Whirlwind strong-suction no-clean smoke exhausting mechanism

A no-cleaning and oil fume extraction technology, which is applied in the exhaust field, can solve the problems of low suction power and easy adhesion of oil stains, and achieve the effects of strong suction force, avoiding or reducing adhesion of oil stains, and novel forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

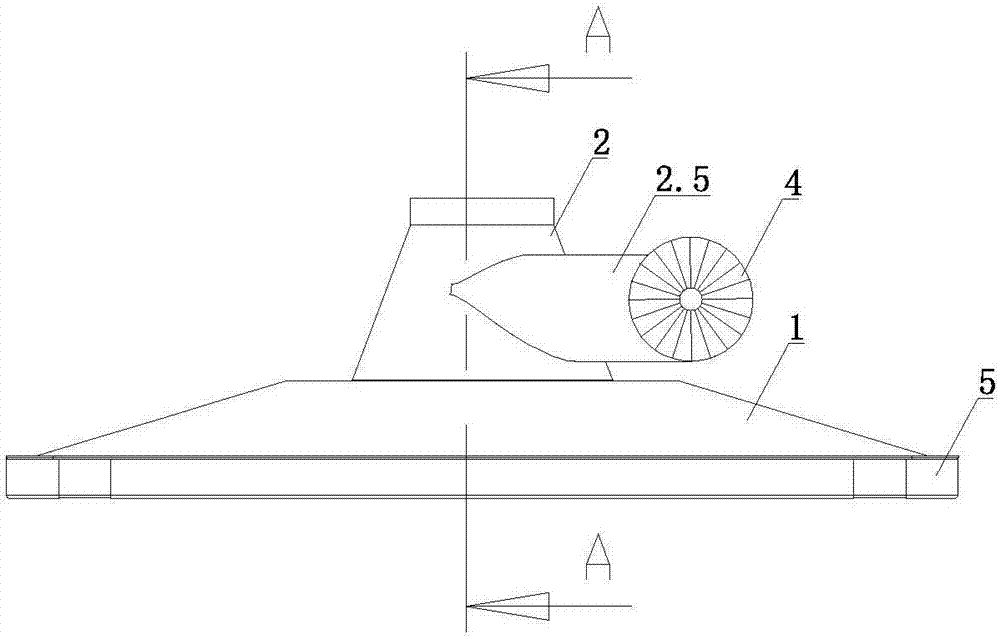

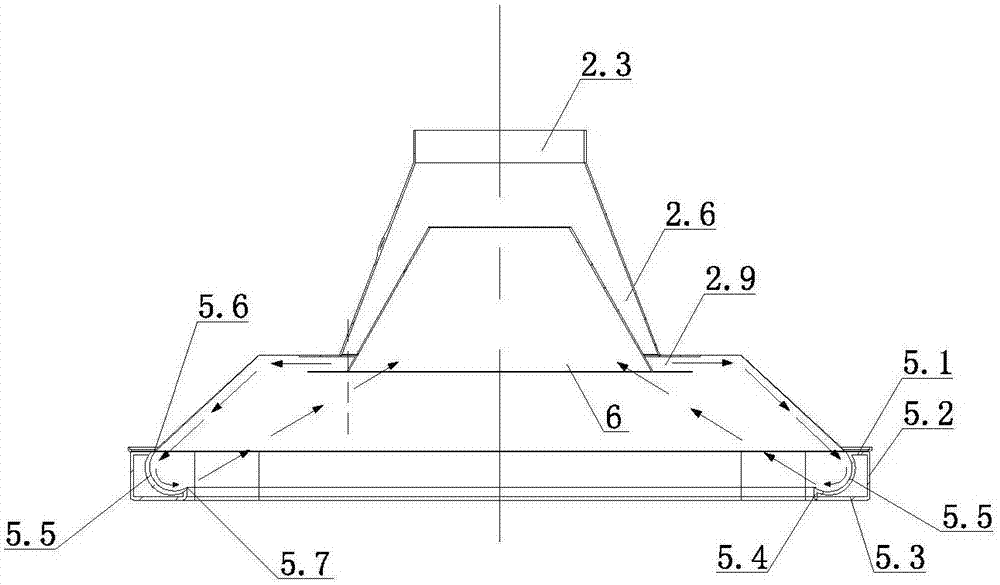

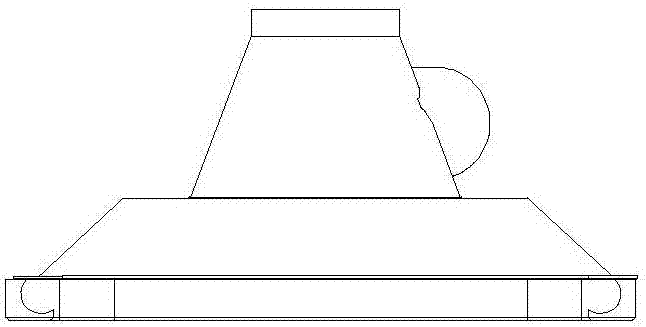

[0052] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of a vortex wind large suction no-cleaning smoke extraction mechanism proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Mode, structure, feature and effect thereof are as follows in detail.

[0053] At present, all range hoods in China adopt the form of direct discharge, and the oil fume is directly discharged into the outdoor atmosphere through the blades, such as Figure 9 shown. The principle of the fume discharge path of the present invention is as follows: Figure 10 As shown, the motor and fan blades are located on one side of the exhaust passage of the present invention, and the oil fume is discharged through the exhaust passage without passing through the motor and fan blades. Therefore, the present invention eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com