Curtain wall connection structure and installation and disassembly method

A technology for connecting structures and curtain walls, applied in the direction of walls, building components, building structures, etc., can solve the problems of complex connection structures of curtain walls and difficult to disassemble, and achieves simple installation and disassembly process, easy application of force, and guaranteed strength and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

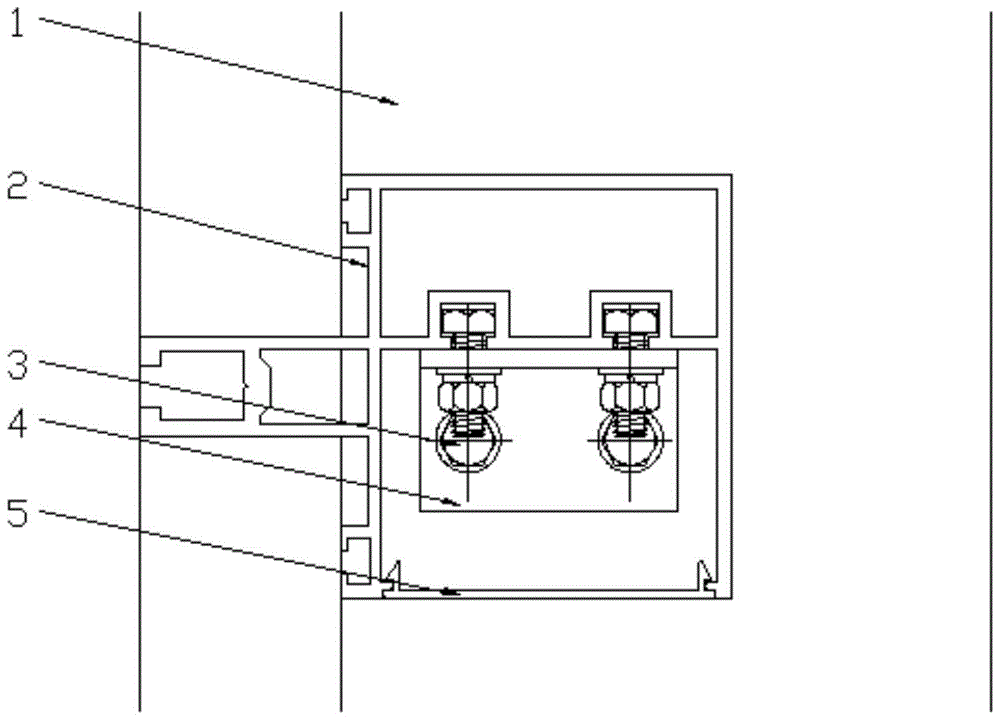

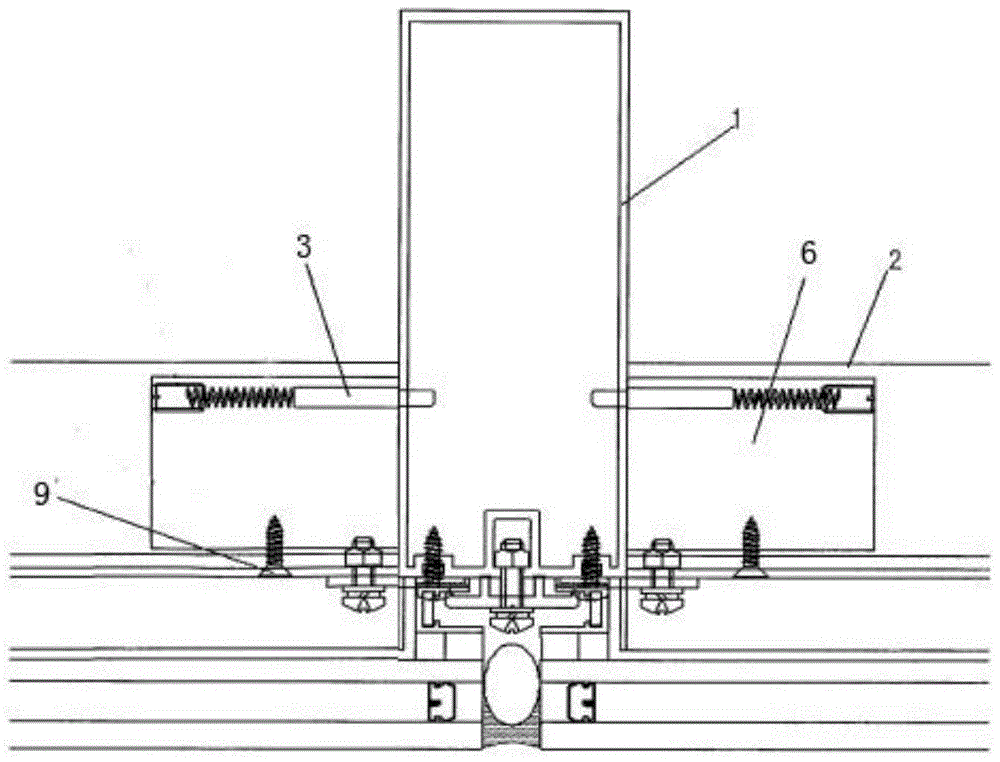

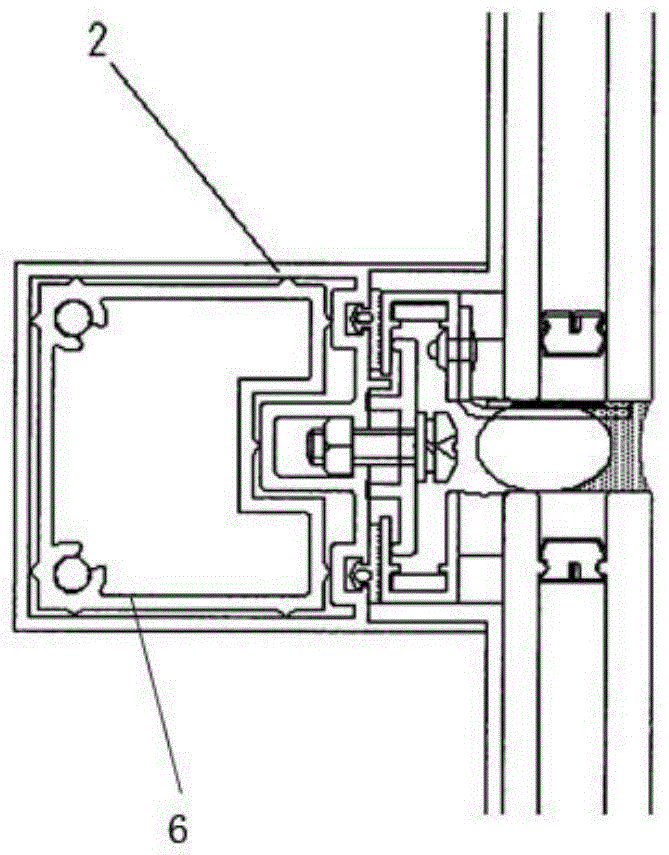

[0049] This embodiment provides a curtain wall connection structure, such as Figure 4 , 5 As shown, it includes a closed crossbeam 2, a crossbeam insert 6 installed inside the crossbeam 2, and a column 1 connected to the crossbeam 2 and the crossbeam insert 6 through a number of mounting structures, and also includes a crossbeam insert 6 The core 6 is connected with an auxiliary connecting piece 7 through a fixed structure. The auxiliary connecting piece 7 has a protrusion extending to the outside of the crossbeam ferrule 6 and connected with the column 1 through a detachable structure, and is connected with the protrusion Under the action of external force, the push-pull portion can drive the beam ferrule 6 to approach or move away from the column 1, so that the mounting structure is released or the connection between the beam ferrule 6 and the column 1 .

[0050] The curtain wall connection structure of this embodiment adopts a closed cross beam 2 to ensure the strength and st...

Embodiment 2

[0065] This embodiment provides a method for installing a curtain wall beam using the connection structure described in Embodiment 1, including the following steps:

[0066] S1: Install a part of the installation structure on the beam ferrule 6, and fix the auxiliary connector 7 with the beam ferrule 6 through the fixing structure; specifically, install the pin 3 into the pin hole of the beam ferrule 6, and The buckle space 75 of the auxiliary connecting piece 7 is clamped in the fixing groove 64 of the bottom wall of the groove 62. If necessary, a self-tapping screw 9 or other method in embodiment 1 is required to connect the auxiliary connecting piece 7 with The beam ferrule 6 is further fixedly connected;

[0067] S2: Install the beam insert 6 in the beam 2;

[0068] S3: Place the crossbeam 2 on the side of 1 so that the mounting structure on the crossbeam ferrule 6 is aligned with the mounting structure on the column 1; specifically, the pin 3 is aligned with the pin on the colu...

Embodiment 3

[0073] This embodiment provides a method for disassembling a curtain wall beam using the connection structure described in Embodiment 1, including the following steps:

[0074] S1: Remove the detachable structure to release the connection between the auxiliary connector 7 and the column 1; that is, loosen the fastening screw 8 to disconnect the auxiliary connector 7 from the column 1;

[0075] S2: Push the auxiliary connector 7 to make the beam insert 6 away from the column 1, so that the installation structure (pin 3) on the beam insert 6 and the installation structure (pin socket) on the column 1 are uncoated;

[0076] S3: Remove cross beam 2 to complete the disassembly process.

[0077] The method for disassembling the beam of the curtain wall in this embodiment only needs to disconnect the auxiliary connector 7 and the column 1, and push the auxiliary connector 7 to move the beam insert 6 away from the column 1, then the beam 2 can be removed to complete the disassembly process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com