Laser welding method

A technology of laser welding and laser welding head, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., and can solve problems such as troublesome operation and damage to health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

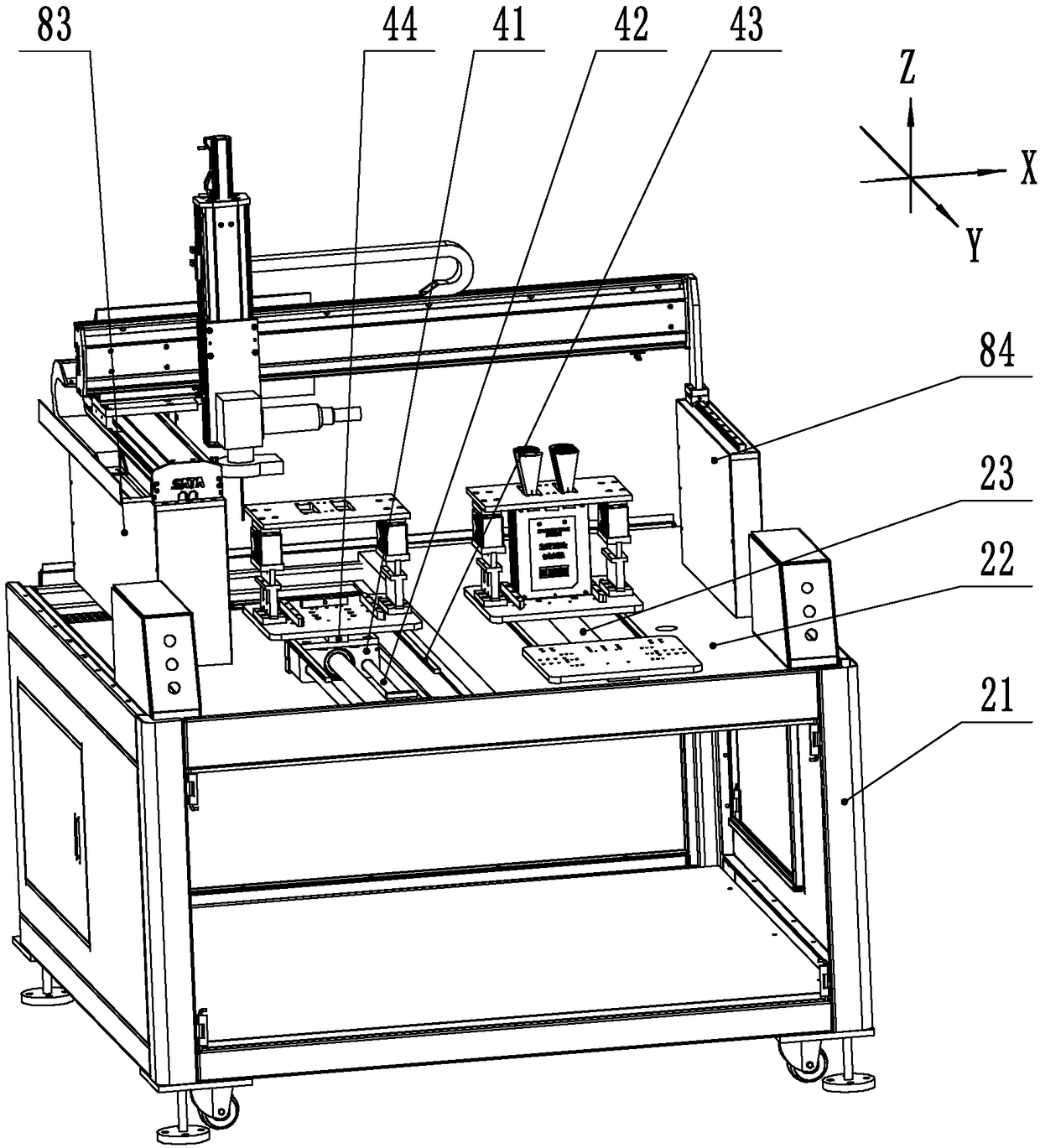

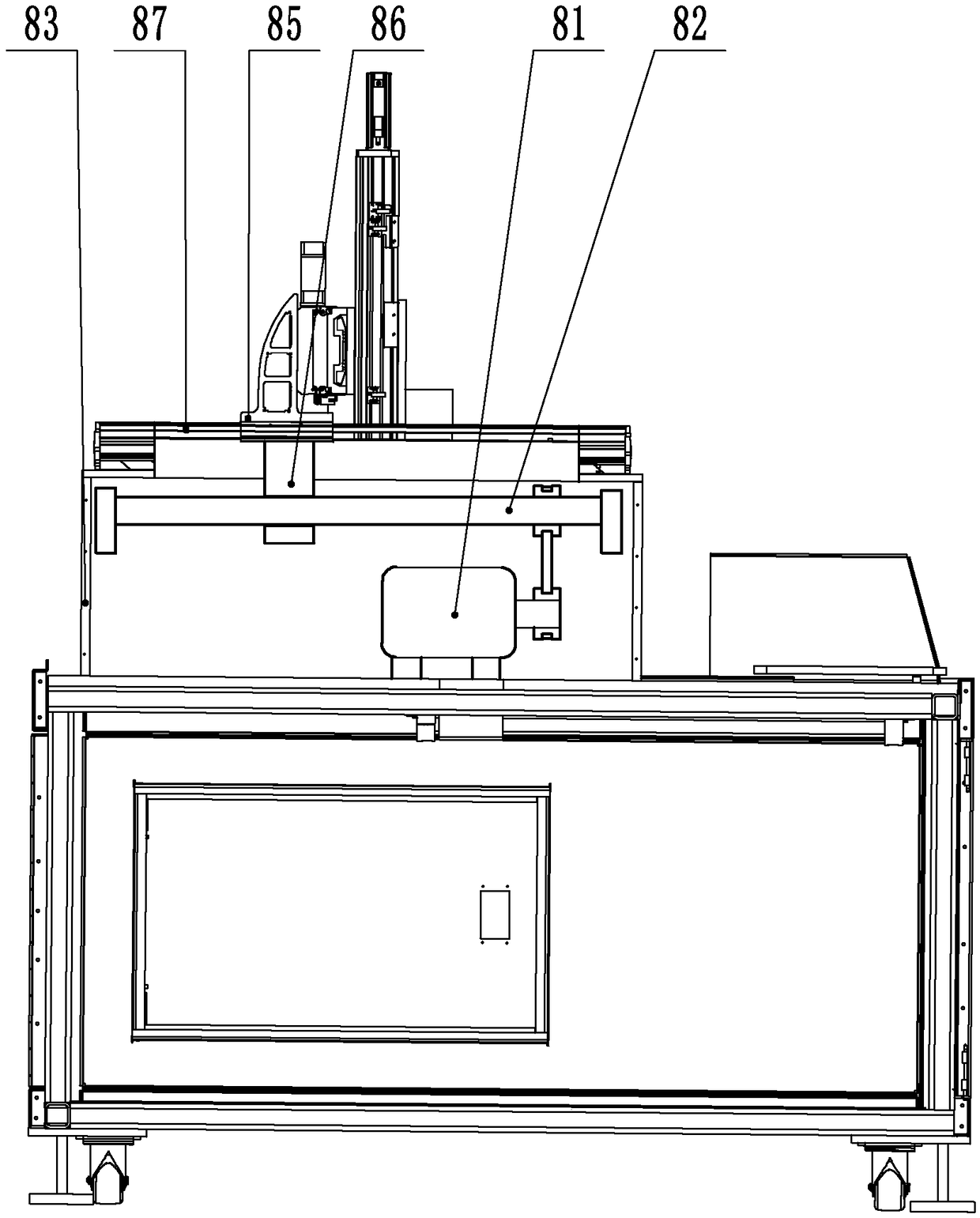

[0036] As an improved specific embodiment, the control mechanism 3 includes an X moving device, a Y moving device and a Z moving device, and the Y moving device includes a Y motor 81, a Y screw 82, a Y chassis 83 and a Y support 84 arranged along the Y direction. , the Y chassis 83 and the Y support 84 are arranged on opposite sides of the workbench 2 parallel to each other and extend along the direction of the operating station 5 and the processing zero position 6, and the top of the Y chassis 83 and the top of the Y support 84 are set There is a Y guide rail 87, a Y motor 81 is installed in the Y case 83, a Y screw 82 is rotated and installed in the Y case 83 and connected with the Y motor 81, a Y guide sleeve 85 is arranged on the X moving device, and the Y guide sleeve 85 and the Y guide rail 87 engagement, the bottom of the Y guide sleeve 85 is fixed with a Y screw sleeve 86, the Y screw sleeve 86 is engaged with the Y screw rod 82, and the X moving device includes an X mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com