Ground lead clip

A grounding wire clip and grounding wire technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of safe operation buried, affecting the physical fitness of operators, and taking a long time to remove the grounding wire clip. The effect of working efficiency, saving the operation time of switching off, and shortening the time of removing the ground wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

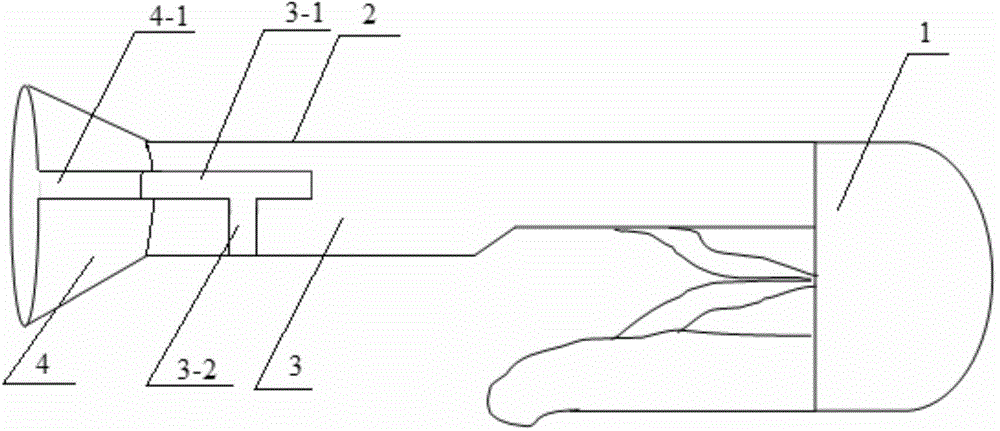

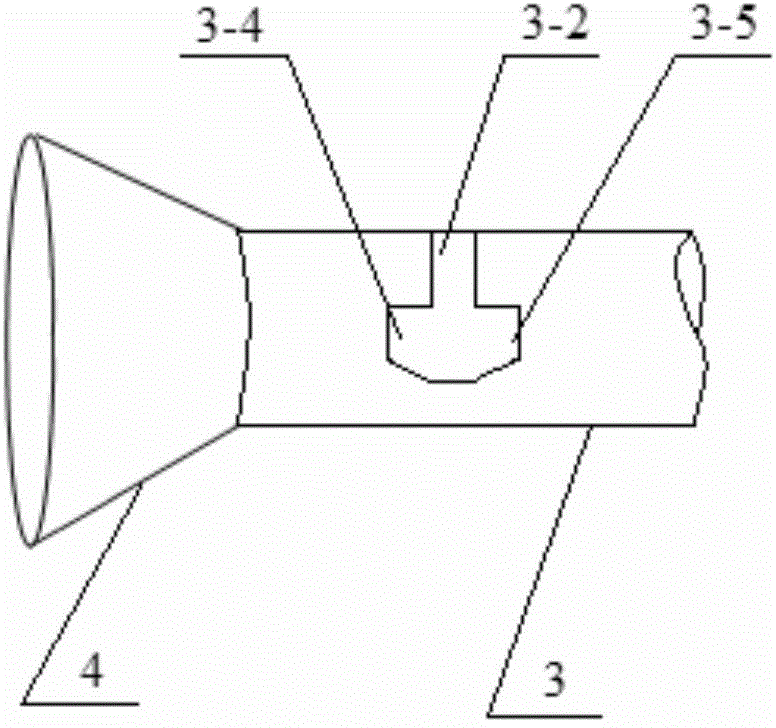

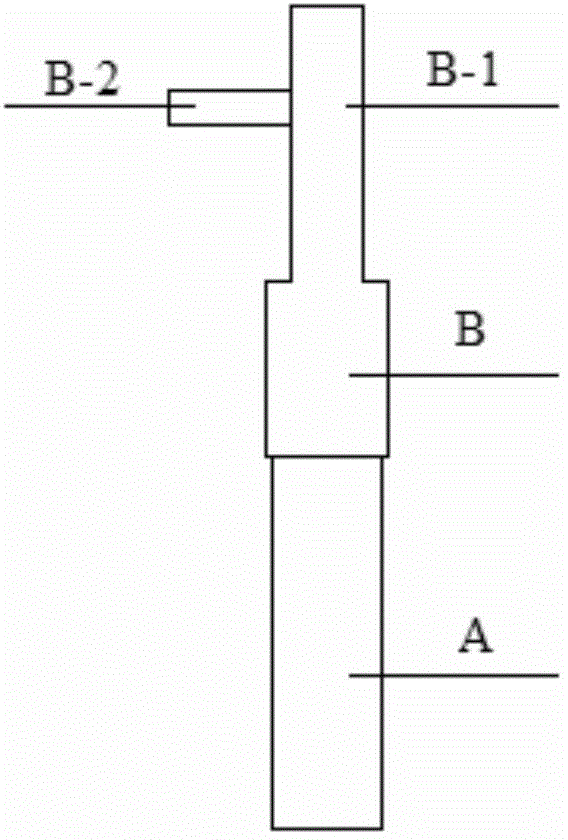

[0013] Specific Embodiment 1: A grounding wire clamp in this embodiment includes a grounding wire clamp body 1 and a sleeve 2 connected to an insulating pull rod. The grounding wire clamp body 1 is provided with a chuck, which is characterized in that the sleeve 2 is made of The straight tube body 3 and the trumpet tube body 4 are composed of the straight tube body 3 and the narrow mouth end of the horn tube body 4 buttted into one structure, and the tube wall of the horn tube body 4 is along the horn type The pipe body 4 is provided with a long first channel 4-1 in the axial direction, and the second channel 3-1 is opened along the axial direction of the straight tube body 3 on the tube wall of the straight tube body 3, and the first channel 4 -1 communicates with the second tunnel 3-1, and there is a turning tunnel 3-2 perpendicular to the second tunnel 3-1 on one side of the closed end of the second tunnel 3-1, and one end of the steering tunnel 3-2 is connected to the secon...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that: the ground wire clamp body 1 and the sleeve 2 are connected by metal crimping, and the interfaces on both sides are reinforced with rivets. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the material of the ground wire clip body 1 is cast aluminum alloy. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com