Displacement construction method of the overall iron tower

A construction method and iron tower technology, applied in building maintenance, construction, building construction, etc., can solve the problems of many links in dismantling and assembling iron towers, cumbersome and complicated construction, and long power outage operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

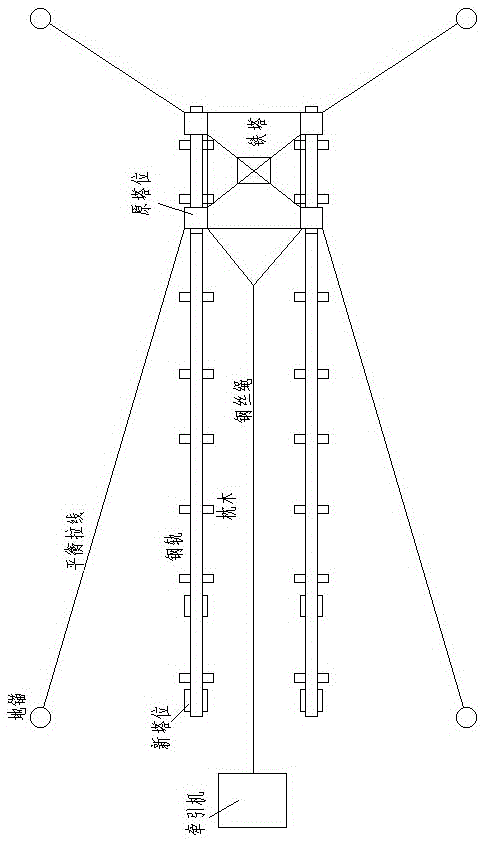

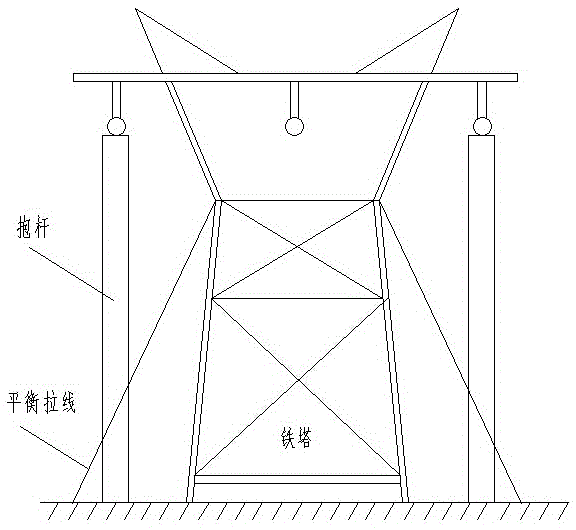

[0019] As shown in the figure, the overall iron tower displacement construction method involved in the present invention comprises the following steps:

[0020] 1) The staff ascend the tower to remove the guide and ground wire accessories on the tower, put the guide and ground wire into the wire pulley, and after the pulley door is sealed, use 4 balanced stay wires, one end of which is fixed on the lower plane of the cross arm , the other end is connected to the ground anchors on both sides of the new tower position and the original tower position on the ground. The staff on the tower conduct a comprehensive inspection, and deal with any problems in time. After there is no problem, the staff on the tower evacuate to the ground. Set up a holding pole on both sides between the front of the new tower position and the original tower position, and drop the wires on both sides of the tower on the top of the holding rod to support the wires;

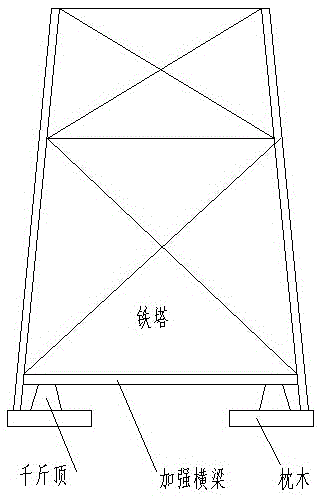

[0021] 2) The ground between the new tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com