Differential gear for a motor vehicle

A technology for differentials and motor vehicles, which is applied in the direction of differential transmissions, transmissions, mechanical equipment, etc., can solve problems such as high manufacturing costs, and achieve the effect of low manufacturing costs and avoiding methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

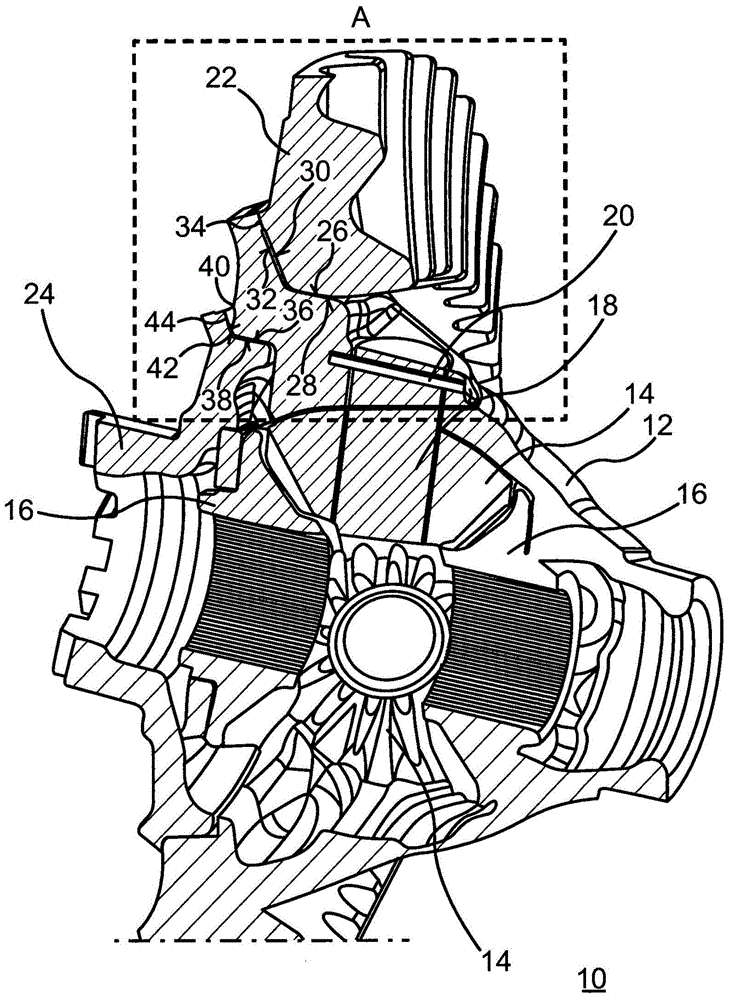

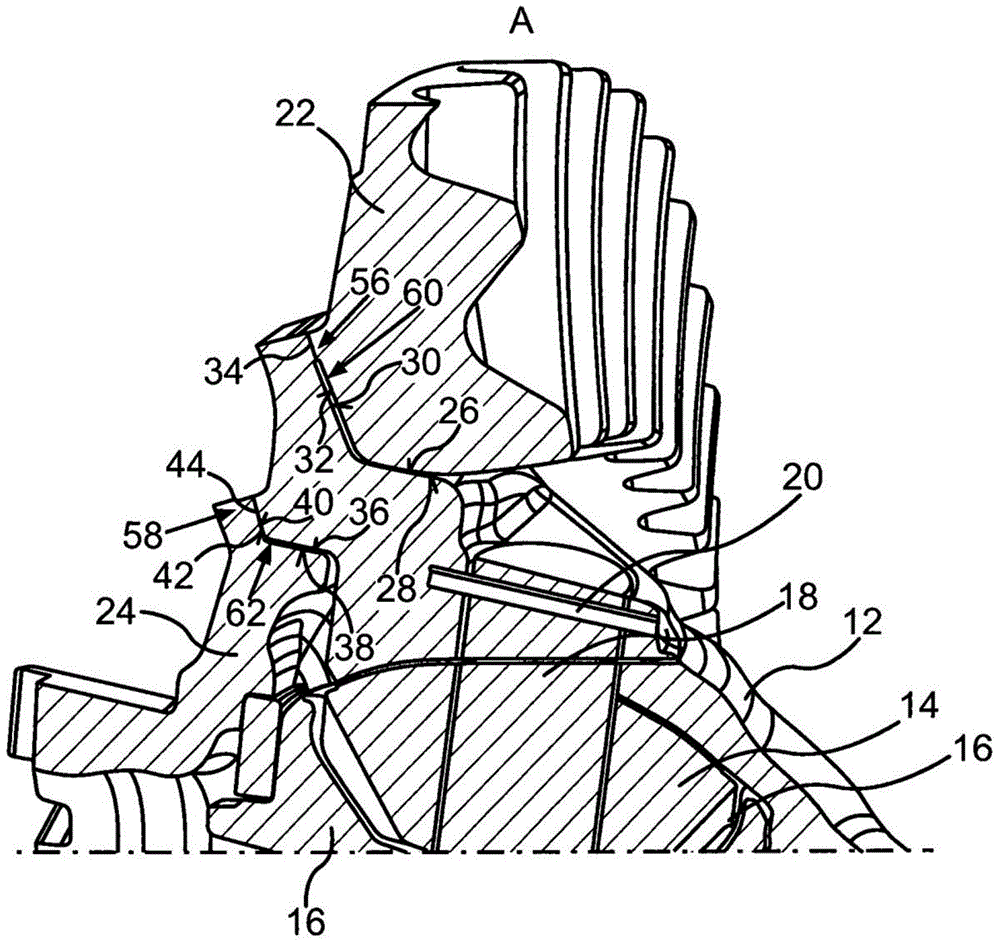

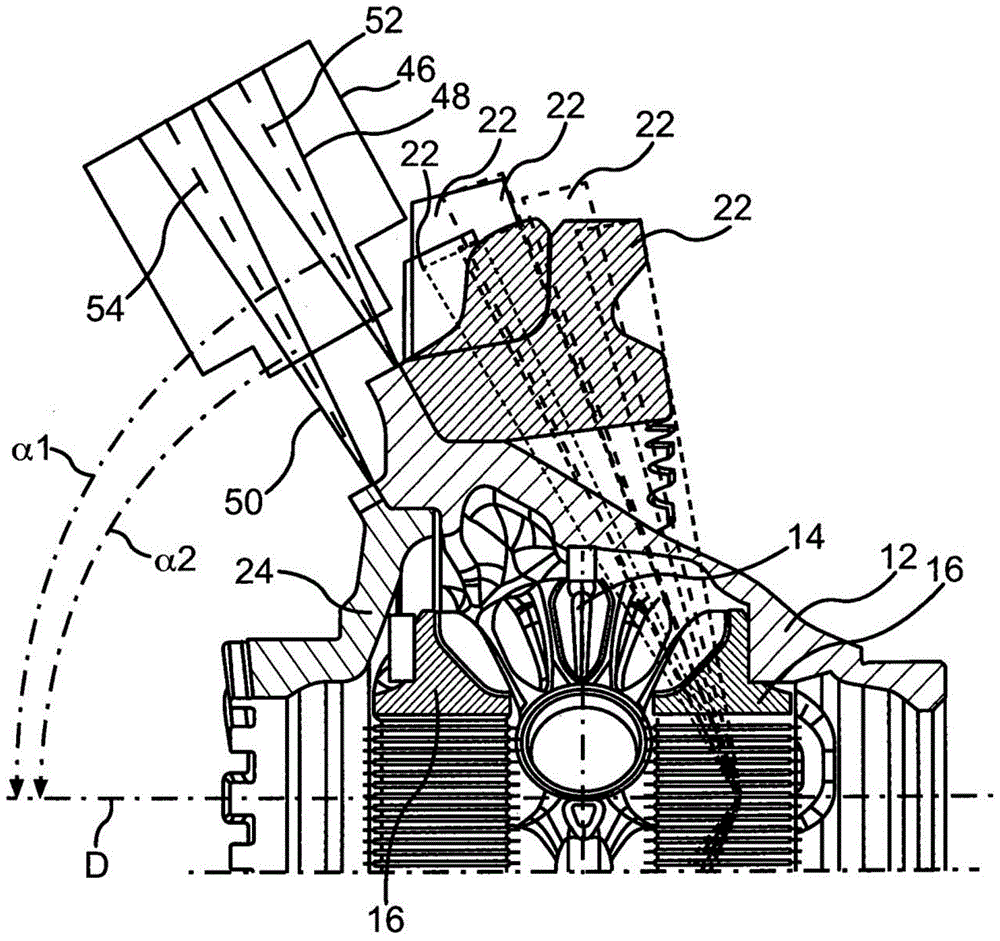

[0030] figure 1 and 2 A differential 10 for a motor vehicle is shown. The differential 10 comprises a first housing part 12 as a first transmission element, which is referred to as a differential housing and serves to accommodate adjusting gears 14 , 16 , which are here designed as bevel gears. The adjusting gear 16 can be connected in a rotationally fixed manner to a drive shaft of the motor vehicle so that the drive shaft of the motor vehicle and via said drive shaft the wheels are driven.

[0031] The adjusting gear 14 is designed, for example, as a warm forged component and is held on the first housing part 12 by means of corresponding screws 18 . Corresponding screws 18 are fastened to the first housing part 12 by means of pins 20 . This means that the screw 18 is immovable relative to the first housing part 12 , whereas the respective adjustment gear 14 is rotatable about it relative to the screw 18 .

[0032] The differential 10 includes a crown gear 22 as a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com