a vacuum furnace

A vacuum furnace and vacuum system technology, applied in heat treatment equipment, quenching devices, manufacturing tools, etc., can solve the problems of difficulty in obtaining vacuum, adsorption on the wall of the quenching pool, weakening the strength and toughness of metal materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

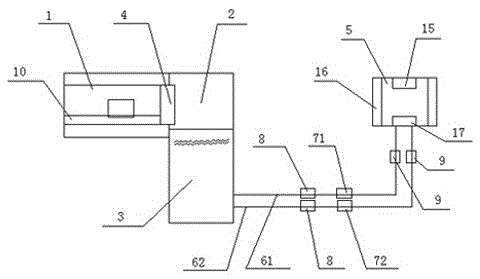

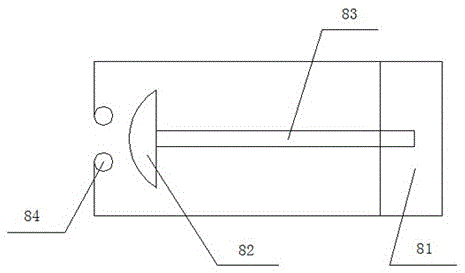

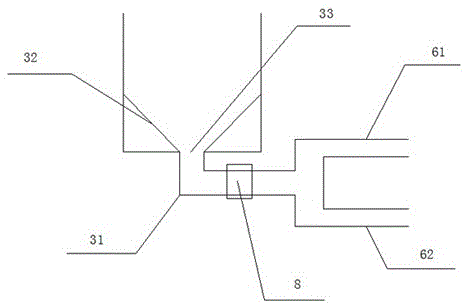

[0022] In this example, refer to Figure 1 to Figure 5 Shown, a kind of vacuum furnace, it comprises quenching pool 3 and precooling chamber 2 and the heating chamber 1 that is connected with precooling chamber 2, is provided with insulation door 4 between described heating chamber 1 and precooling chamber 2; The quenching pool 3 is connected with a preparatory bin 5, and a quenching liquid drain pipe 61 and a quenching liquid return pipe 62 are arranged between the quenching pool 3 and the preparatory bin 5; the quenching liquid drain pipe 61 and the quenching liquid return pipe 62 is respectively provided with a drain pump 71 and a liquid return pump 72; a baffle valve 8 is connected between the liquid drain pump 71 and the quenching pool 3; a valve 8 is connected between the liquid return pump 72 and the quenching pool 3 The baffle valve 8, the baffle valve 8 has effectively prevented the quenching liquid in the preparatory bin 5 from flowing back to the quenching pool 3; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com