Distributing mechanism for clamp assembly device

An assembly equipment and cloth technology, which is applied in the field of cloth mechanism for clip body assembly equipment, can solve the problems of low assembly efficiency and high labor intensity, and achieve the effect of accurate cloth and automatic assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the objects and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention.

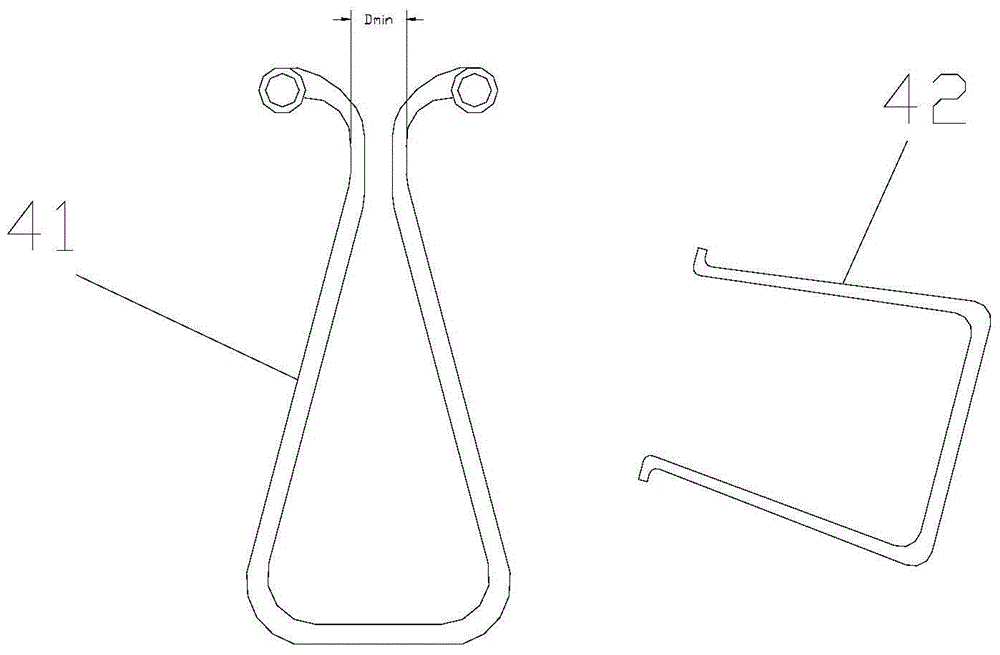

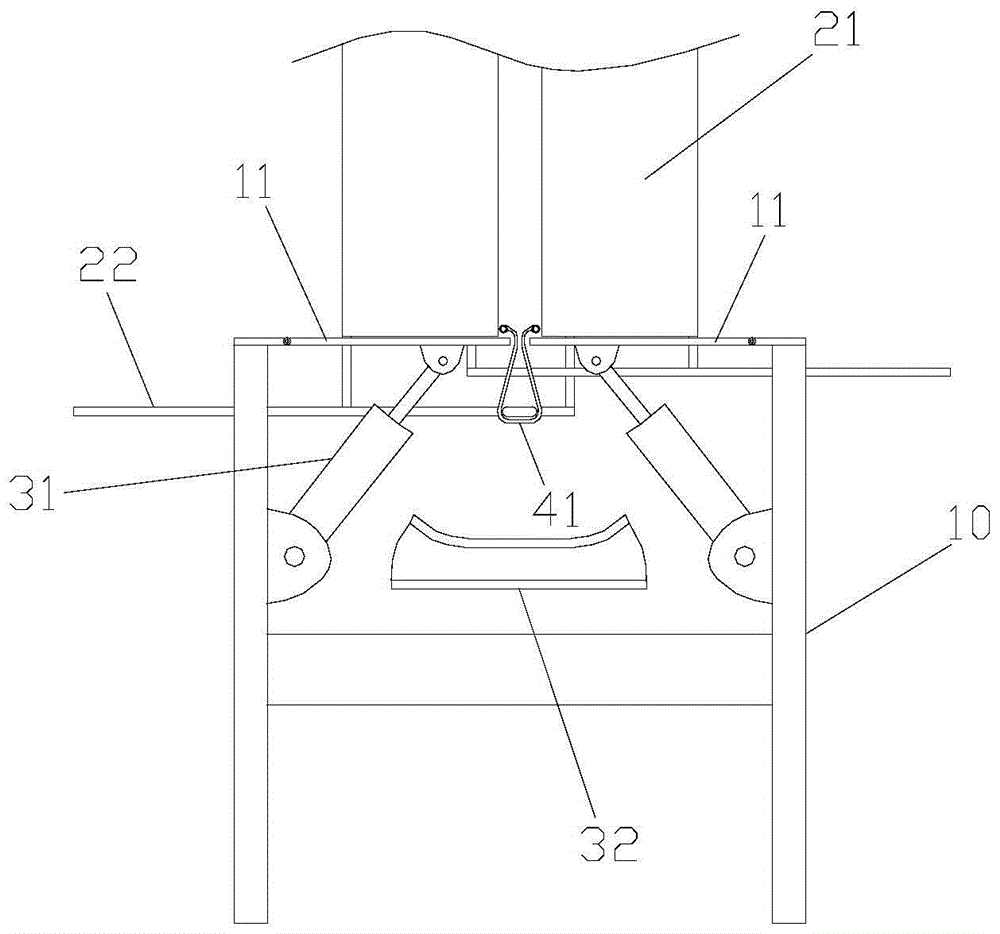

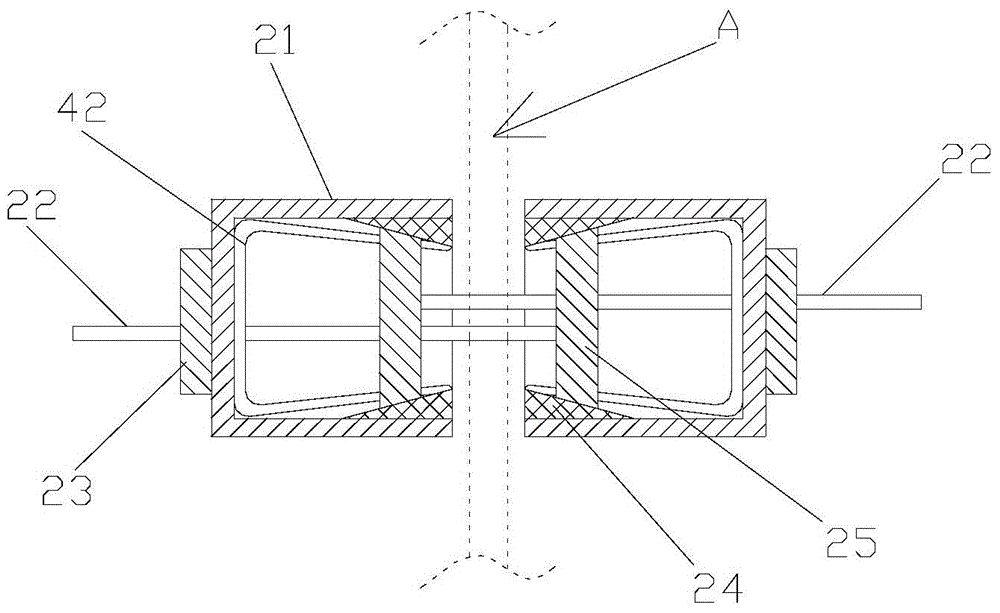

[0012] The technical scheme that the present invention takes is as figure 2 As shown, a distributing mechanism for clip body assembly equipment includes an assembly table for assembling clips. The table top of the assembly table is composed of two left and right boards 11. The size of the gap A between the two boards 11 is the same as the end surface of the clip body 41 The smallest width dimension of the (i.e. figure 1 The size shown in Dmin in the middle) coincides, the clip body 41 is fixed at the gap A between the two table boards 11 and the installation hole o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com