Conveying device used for water curtain scroll paint-spraying room

A conveying device and scroll technology, which is used in spraying devices, devices for coating liquid on surfaces, paint spray booths, etc., can solve problems such as unfavorable maintenance and cleaning, easy entry into the conveyor chain, failures, etc. The effect of avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

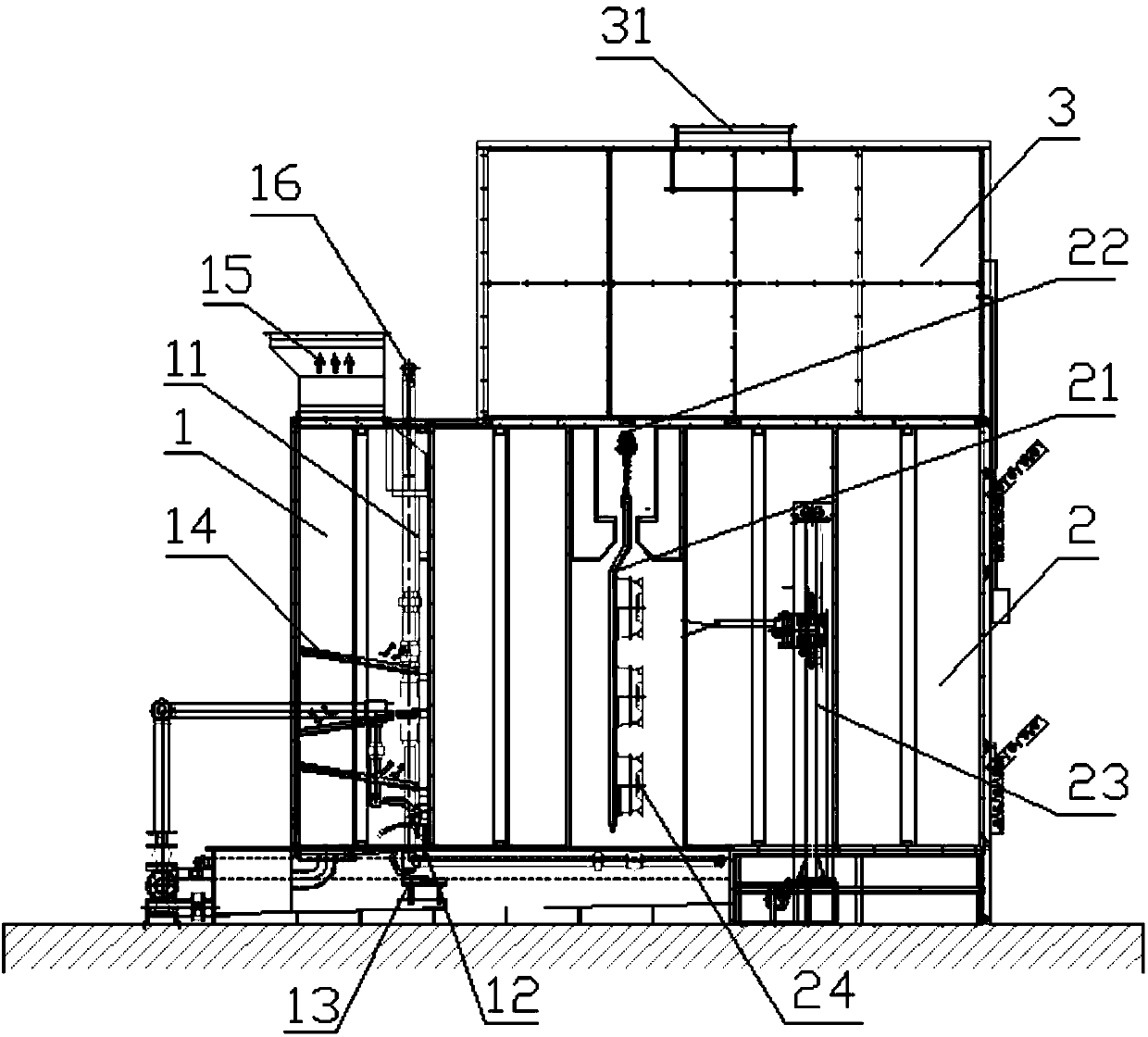

[0013] Such as figure 1 As shown, a water curtain scroll spray booth includes a paint spraying room 2, and a paint mist collection chamber 1 is arranged side by side on one side of the paint spraying work room 2, and the paint spraying work room 2 and the paint mist collection room 1 are connected to each other. In communication, an air supply system 3 is provided above the paint spraying operation room 2 , and an air suction groove 15 is provided above the paint mist collection chamber 1 .

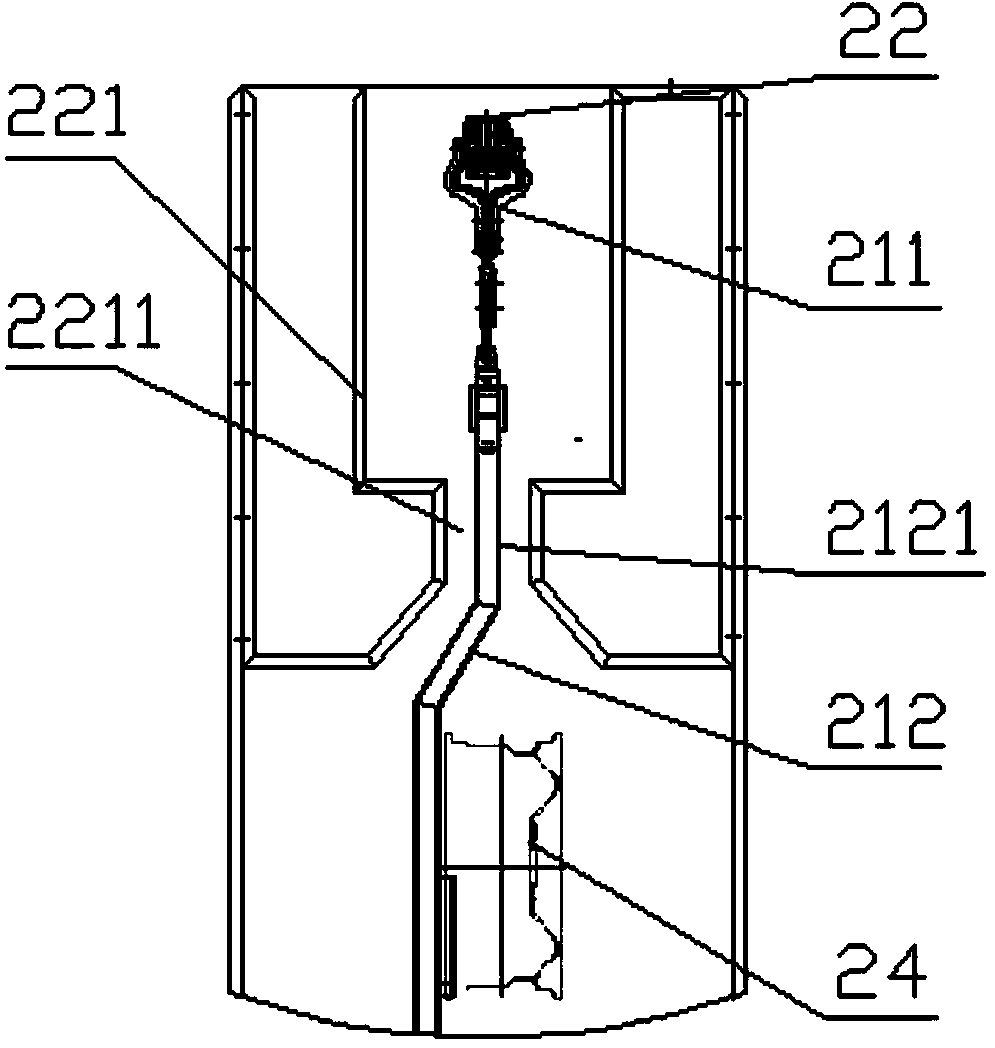

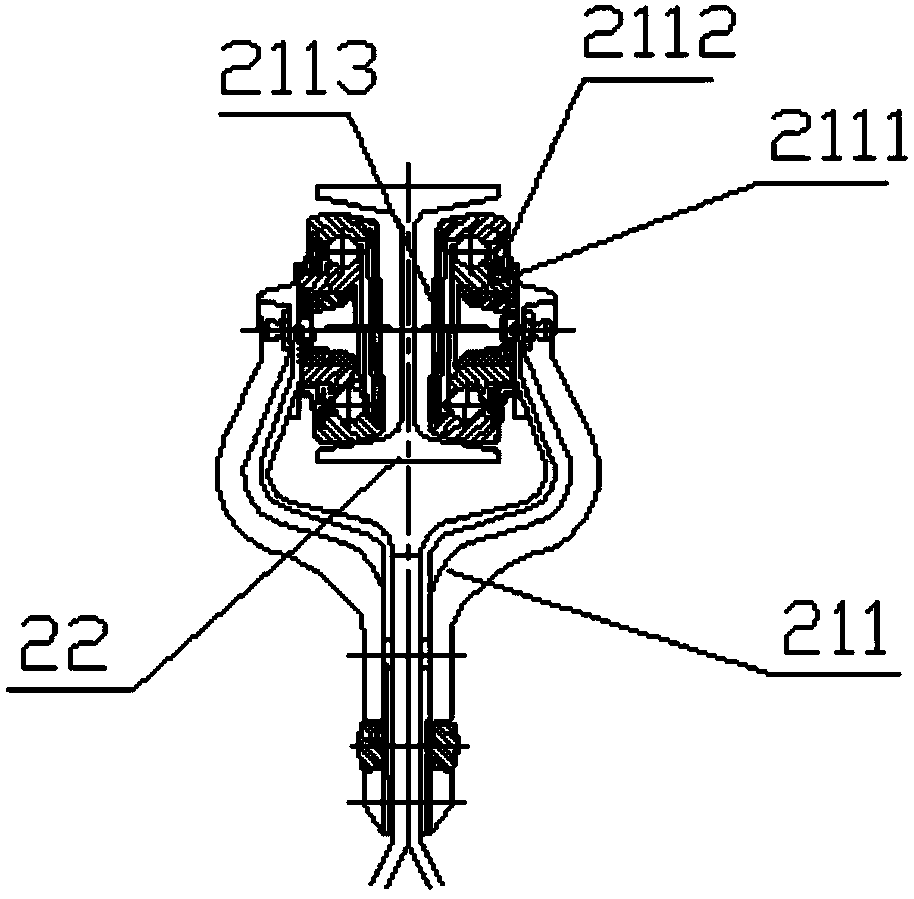

[0014] A conveying track 22 is arranged on the top of the painting work room, and a conveying fixture 21 is suspended on the conveying fixture, and a spraying product 24 is mounted on the conveying fixture, and an automatic spray gun 23 is arranged on one side of the conveying fixture to spray the painted product .

[0015] The inner wall of the paint mist collection chamber 1 is provided with a water curtain plate 11, and the underground of the paint mist collection chamber is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com