Detachable Tower Crane Foundation

A tower crane foundation and dismantling technology, which is applied in the direction of infrastructure engineering, construction, etc., can solve the problems of insufficient construction convenience and low material reuse rate, and achieve good overall stability and subversive resistance, and increase the reuse rate , The effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

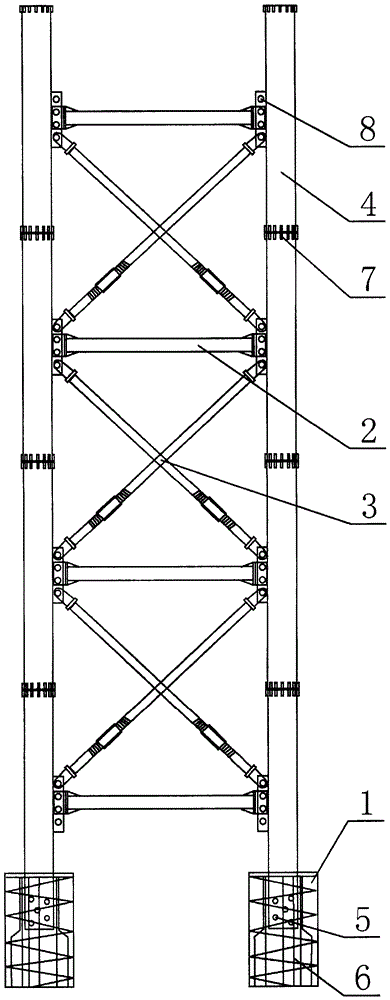

[0012] In the figure, 1. concrete base; 2. horizontal support; 3. cross support;

[0013] Such as figure 1 As shown, four steel lattice columns are fixed on the concrete base 1, and the distance between the steel lattice columns is 3 meters. There are horizontal support 2 and cross support 3 between the steel lattice columns. The cross support 3 is a telescopic structure, consisting of two sections Steel rods and round tubes connected to the steel rods in front of the steel bars. Each steel grid column is composed of five column tubes 4 with a length of 2.5 meters and a cross-section of . The upper part of the pipe 4 extends into the tower crane base, the lower part of the column tube 4 at the bottom extends into the concrete base 1, the lower part of the column tube 4 at the bottom is provided with a grout hole 5, and the concrete base 1 is provided with Reinforcement ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com