Walking Beam Control Method for Regenerative Walking Heating Furnace

A control method and walking beam technology, applied in the heat treatment process control, heat treatment furnace, furnace, etc., can solve the problems affecting the roller table and the temperature of the billet out of the furnace, the uneven distribution of the billet, and the confusion of the step distance, so as to achieve a constant temperature out of the furnace , uniform heating, constant control step effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

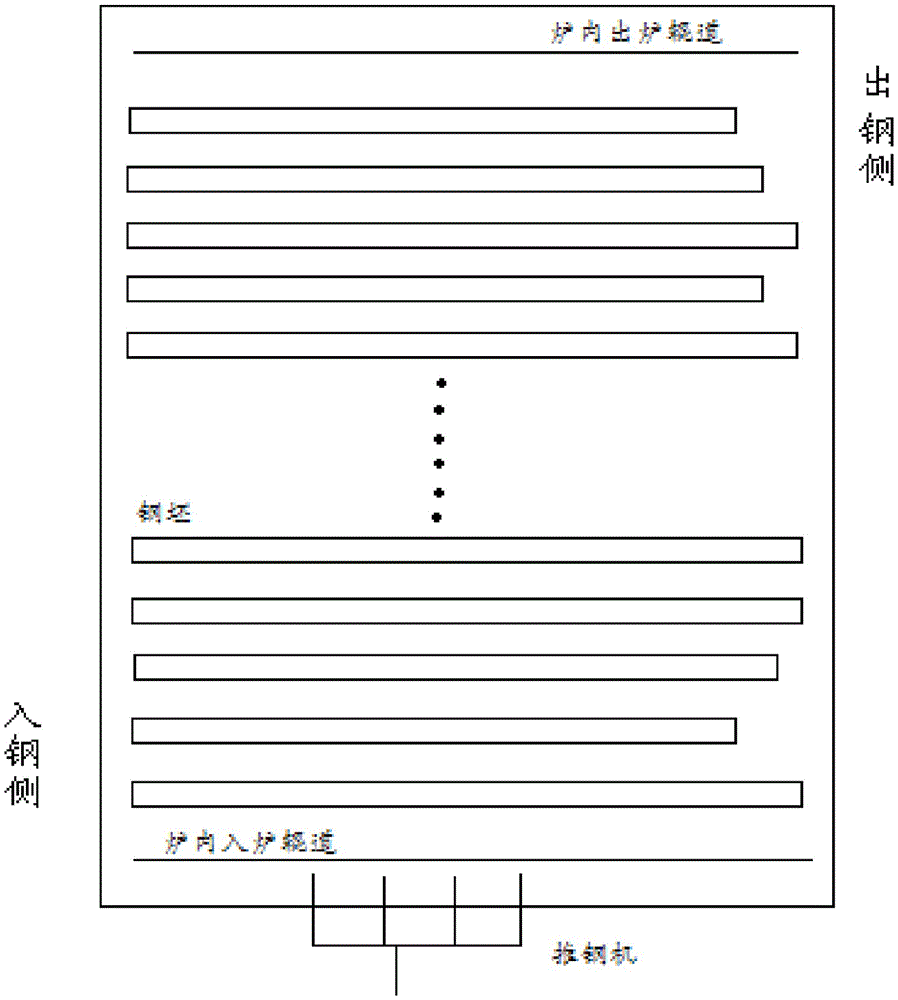

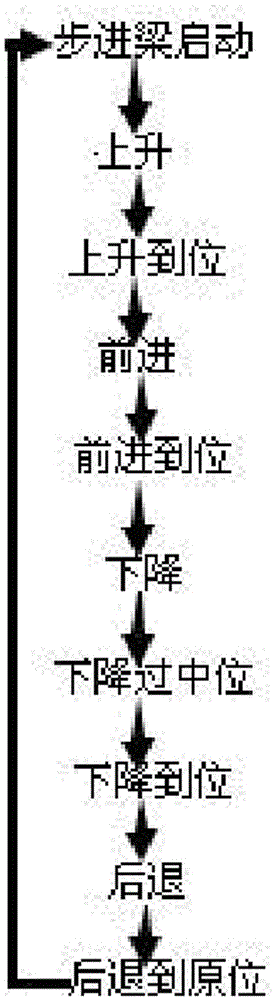

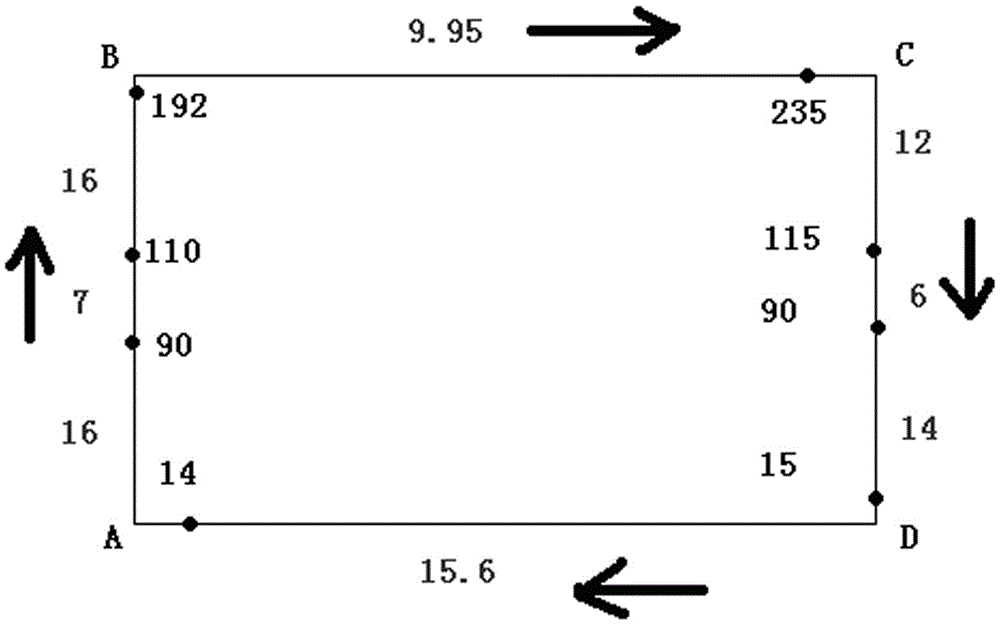

[0020] see Figure 1 to Figure 4 , a walking beam control method for a regenerative walking heating furnace, comprising the following steps:

[0021] 1) Set the standard step distance D and the allowable maximum error value △Dmax of the walking beam in the walking beam control system of the heating furnace, and subtract the standard step distance D from the allowable maximum error value △Dmax to obtain the initial translational step distance of the walking beam The set value is D 0 . The centerline distance of the charging and discharging of the heating furnace in the practical application of the present invention is 16500mm. The standard step distance D of the walking beam is 250 mm, and the maximum allowable error value ΔDmax is 8 mm.

[0022] 2) Put the steel billet on the fixed beam, start the walking beam, and detect the translation distance of the walking beam through the translation sensor at the same time. Then follow the initial translation step set value D 0 Tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com