Electrolysis plant for electrolytic refining of metals

An electrolytic device and metal technology, applied in the direction of process efficiency improvement, photographic process, instruments, etc., can solve the problems of effect limitation, achieve the effects of reducing cell voltage, improving current efficiency, and reducing DC power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

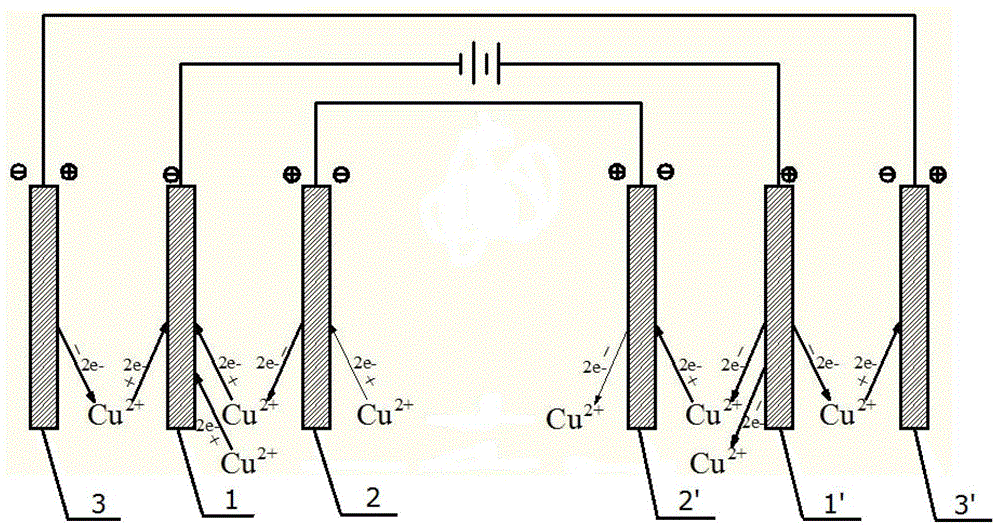

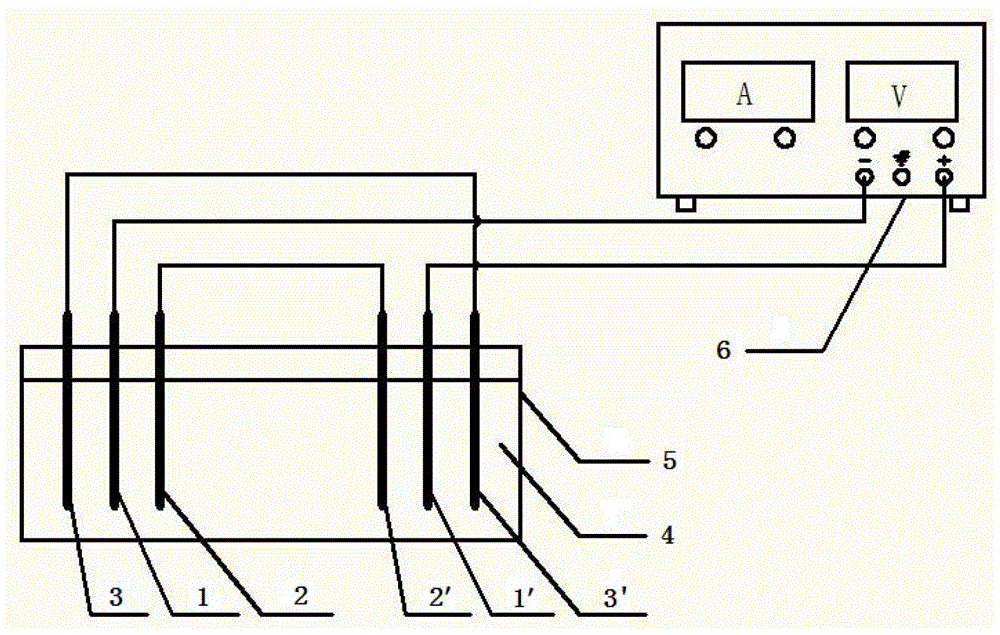

[0036] according to figure 2 Constitute an electrolysis device for preparing electrolytic copper, wherein the electrode 1' (anode) is a metal copper plate with a copper content of 98.5wt% to 99.5wt% (copper needs to be purified), and the materials of the auxiliary electrodes 2 and 3 around it are the same as the anode;

[0037] Electrode 1 (cathode) is a metal copper plate with a copper content of 99.997wt% or more, and the surrounding auxiliary electrodes 2' and 3' are made of the same material as the cathode; the distance between the anode and the cathode is 5cm;

[0038] When the power is turned on, the cathode and the anode are negatively charged and positively charged respectively. Due to the mutual repulsion of the same charges, the sides of electrodes 2 and 3 facing the cathode are respectively positively charged (abbreviated as "positive charge side"). The other sides of electrodes 2 and 3 are respectively negatively charged (abbreviated as "negative charge side");

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com