Mounting method of engine suspension device for four-cylinder diesel engine

A technology of engine mount and installation method, which is applied in the direction of power plant, jet propulsion device, internal combustion propulsion device, etc., and can solve the problems of increased diesel engine vibration, severe vibration, unreasonable installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

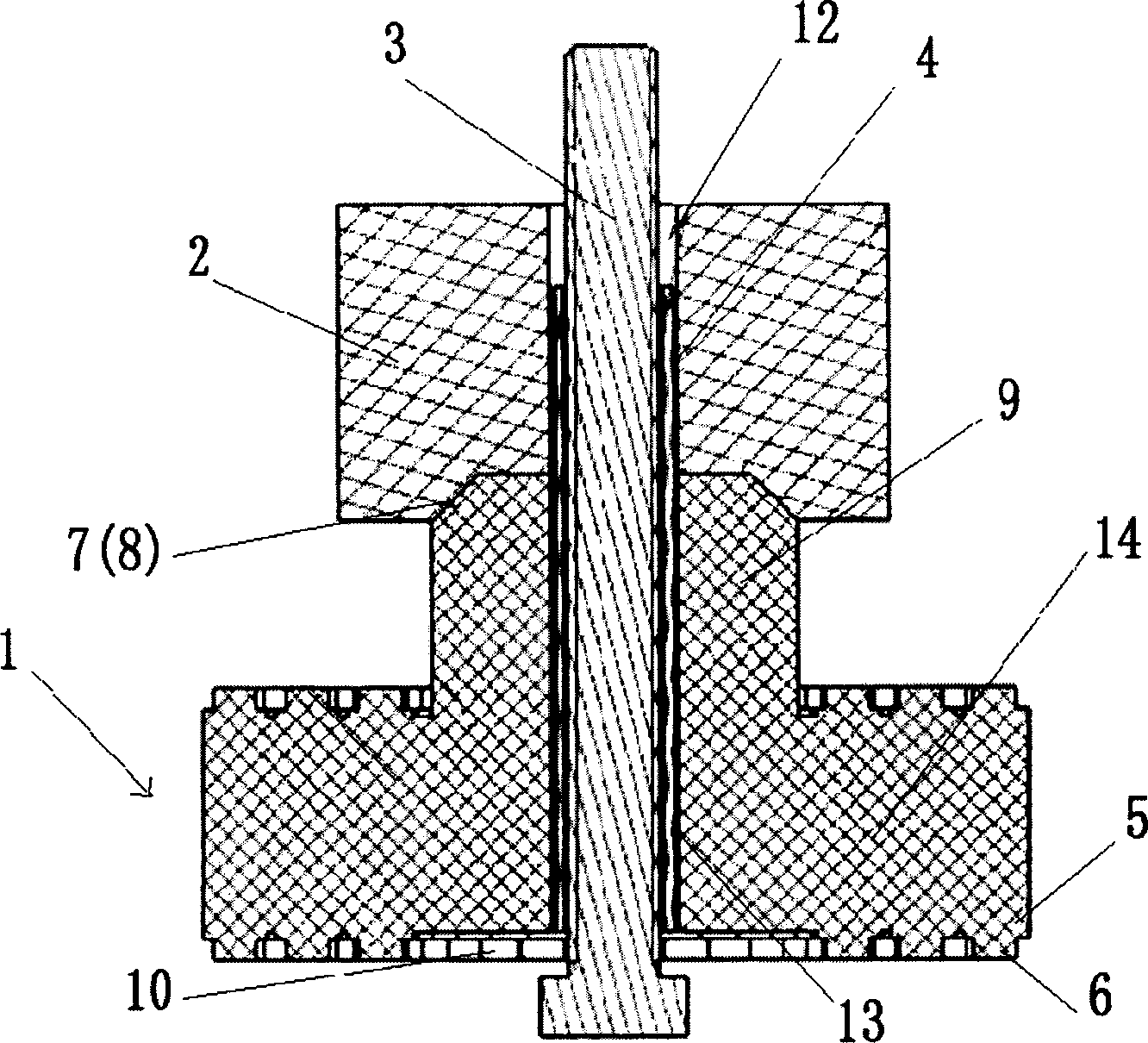

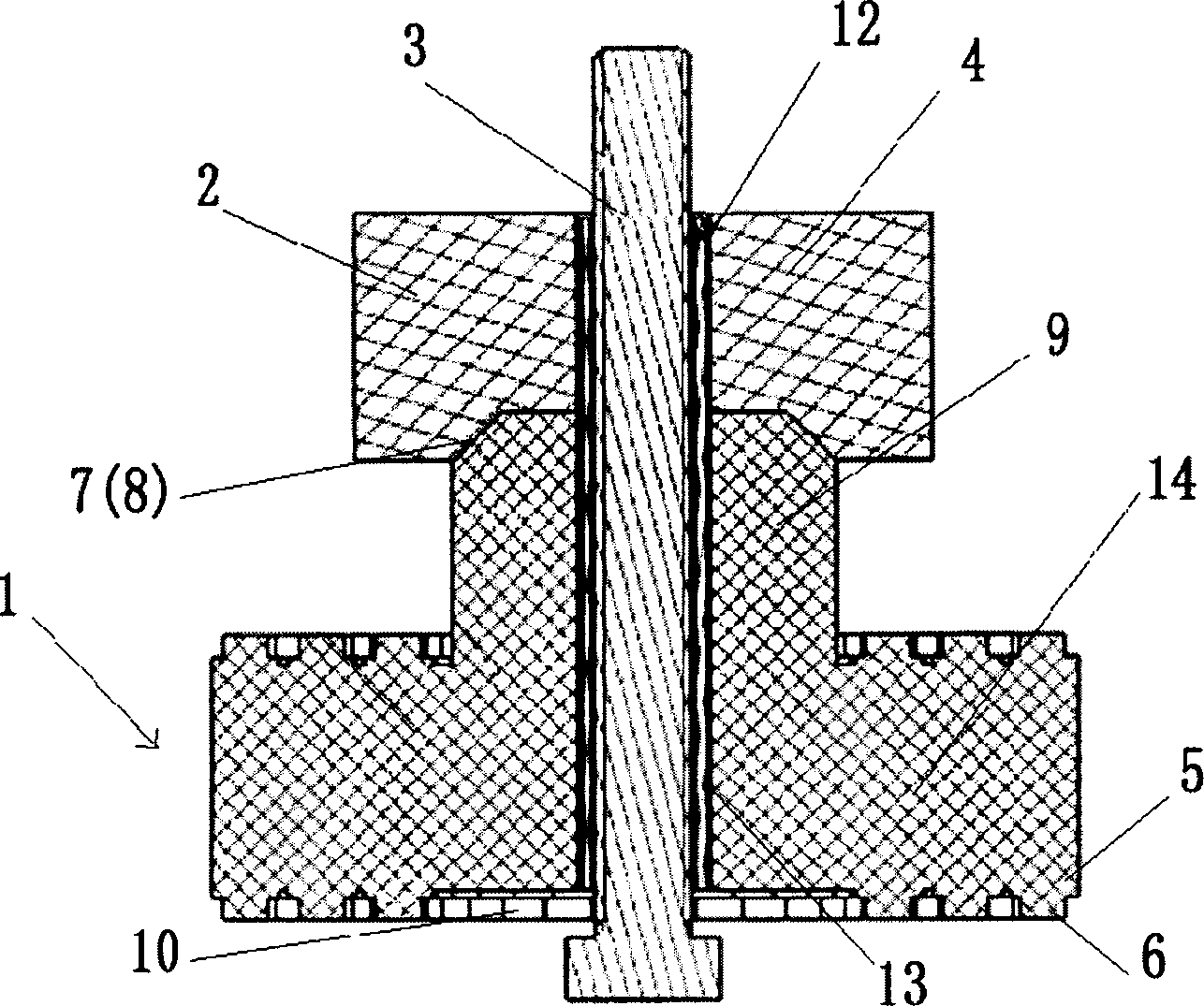

[0014] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0015] The installation method of an engine mount device for a four-cylinder diesel engine according to the present invention, wherein the mount device includes: a lower vibration-damping rubber pad 1, an upper vibration-damping rubber pad 2, a connecting screw 3, and a screw bushing 4. The lower vibration-damping rubber pad 1 includes a bump 9, a large-diameter round platform 14 and a lower through hole 13, and the outer chamfer 7 is arranged on the bump 9, and there is a first-level boss 5, a second-level boss 6, and a screw on the large-diameter round platform 14. The head groove 10, the upper damping rubber pad 2 includes an inner chamfer 8 and an upper through hole 12.

[0016] A method for installing an engine mount for a four-cylinder diesel engine, comprising the following steps:

[0017] a: Place the connecting screw 3 in the fixing hole on the base of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com