Overpressure-resisting combined gasket

A gasket and overpressure technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as flattening, extrusion, sealing performance degradation, and compressive stress failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

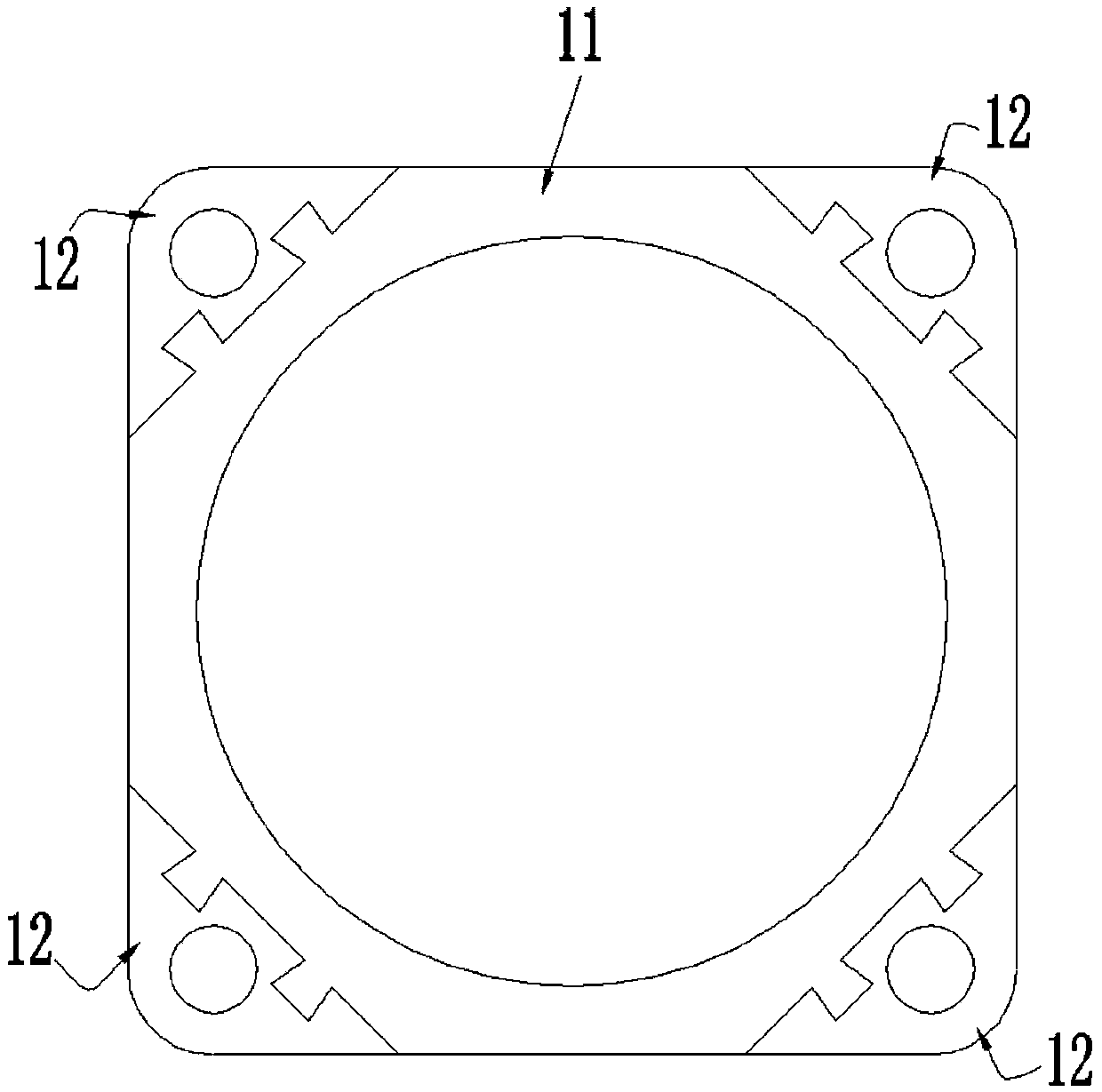

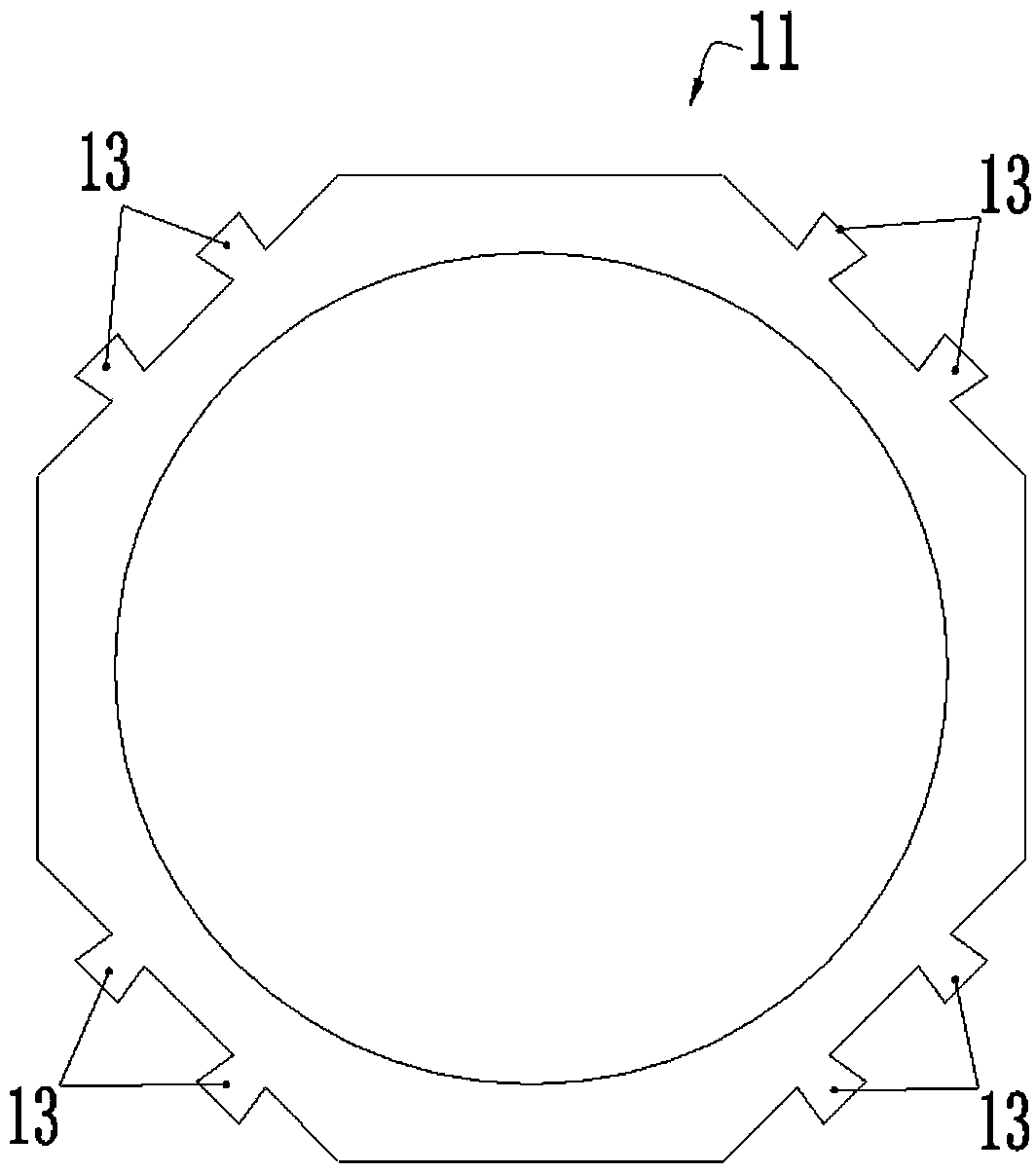

[0017] Examples of anti-overpressure combination gaskets, such as Figure 1-4 As shown, the gasket includes a rubber ring 11 and a hard backing plate 12 arranged on the outer periphery of the rubber ring 11 .

[0018] The outer contour of the rubber ring 11 is a regular hexagon, and four pairs of dovetail-shaped clamping blocks 13 are evenly distributed on the outer peripheral surface thereof, and the clamping blocks 13 extend toward the outer circumference of the rubber ring 11 .

[0019] There are four hard backing plates 12, and each hard backing plate 12 is approximately a right triangle, and each hard backing plate is respectively provided with a bolt connection hole, and the hard backing plate 12 is formed on the oblique side of the right triangle. There are dovetail grooves 14 corresponding to the clamping blocks one by one on the side, and the hard backing plate 12 is made of a plastic plate.

[0020] The hard backing plate 12 and the rubber ring 11 are connected toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com