A kind of manufacturing method of large-diameter folding table spoke wheel

A manufacturing method and large-diameter technology, applied in the direction of web-type wheels, wheels, vehicle parts, etc., can solve the problems affecting the distribution of web plate folding table allowance, web plate cracking, and low rolling quality, so as to improve the quality of metal products The effect on rate and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

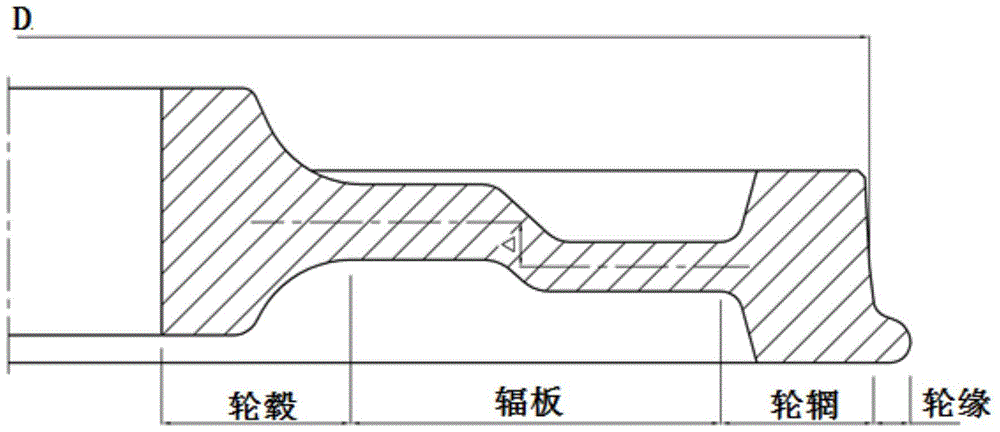

[0023] The manufacturing method of the large-diameter folding table wheel includes the following technological process: billet sawing process-heating process before forging-die forging process-rolling process-bending process, wherein,

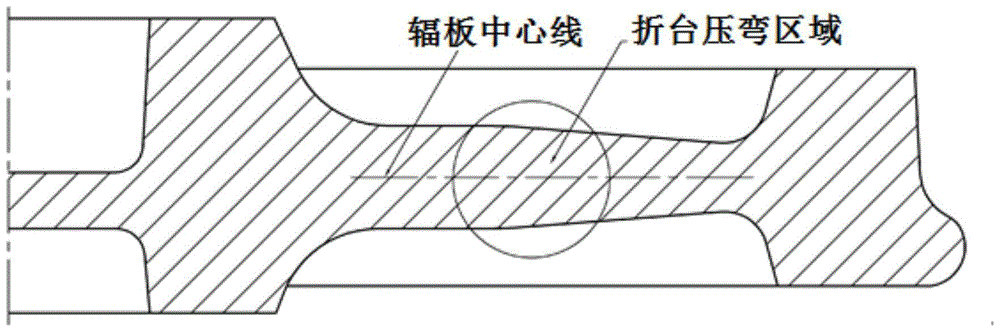

[0024] Die forging process, when the wheel is formed, the folding table of the wheel web is pressed on the blank, and the metal distribution inside and outside the folding table is reasonable in the preforming stage;

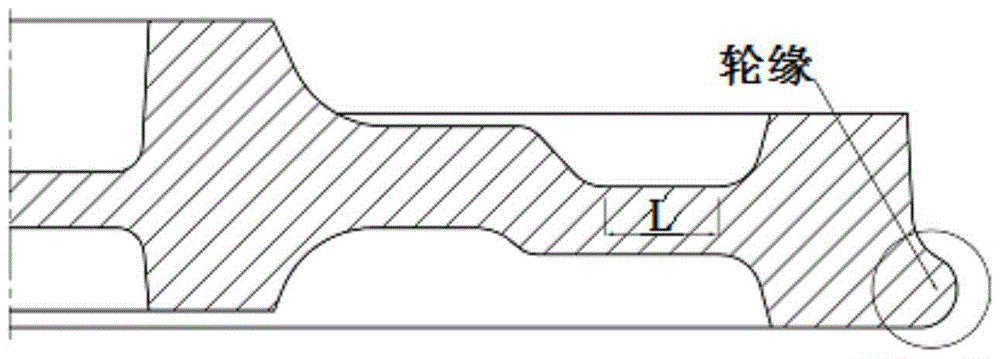

[0025] In the rolling process, the length of the roll head of the web roll is reduced, the profile of the web roll is advanced in the direction of the roll head and the diameter of the web roll is increased, so that the profile of the web roll goes deep into the groove of the web and touches the surface of the web , so that the web roll does n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com