Ore feeding hopper device

A funnel and ore feeding technology, which is applied in the field of unloading equipment and storage, can solve the problems affecting the continuity and stability of funnel unloading, high cost of wear-resistant lining board, difficult to clean and maintain, etc., to achieve convenient cleaning and maintenance, Good blocking effect, guaranteed continuity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

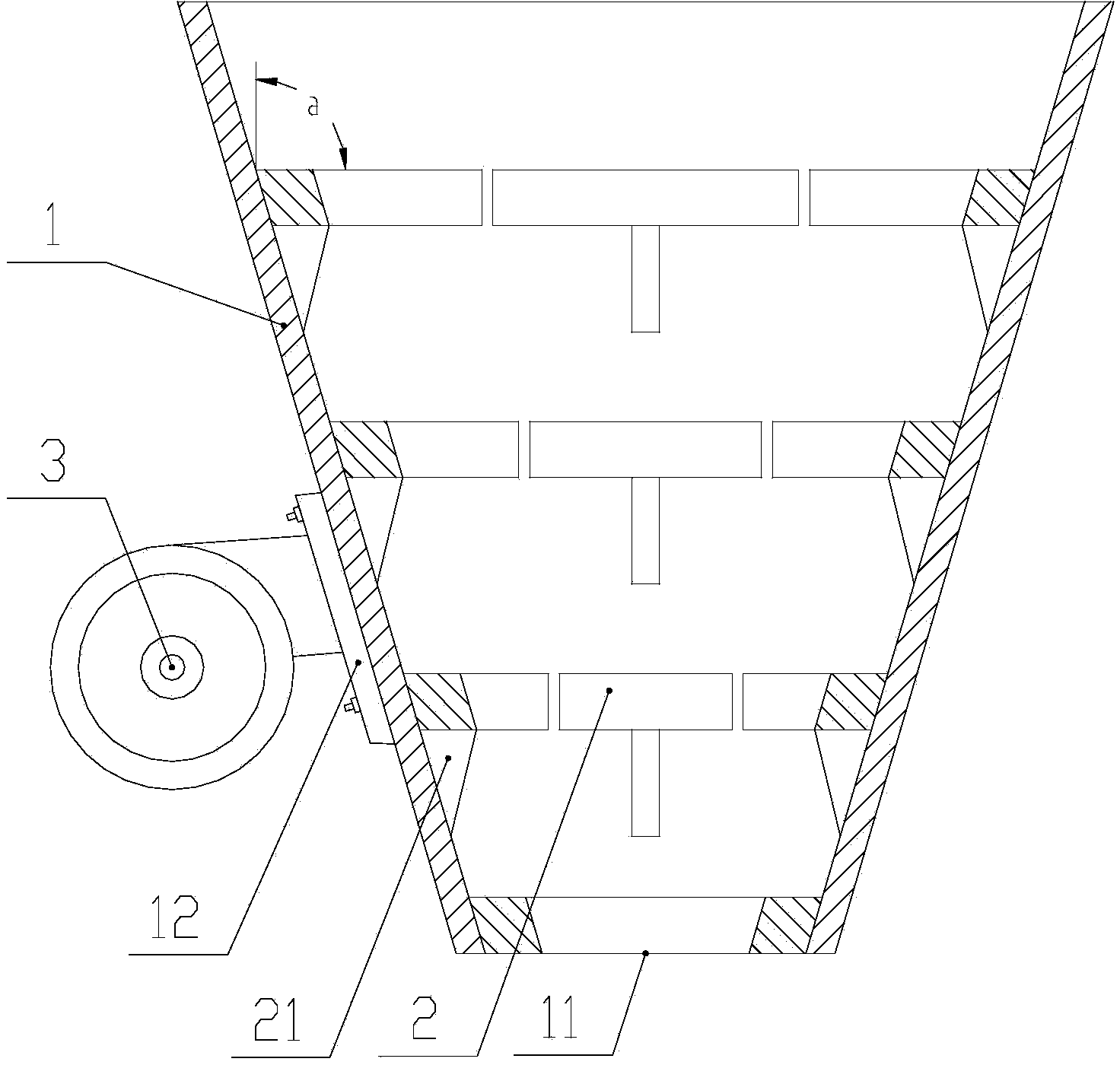

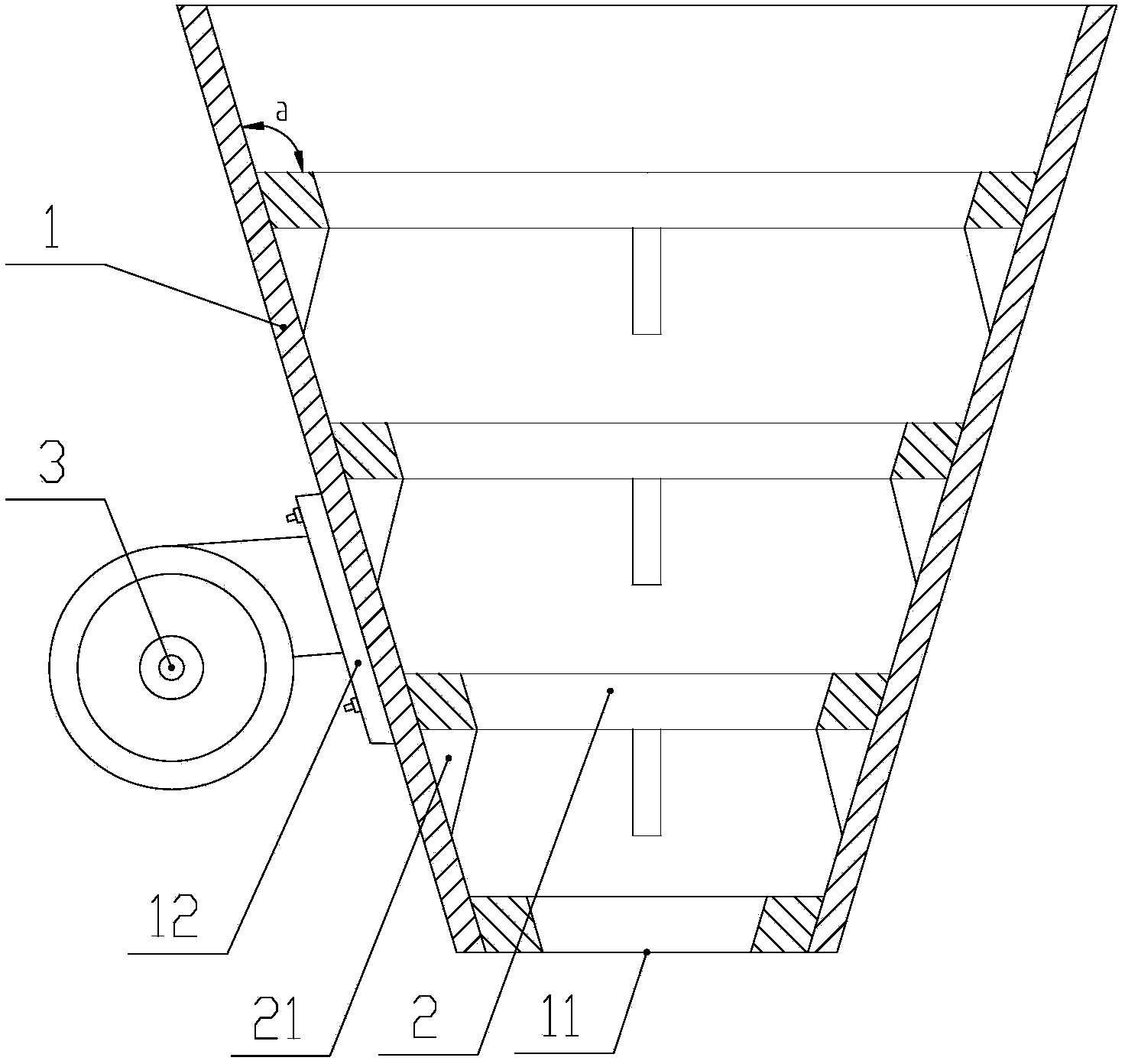

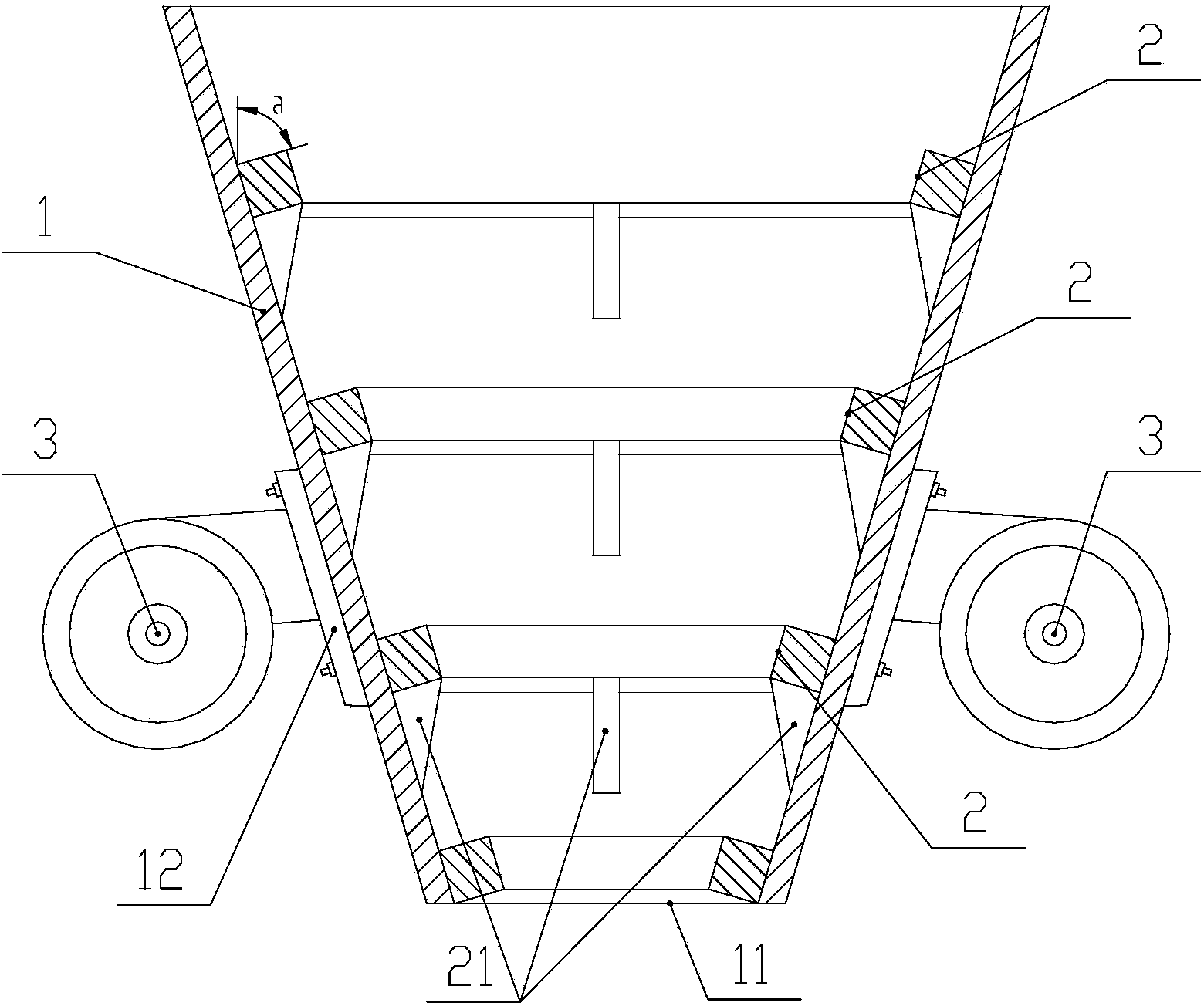

[0022] Such as figure 1 As shown, a kind of ore feeding funnel device comprises a funnel body 1, a barrier layer 2 and a stripping device 3; the lower end of the funnel body 1 is provided with a discharge port 11; The inner circumference is arranged for one week, and the barrier layer 2 has at least two layers and is arranged at intervals in the inside of the funnel body 1 from bottom to top. The angle a between the upper surface of the barrier layer 2 and the vertical upward direction is less than or equal to 90°; there is at least one stripping device 3 installed on the outer wall of the funnel body 1, and the stripping device 3 can vibrate and / or rap the funnel body 1 to shed minerals.

[0023] Wherein, the blocking plate layer 2 can be composed of plates or blocks arranged on the inner wall of the funnel body 1, or can be an integrated structure arranged around the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com