croissant machine

A technology of bread machine and ox horn, applied in the direction of dough forming and cutting equipment, etc., can solve the problems of slow turning process, low production efficiency, high labor cost, etc., and achieve the effect of efficient production, liberating labor force, and fast rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, objectives and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0018] An embodiment of the invention is:

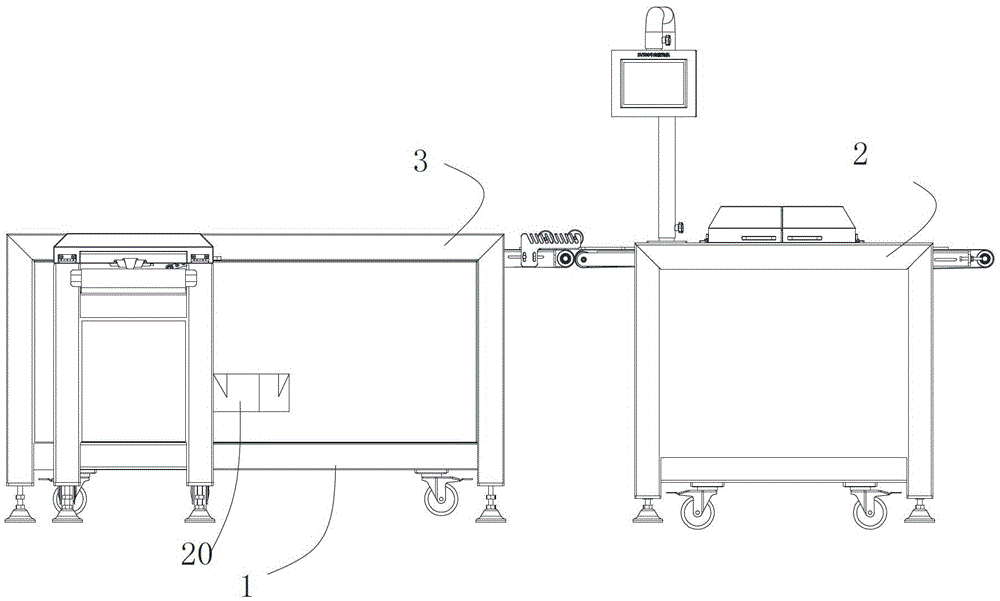

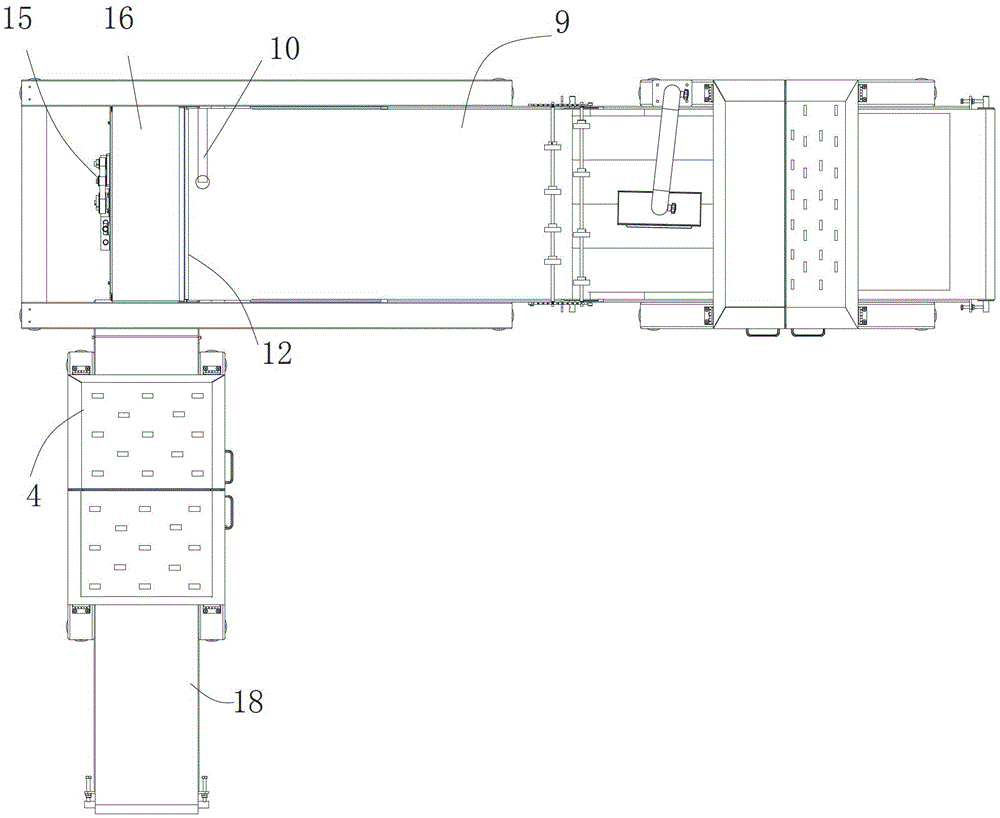

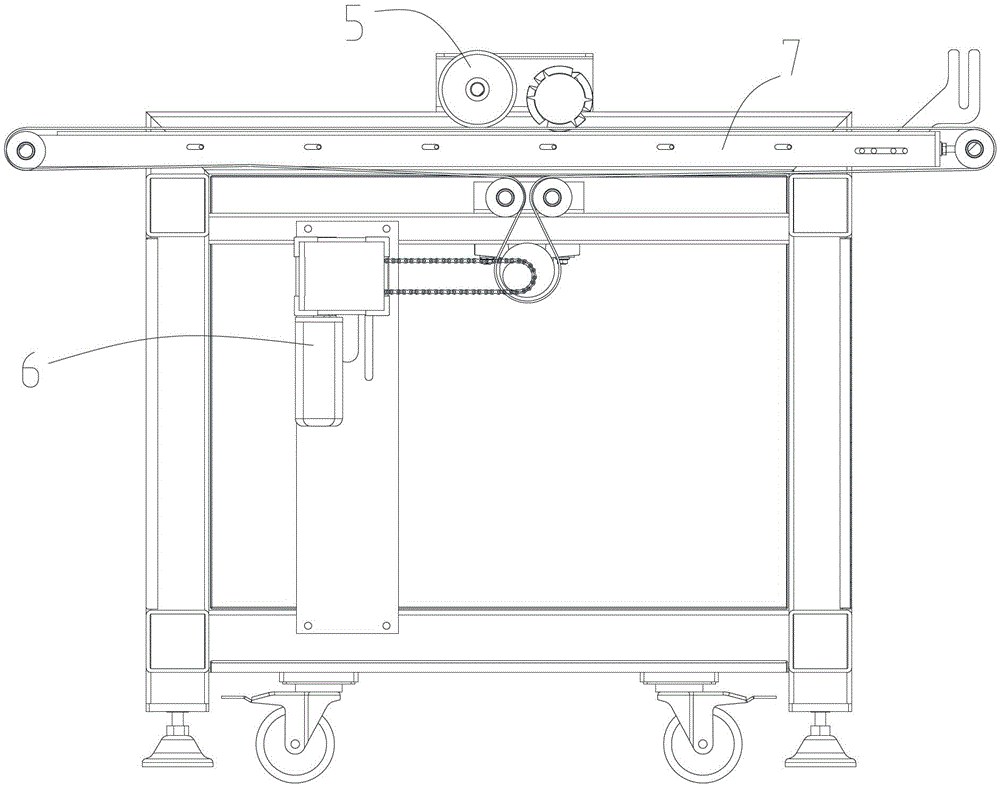

[0019] A croissant machine, comprising: a frame 1, a dividing table 2, a rotating table 3, a rolling table 4 and a PLC controller 20; the dividing table 2, the rotating table 3 and the rolling table 4 are installed on the frame 1; A cutting knife 5, a feed conveyor motor 6 and a feed conveyor belt 7 are arranged on the top; a rotary conveyor motor 8, a rotary conveyor belt 9, a photoelectric sensor 10, a slider motor 11, a roller 12, and a slider 13 are arranged on the rotary table , guide rail 14, steering motor 15, steering conveyor belt 16 and steering conveyor belt motor 21; guide rail 14 has two, is respectively fixed on the both sides of frame 1; two guide rails 14 respectively wear a slide block 13, slide block 13 slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com