engine

A technology of engine and vibration center, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., and can solve problems such as difficulty in miniaturization of the engine, easy increase in the weight of the main body of the engine, and easy deterioration of fuel efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] An engine as an embodiment will be described with reference to the drawings. In addition, the embodiment shown below is just an illustration, and it does not intend to exclude various deformation|transformation and technical application which are not expressly shown in the following embodiment. The respective configurations of the present embodiment can be modified and implemented in various ways without departing from the gist thereof, and can be selected or selected as necessary, or can be combined appropriately.

[0042] (1. Overall composition)

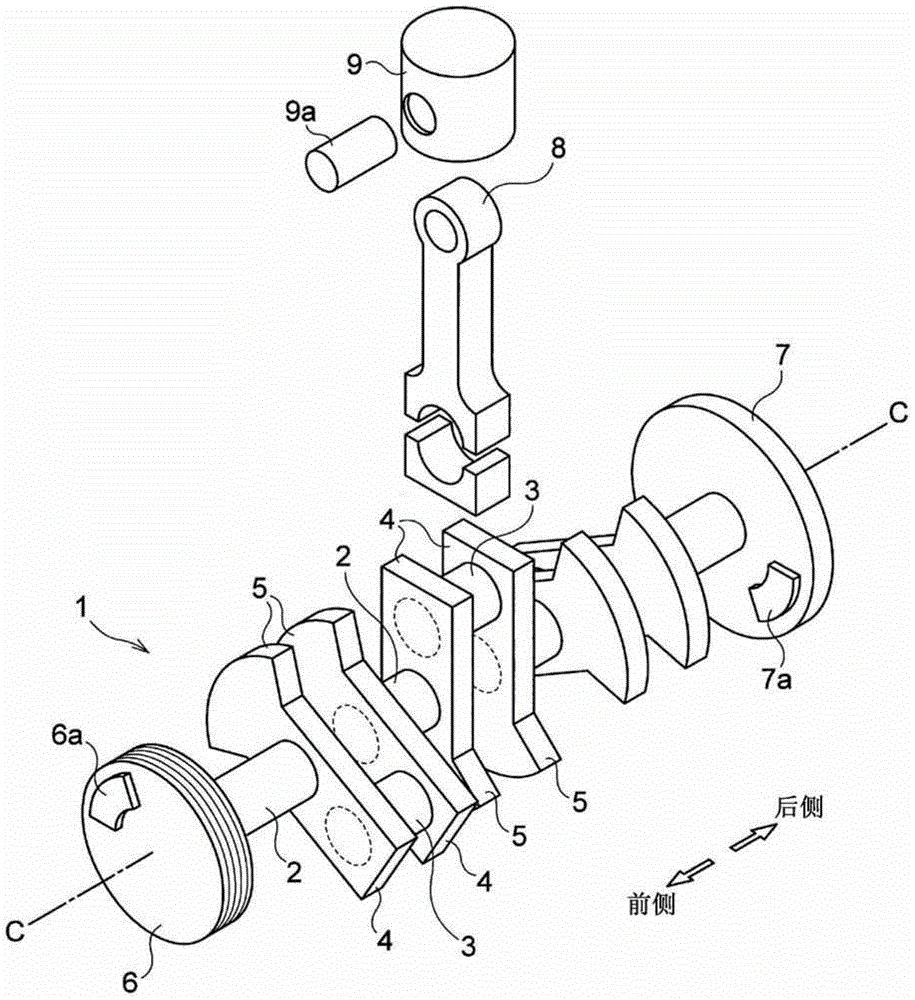

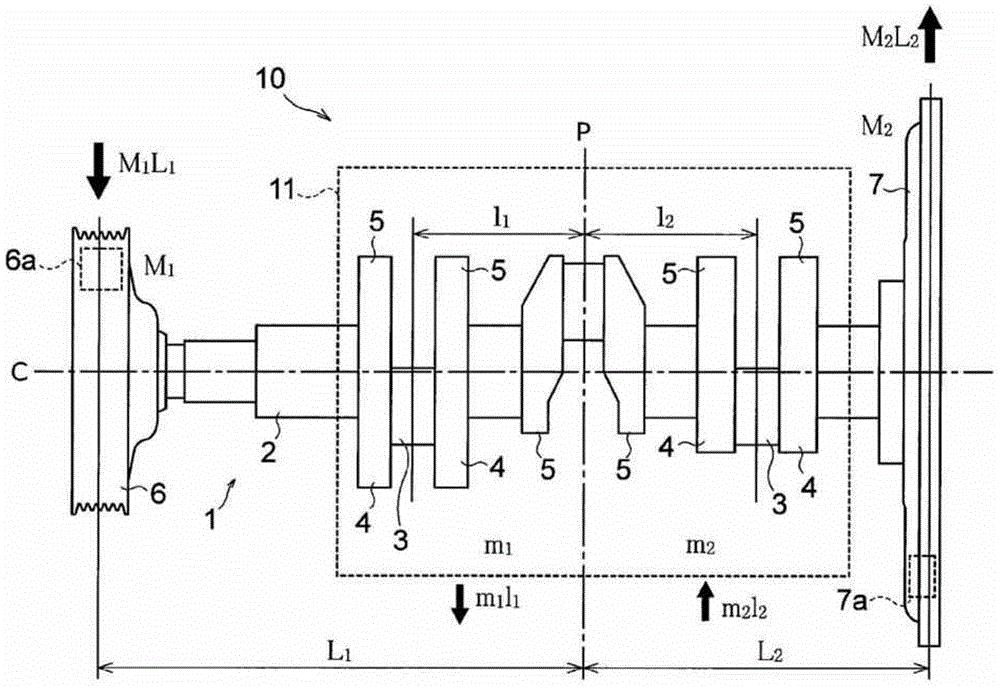

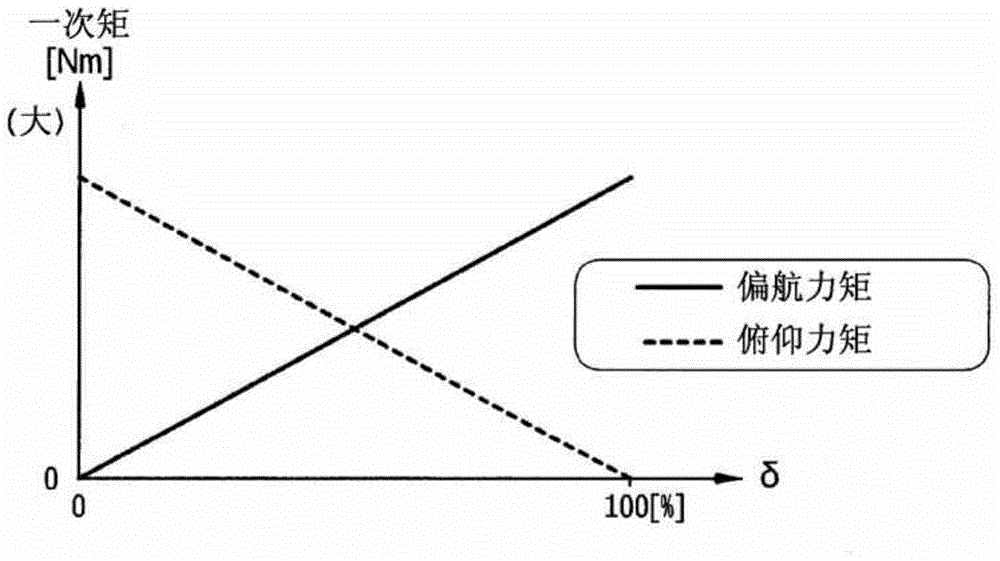

[0043] figure 1 It is an exploded perspective view for explaining the main mechanical elements from the crankshaft 1 to the piston 9 built in the engine 10 of this embodiment, figure 2 It is a plan view showing the state when the crankshaft 1 is seen from the cylinder side. Such as figure 1 , figure 2 As shown, the engine 10 is a tandem three-cylinder engine without a balancer shaft, and is installed in such a manner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com