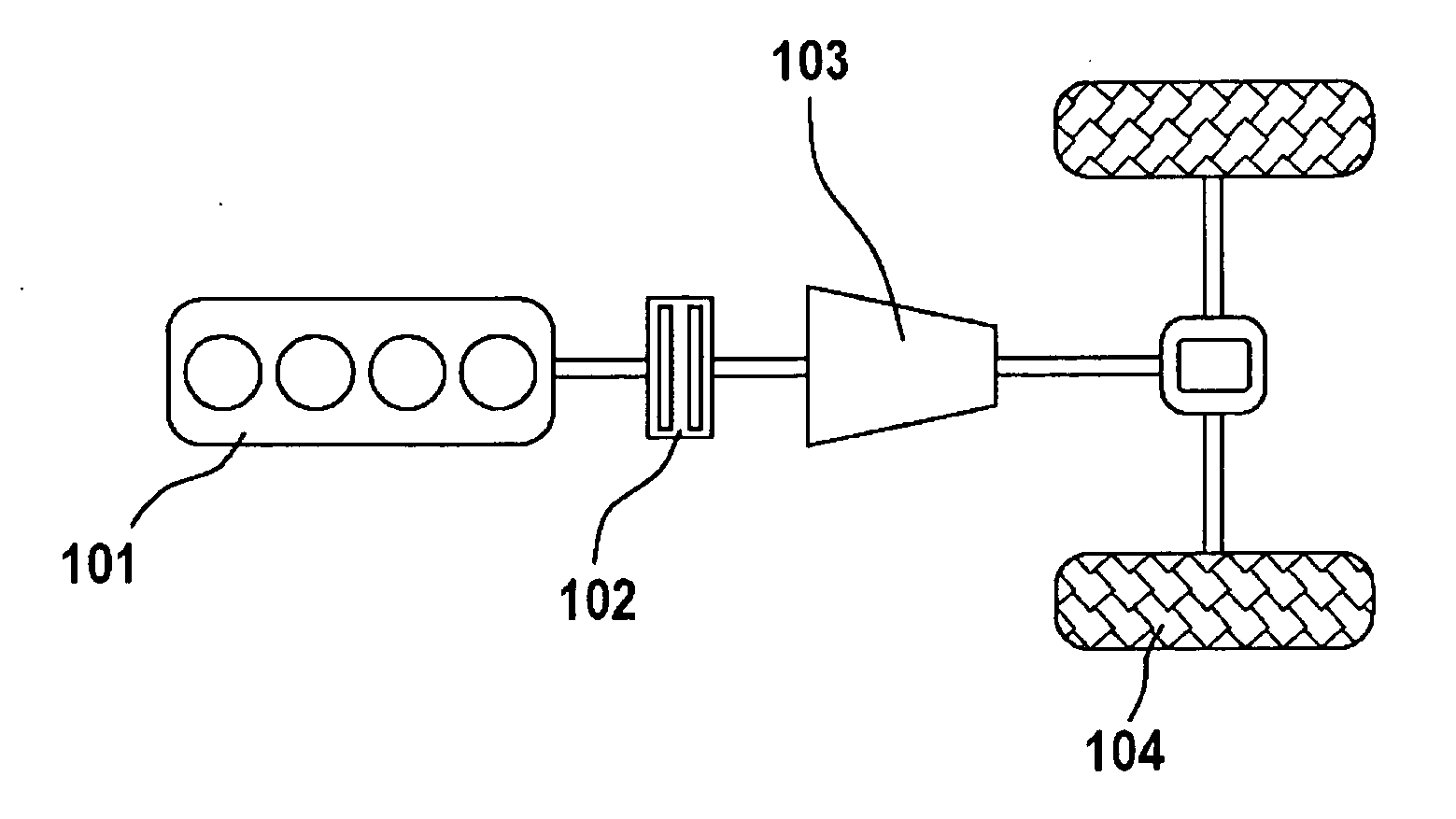

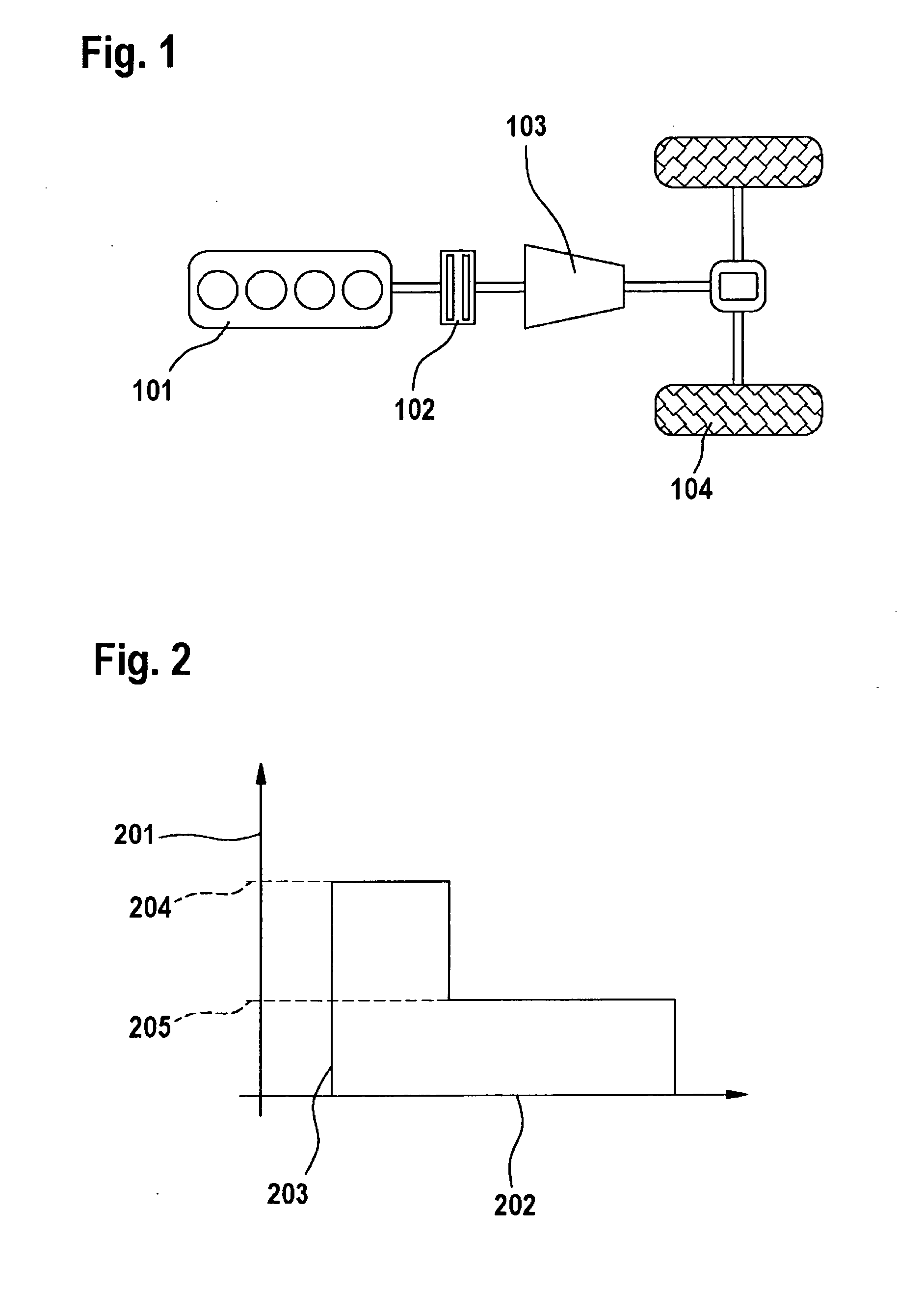

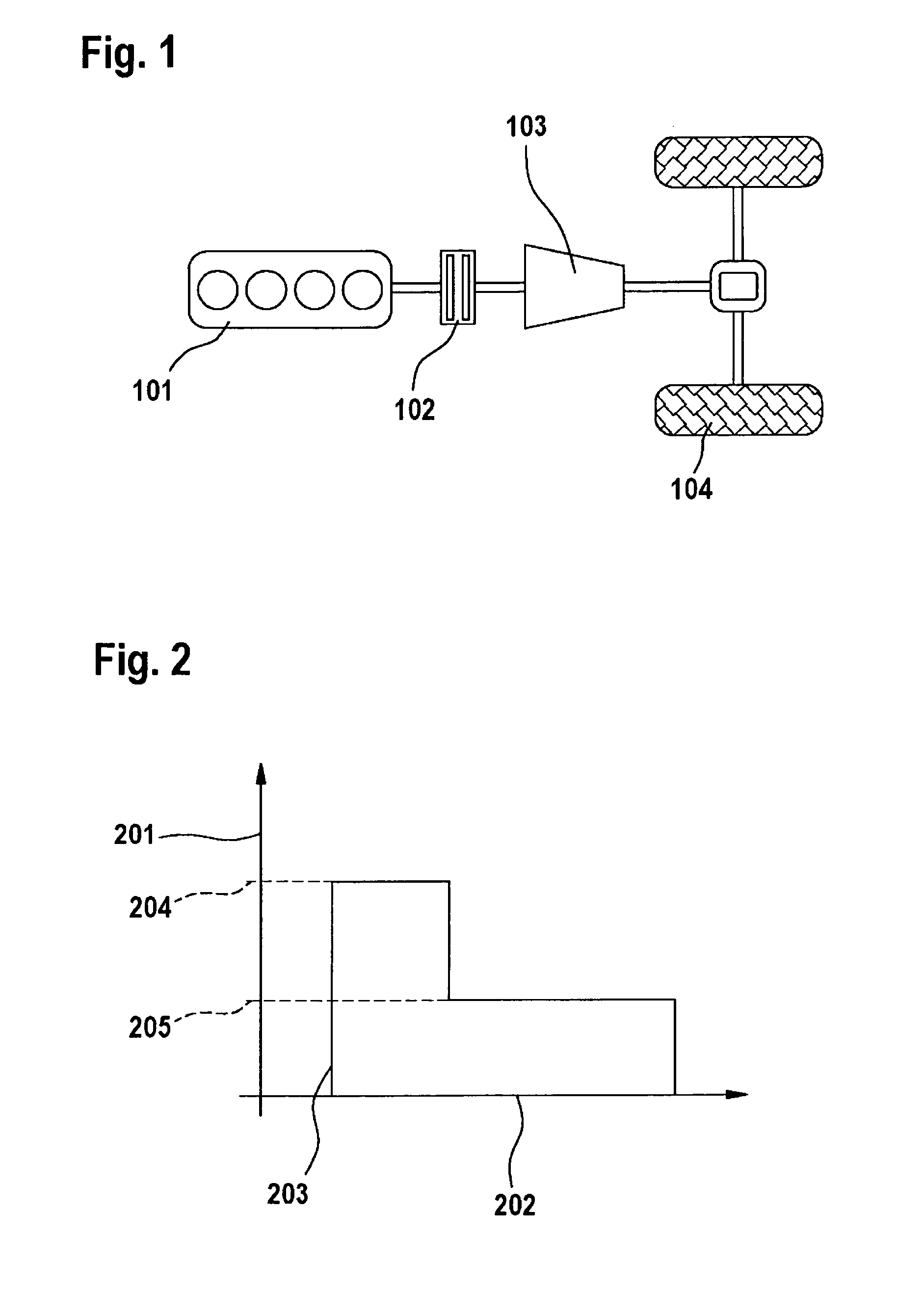

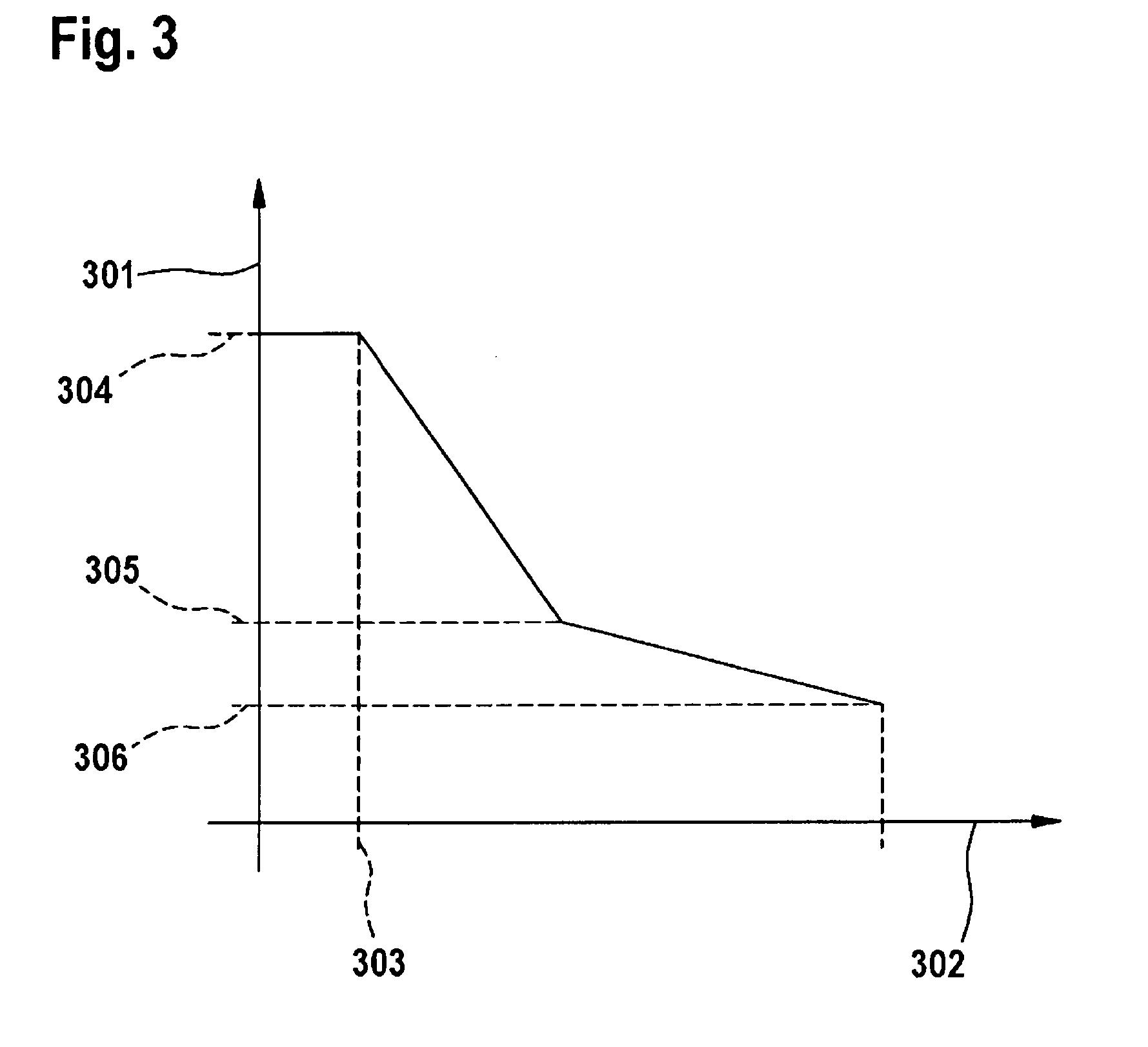

Method and device for engaging a clutch

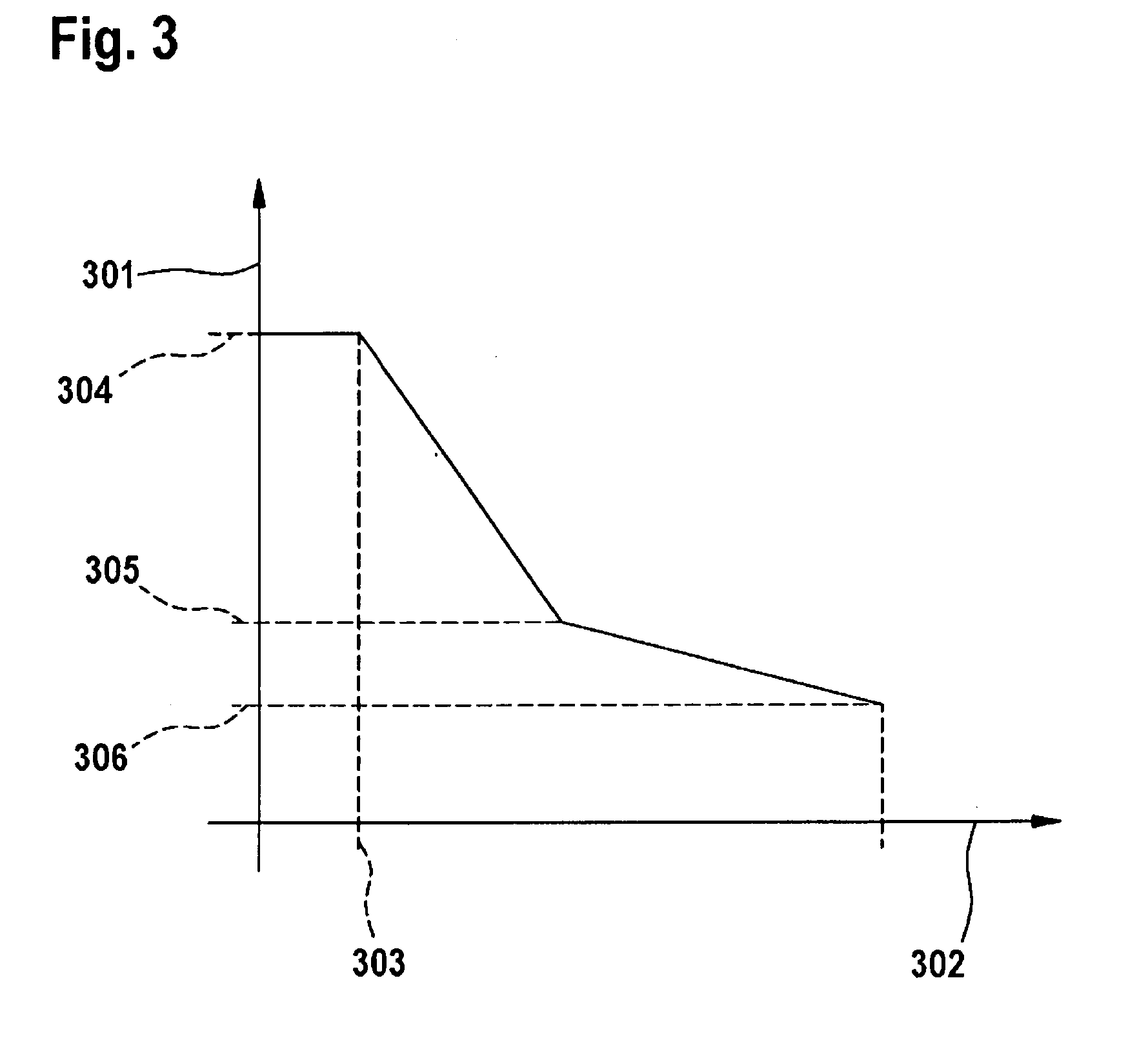

InactiveUS20110093175A1Shortened methodShorten speedClutchesDigital data processing detailsControl theoryClutch

Owner:ROBERT BOSCH GMBH

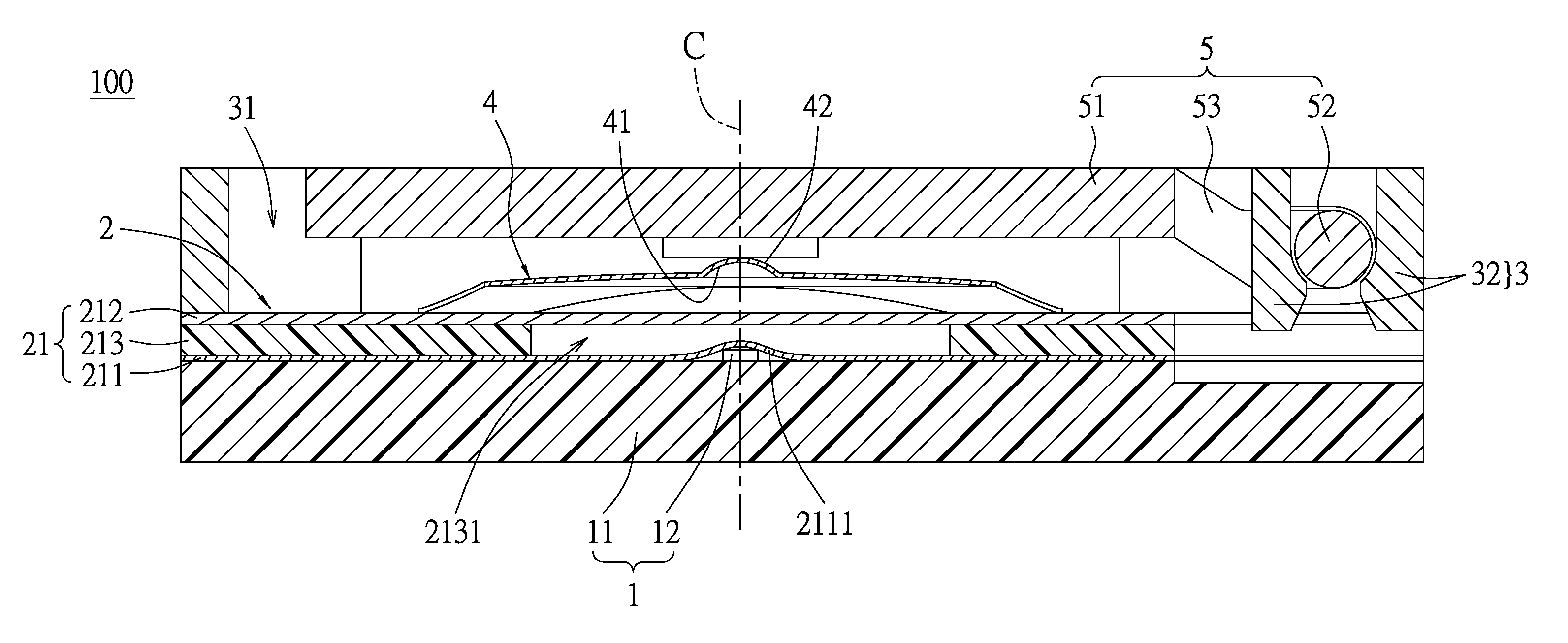

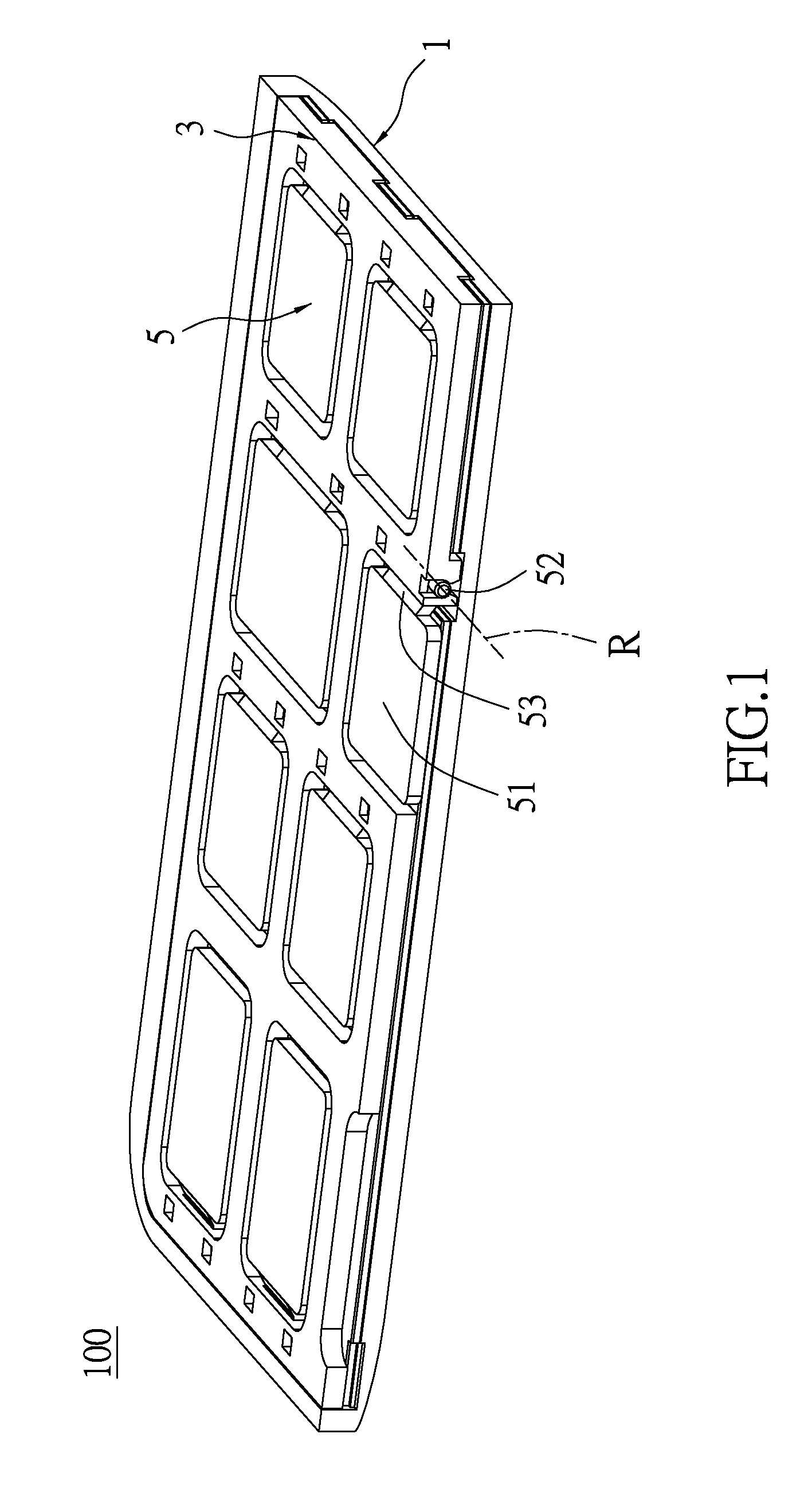

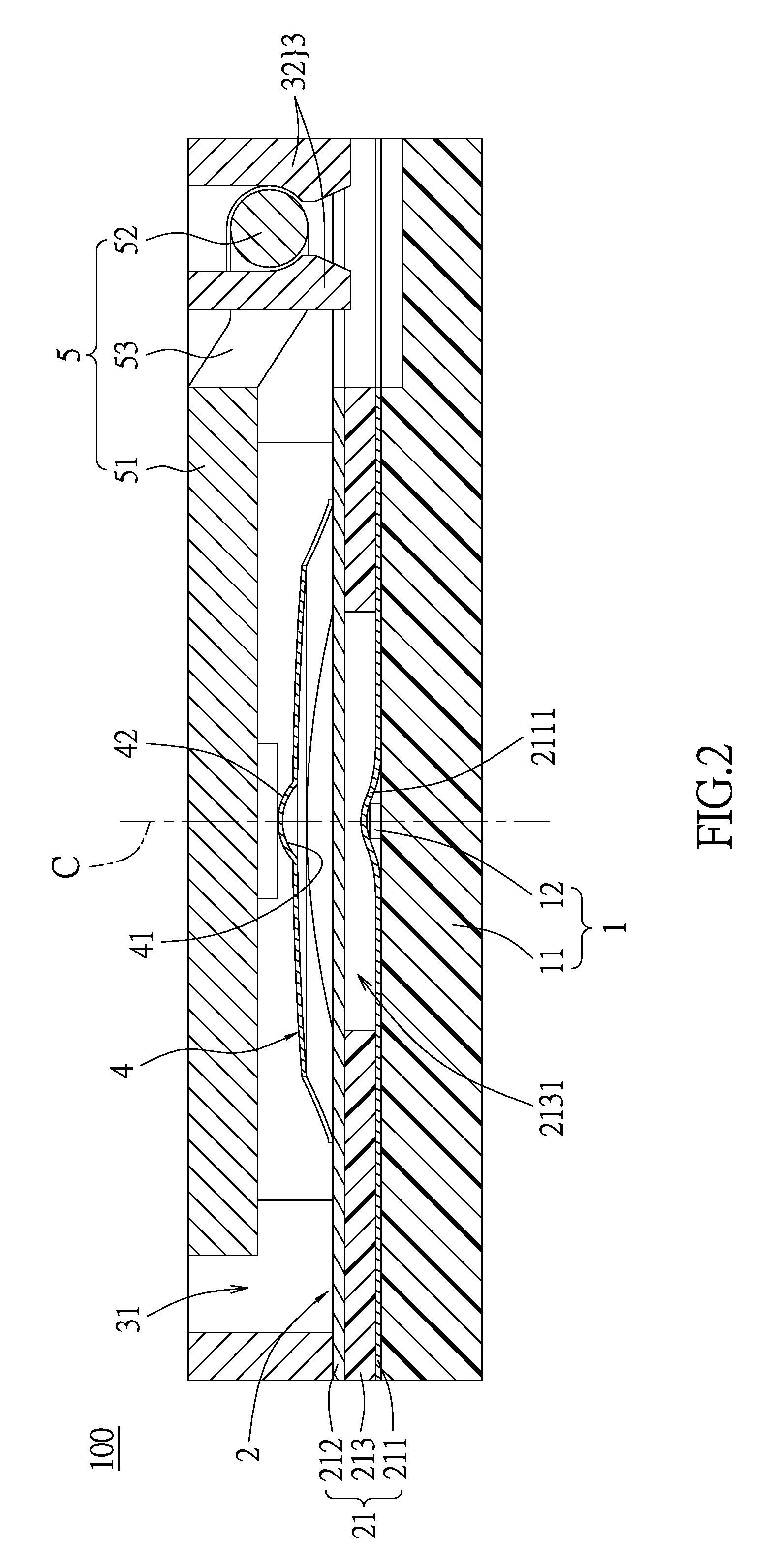

Thin key structure

InactiveUS9105422B2Avoid misalignmentMaintain electrical connectionEmergency actuatorsElectric switchesEngineeringMechanical engineering

A thin key structure includes a supporting module, a circuit module disposed on the supporting module, a frame and a metal dome disposed on the circuit module, a pressable module, and a guiding portion. The supporting module has a supporting plate and a protrusion disposed on the supporting plate. The supporting plate has a plane defined therein, the plane defines a perpendicular central axis, and the protrusion is arranged on the central axis. The circuit module has a protruding segment formed by the protrusion. The metal dome is arranged in the frame, and has a contact portion arranged on the central axis. The guiding portion arranged on the central axis and is disposed between the contact portion and the pressable module. The metal dome is pressed by the guiding portion to move the contact portion along the central axis and selectively abuts the circuit module.

Owner:ICHIA TECH

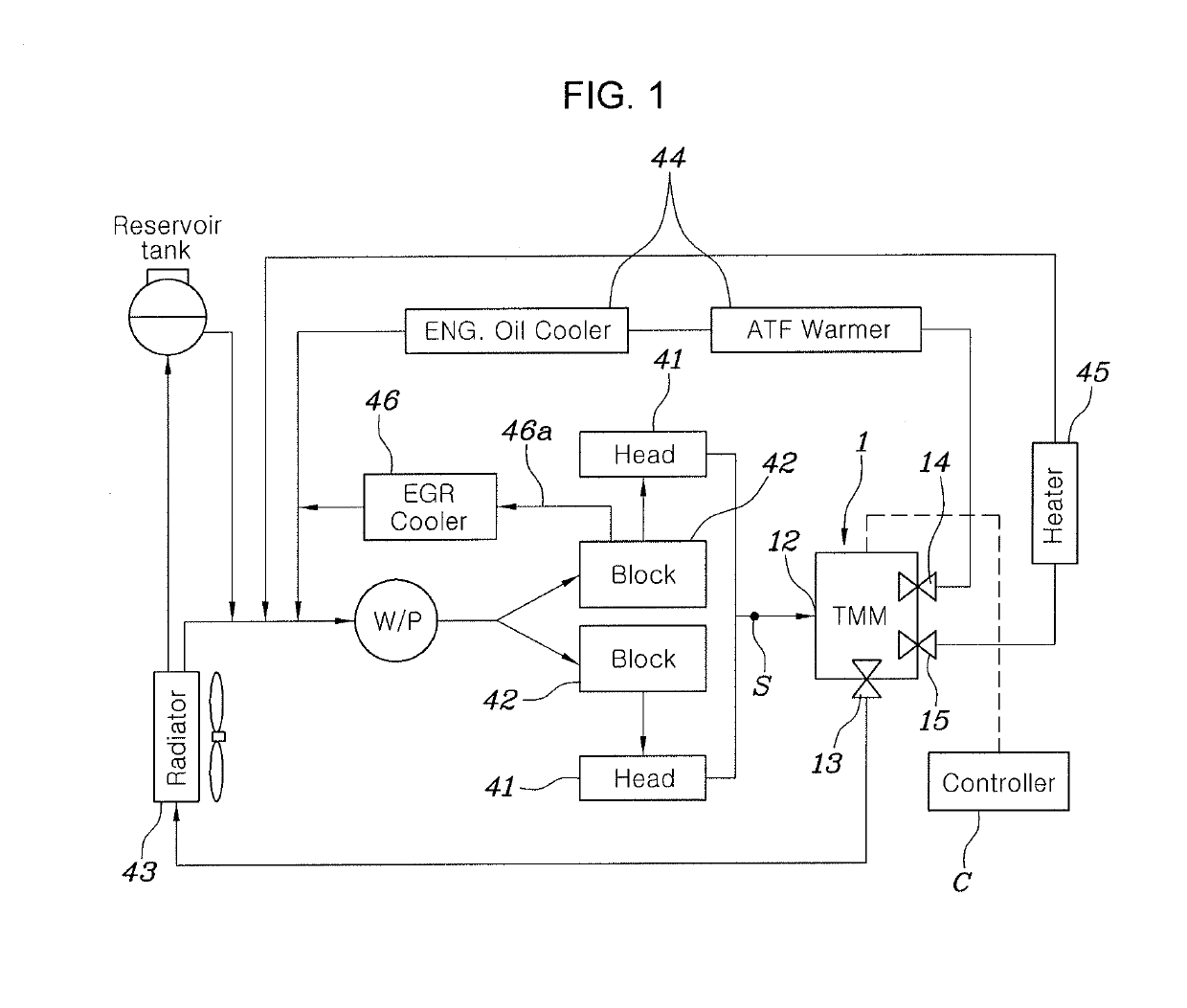

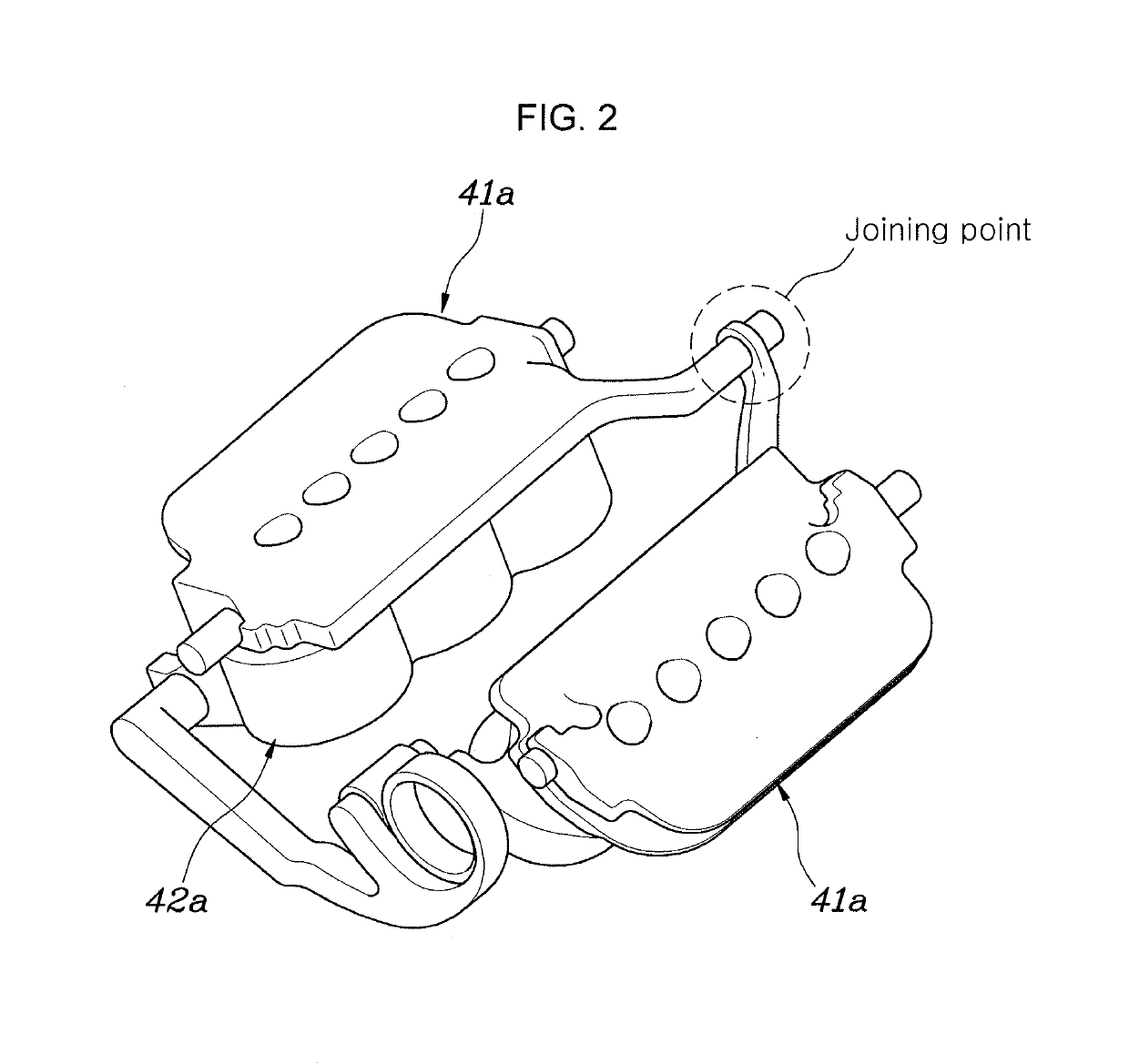

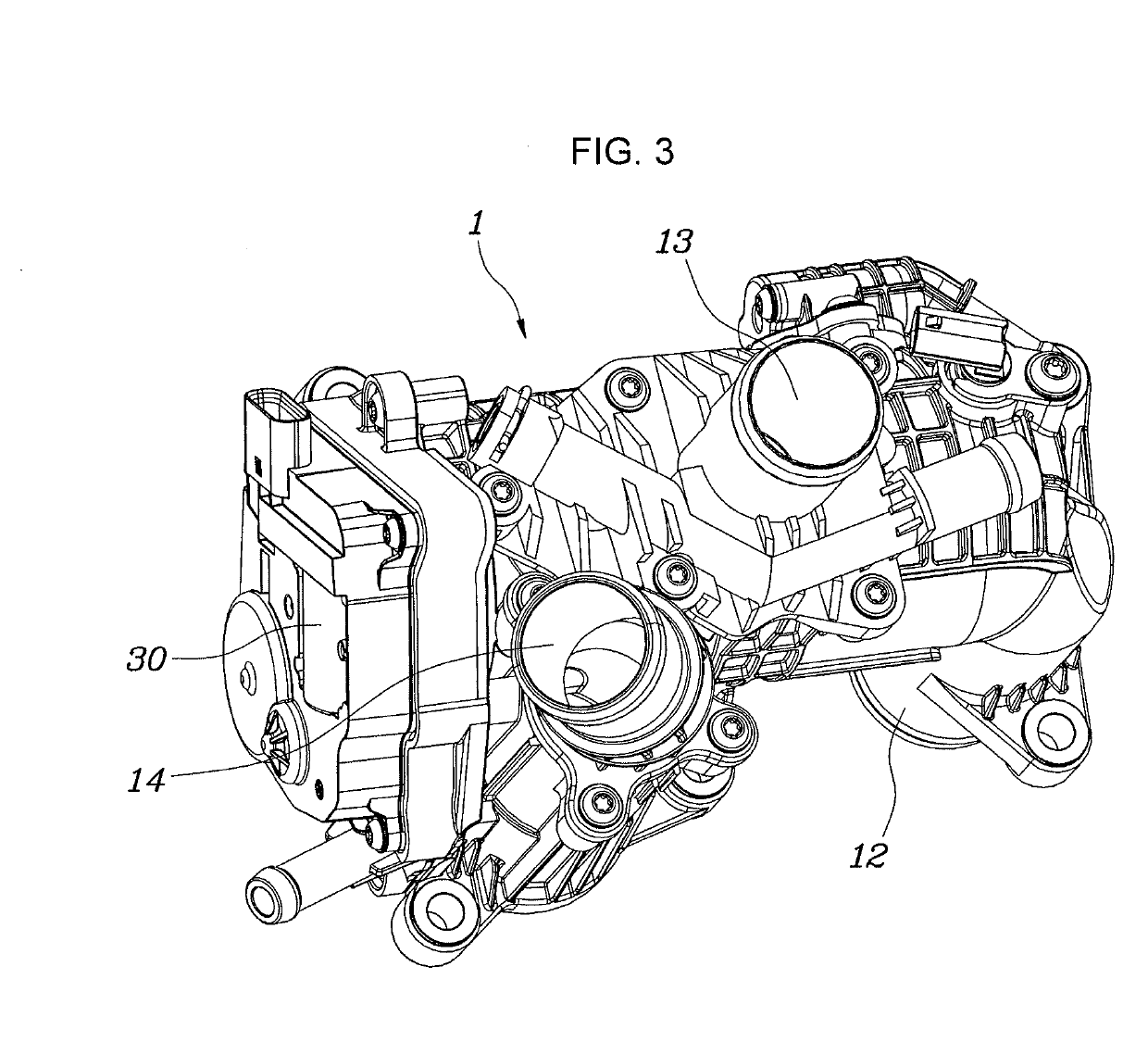

Flow control valve and cooling circuit for vehicles with flow control valve

A cooling circuit for a vehicle may include a plurality of cylinder heads into which cooling water is continuously introduced from a plurality of cylinder blocks oppositely disposed parallel with each other, wherein a flow control valve may include a head port, through which the cooling water discharged from the plurality of cylinder heads is joined and the joined cooling water is introduced into the flow control valve, and wherein the flow control valve also may include a set of ports including a radiator port, a heat exchanger port, and a heater core port, through which the cooling water introduced into the flow control valve is discharged towards a radiator, an oil heat exchanger, and a heater core, respectively.

Owner:HYUNDAI MOTOR CO LTD +1

Method and device for engaging a clutch

InactiveUS8682553B2Shorten speedShorten the operating distanceAnalogue computers for vehiclesClutchesControl theoryClutch

Owner:ROBERT BOSCH GMBH

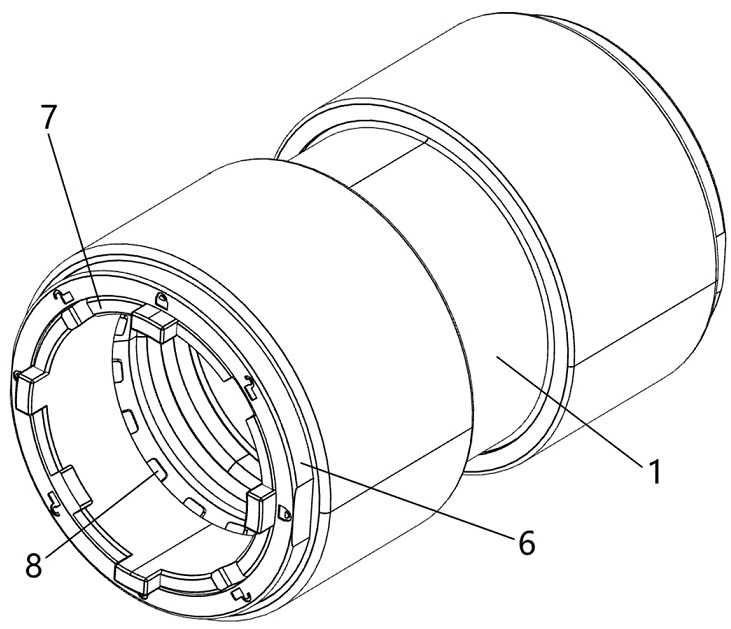

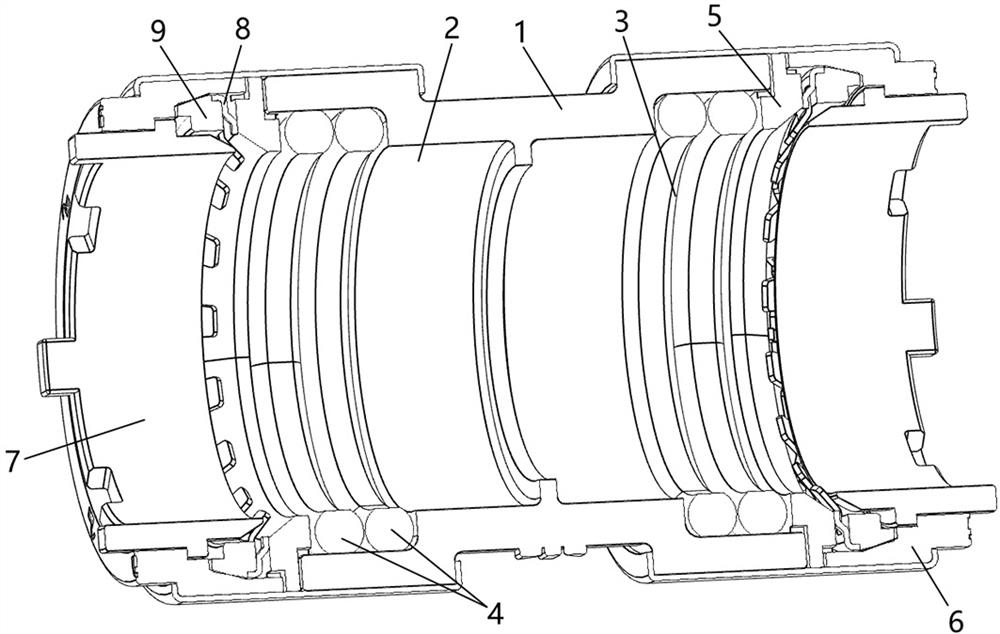

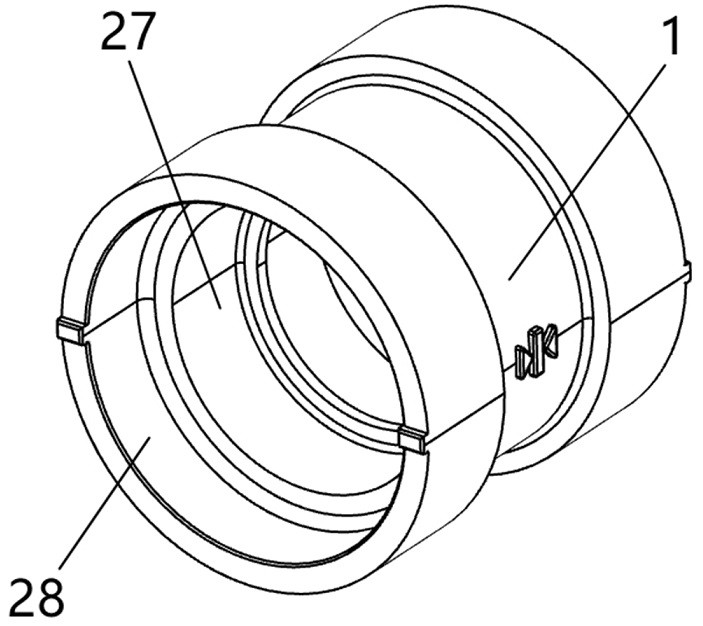

Stable and convenient quick pipeline connector

PendingCN113983260AEasy to insertConvenient to accommodateCouplingsStructural engineeringMechanical engineering

The invention discloses a stable and convenient quick pipeline connector which comprises a connector shell, a sealing assembly and a pipe locking assembly; the connector shell is provided with one or more quick connecting ports, the quick connecting ports are sleeved with the sealing assembly and the pipe locking assembly, and the end face of the connector shell is provided with an inner ring cover used for fixing the sealing assembly; the pipe locking assembly comprises an outer ring cover, an unlocking ring, an open-loop steel tooth clamping jaw and an open clamping jaw supporting ring; a beveling climbing structure is arranged on the outer ring cover and the unlocking ring; and the beveling climbing structure comprises a fixed beveling face and a movable beveling face, and the movable beveling face is matched with the fixed beveling face in a beveling mode. According to the pipeline connector, the situation that an inserted pipe is scratched by the steel tooth clamping jaw in the assembling and disassembling process can be avoided, the operation distance needed by the pipeline connector during assembling and disassembling operation of the pipe can be reduced through the beveling climbing structure, the unlocking force needed for disassembling the pipe is reduced, the assembling and disassembling operation of the pipe is simple and convenient, the internal structure is stable, and the pipe fixing effect is good.

Owner:深圳市安第斯制品有限公司

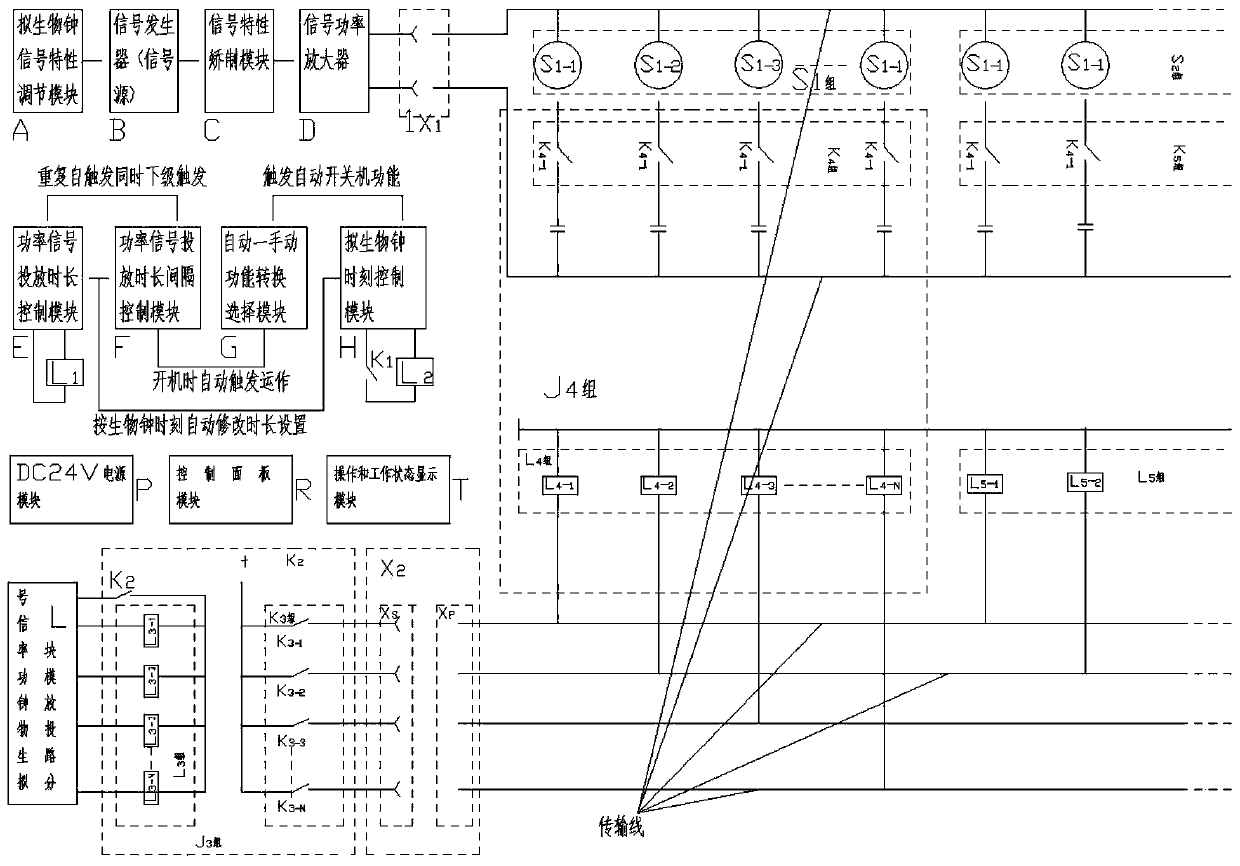

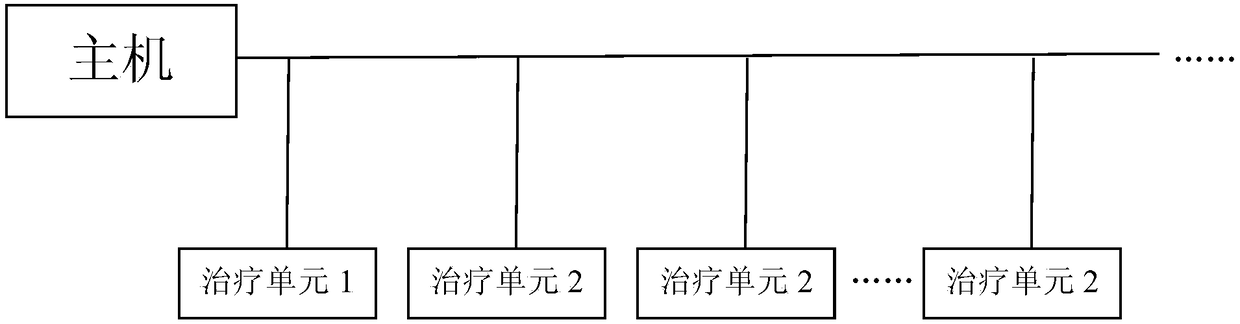

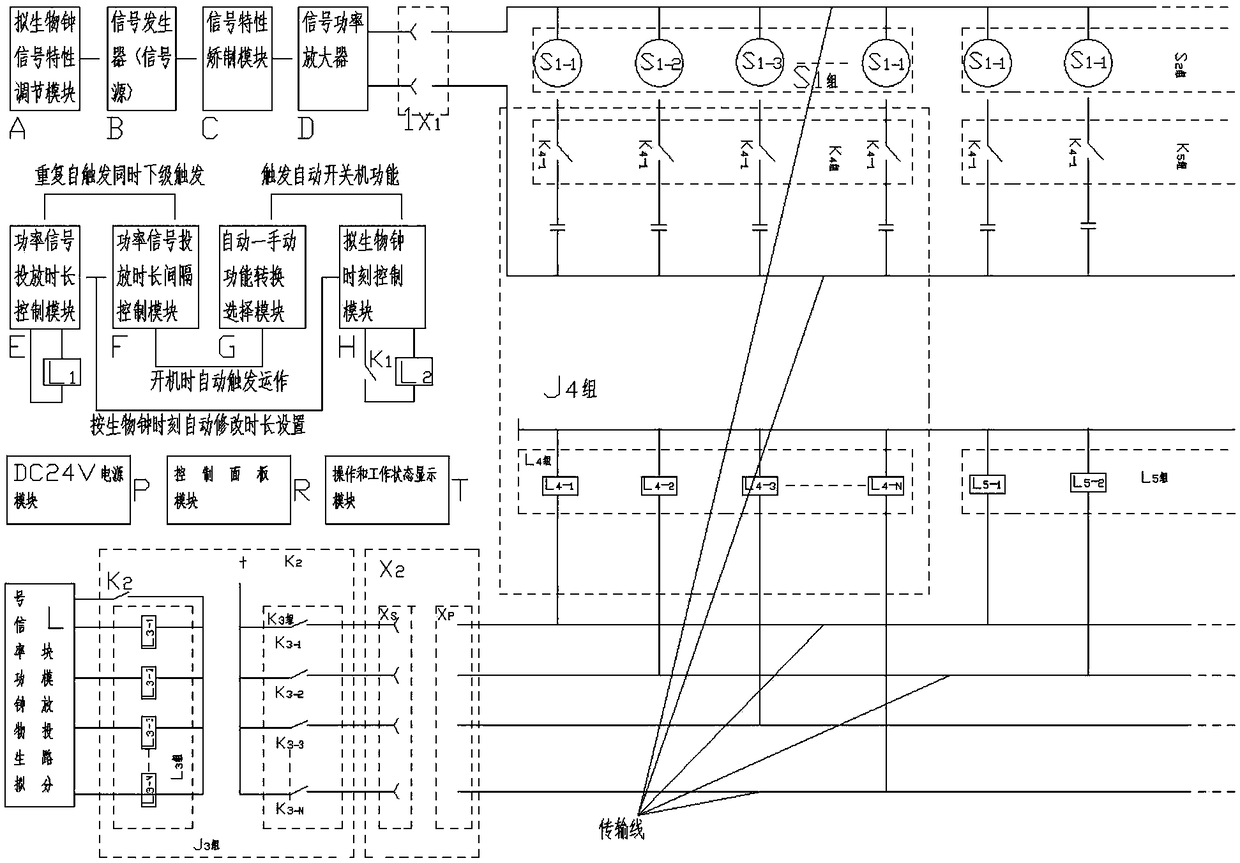

A remote probe type focused electromagnetic pulse electronic acupuncture treatment machine

ActiveCN108543223BAchieve healingSufficient self-healing abilityDevices using electromagnetic wavesRadiation therapyAcupuncture treatmentControl signal

The invention provides a remote detection type focusing electromagnetic pulse electronic acupuncture treatment machine. The machine comprises modules of a case, a power supply module, a control panelmodule, an operation and working state display module, a signal generator, a simulation living clock signal characteristic adjustment module, a signal characteristic correction processing module, a signal power amplifier, a simulation living clock control module, a simulation living clock power signal branching putting control module, a power signal putting duration control module, a power signalputting time interval control module, a power signal branching putting relay group, a power signal output port, a power signal branching putting control signal output port and a power supply input port. Under the mode of human living clock rules, weak eddy generated by electromagnetic induction is used for carrying out noninvasive stimulation on acupuncture points, and carrying out simulation acupuncture stimulation on related meridians and acupuncture points of a patient, so the related functions of the patient can be correspondingly repaired and improved in a noninvasive and painless manner,and simplicity and reliability of operation and efficiency of effects are improved.

Owner:孔祥伟

Laser welding method

InactiveCN108994456AShorten the operating distanceEasy to controlLaser beam welding apparatusEngineeringLaser

The invention discloses a laser welding method. The laser welding method comprises the steps that firstly, a clamp is arranged on a workbench; secondly, a moving device moves the clamp to an operationstation from a machining zero position; thirdly, an operator installs a component to the clamp; fourthly, the clamp and the component are moved to the machining zero position from the operation station; and fifthly, a control mechanism controls a laser welding head to move, a welding line is formed on the component, and the component is welded. Through the above steps, the clamp is moved to the operation station, the operation distance of the operator is shortened, operation is convenient, and after operation is convenient, control over the component from a worker is improved, and operation accuracy is improved. The clamp and the component are sent to the position near the operation station, the body of the worker can conduct operation without entering a work bin, and hurt to the worker from harmful gases is reduced.

Owner:WENZHOU FIBER LASER

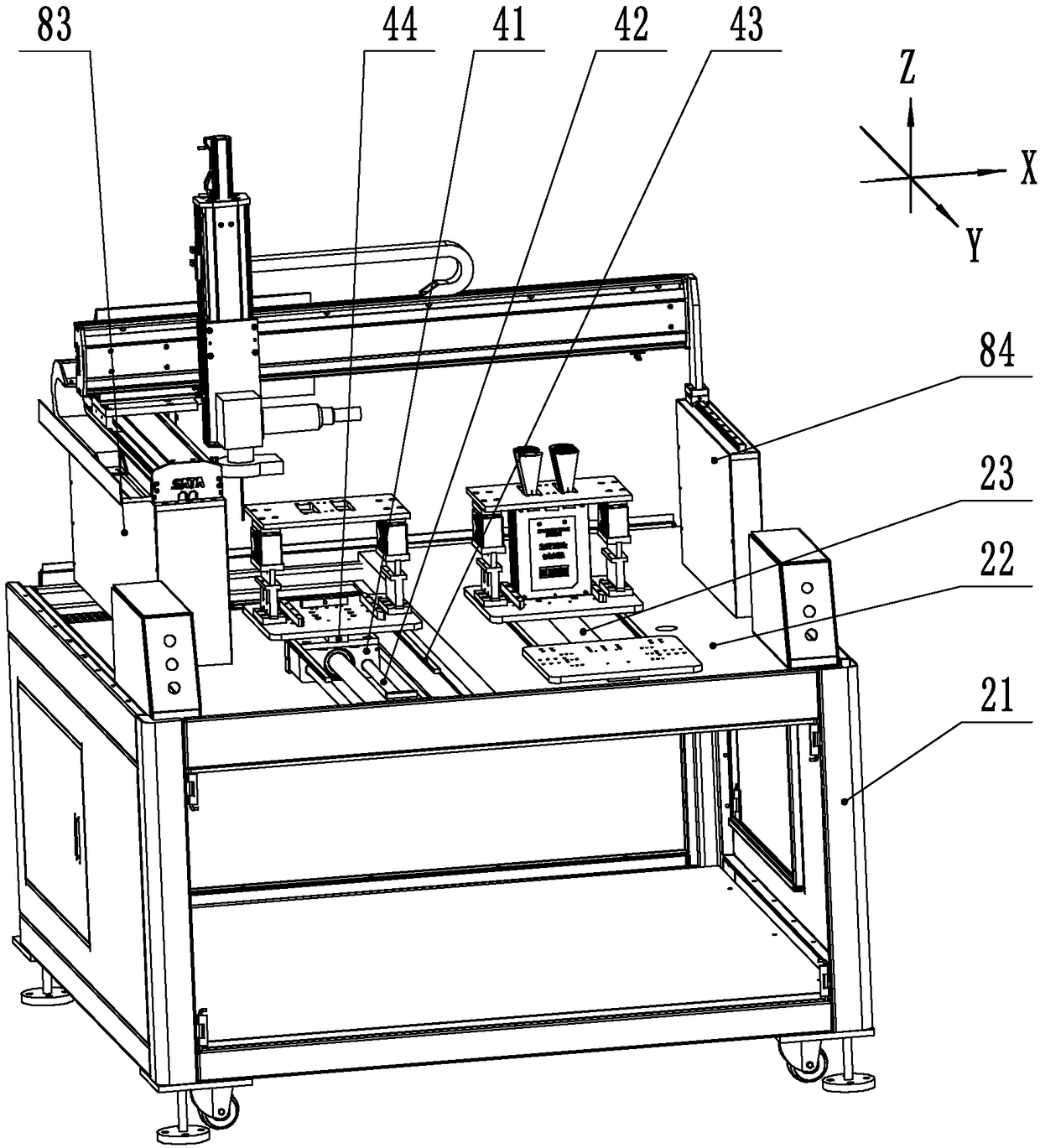

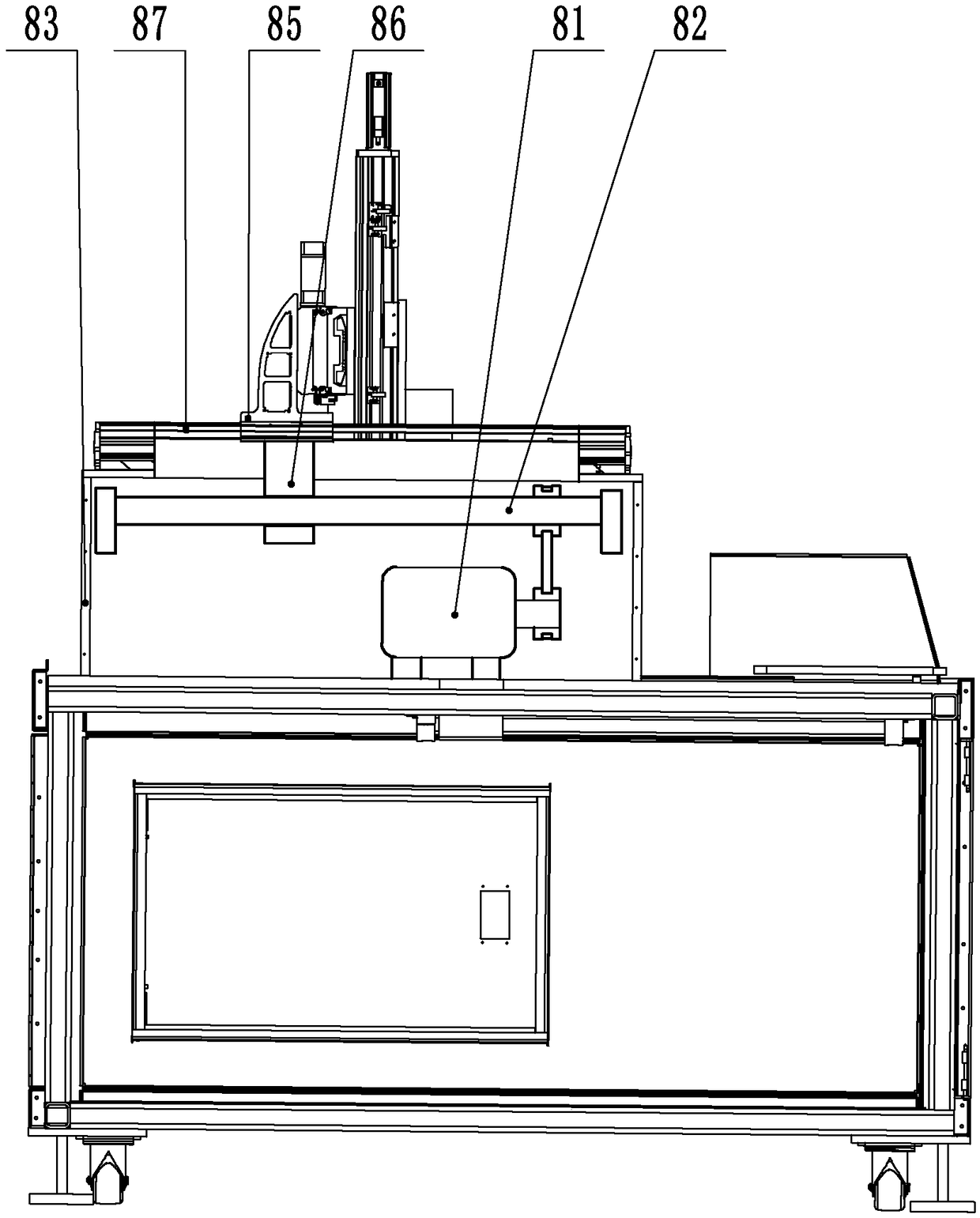

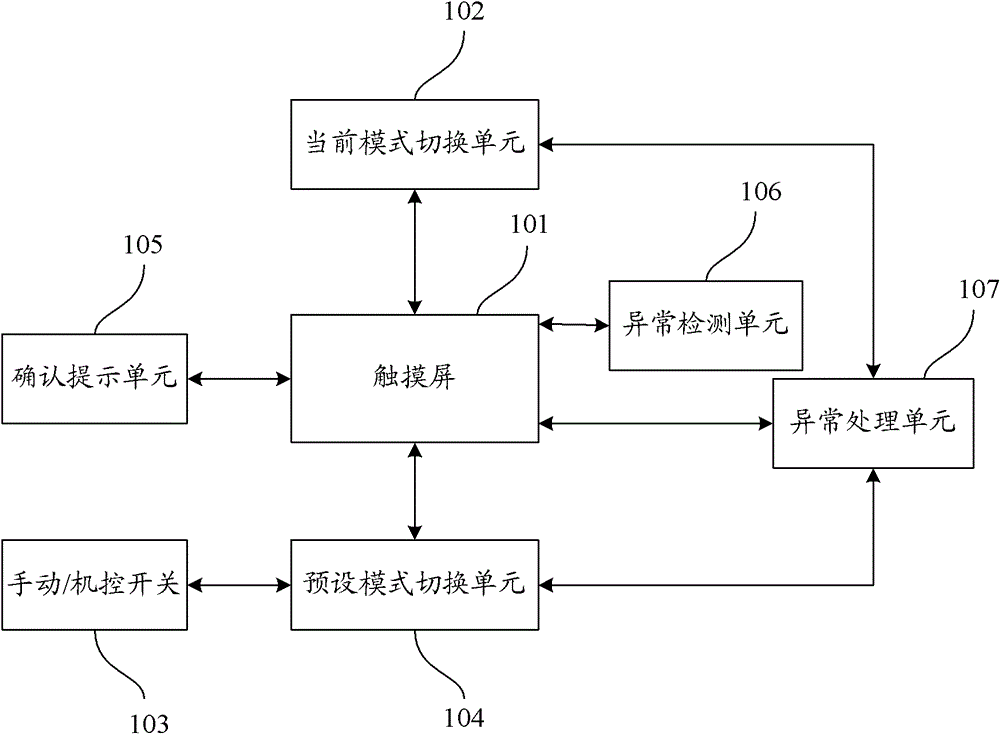

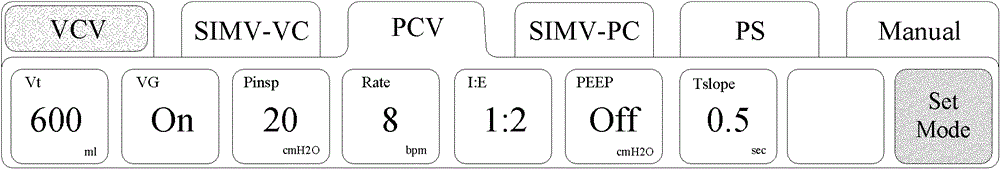

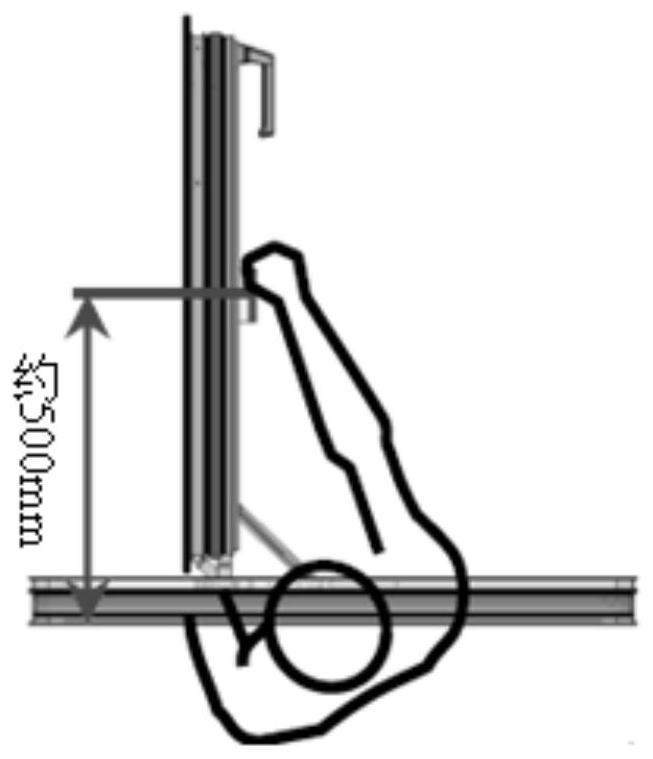

A ventilation mode switching device, method, anesthesia machine, and ventilator

ActiveCN102441209BShorten the operating distanceReduce operational complexityRespiratorsMedical equipmentEngineering

The invention is applicable to the field of electronic medical equipment and provides a ventilation mode switching equipment and method as well as an anesthesia machine and a breathing machine. The ventilation mode switching equipment comprises a touch screen used for receiving pending ventilation mode selection information and current ventilation mode switching information, and a current mode switching unit used for switching the current ventilation mode into a ventilation mode specified in pending ventilation mode selection information outputted by the touch screen after receiving current ventilation mode switching information outputted by the touch screen. According to the invention, the current mode switching unit switches the current ventilation mode into the ventilation mode specified in the pending ventilation mode selection information outputted by the touch screen after receiving the current ventilation mode switching information outputted by the touch screen, and the pending ventilation mode selection information and the current ventilation mode switching information, which are inputted by a user, are received by the touch screen completely, so that the operation distance and the operation complexity can be reduced when the ventilation mode is switched, and the operation efficiency can be improved.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

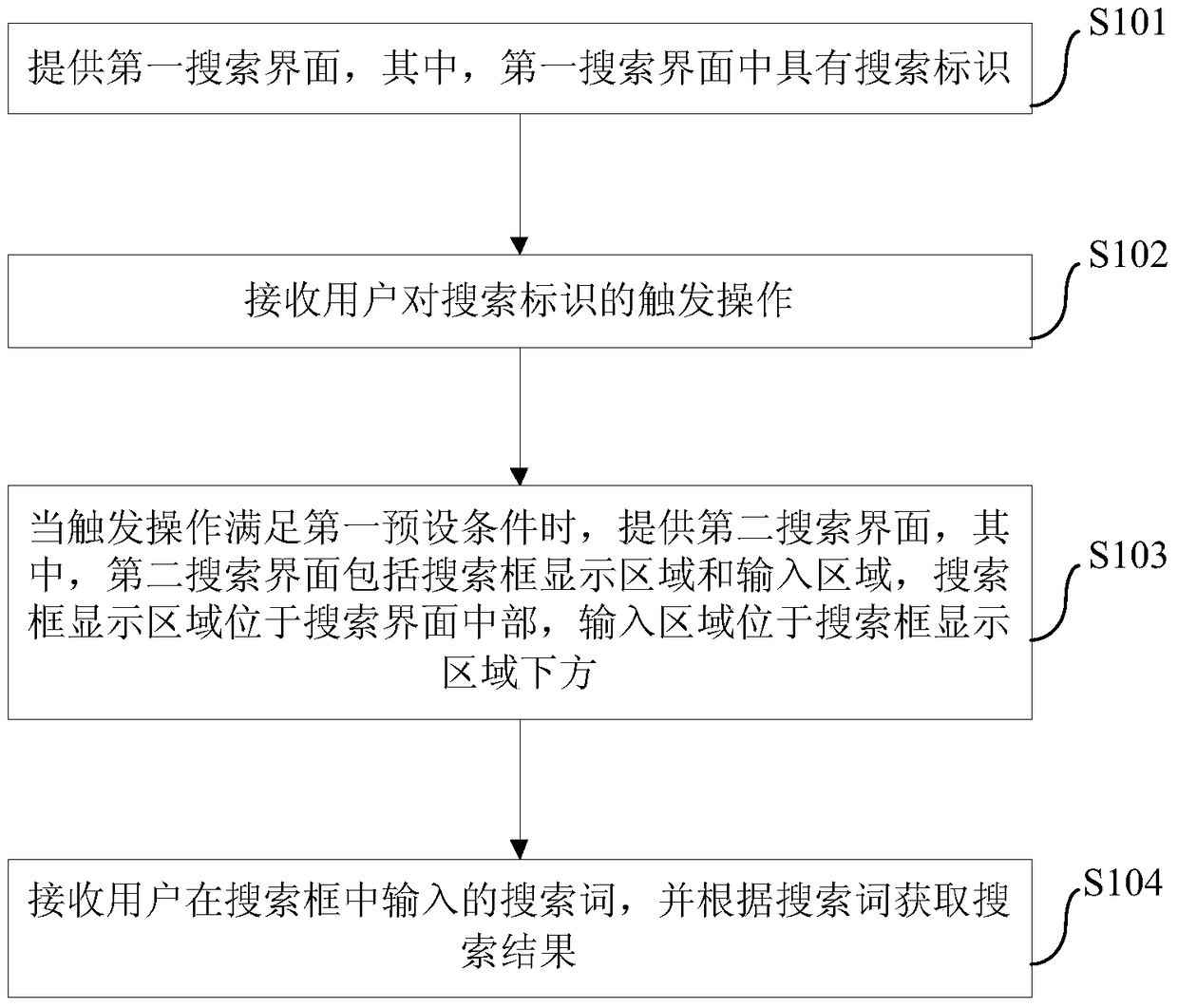

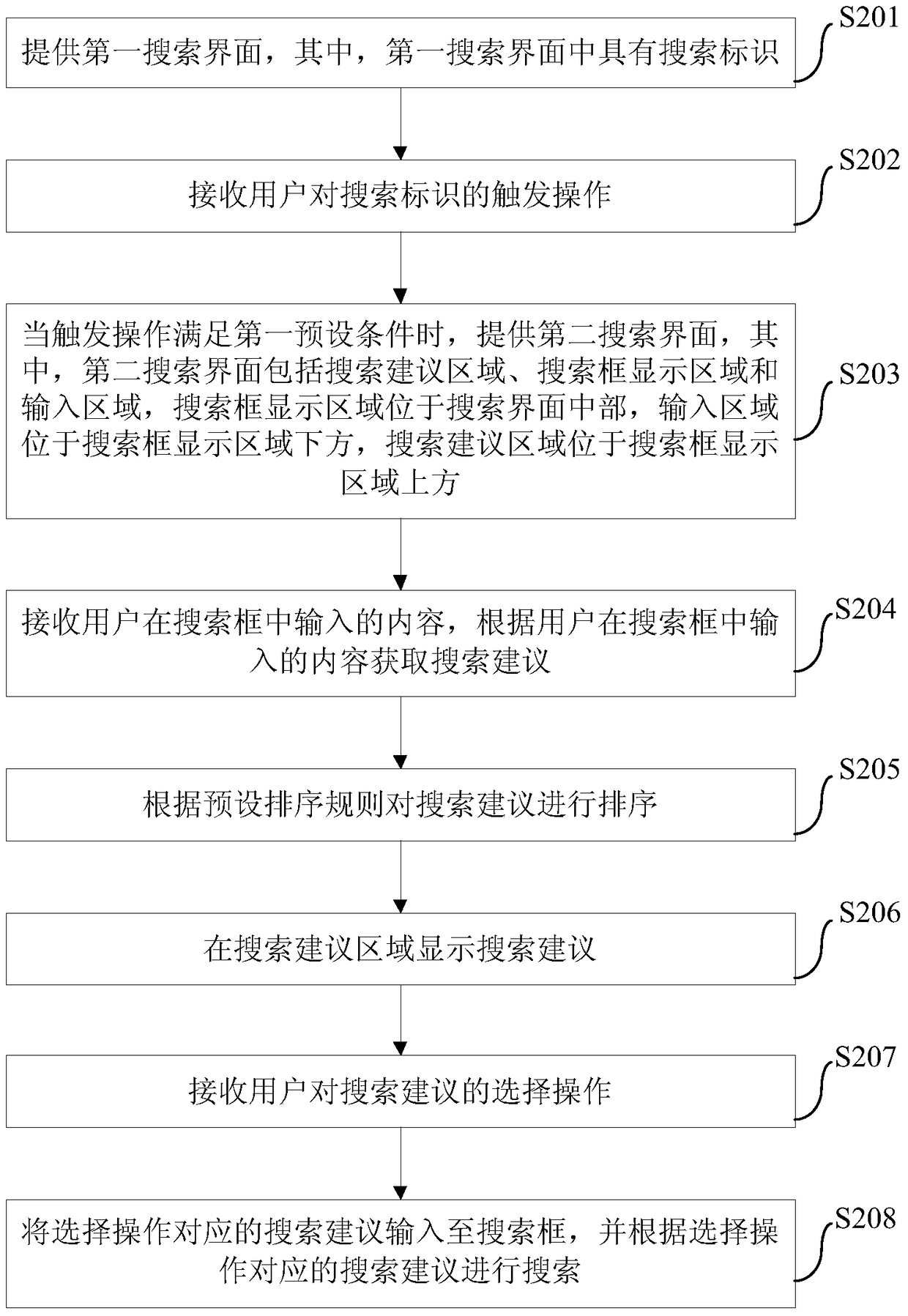

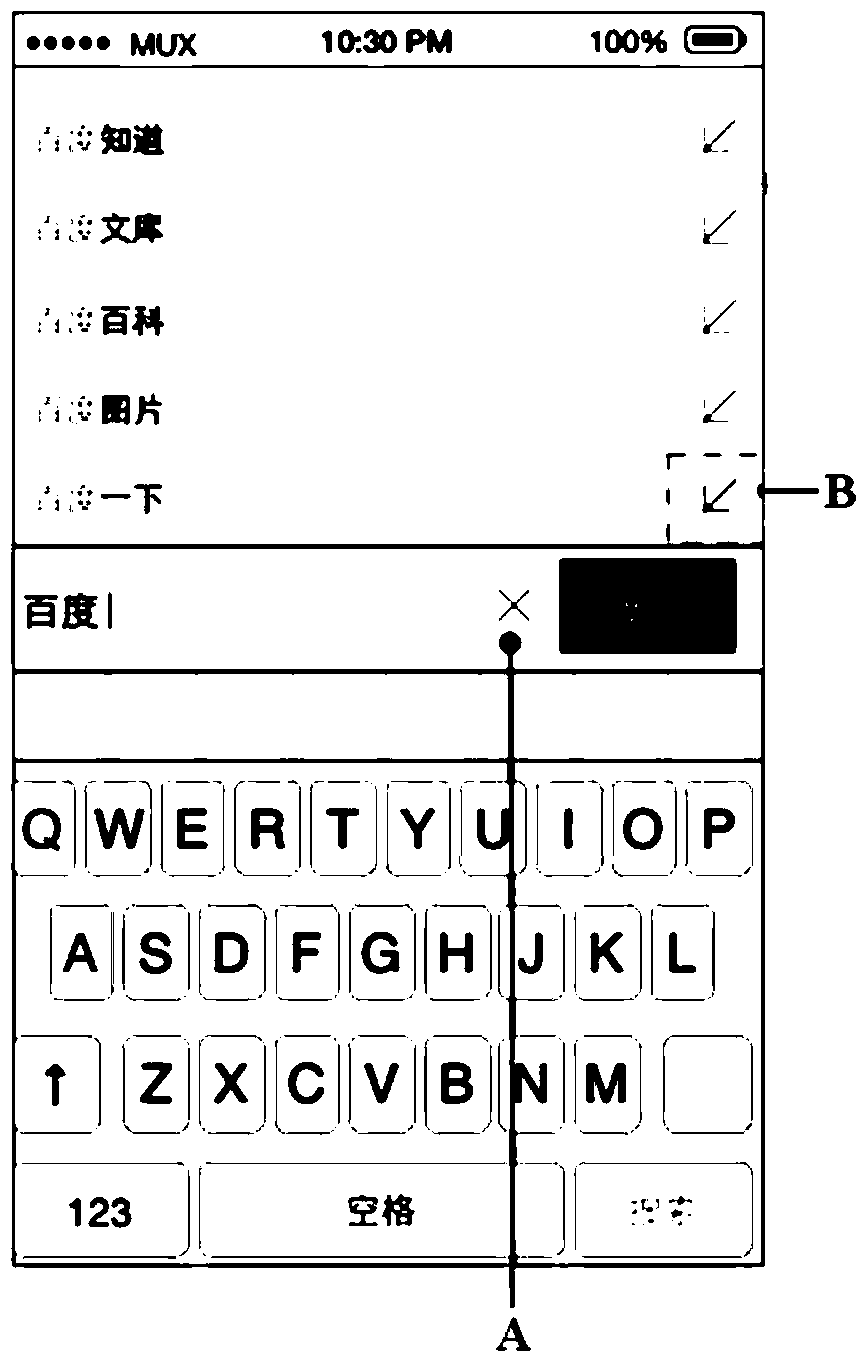

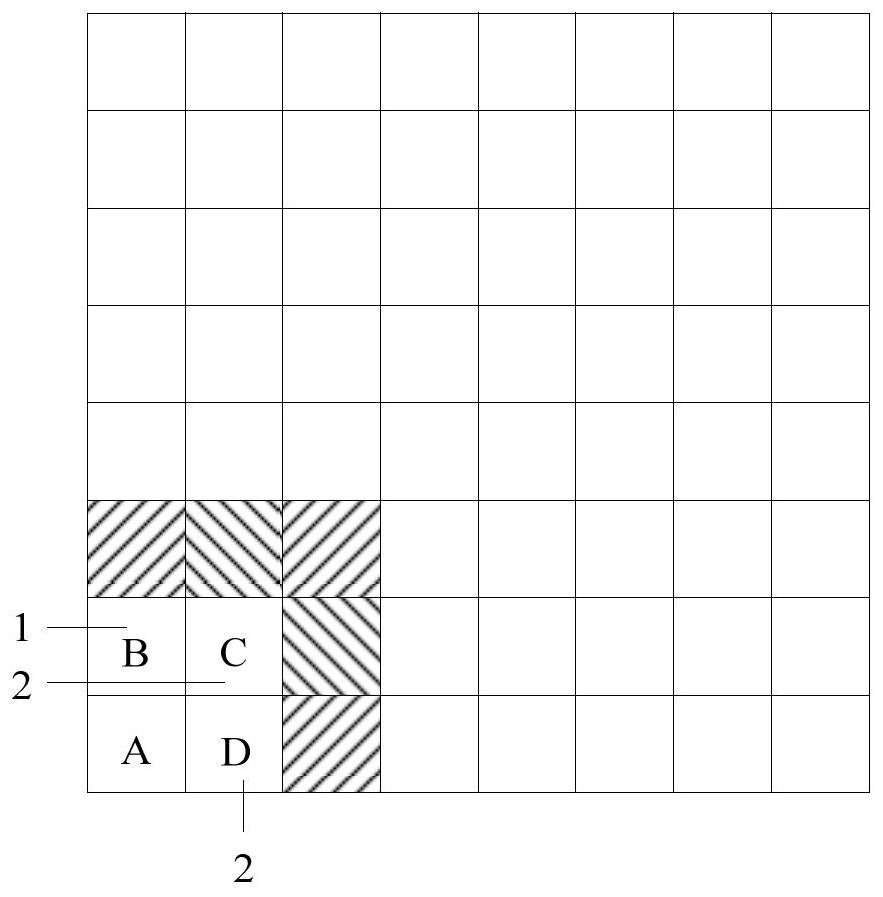

Search method, device and mobile terminal

ActiveCN104462496BShorten the operating distanceImprove experienceWeb data indexingSpecial data processing applicationsSearch wordsComputer terminal

The invention provides a search method, device and a mobile terminal. The search method includes the steps that a first search interface is provided, wherein the first search interface is provided with search identification; a trigger operation of the search identification by a user is received; when the trigger operation meets the first preset condition, a second search interface is provided, wherein the second search interface comprises a search box display region and an input region, the search box display region is located in the middle of the search interface, and the input region is located below the search box display region; a search word input in a search box by a user is received, and the search result is obtained according to the search word. By means of the search method, the operation distance generated when a user moves between the search box and the input region is greatly reduced, one-hand operation is facilitated, the search method, device and the mobile terminal are more convenient and faster to use, and input efficiency and search efficiency are improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

A single-chip microcomputer-based automobile gesture control device and its control method

ActiveCN108732969BReduce occupancyLower requirementProgramme controlInput/output for user-computer interactionMicrocontrollerMicrocomputer

The present invention proposes a single-chip microcomputer-based automobile gesture control device and its control method. The present invention uses a single-chip microcomputer as the main control unit, uses an infrared supplementary light to project infrared light, and uses a monocular camera with an infrared filter to capture user gestures. The image is sent to the single-chip microcomputer module. The single-chip microcomputer module analyzes, processes and recognizes the user gesture image, and controls the equipment control module to operate the vehicle equipment, thereby realizing the gesture control of the vehicle equipment. The single-chip microcomputer module of the present invention has excellent expansibility, and can be connected with different device drive modules according to actual needs to drive different automobile devices, so as to achieve the purpose of using gestures to control various in-vehicle devices. At the same time, the present invention uses an infrared supplementary light device with a monocular camera, which can be used under low-illumination conditions, and is more suitable for use in cars, especially when driving at night without daylight illumination, it can still be used normally.

Owner:哈尔滨拓博科技有限公司

Remote detection type focusing electromagnetic pulse electronic acupuncture treatment machine

ActiveCN108543223AAchieve healingSufficient self-healing abilityDevices using electromagnetic wavesRadiation therapyAcupuncture treatmentControl signal

The invention provides a remote detection type focusing electromagnetic pulse electronic acupuncture treatment machine. The machine comprises modules of a case, a power supply module, a control panelmodule, an operation and working state display module, a signal generator, a simulation living clock signal characteristic adjustment module, a signal characteristic correction processing module, a signal power amplifier, a simulation living clock control module, a simulation living clock power signal branching putting control module, a power signal putting duration control module, a power signalputting time interval control module, a power signal branching putting relay group, a power signal output port, a power signal branching putting control signal output port and a power supply input port. Under the mode of human living clock rules, weak eddy generated by electromagnetic induction is used for carrying out noninvasive stimulation on acupuncture points, and carrying out simulation acupuncture stimulation on related meridians and acupuncture points of a patient, so the related functions of the patient can be correspondingly repaired and improved in a noninvasive and painless manner,and simplicity and reliability of operation and efficiency of effects are improved.

Owner:孔祥伟

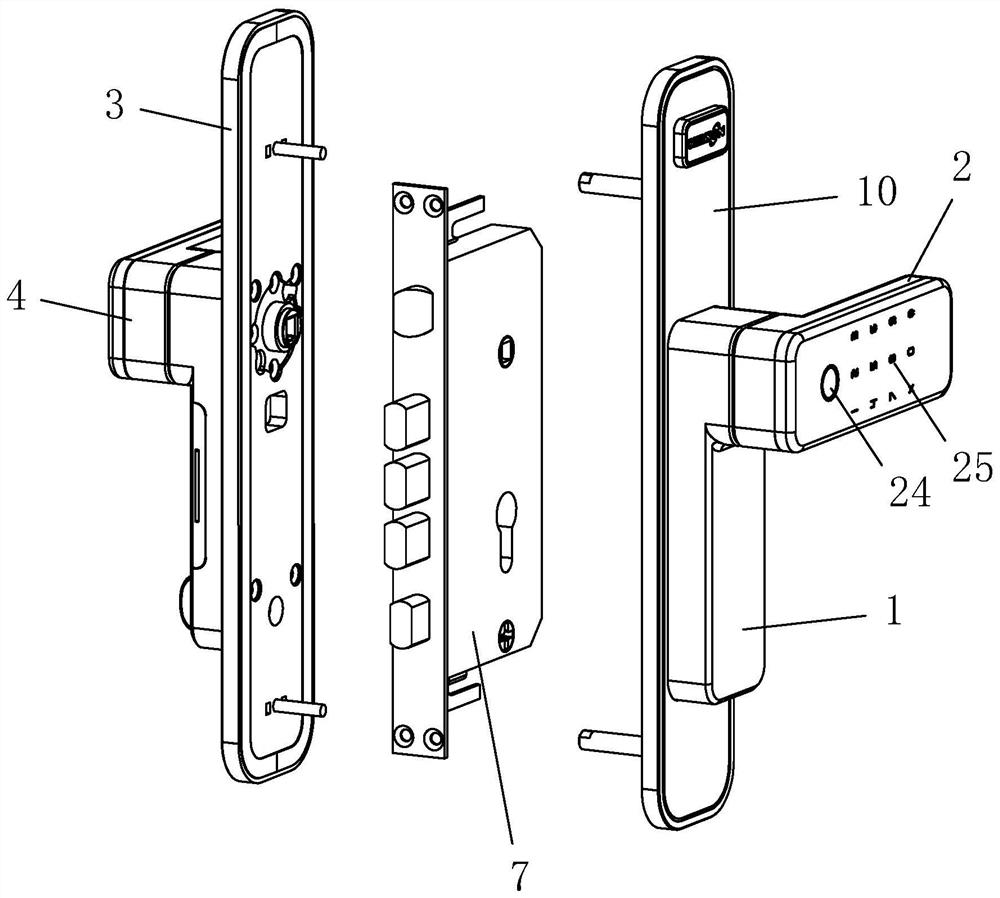

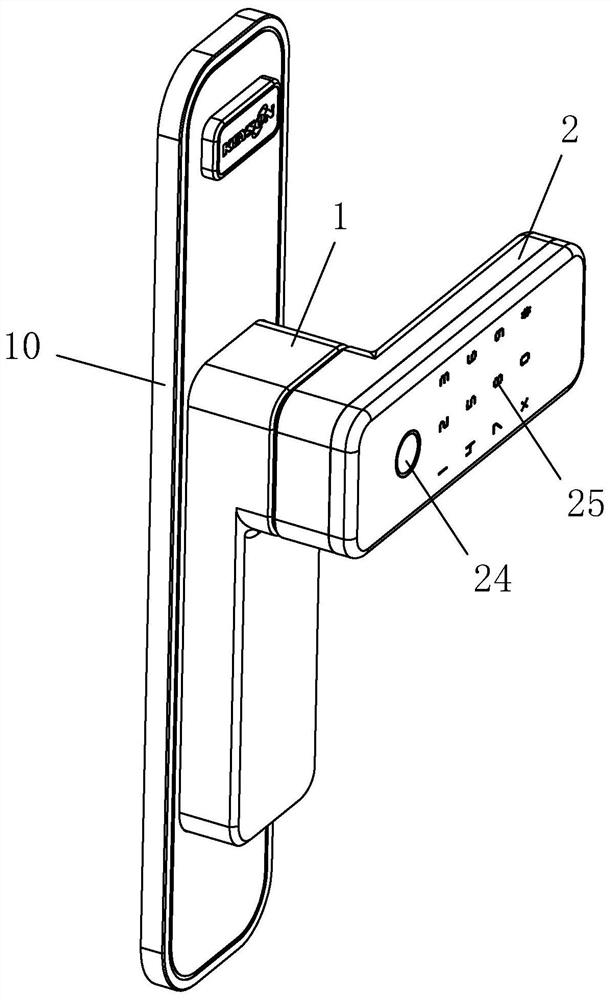

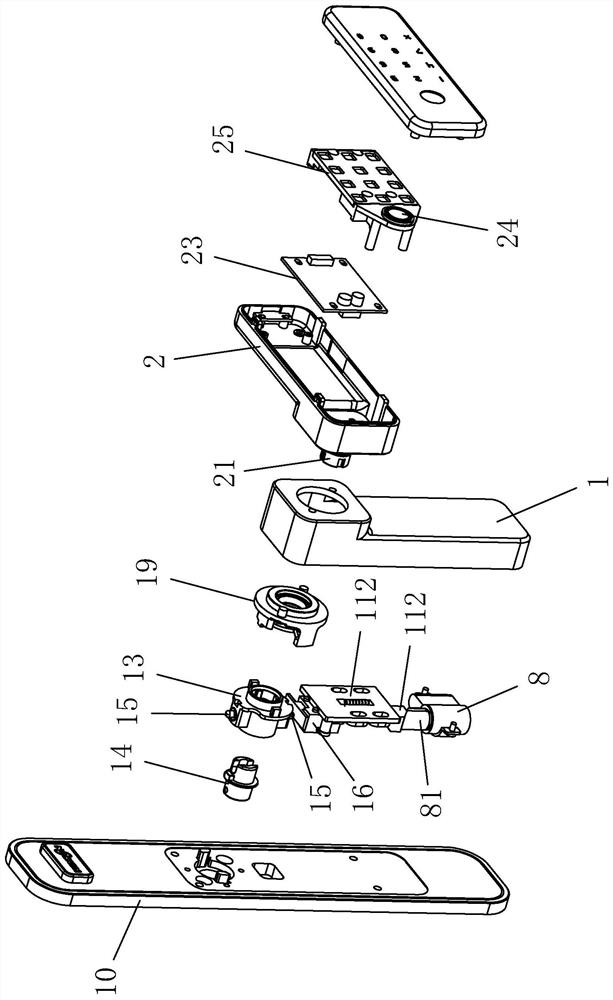

Novel intelligent door lock

PendingCN111852189AShorten unlock timeImprove securityNon-mechanical controlsLock casingsEmbedded systemClutch

The invention relates to a novel intelligent door lock comprising a front panel, a front lock case and a front handle. A main control circuit board used for controlling a driving device is arranged inthe front handle, and a fingerprint module and a password key module which are connected with the main control circuit board separately are arranged on the handle; the rear end of the front handle isprovided with a first linkage part which extends into the front lock case and is used for driving an outer clutch part to rotate; and one end of the outer clutch part is provided with a first linkagehole fit with the first linkage part. The fingerprint module and the password key module are arranged on the handle, and a door can be unlocked or quickly unlocked after passwords are input while fingerprint identification is performed; time delay is not required after the lock is driven by the driving device to unlock, and the safety is high; meanwhile, the packaging cost can be further reduced;in addition, a door viewer button is arranged on a rear handle, and the door viewer button needs to be pressed for unlocking; and the lockset safety is improved.

Owner:ZHONGSHAN CITY JIXIN CORE LOCK CO LTD

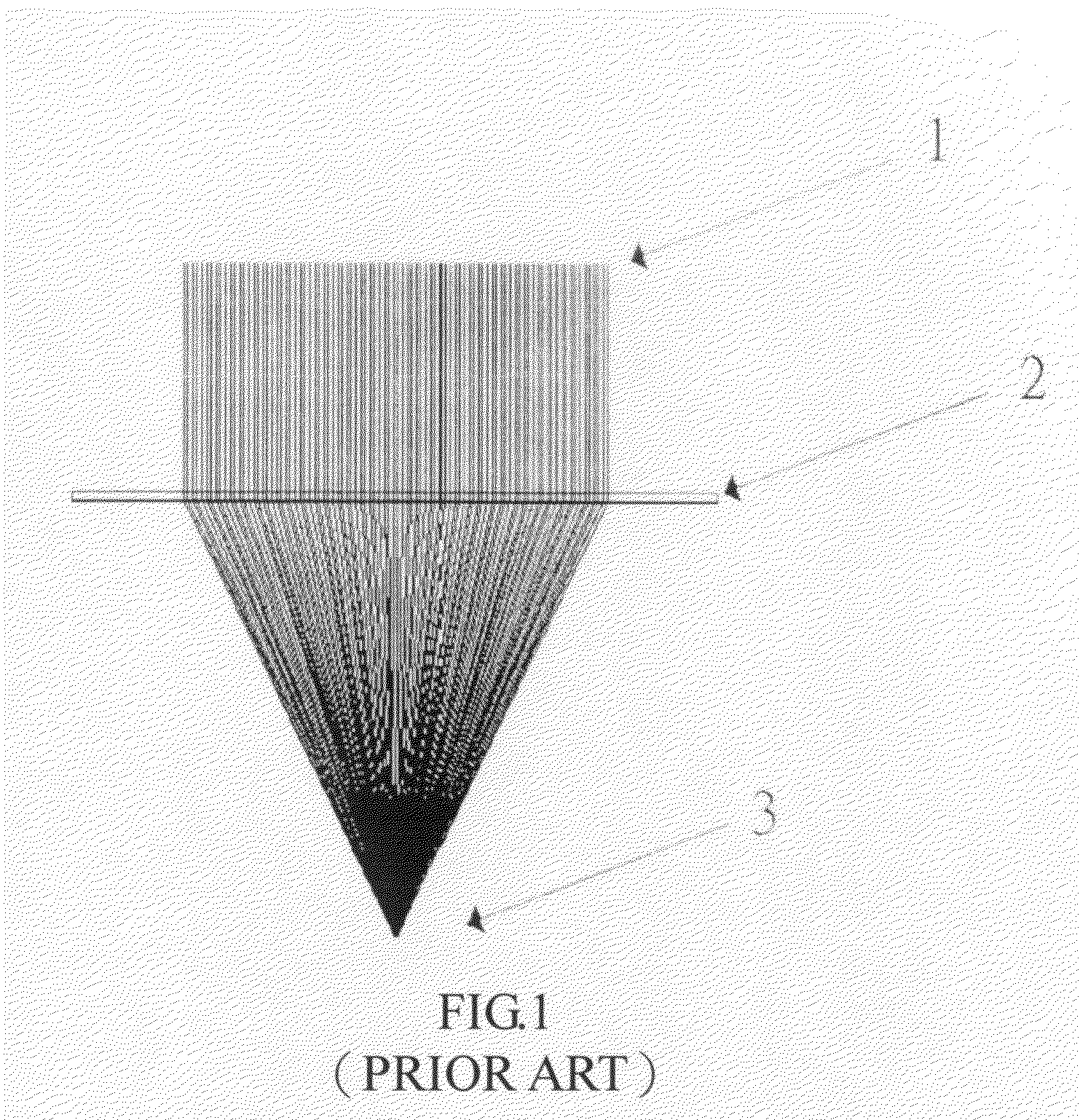

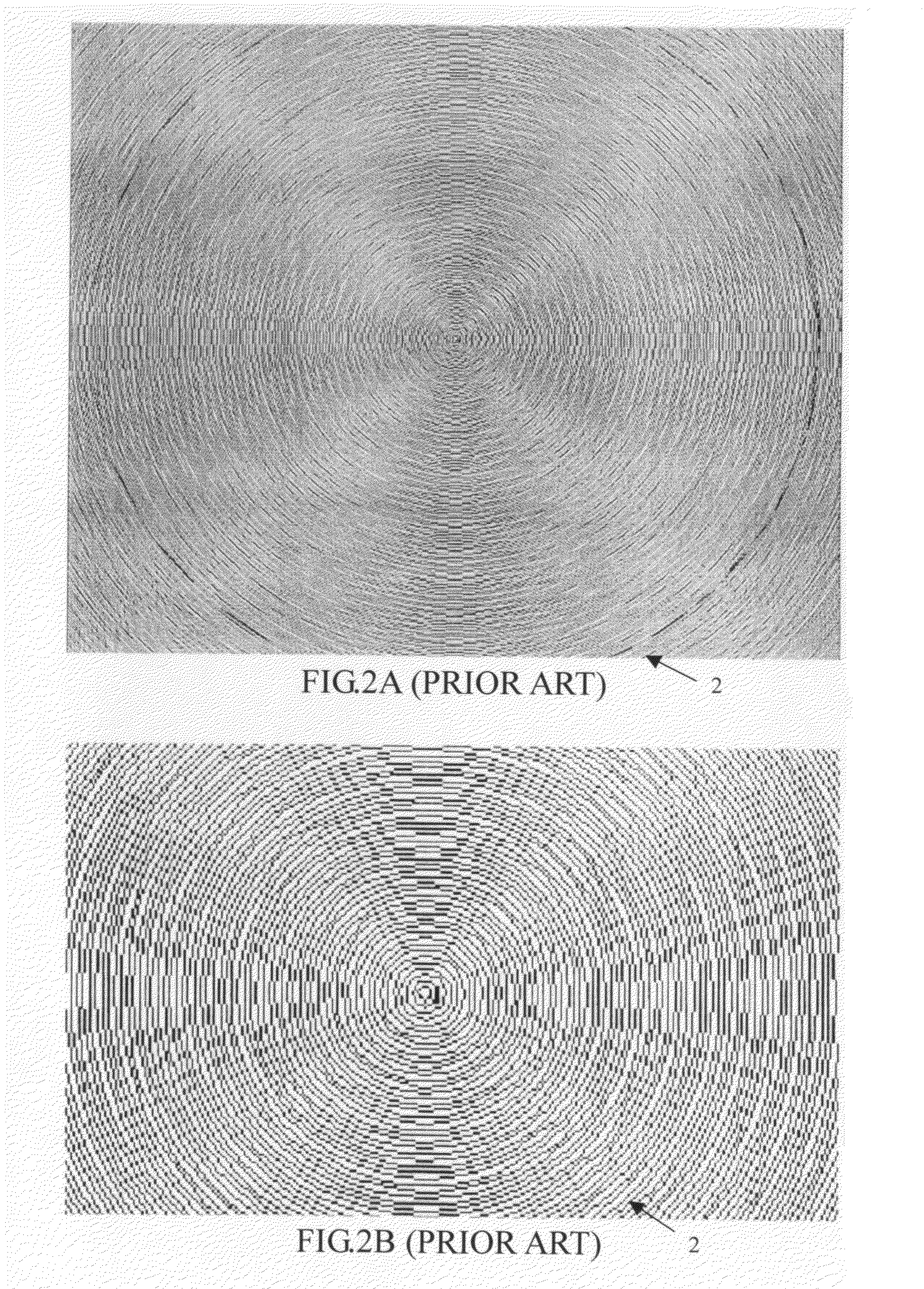

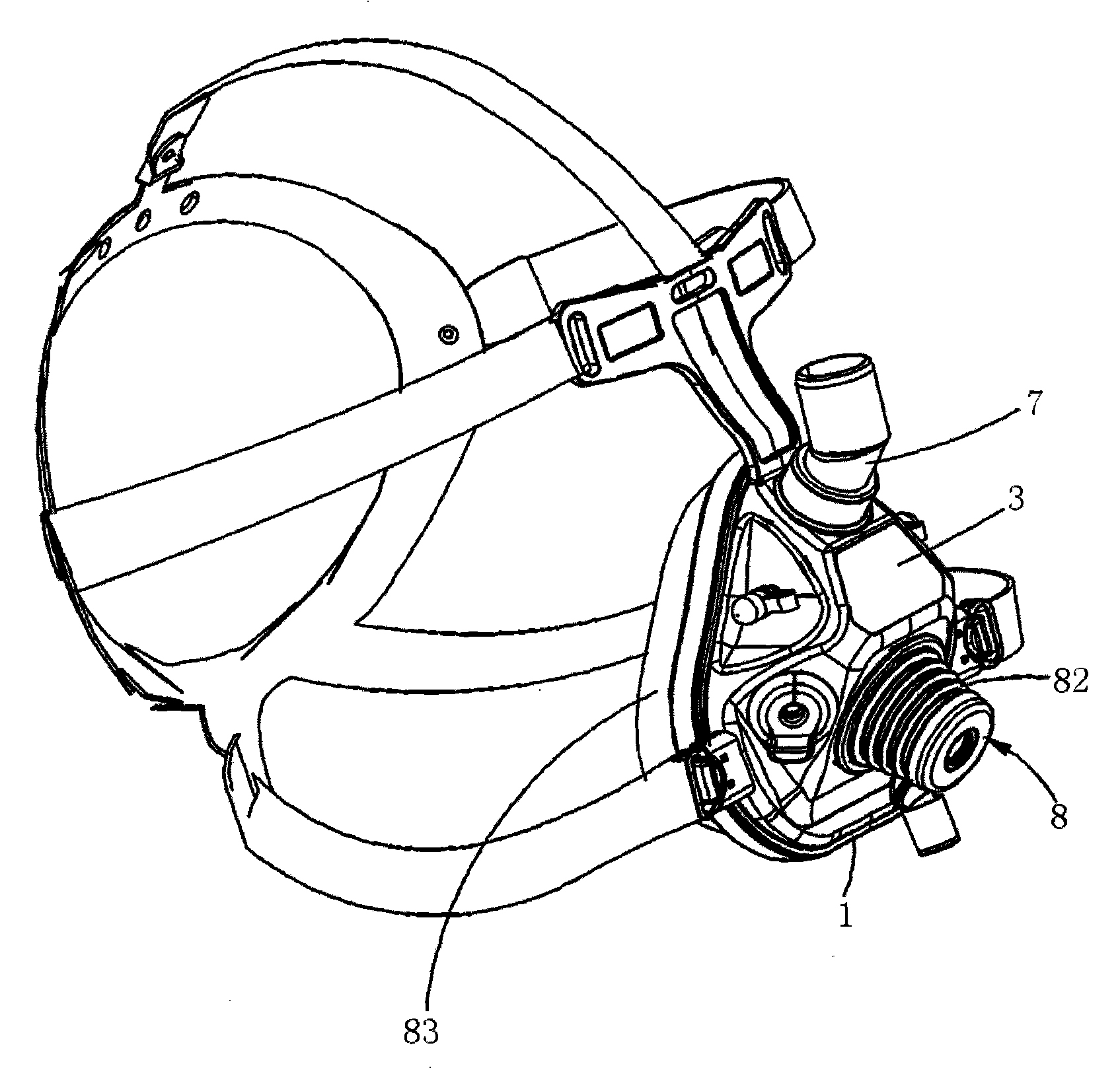

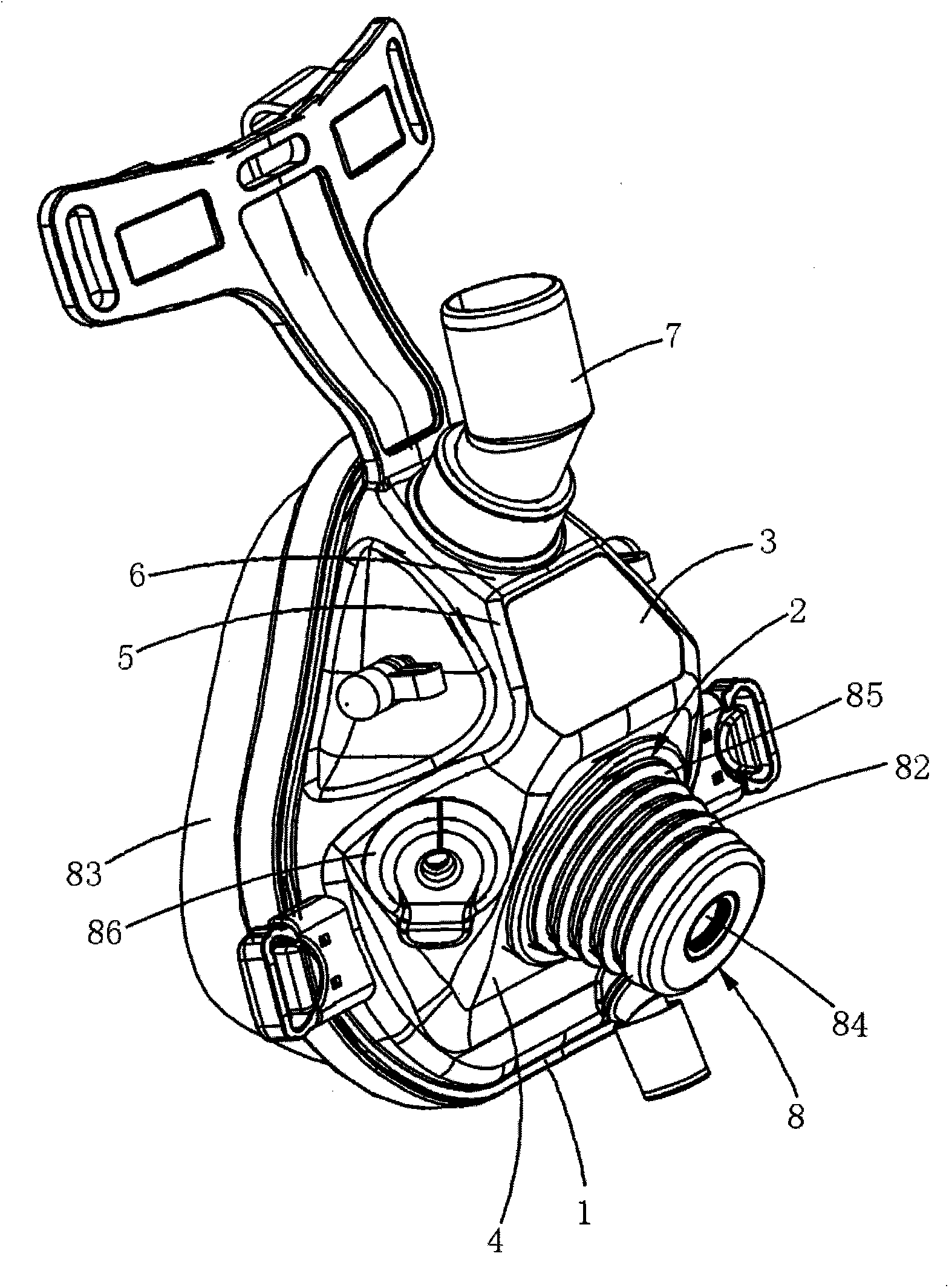

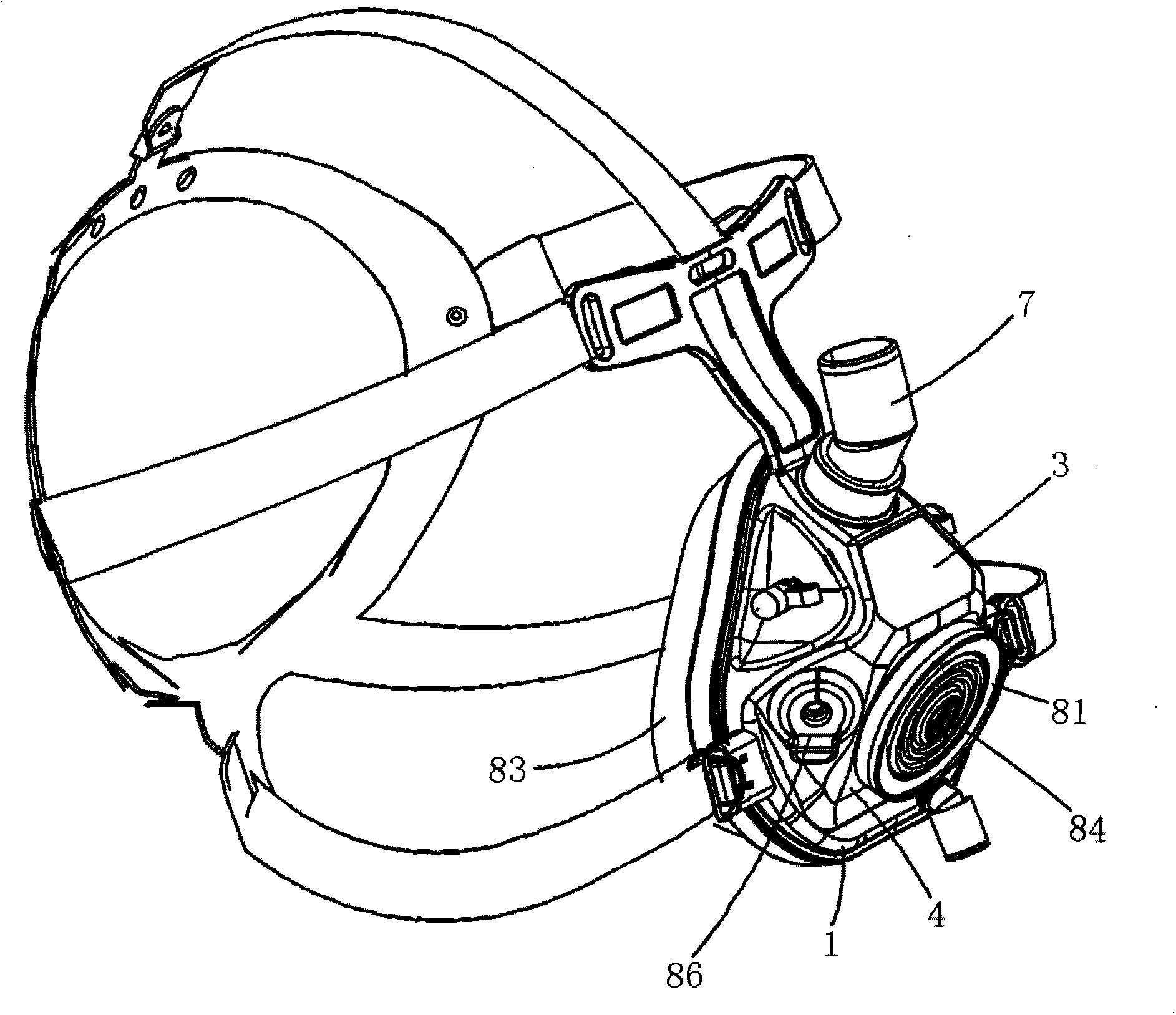

Noninvasive positive-pressure ventilation mask

InactiveCN103480075AShorten the operating distanceEasy to operateRespiratory masksNasal cavityNoninvasive ventilation

The discloses a noninvasive ventilation mask capable of assisting in fiber bronchoscope interventional diagnosis and treatment and tracheal intubation via fiberoptic bronchoscopy under the condition of no air leakage and on the basis of ensuring continuous noninvasive mechanical ventilation. The noninvasive positive-pressure ventilation mask comprises a mask body, an air bag and a magnifying lens, the air bag can be guided by a fiber bronchoscope to be inserted into trachea intubation, and the magnifying lens can observe a whole process that an inserting structure enters the air bag and is inserted into the nasal cavity. The air bag is cone-shaped or boss-shaped and the like in a manner that the top of the air bag is larger than the bottom of the same, a round hole allowing the fiber bronchoscope to be inserted into or allowing the trachea intubation guided by the fiber bronchoscope is formed in the top of the air bag, and the top of the air bag can be turned up inwardly with the inserting structure and enters the mask body via the bottom of the air bag, so that distance from the top to the nasal cavity can be shortened.

Owner:THE FIRST AFFILIATED HOSPITAL OF GUANGZHOU MEDICAL UNIV (GUANGZHOU RESPIRATORY CENT) +1

A kind of manufacturing equipment for self-adhesive glass fiber-wrapped composite film wrapping electromagnetic wire

ActiveCN103489507BCompact structureShorten the operating distanceInsulated cablesCable/conductor manufactureGlass fiberComposite film

The invention relates to equipment for manufacturing self-adhesive glass silk covered composite film lapping electromagnetic wires. The equipment comprises a pay-off rack, a meter counting device, a straightening device, a polishing device, a cleaning device, an air drying device, a film lapping device, an induction heating device, a rolling device, a water cooling blow-drying device, a traction device and a take-up machine. The equipment further comprises a first paint cylinder, a first glass silk covered head, a second paint cylinder, a second glass silk covered head, a third paint cylinder, a self-adhesive coating paint cylinder and a drying oven assembly. The pay-off rack and the take-up machine are located on the same side. The equipment is compact in structure. With the cooperation with the intensive requirement, operation quality control points are relatively centralized, the operation distance is beneficially shortened, and production efficiency is improved. The self-adhesive glass silk covered composite film lapping electromagnetic wires can be formed on the production equipment at one time, and therefore production efficiency is improved.

Owner:SUZHOU GUANLONG MAGNET WIRE

Object processing method and device as well as electronic equipment

ActiveCN102486715BImprove operational efficiencyReduce distanceInput/output processes for data processingComputer scienceElectric equipment

The invention provides an object processing method and device as well as electronic equipment. The object processing method comprises the following steps of: determining a first object according to a first operation executed by a user; determining at least one second object which has an incidence relation with the first object; indicating the incidence relation between the second object and the first object by utilizing a visualized effect; judging whether the user executes a second operation on the first object; executing a corresponding processing operation on the first object according to the type of one object in the second object when the judged result shows that the user executes the second operation on the first object, wherein the a result generated by the processing operation is the same as the result generated by that the first objected is selected by a pointer, dragged to the position of the second objected and released, and with the adoption of the second operation, the moved distance of the first object is less than the distance between the first object and the second object before the second operation is executed. According to the invention, the operation efficiency of the user is improved.

Owner:LENOVO (BEIJING) LTD

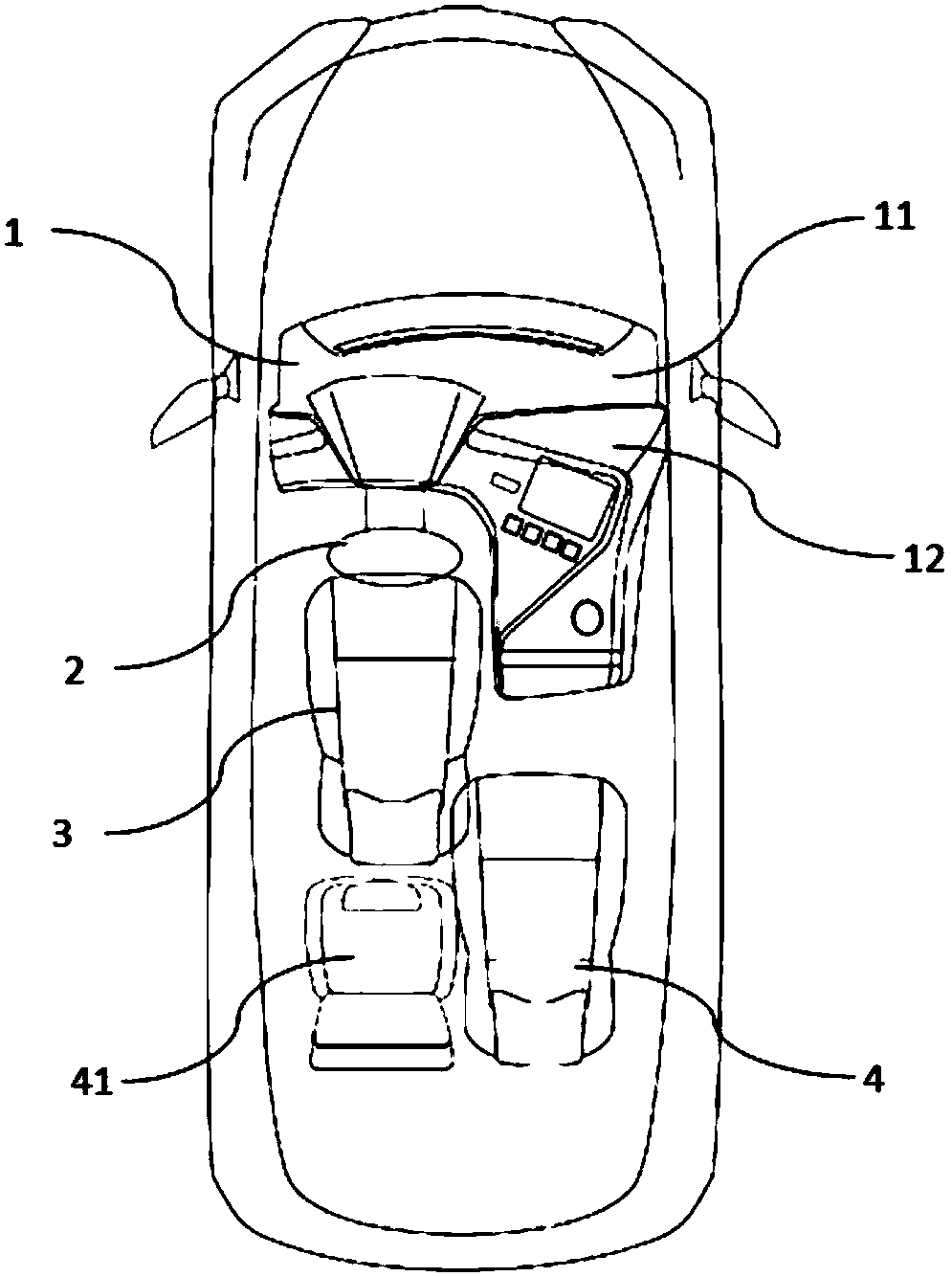

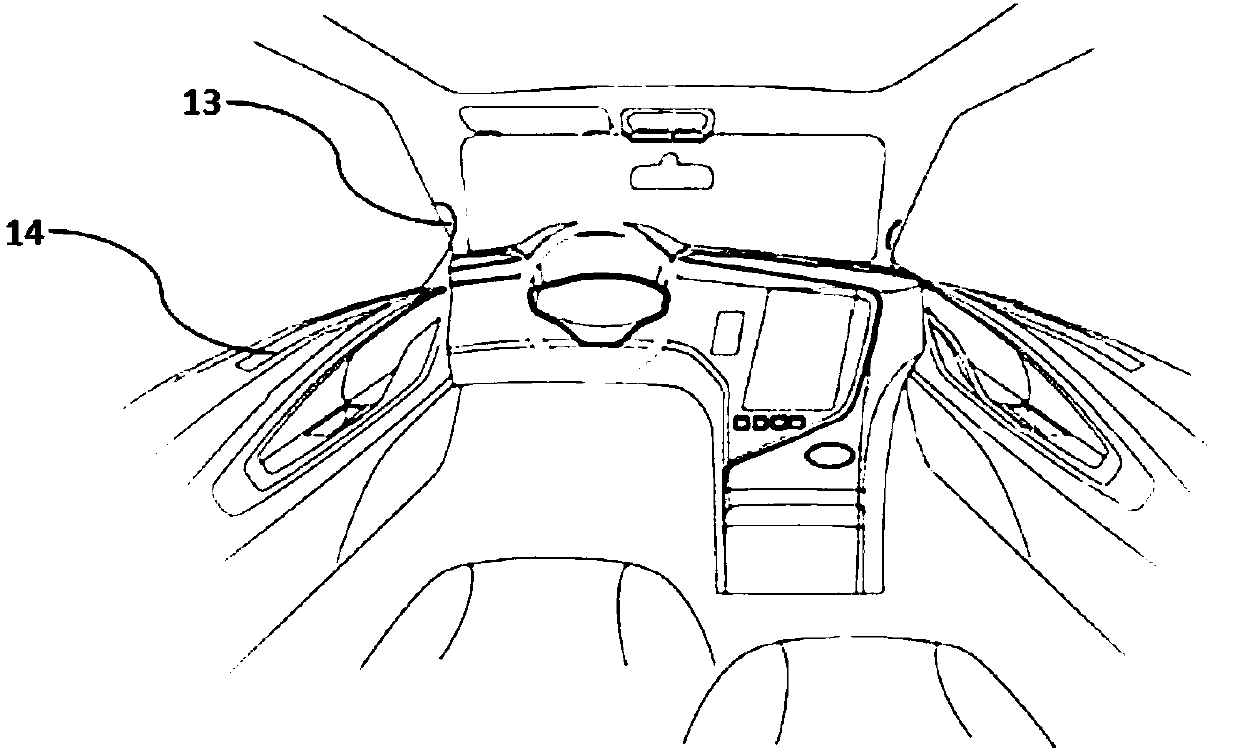

Automotive interior arrangement structure

InactiveCN107792200ASufficient operating spaceAvoid wastingVehicle seatsSuperstructure subunitsSteering wheelEngineering

The invention provides an automotive interior arrangement structure which comprises a dashboard, a steering wheel and a driver seat, wherein the dashboard comprises a front dashboard and a side dashboard; the front dashboard and the side dashboard form an L-shaped structure; and the side dashboard is arranged at the position of a front passenger seat. The automotive interior arrangement structurehas the advantages of providing a driver with sufficient operation space, shortening the distance between the driver and the dashboard, facilitating the operation and control of related functions of avehicle, improving the human-computer interaction efficiency, widening the vision of the driver, effectively improving the safety performance of the vehicle and improving the space utilization of theentire vehicle.

Owner:MICROVAST POWER SYST CO LTD

Image display method, device, and computer-readable storage medium

ActiveCN108009273BEasy to browseBrowse implementationStill image data browsing/visualisationFile/folder operationsInformation processingComputer graphics (images)

The present disclosure relates to an image display method, device, and computer-readable storage medium, and relates to the technical field of information processing. The method includes: acquiring multiple images; the surface of the image ball includes multiple display positions, and different The image is displayed on a different display position among the plurality of display positions. Since different images in multiple images can be collectively displayed on multiple display positions included in the image ball, when users are browsing images, they can conveniently browse multiple images as a whole through the image ball, bringing users A more intuitive visual experience is provided, so that the user can quickly find the image he is interested in from the multiple images. Moreover, when the user browses the images, the browsing of multiple images can be realized by operating the image ball. Compared with the related art in which multiple images are tiled and displayed on multiple display pages, the user scrolls up and down to display the pages. Multiple images are browsed, shortening the operating distance.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

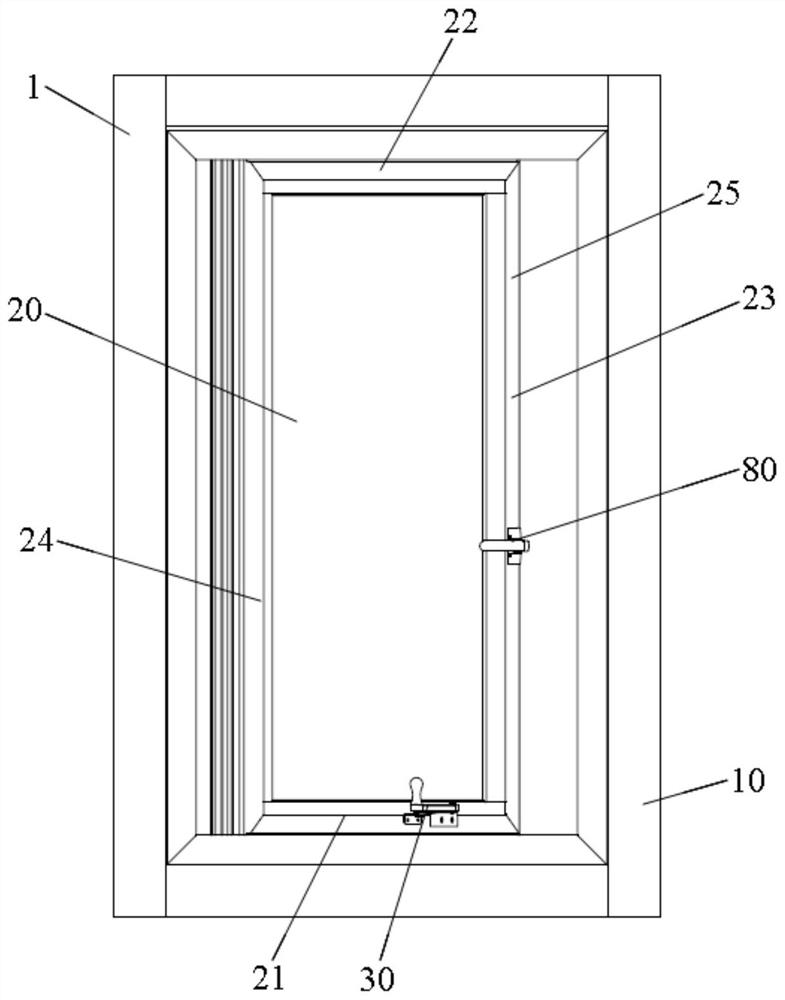

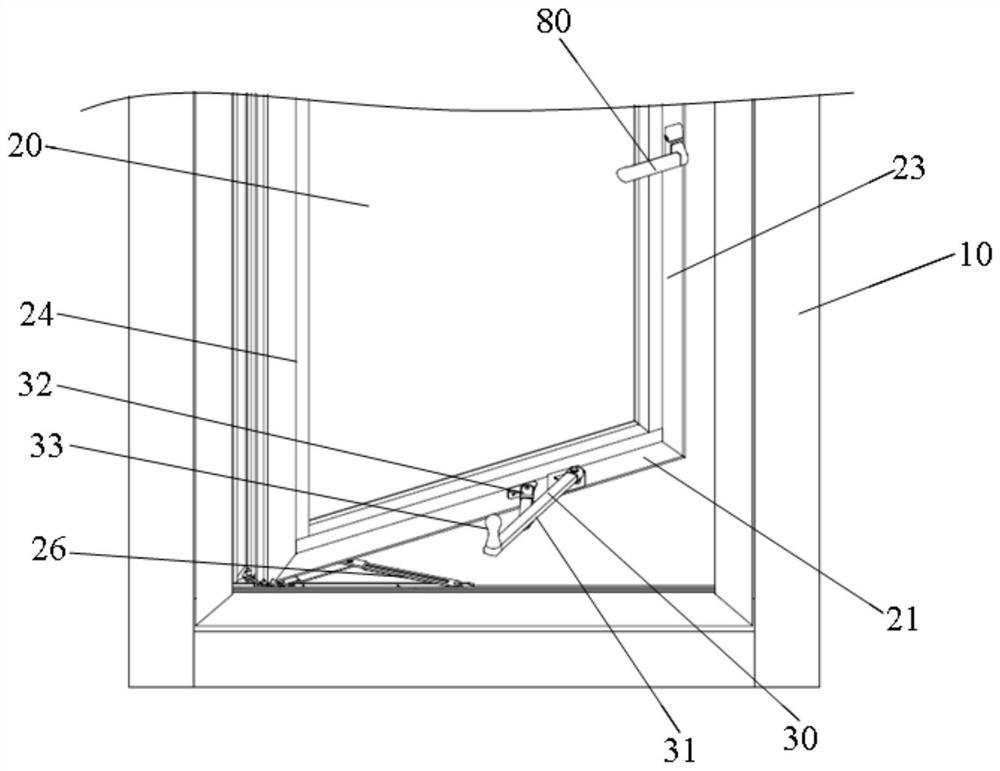

Window

PendingCN112502572AShorten the operating distanceEnsure safetyMan-operated mechanismWing arrangementsEngineeringMechanical engineering

Owner:吉田建材(苏州)有限公司

An auxiliary ventilation device for dust and smoke removal in tunnel construction

ActiveCN106761890BNo pollutionShorten the operating distanceDispersed particle separationDust removalFiltrationProduct gas

The invention discloses a dedusting smoke-removing assistant ventilating device for tunnel construction. One side of the inlet of a dedusting box (7) is connected with a dust hood (1), and the other side of the dedusting box is connected with the inlet of a drawing-type ventilator (14). A smoke-removing box (16) is installed at the tail part of the device, and connected with the outlet of the drawing-type ventilator. The foul air generated in the tunneling process is pumped into the dedusting box through the dust hood so as to execute the dust filtration, and the air is pumped into the smoke-removing box so as to execute the fume treatment, finally the purified air is discharged from the outlet of the drawing-type ventilator. The smoke-removing box is capable of conveying sodium hydroxide solution in a liquid inlet box to a spray pipeline (9) through a water pump (20) and spraying by an atomizer (12), sprayed alkaline solution mist executes the neutral reaction with the acid gas in the fume, so that the purification treatment of the fume is realized. The dedusting smoke-removing assistant ventilating device for the tunnel construction is capable of integrating the dust filtration, the fume treatment and the assistant ventilation, realizing the efficient purification of the foul air, and improving the ventilation condition in the tunnel.

Owner:CHINA UNIV OF MINING & TECH

Parameter setting method and device for medical equipment and medical equipment

ActiveCN102441215BIntuitive input operationAvoid frequent operationsRespiratorsMedical equipmentInput control

The invention discloses a parameter setting method and device for medical equipment and medical equipment. The method comprises the following steps of: presetting data input controls of parameter items, and building a first corresponding table of the parameter items and the data input controls, wherein the data input controls include basic keys for all the parameter items and additional keys dynamically appointed in the first corresponding table according to the parameter items; inquiring the first corresponding table according to the to-be-adjusted parameter items input by a user, and loading the data input controls corresponding to the to-be-adjusted parameter items; receiving novel parameter values and parameter modifying instructions input by the user through the data input controls; and sending the modified novel parameter values to a lower computer, and confirming if the parameter values are modified according to the feedback from the lower computer. According to the parameter setting method and device disclosed by the invention, the parameter setting process is more intuitive and the operating distance is shortened, so that the parameters setting process can be finished in a step; and a rotary encoder is avoided being operated frequently, so that the operator can more quickly complete the parameter setting process.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com