Multi-chip eutectic-bonding pressure dividing device

A distribution device and eutectic welding technology, applied in welding equipment, non-electric welding equipment, electrical components, etc., can solve problems such as undervoltage welding of chips, easily crushed chips, overvoltage and crushed chips, etc., to achieve reasonable distribution and avoid The effect of damaging the chip and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

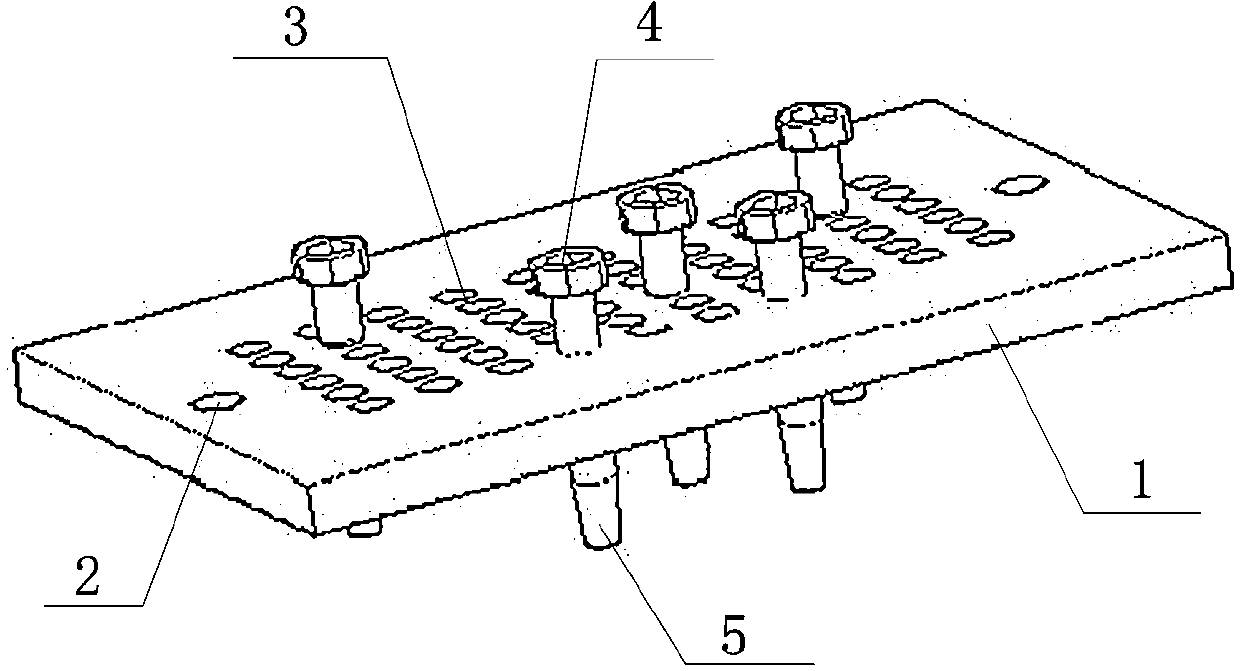

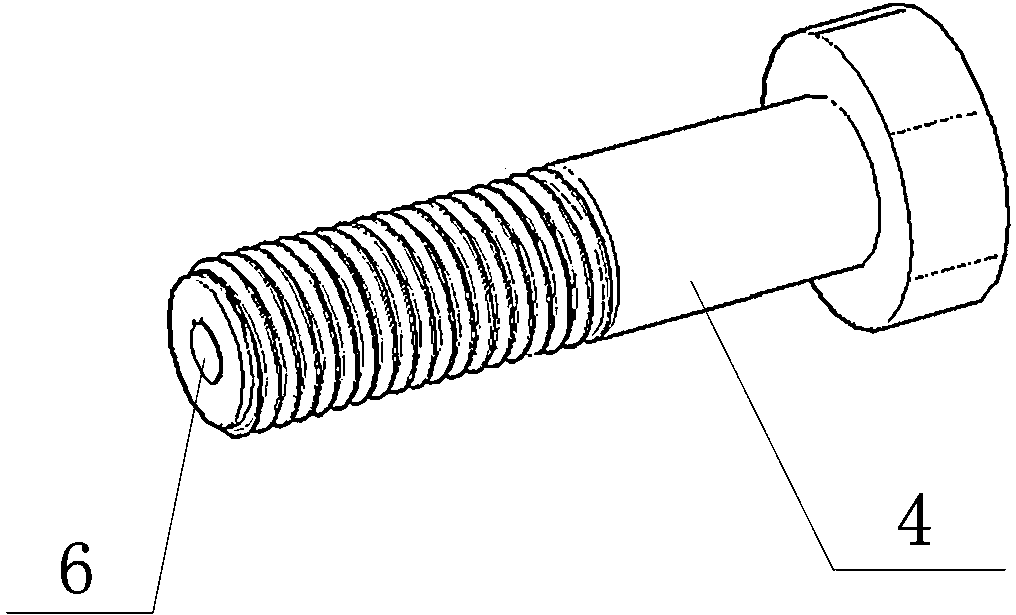

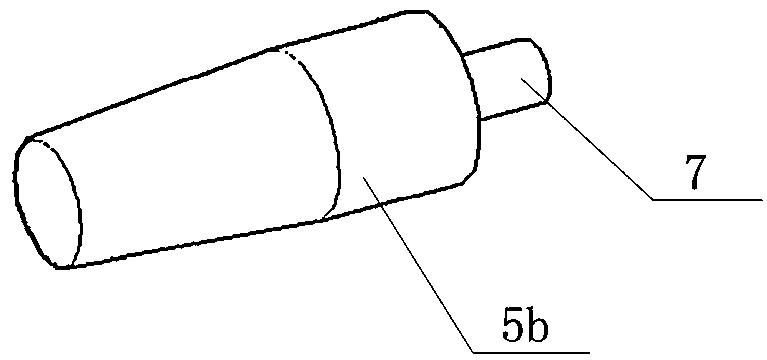

[0017] Such as figure 1 As shown, a multi-chip eutectic welding pressure distribution device provided by the present invention includes a pressure plate 1, and the pressure plate 1 is provided with a positioning hole 2 that matches the positioning column 14 of the graphite fixture 13. The pressure plate 1 The board surface is also provided with a screw hole array 3 penetrating the board body, and a group of bolts 4 cooperating with its thread are arranged in the screw hole array 3, and a pressure head 5 for pressing the chip is arranged at the bottom of the bolt 4; figure 2 As shown, the bottom of the bolt 4 is provided with an insertion hole 6; image 3 , Figure 4 and Figure 5 As shown, the top of the indenter 5 is provided with a plug 7 that matches the socket hole 6. In order to adapt to chips of different areas, the bottom of the indenter can be a first conical indenter 5a, and a second column-shaped bottom. Indenter 5b, or the third indenter 5c whose bottom is irreg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com