Conductive contact finger, and wiring board using the conductive contact finger

A technology of conductive contacts and wiring boards, which is applied in the direction of conductive connections, circuits, connections, etc., can solve the problems of loose contact, inaccurate resistance value, hidden safety hazards, etc., and achieve the effect of uniform and good contact and accurate resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

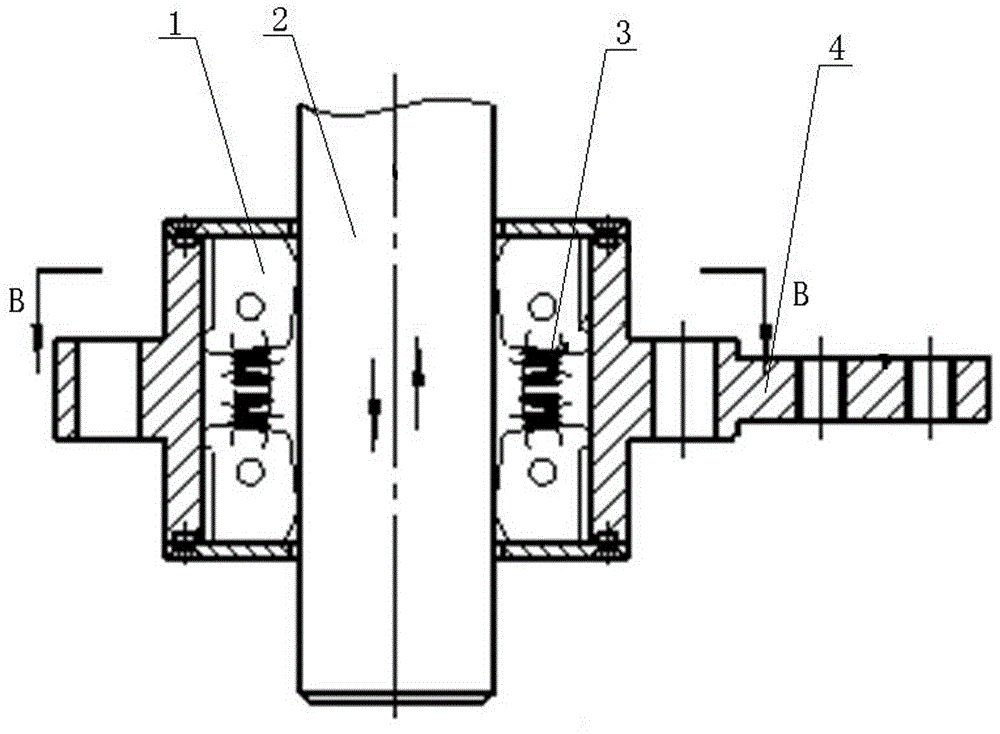

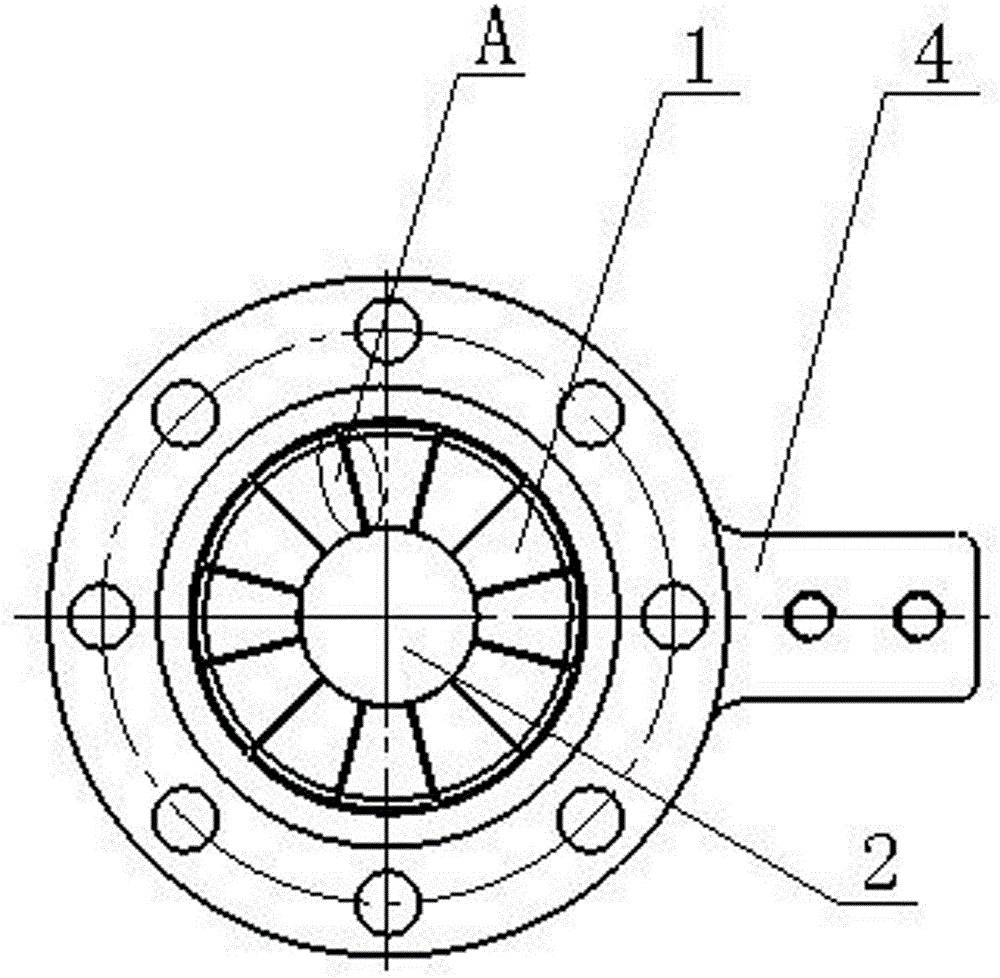

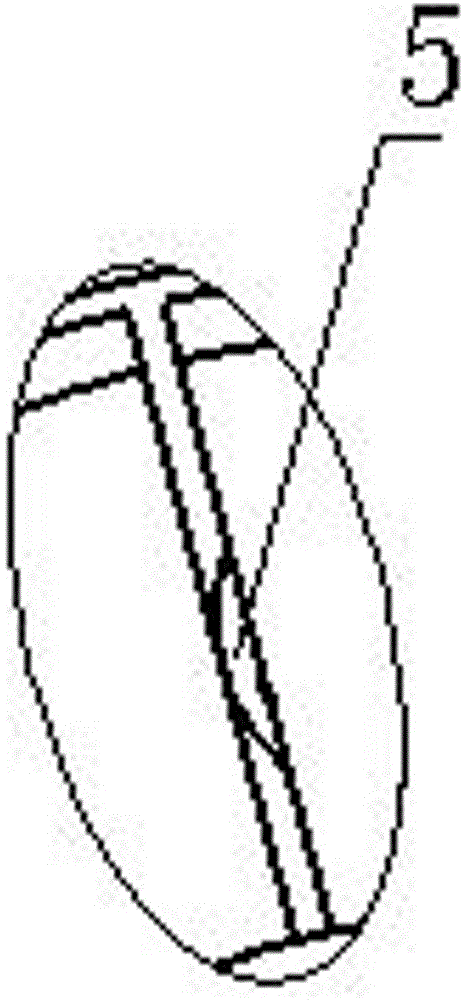

[0026] Embodiment 1 of the wiring board of the present invention: as Figure 1 to Figure 5 As shown, the wiring board includes a wiring board body 4, and the wiring board body 4 is provided with mounting holes for installing conductive contacts. In the mounting holes, upper and lower layers of conductive contacts are arranged along the inner circumference thereof, and each layer of conductive contacts They are all arranged around the center line of the installation hole in the circumferential direction and have a central through hole for the corresponding conductive rod 2 to pass through. Each layer of conductive contact fingers includes a plurality of conductive contact fingers 1, and each conductive contact finger 1 has a The inner wall surface 11 that is electrically connected to the corresponding conductive rod 2, the outer wall surface 12 that is used to contact and electrically connect with the wiring board body 4, and the side surfaces 13 that are respectively arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com