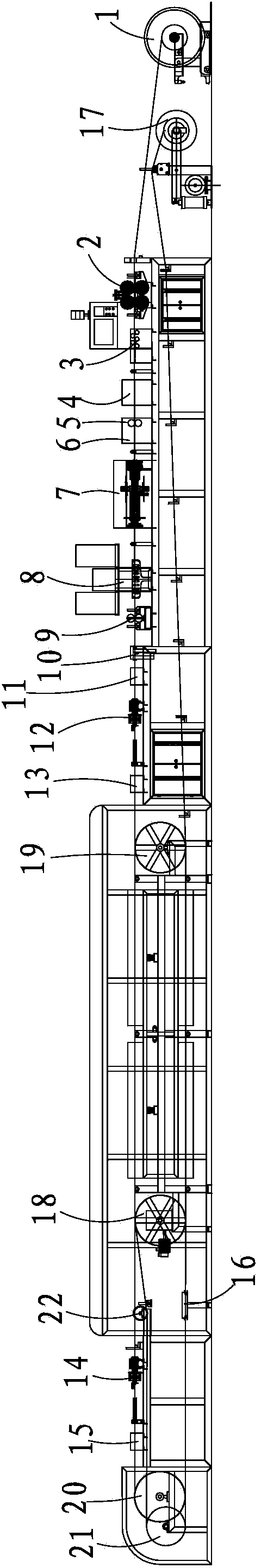

Equipment for manufacturing self-adhesive glass silk covered composite film lapping electromagnetic wires

A composite film and manufacturing equipment technology, applied in the direction of cable/conductor manufacturing, circuit, insulated cable, etc., can solve the problems of low efficiency, long production line, etc., and achieve the effect of improving production efficiency, compact equipment structure, and shortening the operating distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

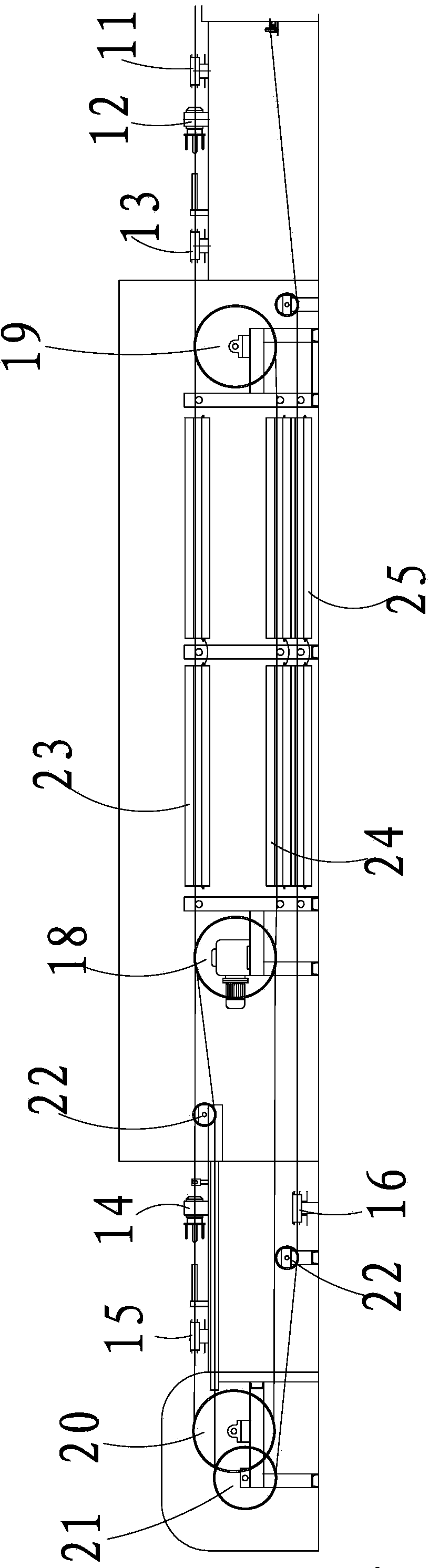

[0024] Embodiment 1: Production of small gauge magnet wire

[0025] as attached figure 2 As shown, the traction device includes a driving wheel 18 positioned between one end of the oven assembly and the second glass wool head 14, a driven wheel 19 positioned between the other end of the oven assembly and the second paint vat 13, and a third paint vat located between 15 and the first guide wheel 20 and the second guide wheel 21 between the self-adhesive coating paint vat 16, and a plurality of bridge wheels 22 for changing the direction of the electromagnetic wire. There are 2 bridge wheels 22, and a bridge wheel 22 is positioned between the driving wheel 18 and the second glass fiber toe cap 14, and another bridge wheel 22 is positioned between the second guide wheel 21 and the self-adhesive coating paint vat 16.

[0026] The oven assembly includes a first main oven 23 and a second main oven 24 for baking the dipped magnet wire, and an auxiliary oven 25 for baking the magnet...

Embodiment 2

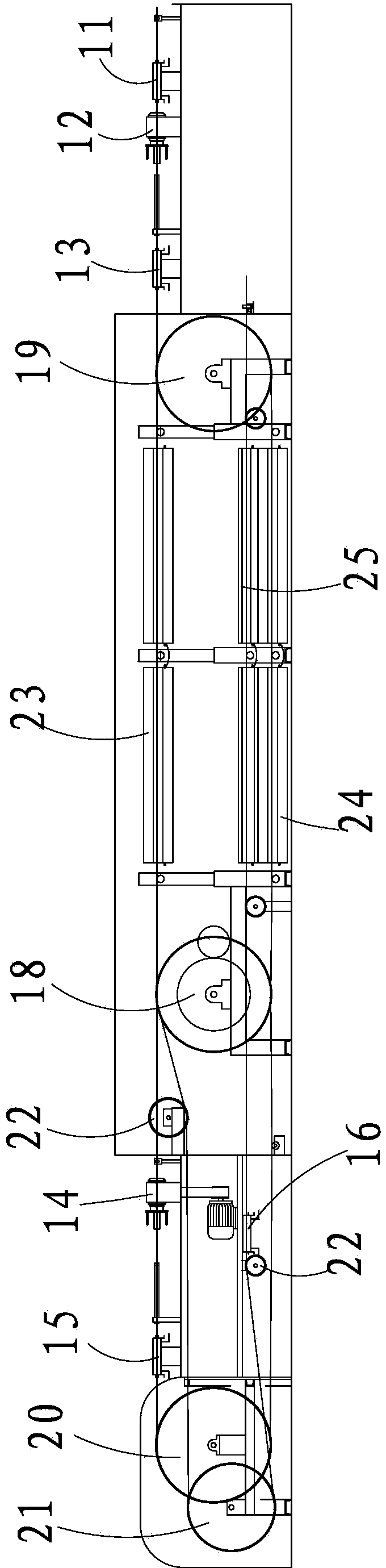

[0029] Example 2: Production of medium-grade gauge magnet wire

[0030] as attached image 3 As shown, the traction device includes a driving wheel 18 positioned between one end of the oven assembly and the second glass wool head 14, a driven wheel 19 positioned between the other end of the oven assembly and the second paint vat 13, and a third paint vat located between 15 and the first guide wheel 20 and the second guide wheel 21 between the self-adhesive coating paint vat 16, and a plurality of bridge wheels 22 for changing the direction of the electromagnetic wire. There are 2 bridge wheels 22, and a bridge wheel 22 is positioned between the driving wheel 18 and the second glass fiber toe cap 14, and another bridge wheel 22 is positioned between the second guide wheel 21 and the self-adhesive coating paint vat 16.

[0031] The oven assembly includes a first main oven 23 and a second main oven 24 for baking the dipped magnet wire, and an auxiliary oven 25 for baking the mag...

Embodiment 3

[0034] Embodiment 3: Production of large wire gauge magnet wire

[0035] as attached Figure 4 As shown, the traction device includes a driving wheel 18 positioned between one end of the oven assembly and the second glass wool head 14, a driven wheel 19 positioned between the other end of the oven assembly and the second paint vat 13, and a third paint vat located between 15 and the first guide wheel 20 and the second guide wheel 21 between the self-adhesive coating paint vat 16, and a plurality of bridge wheels 22 for changing the direction of the electromagnetic wire. There are 3 bridge wheels 22, one bridge wheel 22 is located between the driving wheel 18 and the second glass fiber cap 14, and the other 2 bridge wheels 22 are located between the second guide wheel 21 and the self-adhesive coating paint vat 16 .

[0036] The oven assembly includes a first main oven 23 and a second main oven 24 for baking the dipped magnet wire, and an auxiliary oven 25 for baking the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com