Scrap removing method for treating waste scraps of numerical-control machine tool

A technology of CNC machine tools and chip removal devices, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as incomplete chip removal, and achieve the effect of improving work efficiency and simple and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

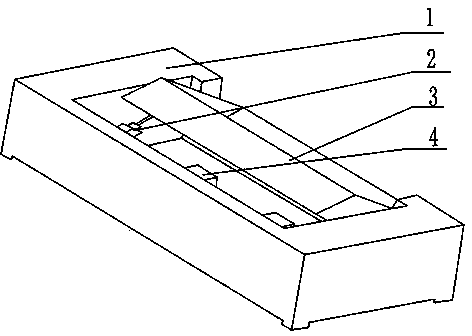

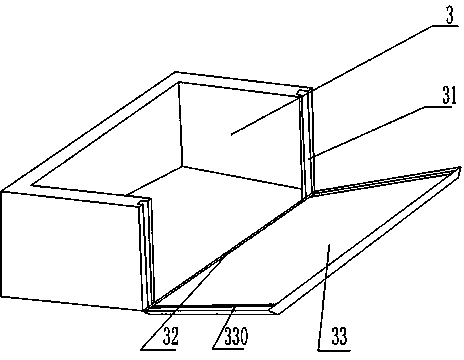

[0015] Example: such as figure 1 , figure 2 As shown, a chip removal method for waste processing of CNC machine tools includes the following steps: firstly, a chip tray 3 is assembled, and the chip tray 3 is a three-dimensional frame without a cover, and its movable plate 33 is fixed by a rotating shaft 32 On the chip tray 3, the movable plate 33 can rotate around the rotating shaft 32, and the opening and closing of the movable plate 33 can be realized by rotation. Protrusion 330, the protrusion 330 is provided with a sealing ring that cooperates with it, through the cooperation of the card groove 31 and the protrusion 330, the perfect seal between the movable plate 33 and the chip tray 3 is realized, and the protrusion 330 on the movable plate 33 is buckled into the setting There is a protrusion 330 with a sealing ring, so that the assembly of the chip tray 3 is completed, and then the assembled chip tray 3 is installed on the base 1, and can be turned over in the base 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com