Contactor

A contactor and contact part technology, applied in relays, electromagnetic relays, electromagnetic relay detailed information, etc., can solve the problems of difficult to achieve automatic assembly, low production efficiency, troublesome winding, etc., to facilitate automatic assembly, improve production efficiency, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

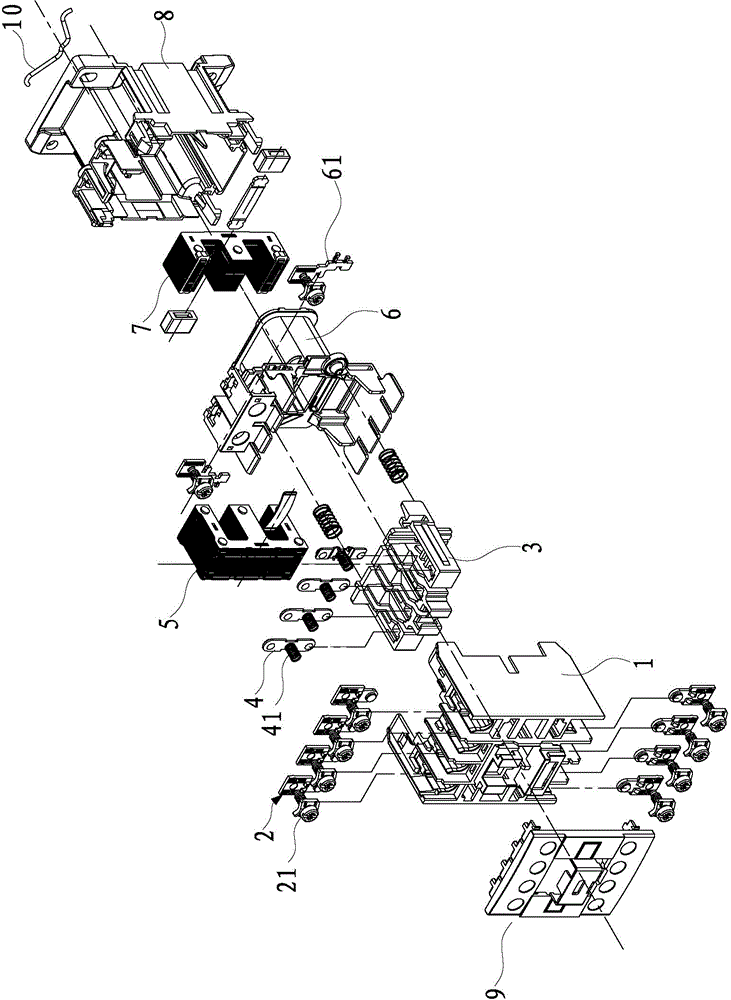

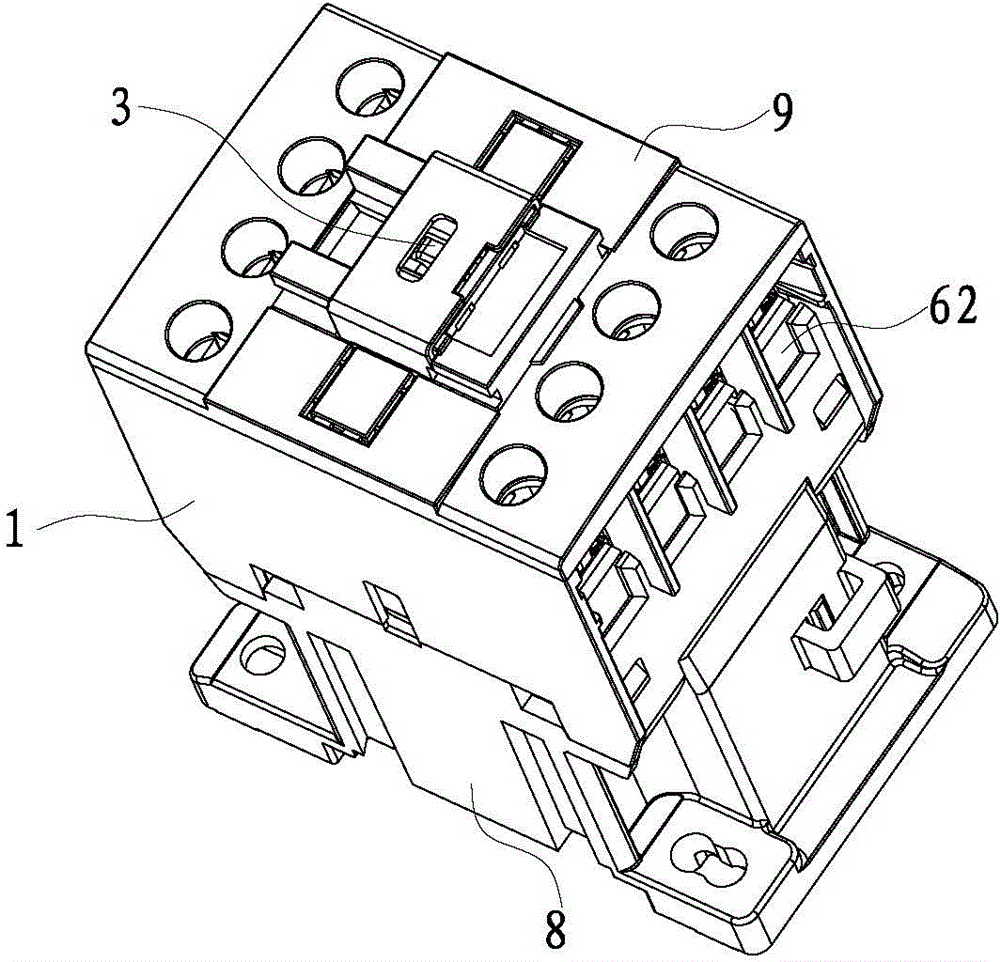

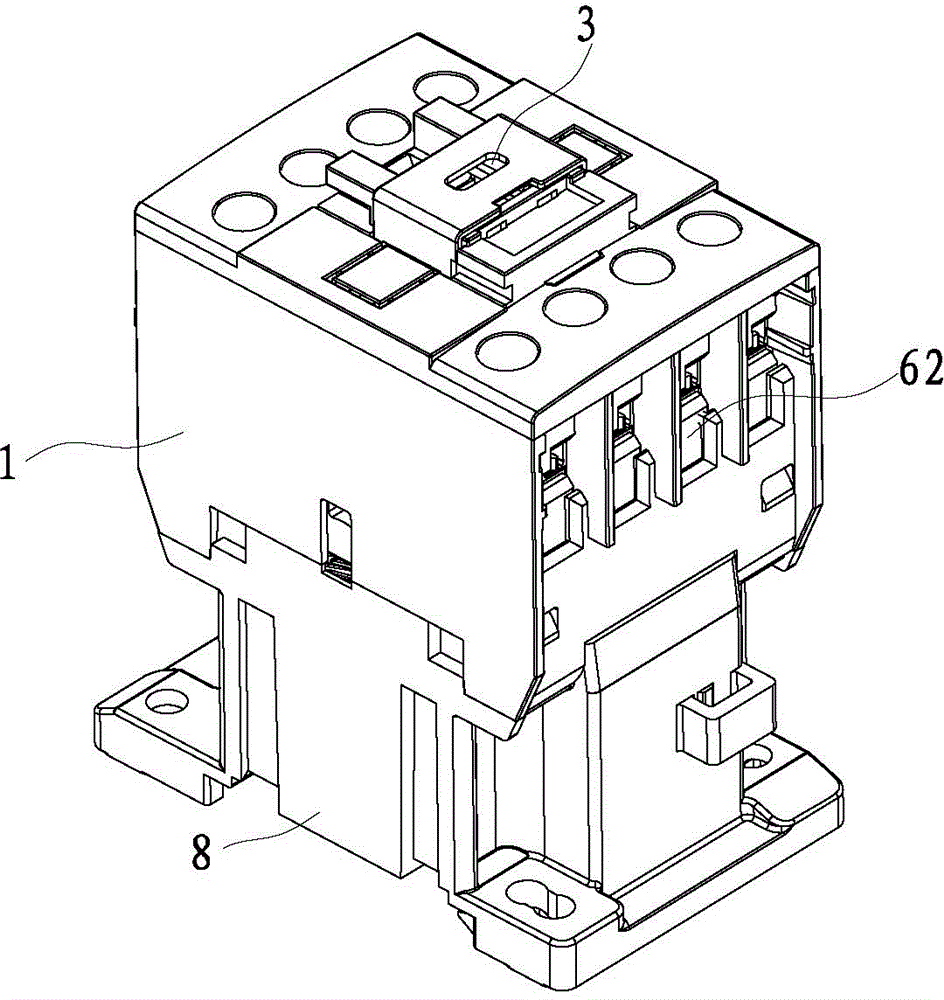

[0053] refer to Figure 1 to Figure 20 As shown, a contactor disclosed by the present invention includes a body 1, a static contact 2, a contact support 3, a moving contact 4, a moving iron core 5, a bobbin 6, a static iron core 7, a base 8 and a cover 9.

[0054] The contact support 3 is movably installed in the body 1, the coil bobbin 6 is placed in the base 8, and inserted into the body 1, and the body 1 is installed on the base; the integrated cover 9 with IP2X protection level is installed on the body 1.

[0055] Such as Figure 18 and Figure 19 As shown, a hollow part 91 is formed on the cover 9, and the hollow part 91 is used for the contact support 3 of the contactor to be exposed to the cover 9 to partially accommodate it. At the same time, two sets of functional auxiliary modules can also be installed on the hollow part 91. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com