Chimney used for glass melting kiln

A kiln and glass technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as affecting the service life of the kiln, falling into the glass liquid, affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

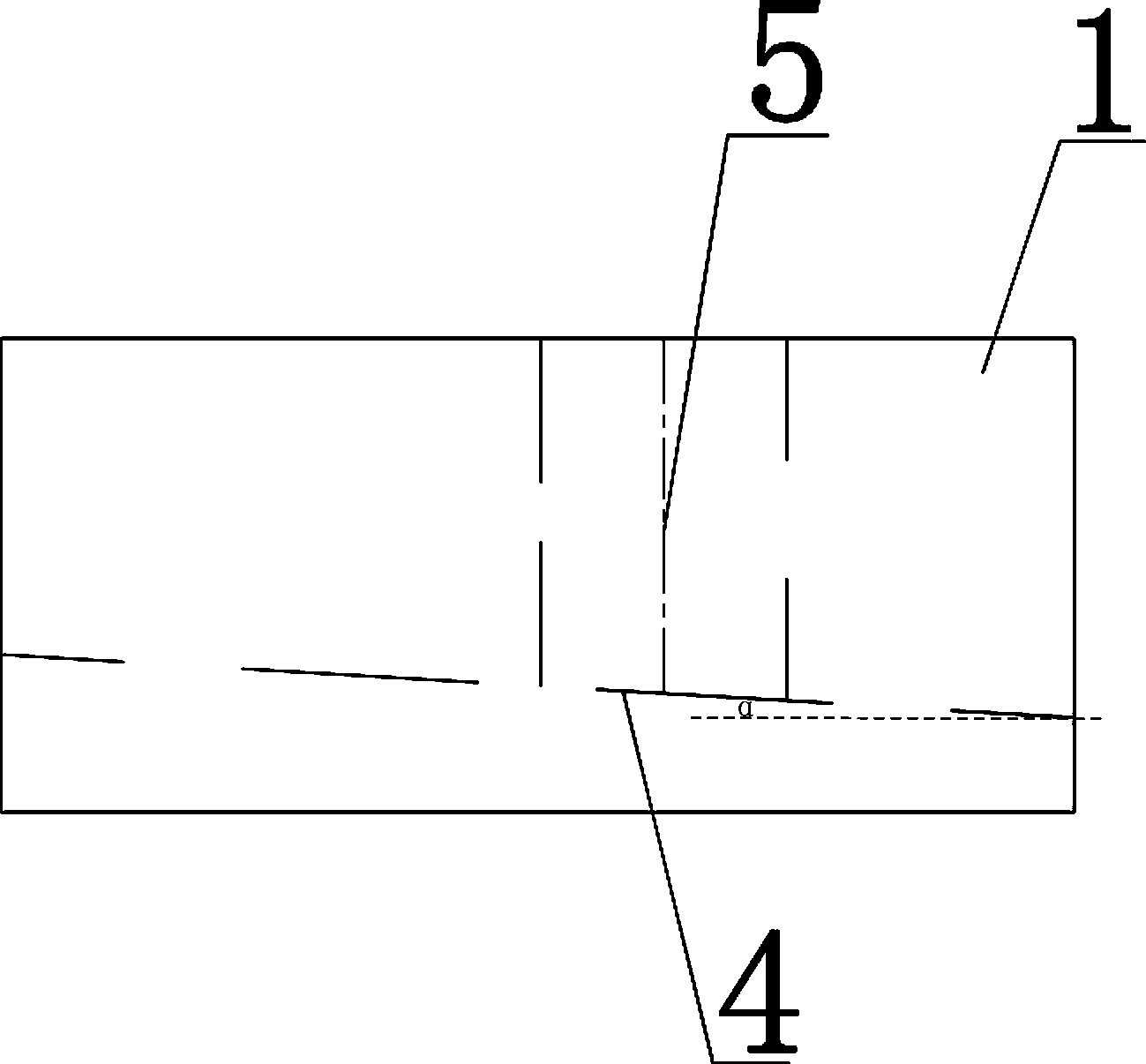

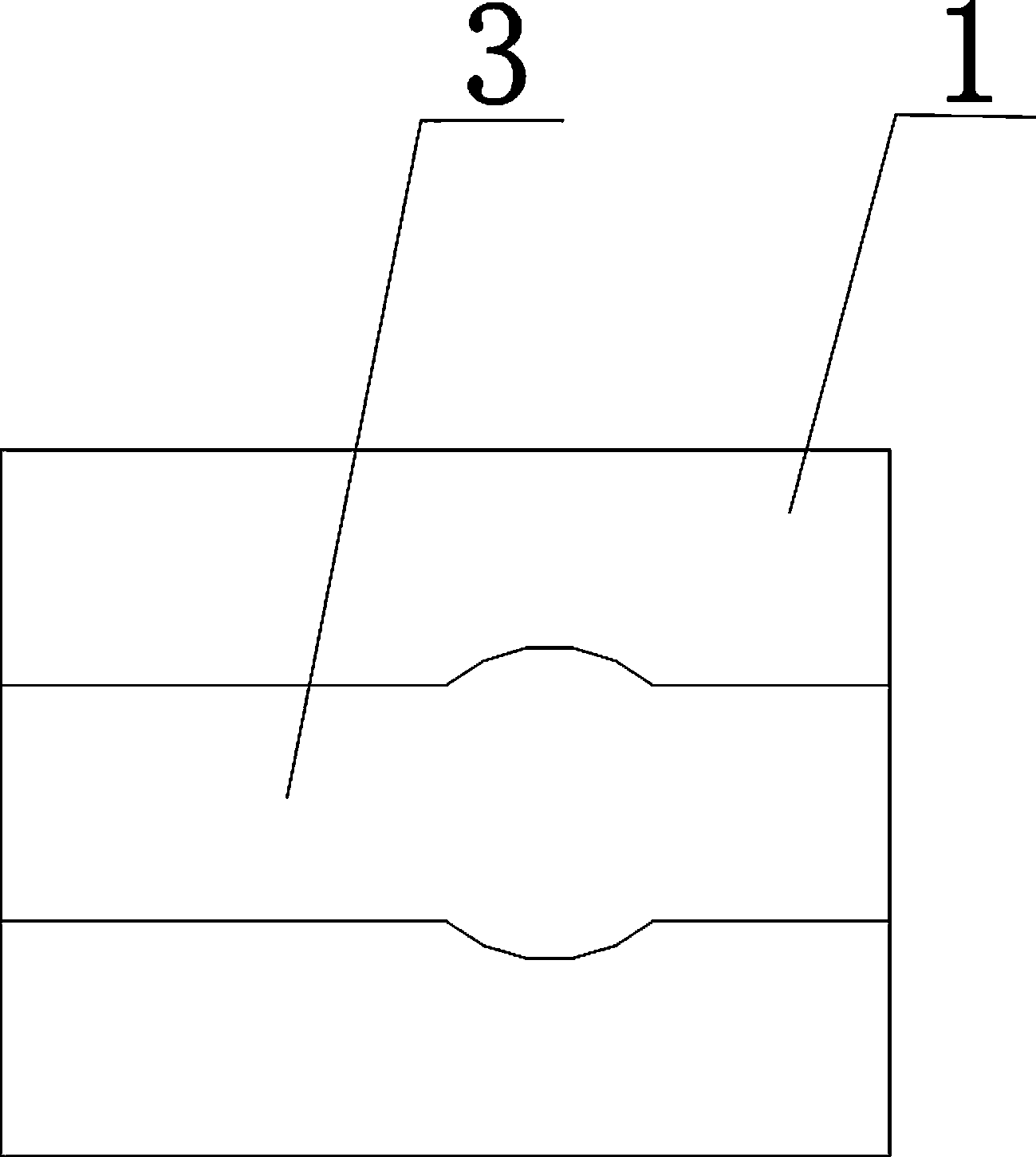

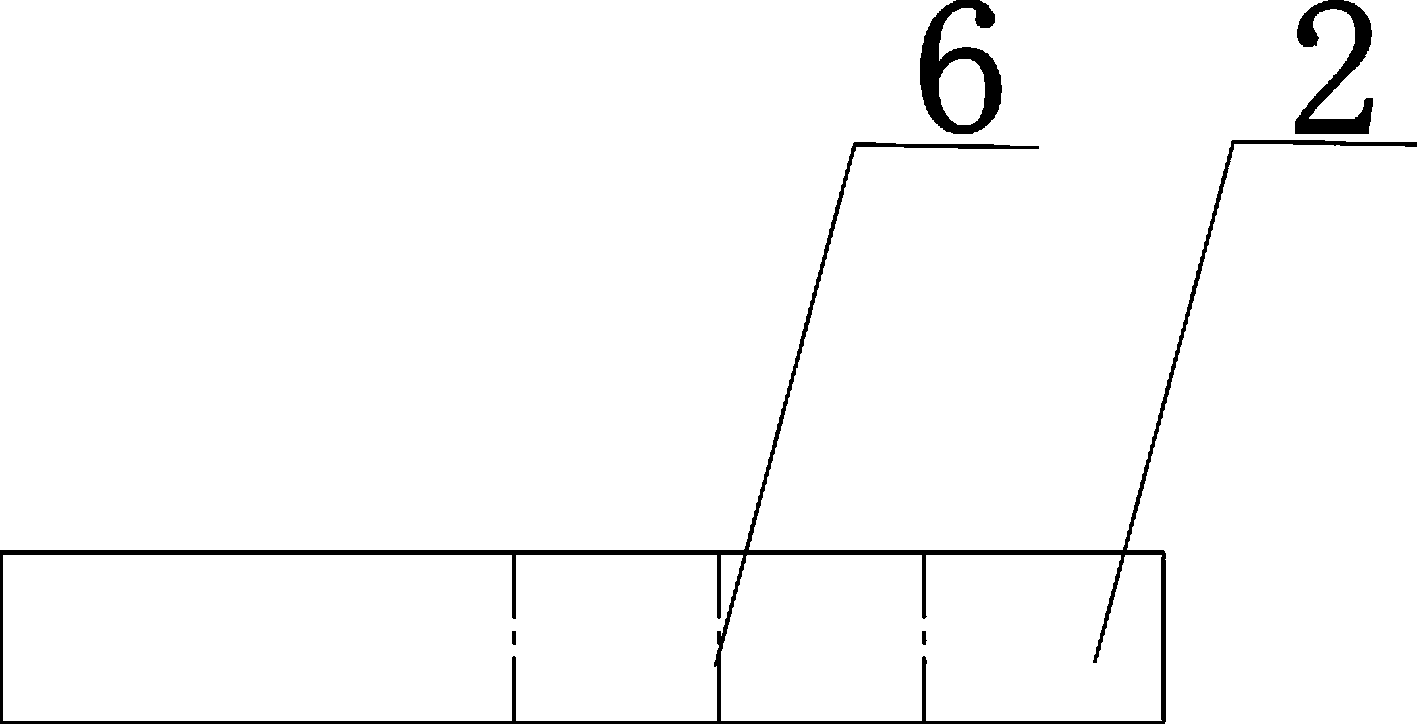

[0017] Such as Figure 1~Figure 5 As shown, a chimney for a glass melting furnace includes a bottom brick 1 and a cover brick 2. The cover brick 2 is located above the bottom brick 1 and fastened with the bottom brick 1. The bottom brick 1 is hollowed out along the horizontal direction to form a A smoke exhaust channel 3 , the bottom of which is an inclined surface 4 , and the bottom brick 1 is hollowed out along the vertical direction to form an air outlet channel 5 . The smoke exhaust channel 3 communicates with the air outlet channel 5 to form a three-way channel shape.

[0018] The cover brick 2 is provided with an air outlet hole 6 corresponding to the air outlet channel 5 . The bottom brick 1 has the same length and width as the cover brick 2 . Both the bottom brick 1 and the cover brick 2 are WSZ-41 type fused zirconia corundum bricks.

[0019] The bottom brick 1 is processed from a whole brick of 340mm*270mm*150mm, such as figure 1 , figure 2 shown. The smoke ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com