A heat treatment method for titanium alloy oil pipe

A technology of titanium alloy tubing and heat treatment method, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of high cost, high strength of oil pipes, poor plasticity, etc., and achieve large-scale benefits, high production efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

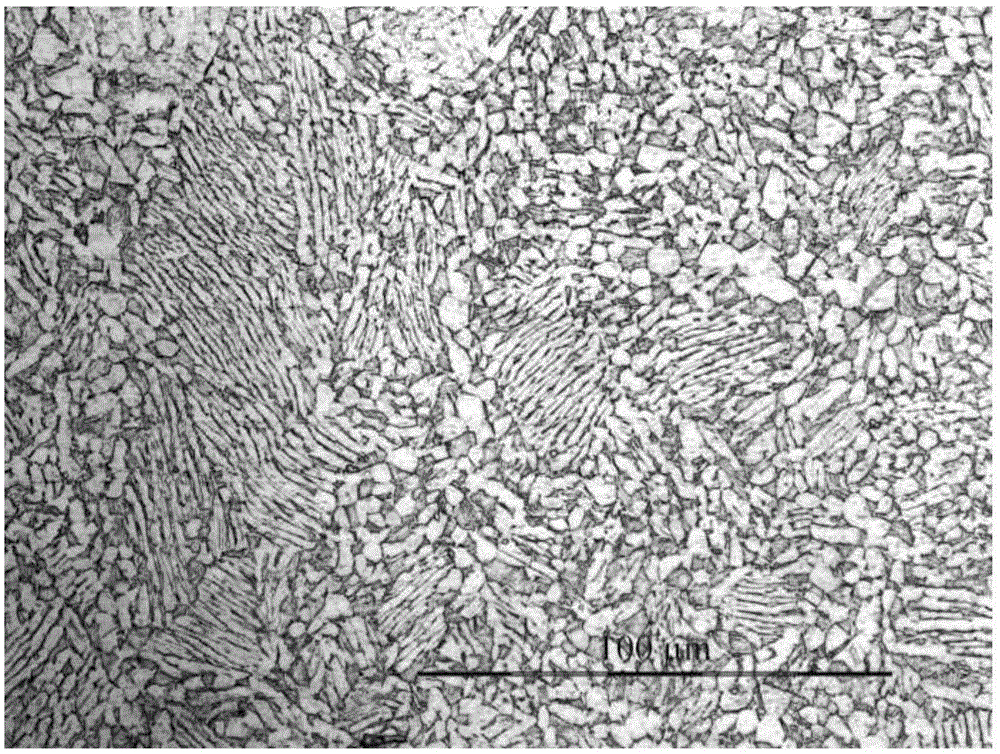

Image

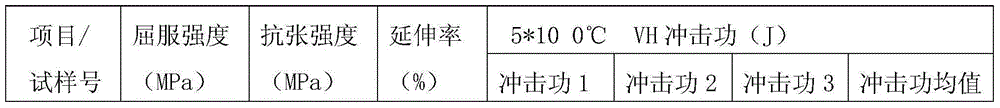

Examples

Embodiment 1

[0059] The steps of the heat treatment method for 88.9×6.45mm cold-rolled TC4 titanium alloy tubing are as follows:

[0060] A. Recrystallization annealing in quenching furnace

[0061] Put the cold-rolled TC4 titanium alloy tubing with a specification of 88.9×6.45mm on the feeding platform of the step-by-step continuous quenching furnace of the 159 heat treatment line. , the quenching furnace has 65 teeth, the first 44 teeth are the heating section, and the last 21 teeth are the heat preservation section, that is, the titanium alloy oil pipe is heated to 900-920°C in 36.67 minutes and held at this temperature for 17.5 minutes for recrystallization annealing; The step-by-step continuous quenching furnace is heated by natural gas, the air-fuel ratio is 12:1, and the volume concentration of residual oxygen in the furnace is 2.4-3.9%.

[0062] B. Air cooling through the quenching device

[0063] Turn off all the cooling water of the quenching device on the production line, lift...

Embodiment 2

[0079] The steps of the heat treatment method for 114.3×6.88mm cold-rolled TC4 titanium alloy oil pipe are as follows:

[0080] A. Recrystallization annealing in quenching furnace

[0081] Put the cold-rolled TC4 titanium alloy tubing with a specification of 114.3×6.88mm on the feeding platform of the step-type continuous quenching furnace of the 159 heat treatment line, and distribute the material one by one, and enter the quenching furnace one by one according to the stepping cycle of 58 seconds , the quenching furnace has 65 teeth, the first 44 teeth are the heating section, and the last 21 teeth are the heat preservation section, that is, the titanium alloy oil pipe is heated to 900-920°C in 42.5 minutes and held at this temperature for 20 minutes for recrystallization annealing treatment; The step-by-step continuous quenching and tempering furnace is heated by natural gas, the air-fuel ratio is 12:1, and the volume concentration of residual oxygen in the furnace is 3.1-4....

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com