A mmc with zero DC voltage fault ride-through capability and its design method

A technology of DC voltage and fault ride-through, which is applied in the direction of electrical components, power transmission AC network, output power conversion device, etc. It can solve the problems of decreased operating efficiency, increased on-state loss, inability to inject reactive power into the grid to support the grid voltage, etc. problem, to achieve the effect of low cost and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The design method of MMC includes the following steps:

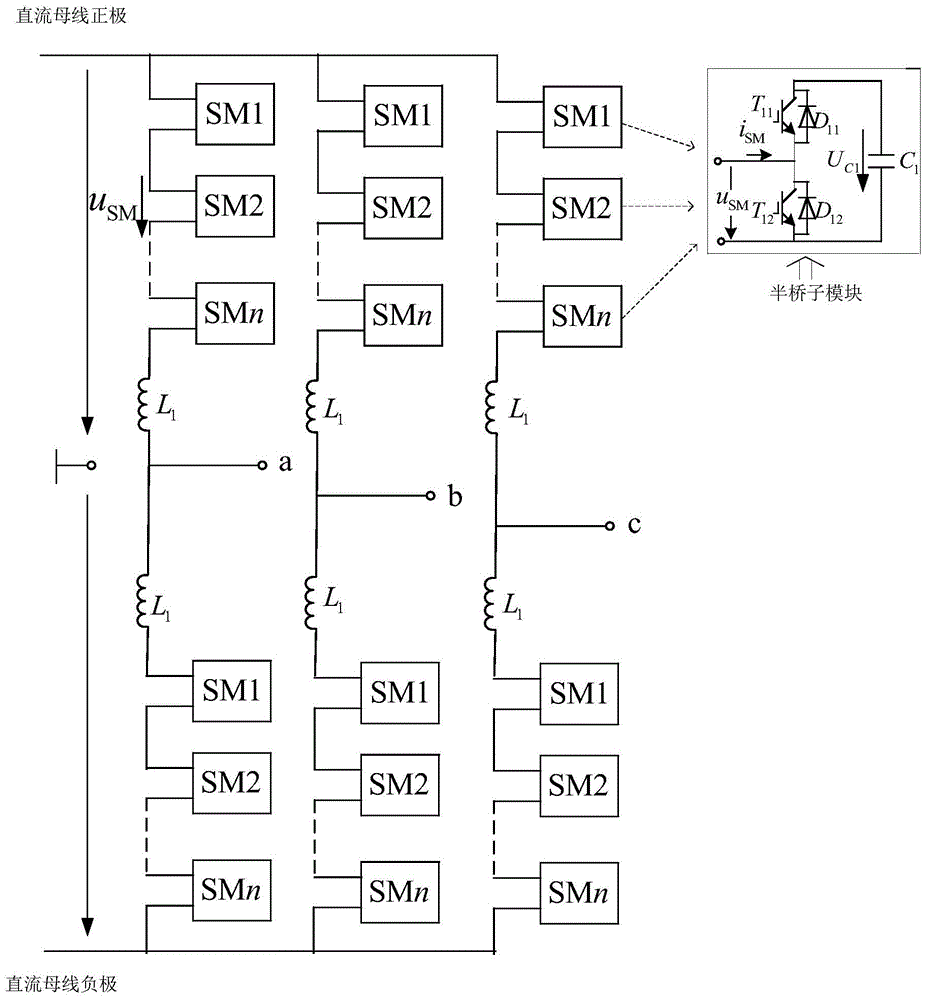

[0036] (1) In order to reduce the design cost of the MMC and improve its operating efficiency, the half-bridge sub-module is selected as the first sub-module of the MMC; in order to enable the MMC to have zero DC voltage ride-through capability, a full-bridge sub-module that can output negative levels in the non-blocking state is selected. The bridge sub-module is the second sub-module of the MMC. The topology of the formed MMC is as Figure 5 shown.

[0037](2) Determine the zero DC voltage fault ride-through scheme. Among them, the ride-through scheme follows the following principles: all half-bridge sub-modules are bypassed, the impedance of the AC current in the bridge arms is ignored, the total output voltage of the full-bridge sub-modules of the same phase upper and lower The total output voltage of the bridge sub-module is the instantaneous value of the phase voltage of the current AC side, and its equiv...

Embodiment 2

[0061] The design method of MMC includes the following steps:

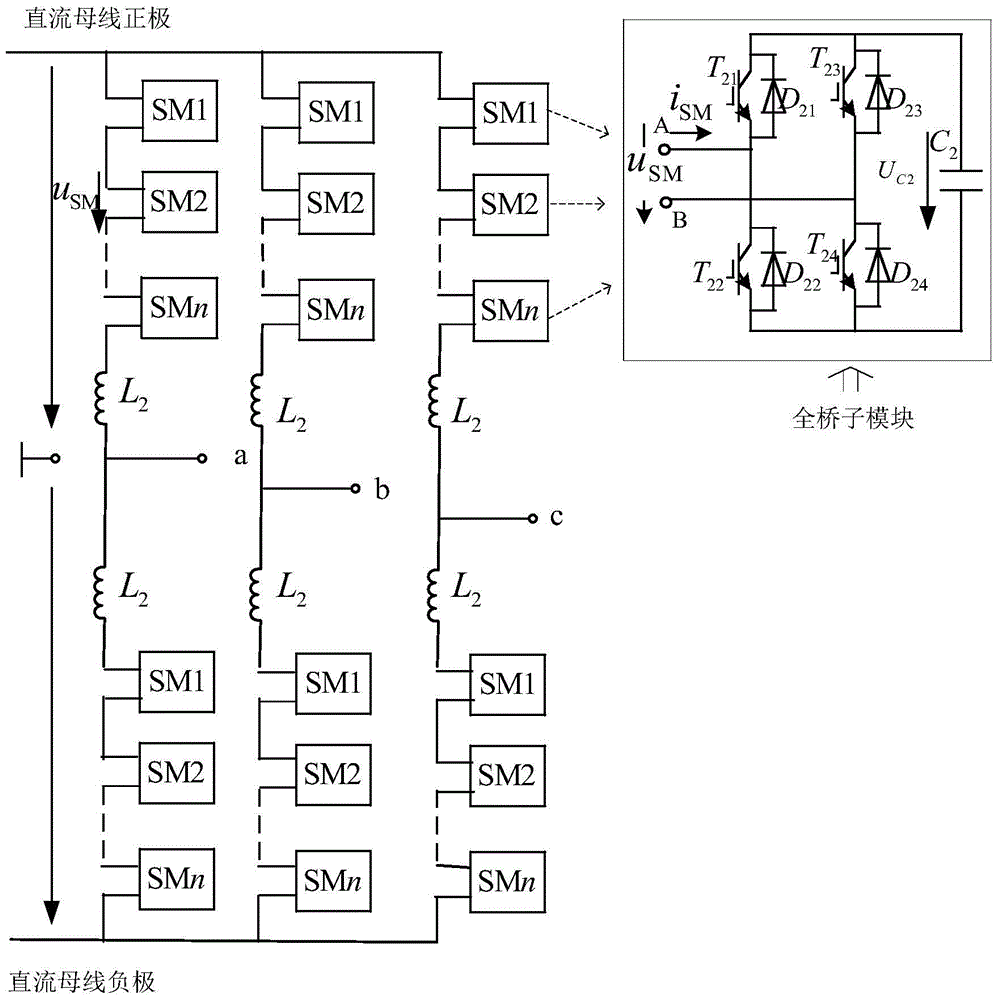

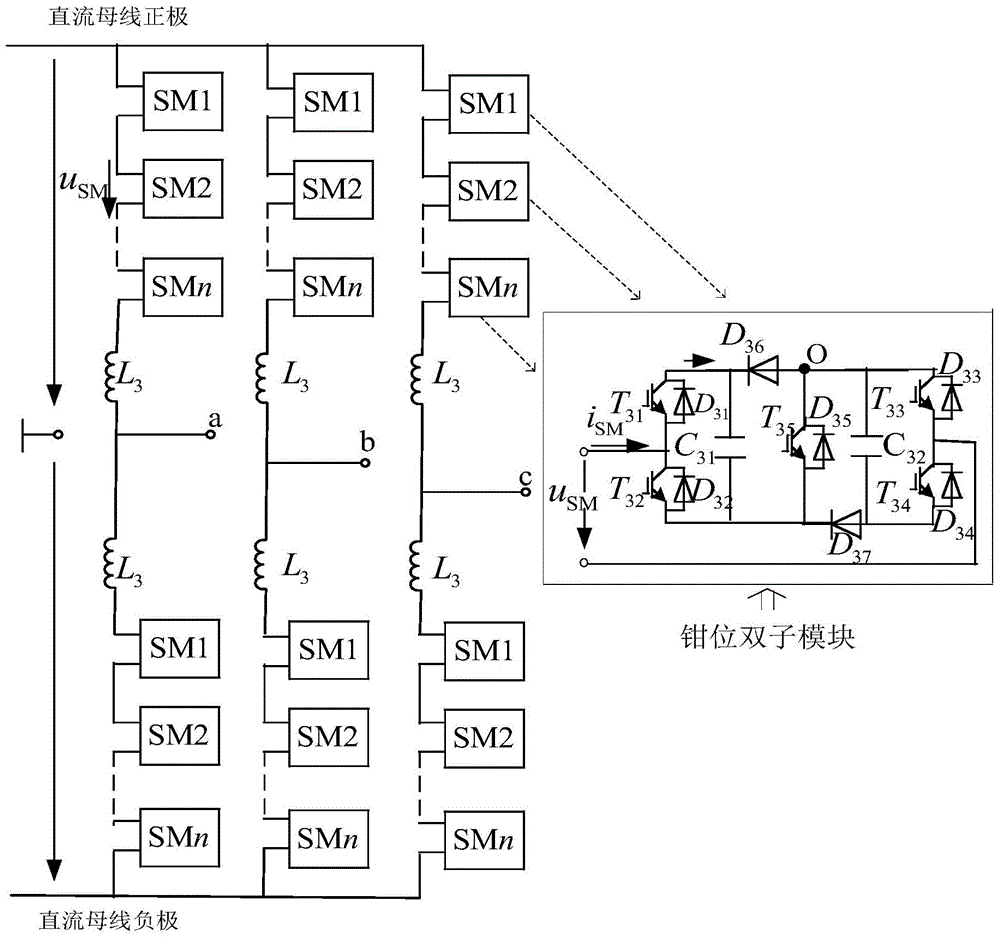

[0062] (1) In order to reduce the design cost of the MMC and improve its operating efficiency, the half-bridge sub-module is selected as the first sub-module of the MMC; in order to enable the MMC to have zero DC voltage ride-through capability, a crossover that can output negative levels in the non-blocking state is selected Connect the dual half-bridge sub-module as the second sub-module of the MMC. The topology of the formed MMC is as Figure 7 shown.

[0063] (2) Determine the zero DC voltage fault ride-through scheme. Among them, the ride-through scheme follows the following principles: all half-bridge sub-modules are bypassed, the impedance of the AC current in the bridge arms is ignored, the cross-connected double half-bridge sub-modules of the same phase upper and lower The total output voltage of the bridge arm cross-connected double-half-bridge sub-module is the instantaneous value of the current phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com