Self-insulation external wall panel and mounting mechanism thereof

An external wall panel, self-insulation technology, applied in building components, building structures, buildings, etc., can solve the problems of low connection strength, low seismic coefficient, overall damage, etc., to improve the seismic strength and thermal insulation coefficient, improve the connection strength Effects of strength and shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

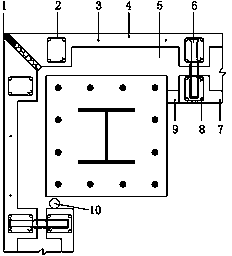

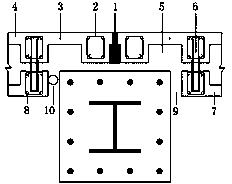

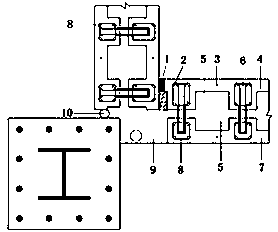

[0022] A self-insulating exterior wall panel, the exterior wall panel is composed of separate inner and outer leaf plates (7, 4), and two sets of symmetrical leaf plate ribs 2 are arranged on the inner and outer leaf plates (7, 4) at a certain distance , the symmetrical blade ribs 2 are provided with blade connectors 6 to make the inner and outer blades (7, 4) connected and fixed at a certain distance. The gap between the inner and outer leaf plates (7, 4) is filled with thermal insulation material 5. Inner ribs 8 for reinforcement are arranged in the blade ribs 2 . One end of the leaf plate connector 6 is anchored to the leaf plate rib 2 of the outer leaf plate 4 , and the other end is anchored to the corresponding leaf plate rib 2 on the inner leaf plate 7 by compounding a low thermal resistance high-strength material. The thermal insulation material 5 is expanded polystyrene. The total thickness of the self-insulating exterior wall panels shall not be less than 200mm, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com