Preparation method of beta-tetrabasic zinc chloride, and application of beta-tetrabasic zinc chloride serving as animal feed additive

A technology of zinc chloride and zinc chloride solution, applied in animal feed, animal feed, application, etc., can solve problems such as reducing phytase activity, reducing pig feed intake, human health hazards, etc. Protection, good palatability, low additive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

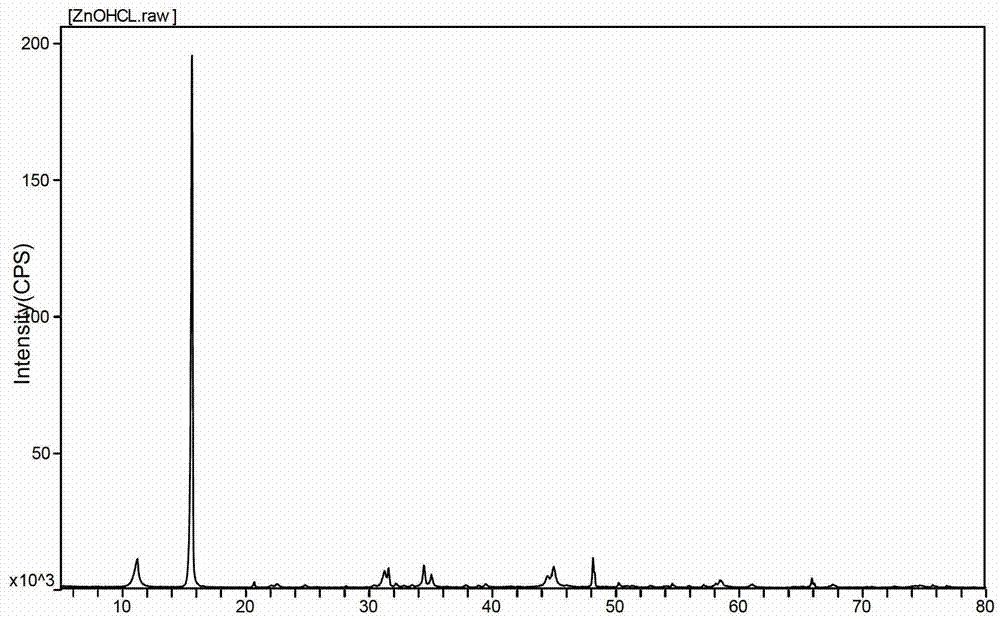

Image

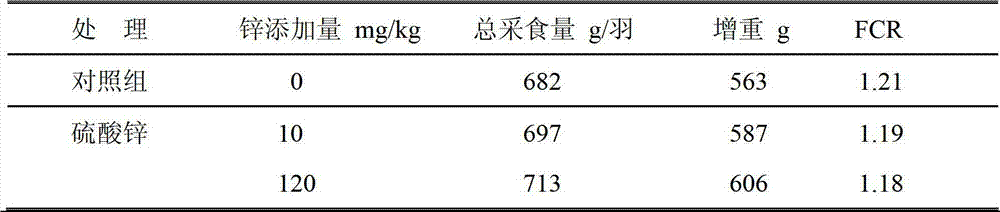

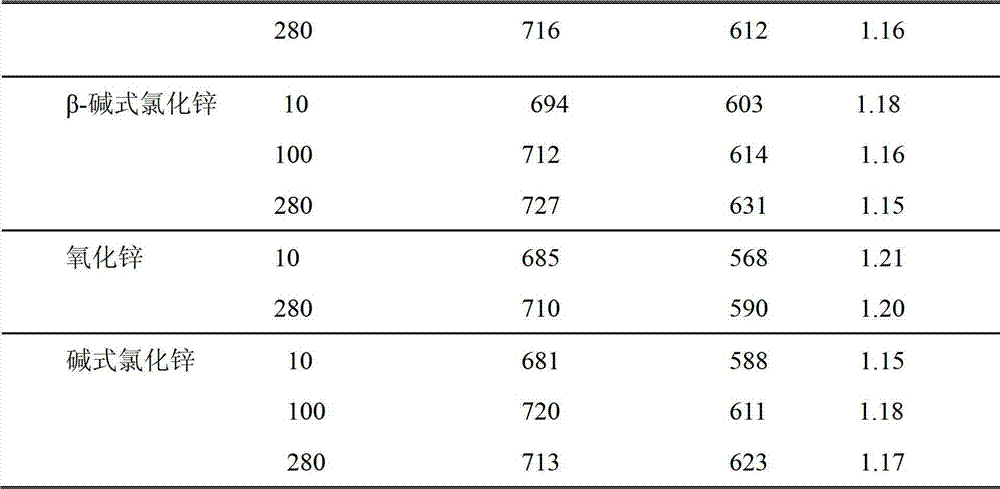

Examples

Embodiment 1

[0026] A preparation method of β-basic zinc chloride of the present invention, comprises the following steps:

[0027] Add zinc chloride (ZnCl 2 ) 150g and water 100g, start stirring to fully dissolve zinc chloride, then slowly add ZnO22.4g to the stirred zinc chloride solution, heat up to 80°C and react at constant temperature for 2h, as the reaction progresses, the reaction system Gradually become viscous; after the reaction, add 1000mL of acetone to the reaction system for crystallization, continue to stir at the reaction temperature for half an hour, then cool down to room temperature, press filter, wash the supernatant with acetone for 3 times, and put it in a drying room at 60℃~ Dry at 100°C, crush and pass through a 40-mesh sieve, and finally prepare the finished product of β-basic zinc chloride (β-Zn(OH)Cl), with a yield of 85%. The content of zinc, arsenic, lead and cadmium in the product is determined by referring to the zinc oxide standard (HG2792-1996 feed additiv...

Embodiment 2

[0029] A preparation method of β-basic zinc chloride of the present invention, comprises the following steps:

Embodiment 3

[0032] A preparation method of β-basic zinc chloride of the present invention, comprises the following steps:

[0033] (1) First, dissolve 2000g of secondary zinc oxide with a zinc content of 50% in 1000ml of 35% hydrochloric acid solution for one pickling. The reaction product is filtered, and the filtered filtrate is subjected to a plate filter press, and then the filtrate is oxidized. During the oxidation treatment, air is continuously introduced into the filtrate. The temperature during the oxidation treatment is controlled at 80°C, and the pH value is controlled at 5.0~ 5.2. After oxidizing for 1.5 hours, carry out the second plate filter press, and then add active zinc powder to the filtrate after the second plate filter press, and the added amount is about 1.2 times the molar number of copper, lead, cadmium and other heavy metal impurities in the filtrate , remove heavy metals such as lead and cadmium in the filtrate, and then obtain 250ml24% zinc chloride aqueous solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com