Chassis driving system for four-wheel drive electromobile and control method of chassis driving system

A technology for electric vehicles and drive systems, applied in control devices, vehicle components, transportation and packaging, etc., can solve problems affecting tire grounding performance and vehicle ride comfort, increase in mean square value of vibration acceleration, increase in unsprung mass, etc. problems, to achieve the effect of improving service life, easy power switching, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limit to the protection scope of the present invention.

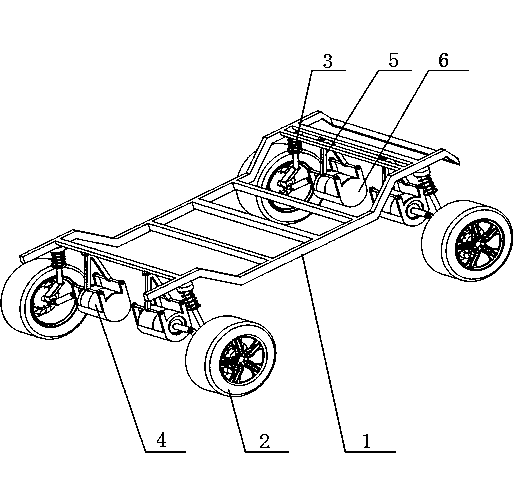

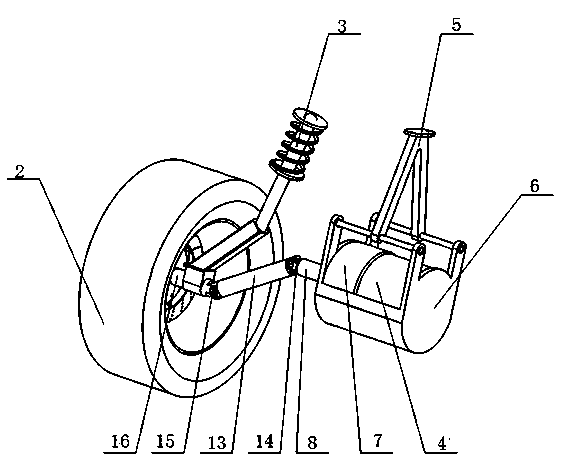

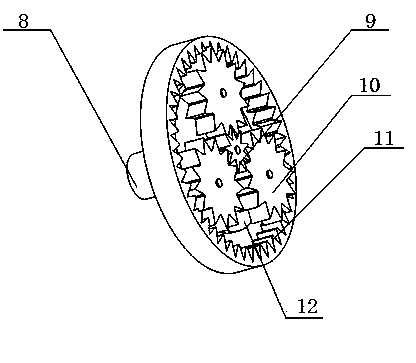

[0016] Such as Figure 1-4 As shown, the present embodiment provides a four-wheel drive electric vehicle chassis drive system, including a vehicle frame 1, wheels 2 and MacPherson independent suspension 3, and the four ends of the vehicle frame 1 are The independent suspension 3 is connected to the wheel 2, and includes a driving motor system and a motor transmission system. The driving motor system includes a motor 4 and a reduction mechanism. The four ends of the support 1 are provided with motor base connectors 5, and the motor The seat connector 5 is provided with a motor seat 6, and the motor 4 is fixed on the motor seat 6, so that the motor 4 is hung upside down on the vehicle frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com