Postweld stabilizing thermal treatment method for pipeline made of TP347 material

A technology for stabilizing heat treatment and piping, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as severe cracks and weld cracks, achieve long holding time, release residual stress, and improve weld quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

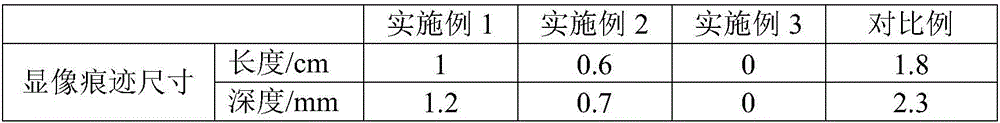

Embodiment 1

[0030] A post-weld stabilization heat treatment method for TP347 material pipelines:

[0031] Before the stabilization heat treatment, the TP347 material pipe is subjected to post-weld pretreatment, including: the two ends of the TP347 material pipe opposite to the weld are continuously injected with a volume fraction of 92% N 2 and 8% CO 2 The protective gas formed is used to heat the weld seam at the same time. When the temperature reaches 400°C, stop heating, keep it for 2 hours, and then cool it to 100°C. After 5 cycles, use ultrasonic impact equipment to process the weld seam, and finally treat the TP347 material pipe Infrared radiation 4h;

[0032] Among them, the flow rate of the shielding gas is 20L / min, and the range of heating the weld is controlled at 100mm from each side of the weld. When heating, the temperature rises to 400°C at a rate of 40°C / h, and when cooling, the temperature is raised to 400°C at a rate of 15°C / h. The cooling rate is reduced from 400°C to ...

Embodiment 2

[0044] A post-weld stabilization heat treatment method for TP347 material pipelines:

[0045] Before the stabilization heat treatment, the TP347 material pipe is subjected to post-weld pretreatment, including: the two ends of the TP347 material pipe opposite to the weld are continuously injected with a volume fraction of 92% N 2 and 8% CO 2 The protective gas formed is used to heat the weld at the same time. When the temperature reaches 400°C, stop heating, keep it for 2.5 hours, and then cool to 100°C. After 6 cycles, use ultrasonic impact equipment to process the weld, and finally the TP347 material pipe Carry out infrared radiation for 4.5h;

[0046] Among them, the flow rate of the shielding gas is 20L / min, and the range of heating the weld is controlled at 150mm from each side of the weld. When heating, the temperature rises to 400°C at a rate of 40°C / h, and when cooling, the temperature is raised to 400°C at a rate of 15°C / h. The cooling rate is reduced from 400°C to 1...

Embodiment 3

[0059] A post-weld stabilization heat treatment method for TP347 material pipelines:

[0060] Before the stabilization heat treatment, the TP347 material pipe is subjected to post-weld pretreatment, including: the two ends of the TP347 material pipe opposite to the weld are continuously injected with a volume fraction of 92% N 2 and 8% CO 2 The protective gas formed is used to heat the weld seam at the same time. When the temperature reaches 400°C, stop the heating, keep it for 3 hours, and then cool it to 100°C. After 8 cycles, use ultrasonic impact equipment to treat the weld seam, and finally the TP347 material pipe Infrared radiation 5h;

[0061] Among them, the flow rate of the shielding gas is 20L / min, and the range of heating the weld is controlled at 200mm from each side of the weld. When heating, the temperature rises to 400°C at a rate of 40°C / h, and when cooling, the temperature is raised to 400°C at a rate of 15°C / h. The cooling rate is reduced from 400°C to 100°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com