Dedusting smoke-removing assistant ventilating device for tunnel construction

A technology of tunnel construction and ventilation device, applied in safety devices, dust prevention, fire prevention and other directions, can solve the problems of large floor space, water mist affecting sight, easy damage of filter bags, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

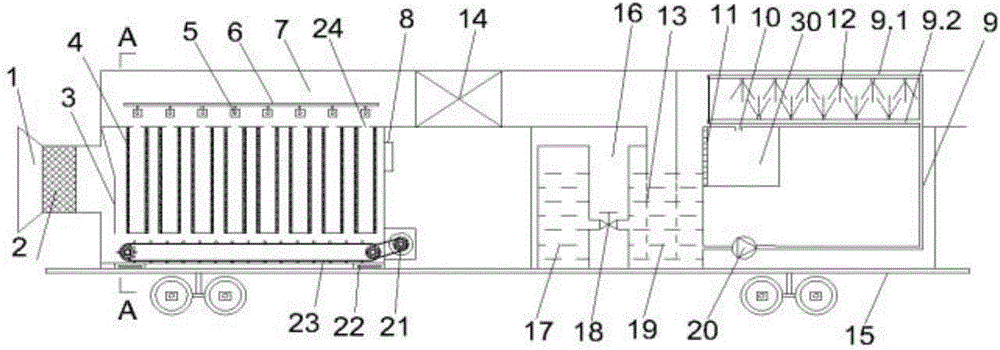

[0023] Such as figure 1 The shown auxiliary ventilation device for dust removal and smoke removal in tunnel construction includes a dust removal box 7, a draw-out fan 14 and a smoke removal box 16 that are centrally arranged on a flatbed truck 15. The inlet side of the dust removal box 7 is connected with a suction Dust cover 1, the other side of dust removal box body 7 is connected with the inlet of draw-out fan 14, and smoke removal box body 16 is arranged on the afterbody of this device, is connected with the outlet of draw-out fan 14,

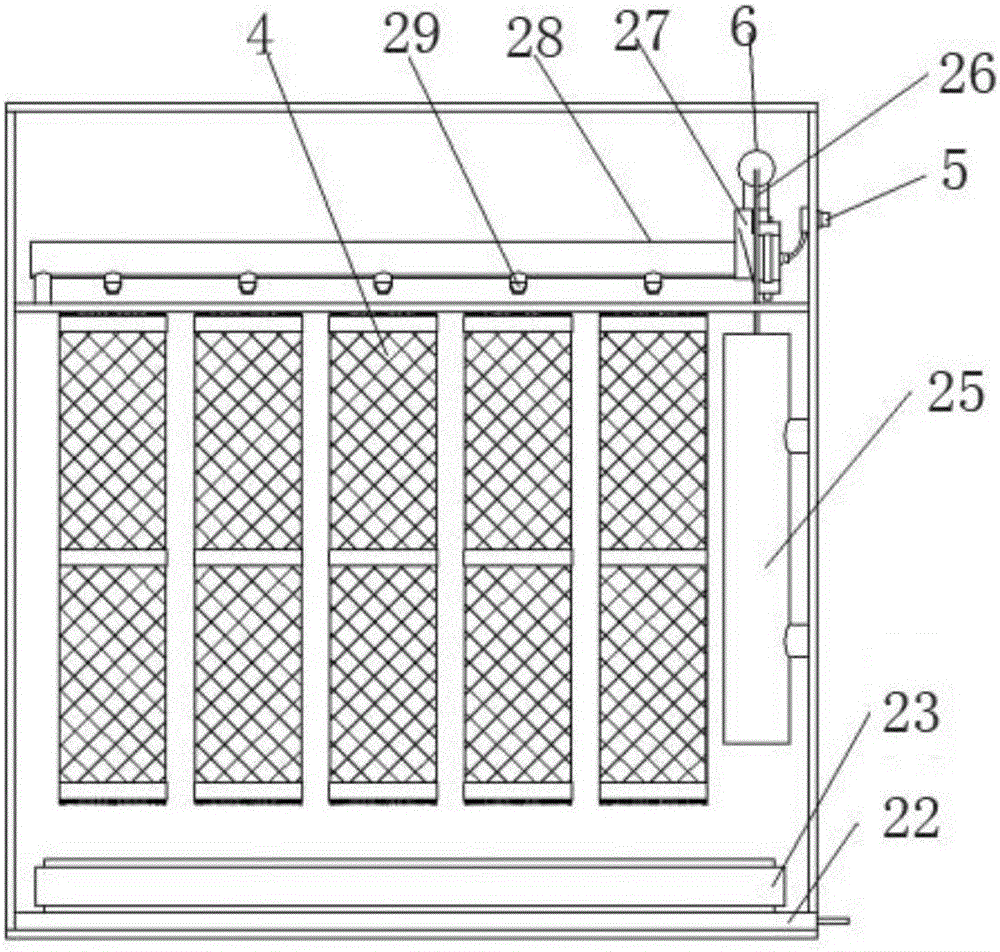

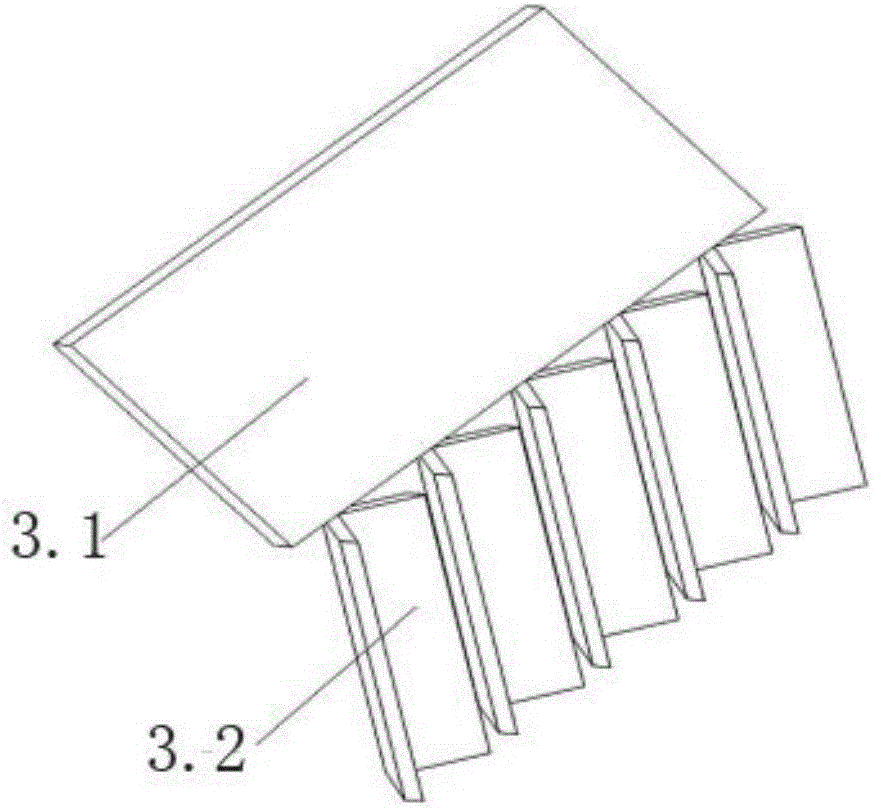

[0024] The dust removal box 7 includes a dry filter dust removal part, a pulse spray dust removal part and a dust collection and unloading part. The dry filter dust removal part is composed of a metal filter 2, a deflector 3 and a filter cartridge 4. The metal filter 2 is arranged on the suction Inside the dust cover 1, the upper e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com